Abstract

Diesel particulate matter (PM) has been associated with adverse health effects in humans and is classified as a human carcinogen. Additionally, the strongly light absorbing fraction, black carbon (BC), has been identified as an important climate forcer. For these reasons, the effectiveness of aftermarket controls on reducing PM and BC from three stationary diesel gensets (230, 400, and 600 kW) of varying engine displacement (from 8.8 to 27 L) and physical size was investigated. Uncontrolled emissions were compared with emissions controlled with a passive (P-DPF) and active diesel particulate filter (A-DPF) and a diesel oxidation catalyst (DOC). Overall, the DPFs resulted in significant PM mass removal (~80–99 %), while the DOC resulted in statistically insignificant reductions (~0–25 %). Both BC and elemental carbon (EC) removal followed a similar trend, but EC/PM ratios varied from 0 to 0.79 over all test conditions, indicating changes in PM composition with the addition of aftermarket controls or changes in load. Further, the single scattering albedo of PM was slightly decreased from the DPFs compared to the uncontrolled case. Particle number concentrations were also significantly reduced when using DPFs, with a greater than 97 % reduction in particle concentrations with the P-DPF and greater than 82 % reduction with the A-DPF. The DOC exhibited much lower particle reductions, reducing the particle concentration by only 5–35 %, depending upon the genset or load. These results demonstrate that while DPFs are effective at reducing PM and BC emissions, the particle characteristics are altered from those of uncontrolled emissions.

Similar content being viewed by others

Introduction and background

As early as 1970, when the United States Congress first passed the Clean Air Act, finding ways to mitigate or eliminate particulate matter (PM) emissions from combustion sources has been a focus of research and regulatory communities in an effort to improve human and environmental health, visibility, and more recently global climate. Epidemiological evidence has linked ambient PM2.5 with adverse human health effects (Pope and Dockery 2006; Brito et al. 2010), and more specifically the World Health Organization (WHO) has determined that diesel emissions are a human carcinogen (IARC 2012). Diesel emissions in the U.S. at one point were estimated to contribute up to 75 % of visibility degradation in urban areas (Eldering and Cass 1996), but more recent diesel engine emission regulations in the U.S. and other nations have led to an overall increase in visibility by requiring decreased PM and NO x emissions (40 CFR part 89 and 1039).Footnote 1

Black carbon (BC), a subset of PM found in diesel emissions, is an important contributor to global climate change as it directly warms the atmosphere by absorbing solar radiation and reduces the surface albedo when deposited on snow and ice covered surfaces (Bond et al. 2013). It is estimated from climate models as second only to CO2 as the largest climate warming agent (Jacobson 2002; Ramanathan and Carmichael 2008; Bond et al. 2013). As BC has a much shorter residence time (~1 week) in the atmosphere than CO2 (~150 years), it is possible that a reduction in BC emissions could lessen the effects of global climate change in the near-term (Ramanathan and Carmichael 2008). However, the impact of BC on climate is dependent upon its optical properties. Particularly, the ratio of the scattering coefficient to the extinction coefficient (single scatter albedo, SSA) determines whether BC will warm or cool the surrounding atmosphere (Bond et al. 2013). Also, of importance is the variation of the absorbance with wavelength, which is quantified with the absorption angstrom exponent (α) and can indicate the presence of coatings or light absorbing organic compounds (Lack and Cappa 2010). How these optical properties vary with engine load and control technology has not been characterized.

While it is possible to achieve emissions reductions from diesel combustion through engine modifications, post-combustion control technologies such as diesel particulate filters (DPFs) and diesel oxidation catalysts (DOC) offer an array of options for mitigation or elimination of gaseous and particulate emissions, and can be utilized for both on- and off-road applications (Shah et al. 2007; Wien et al. 2004; Konstandopoulos 2000; Mayer et al. 1995, 1996). Due to regulations, predominately stemming from on-road use, in the U.S. and the European Union (EU), these technologies have become more sophisticated and more capable over the past few decades. Use of fuel-borne catalysts such as platinum or iron (Nash et al. 2013; Lee et al. 2006) or ultra-low sulfur diesel (ULSD) fuel (U.S. DOE 2000) can also alter the emissions from diesel combustion. ULSD must contain less than 15 ppm of sulfur, and is required for on- and off-road use in the U.S. However, studies have shown that even lower levels of sulfur (<10 ppm) optimize the PM removal efficiency of DPFs (Allansson et al., 2000; U.S. DOE 2000), as less sulfate PM is formed.

