Abstract

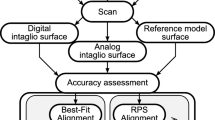

This work attempted to integrate the technologies of computer-aided design and computer-aided manufacture (CAD/CAM) and laser rapid forming (LRF) for the fabrication of the titanium plate of a complete denture. By the combination of laser scan and reverse engineering software, the standard triangulation language (STL)-formatted denture base plate was finally designed and sliced into a sequence of numerical controlled codes. The titanium (Ti) complete denture plate was finally built, layer-by-layer, on the LRF system. To evaluate the quality of fit, a virtual adaptation test that measured and compared the profiles of the laser free formed denture plate and those of the edentulous plaster cast had been conducted, and the mean deviation was found to be 0.34 mm. After traditional dental finishing techniques, a complete denture with a Ti base plate was then made and judged to be acceptable. The CAD/CAM/LRF system is a potential candidate and a new platform for the design and manufacture of custom-made Ti denture plates and restorations.

Similar content being viewed by others

References

Carrieri TCD, de Freitas PM, Navarro RS, Eduardo CP, Mori M (2007) Adhesion of composite luting cement to Er:YAG-laser-treated dentin. Lasers Med Sci 22:165–170. doi:10.1007/s10103-006-0433-7

Birang R, Poursamimi J, Gutknecht N, Lampert F, Mir M (2007) Comparative evaluation of the effects of Nd:YAG and Er:YAG laser in dentin hypersensitivity treatment. Lasers Med Sci 22:21–24. doi:10.1007/s10103-006-0412-z

Mörmann W, Schug J (1997) Grinding precision and accuracy of fit of CEREC 2 CAD-CAM inlays. J Am Dent Assoc 128:47–53

Duret F, Preston J, Duret B (1996) Performance of CAD/CAM crown restorations. J Calif Dent Assoc 24:64–71

Wu M, Tinschert J, Augthun M, Wagner I, Schädlich-Stubenrauch J, Sahm PR et al (2001) Application of laser measuring, numerical simulation and rapid prototyping to titanium dental castings. Dent Mater 17:102–108. doi:10.1016/S0109-5641(00)00037-3

Santosa EC, Shiomia M, Osakada K, Laoui T (2006) Rapid manufacturing of metal components by laser forming. Int J Machine Tools Manuf 46:1459–1468. doi:10.1016/j.ijmachtools.2005.09.005

Cao Y, Choi J (2006) Multiscale modeling of solidification during laser cladding process. J Laser Appl 18:245–257. doi:10.2351/1.2227021

Willer J, Rossbach A, Weber H-P (1998) Computer-assisted milling of dental restorations using a new CAD/CAM data acquisition system. J Prosthet Dent 80:346–353. doi:10.1016/S0022-3913(98)70136-2

Williams RJ, Bibb R, Eggbeer D, Collis J (2006) Use of CAD/CAM technology to fabricate a removable partial denture framework. J Prosthet Dent 96:96–99. doi:10.1016/j.prosdent.2006.05.029

Suzuki Y, Ohkubo C, Abe M, Hosoi T (2004) Titanium removable partial denture clasp repair using laser welding: a clinical report. J Prosthet Dent 91:418–420. doi:10.1016/j.prosdent.2004.01.019

Iglesia-Puig MA (2005) Custom-made laser-welded titanium implant prosthetic abutment. J Prosthet Dent. 94:401–403 doi:10.1016/j.prosdent.2005.06.004

Huang YL, Liu J, Ma NH, Li JG (2006) Three-dimensional analytical model on laser-powder interaction during laser cladding. J Laser Appl 18:42–46. doi:10.2351/1.2164476

Hedges M (2004) Laser based additive manufacturing using LENSTM and M3DTM. In: Proceedings of the 4th Conference on Laser Assisted Net Shape Engineering (LANE 4), vol 1, pp 523–534

Gao B, Zhou J, Mao Y, Wang ZY, Huang WD (2000) Fabrication of dental prosthesis with laser engineered net shaping method. Part 1: measurement of dentognathic gypsum models with a 3-D digitizer by cutting and scanning layer-by-layer. J Pract Stomatol 16:4–6

Gao B, Tan YS, Li YM, Huang WD, Wang J, Wang ZY (2000) Fabrication of dental prosthesis with laser engineered net shaping method. Solid dentognathic models built with the 3-D data by laminated object manufacturing. J Pract Stomatol 16:341–343

Li YM, Yang HO, Lin X, Huang WD, Li JQ, Zhou YH (2003) The influences of processing parameters on forming characterizations during laser rapid forming. Mater Sci Eng 360:18–25. doi:10.1016/S0921-5093(03)00435-0

Haraguchi M, Mukohyama H, Taniguchi H (2006) A simple method of fabricating an interim obturator prosthesis by duplicating the existing teeth and palatal form. J Prosthet Dent 95:469–472. doi:10.1016/j.prosdent.2006.04.004

Zhao JF, Wu XM, Tang YX (1999) Synthesis error analysis of rapid prototyping technology by using laser sintering. J Aero Manuf Technol 2:26–29

Rudolph H, Luthardt RG, Walter MH (2007) Computer-aided analysis of the influence of digitizing and surfacing on the accuracy in dental CAD/CAM technology. Comput Biol Med 37:579–587. doi:10.1016/j.compbiomed.2006.05.006

Hu DM, Kovacevic R (2003) Sensing, modeling and control for laser-based additive manufacturing. Int J Machine Tools Manuf 43:51–60. doi:10.1016/S0890-6955(02)00163-3

Kizaki Y, Azuma H, Yamazaki S, Sugimoto H, Takagi S (1993) Phenomenological studies in laser cladding. Part I. Time-resolved measurements of the absorptivity of metal powder. Jpn J Appl Phys 32:205–212 doi:10.1143/JJAP.32.205

Acknowledgments

The authors would like to express their gratitude to the National High Technology Research and Development Program of China under grant no. 2002AA336050, and the Key Technologies Research and Development Program of Shaan Xi Province under grant no. 2006k05-G4. Moreover, the authors would also like to thank the support from the Research Grants Council of Hong Kong (PolyU5276/06E).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Gao, B., Tan, H. et al. A feasibility study on laser rapid forming of a complete titanium denture base plate. Lasers Med Sci 25, 309–315 (2010). https://doi.org/10.1007/s10103-008-0603-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10103-008-0603-x