Post-combustion control technologies vary a great deal for on- and off-road vehicles and equipment, but ultimately accomplish emission reductions in a similar manner. DPFs are often used to control PM emissions, and can be used with or without selective catalytic reduction (SCR) or DOC technologies depending on the nature of the diesel engine and its use. DPFs can operate under a passive or active approach, with passive technologies using the heat from the engine exhaust and active technologies using an external heat or electrical source to clean or “burn off” PM collected on the filter substrate. A review and further discussion of DPFs for comparison to on-road applications can be found in the literature (Resitoglu et al. 2014; Bauner et al. 2009). DOCs are typically used to control gaseous emissions such as hydrocarbons or CO. However, possible co-benefits of PM reduction up to 40 % with the use of this technology (U.S. Environmental Protection Agency 2010) have been discussed. This (EPA report 2010) suggests PM removed by the DOC is likely in the soluble organic fraction rather than the elemental carbon (EC) fraction. While other post-combustion control technologies and combinations of these technologies do exist (i.e., SCR, and NO x adsorbers), the active and passive DPF and the DOC were used here, as particle removal was the focus of this investigation.

The U.S. EPA’s Reciprocating Internal Combustion Engine (RICE) Rule (40 CFR part 63)Footnote 2 regulates the emissions from stationary diesels. Non-road diesel gensets often fall under this regulation as a trailer-mounted diesel genset can be deemed stationary if it is in the same location for more than 12 months. It is also common for manufacturers to use the same engine in both the trailer-mounted, non-road gensets as they do in the stationary diesel gensets, thus certifying the same engine for both applications. While extensive studies have been completed for investigating the emissions of diesel engines on dynamometers for on-road applications with and without DPFs (Fontaras et al. 2014; Kittelson et al. 2004), few studies have focused on non-road or stationary diesel gensets (Shah et al. 2004; U.S. DOE 2000; Ryan et al. 2002), and even fewer with the application of post-combustion PM controls (Shah et al. 2007; Wien et al. 2004). Further, comparisons of particle size distributions with and without PM controls are limited in the literature for large-scale gensets (Shah et al. 2007), while much more common for on-road diesel engines (Liu et al. 2007; Kittelson et al. 2004). A better understanding of how the implementation of aftermarket PM controls for non-road applications affects the particle EC composition, number count, and size distribution of these emissions is needed. Therefore, the current study focused on taking both gaseous and particulate emissions measurements to assess the particle characteristics and PM emission reduction (including EC and BC) potential for these aftermarket controls.

Experimental approach

Equipment

Three four-stroke diesel gensets manufactured by Caterpillar (XQ230, XQ400, and XQ600) were rented spanning a range of power outputs. Each genset, described further in Table 1, was trailer mounted and EPA certified for non-road mobile applications at varying tier levels and operated using ULSD (analysis shown in Table S1). A resistive load bank (Avtron model K580) was used to apply the load during steady-state testing. This load bank was capable of exceeding the 540 kW load needed to achieve a 90 % loading on the largest genset.

Three aftermarket control technologies were tested on each of the three gensets: an active DPF (A-DPF), a passive DPF (P-DPF), and a DOC for 50–90 % load conditions. Under normal conditions these control technologies would be mounted directly after the exhaust manifold to retain the heat of the exhaust. As these gensets were rented, some modifications to the installation were made due to the temporary nature of the installation. Metal ductwork (16 in. diameter, ~10 ft length) was used to route the exhaust downstream of the engine muffler to the different control technologies. The duct was insulated and the duct length was minimized to reduce heat and particle losses to the walls.

The A-DPF consists of four cylindrical sections (cans) containing a light-weight filter (proprietary material) followed by a DOC. For the largest genset tested (XQ600), it was necessary to install an exhaust splitter such that a portion of the exhaust could go to the A-DPF unit and a portion could vent to an in-house air handling system. This was necessary to avoid overloading the A-DPF (i.e., providing too high a face velocity) that was not sized large enough for the exhaust volume from the XQ600. Active regeneration is carried out by direct heating of the filter material to burn off the deposited PM. Regeneration is done with one can at a time and during this testing was set to occur periodically regardless of the engine backpressure. Unlike a typical installation where the genset would power the A-DPF regeneration, this was supplied from the laboratory in order to maintain constant load for steady-state testing conditions.

The P-DPF consists of as many as five cans containing a DOC followed by a ceramic filter substrate (proprietary material). The number of cans was varied depending upon the size of the genset, three for the XQ230, four for the XQ400, and five for the XQ600. Regeneration is achieved by operating the engine at high load, increasing the exhaust temperature to burn off deposited PM in the filter. Backpressure was monitored during testing to determine if a regeneration was necessary (i.e., switching to a higher load). However, the manufacturer’s backpressure limit was never reached during testing and no regeneration cycles were needed.

The DOC used here was constructed of cordierite and a catalyst contained in a can. As with the P-DPF, as many as five DOC cans were used depending on the size of the genset.

Gas and particle phase measurements

Table 2 describes the instruments and measurement methods used. Undiluted gas-phase measurements of CO2, CO, O2, and NO x were made following the EPA methods. Particulate phase measurements were made from a dilution manifold (described below) along with a second CO2 analyzer used to calculate the dilution ratio.

PM mass was measured on Teflon filters (Pall, 47 mm Teflo) and EC was measured on quartz-fiber filters (Pall, 47-mm Tissuquartz). Although thermal–optical methods were used to determine EC emissions, organic carbon (OC) emissions are not reported as high OC concentrations were observed in the background air samples. Attempts to quantify this OC contamination in the sample lines and manifold resulted in varying OC artefact that could not be used for correcting samples in a manner representative of all conditions tested. X-Ray Fluorescence (XRF) was used to quantify the non-carbon compounds in several of the particulate filters collected. BC mass concentration was measured with an Aethalometer (AE-633). The light absorption coefficient and scattering coefficient were measured with a photoacoustic soot spectrometer (PASS-3). The particle size distribution was measured with a Scanning Mobility Particle Sizer (SMPS) operated with a sample and sheath flow of 0.3 and 3 lpm, respectively, resulting in a size range of 14.6–615.3 nm. Distributions were bimodal with a minimum at approximately 20 nm, which was used to define the two modes: nuclei mode (<20 nm) and accumulation mode (>20 nm). A portion of the nuclei mode was not measured since it was below the size range of the SMPS causing a low bias of the nuclei concentration. The implications of this bias on the nuclei concentration will be discussed in the results section.

A Welch’s t test (two-tail, 90 % confidence level) was performed to compare emissions between the controlled and uncontrolled cases. This analysis determined whether or not the PM, BC, and EC reduction provided by a given control device was statistically significant.

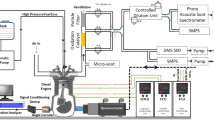

Sampling design

The gensets and the load bank were operated outdoors under varying ambient conditions. No testing was done during precipitation events due to the potential damage to the load bank. Each genset was tested with the three aftermarket controls in random order. When resources permitted, an initial and final uncontrolled test were done before and after testing the aftermarket controls. Exhaust from the genset was routed to each control and then to the exhaust duct where a sampling probe was placed in the center to avoid wall effects while sampling occurred. A schematic of the exhaust sampling arrangement is shown in Fig. 1.

An undiluted and filtered sample was taken for gas-phase measurements. A diluted sample for PM measurements was obtained with an eductor supplied with filtered dry dilution air scrubbed of CO2. Varying dilution ratios were obtained by changing the orifice (diameter ranging from 0.01 to 0.04 inches) in the eductor. Dilution ratios were optimized for each condition to obtain PM concentrations within the instrument measurement ranges.

The diluted sample was routed through 3/8′′ anti-static silicone tubing (approximately 25 ft) to a stainless steel manifold and to each instrument through 1/4′′ anti-static silicone tubing (less than 10 ft). Residence time to most instruments was generally less than two seconds. The longest residence time was to the SMPS at approximately 12 s. Particle losses in the sampling line are expected to be dominated by diffusional losses due to the small particle size and amounted to less than 0.5 % to most instruments and filters. The largest losses were calculated for the SMPS at less than 6 %.

Results and discussion

Three diesel gensets were used to test the removal efficiency of three different aftermarket control technologies and compared to uncontrolled emissions from the same gensets. The emissions averages for each condition and load are shown in Tables 3 and 4 and discussed in further detail below.

Gaseous emissions

Increases in load from 50 to 90 % on the uncontrolled gensets caused increases in CO2 and NO x emissions, and decreases in CO emissions. This is in agreement with reported data from a similar uncontrolled diesel genset (Caterpillar 500 kW) tested at 50 and 75 % load by Wien et al. (2004). Also, as expected, CO2 and O2 were inversely correlated across all cases tested (both uncontrolled and controlled). Further, CO2 in many cases (with the exception of the XQ230) increased when either the P-DPF or A-DPF were used, which is likely attributable to increased fuel consumption while controls were in use and/or partially attributable to oxidation of hydrocarbons and PM conversion to CO2.

For the tests conducted with uncontrolled gensets, the NO x emissions overall were higher at 90 % rather than 50 % load. Several instances of higher NO x average emissions were measured (particularly the XQ230) with an aftermarket control in use as compared to uncontrolled. The largest average NO x emission measured was from the XQ600 with the DOC at 90 % load, 1.26 lb/MMBtu (1.95 g/kW h). This “worst-case scenario” measured through the investigation on the XQ600 still maintains compliance with EPA’s RICE rule (40 CFR part 63) for stationary engines for Tier 2. Further, for its size with the DOC in place, it achieves the emissions limits required for 2014 and newer engines under Tier 4. The same is true for the largest average CO emission measured during the study of 0.831 lb/MMBtu (1.29 g/kW h), from the XQ400 uncontrolled at 50 % load.

Particulate emissions

While the gaseous emission trends (higher CO2, CO, and NO x emissions at higher load) from the current study agree well with those of Wien et al. (2004), the PM emissions (shown in Table 4) do not share the similar trend as the 500 kW genset they tested, which had higher PM at lower load.

For the current study, the XQ230 average PM mass decreased from 1.70e-2 to 6.05e-3 lb/MMBtu, when changing from 50 to 90 % load for the uncontrolled condition. However, the opposite is seen from the uncontrolled XQ400 and XQ600, where the average PM mass increased with increased load. With the exception of the XQ230 at 50 % load with the DOC, the uncontrolled gensets had higher PM emissions than any controlled cases, which is in agreement with Wien et al. (2004). However, Wien et al. (2004) also found for the DPF-controlled cases that there were higher PM emissions at 50 % as opposed to 90 % load, which agreed with the PM emissions from the XQ230 and XQ400, but not the XQ600. Interestingly, the largest PM emission of 1.99e-2 lb/MMBtu (0.03 g/kW h) was measured during testing of the XQ230 at 50 % load with the DOC. Rather than the DOC providing a co-benefit of PM removal, in this instance the average PM emissions were greater (although not statistically significant) than that of the uncontrolled XQ230 genset at 50 % load. It should be noted, however, that even this highest level of PM emissions measured (XQ230 with DOC) would not only meet and exceed requirements for the Tier 3 rating required for the manufacturing year of this genset under EPA’s Control of Emissions from New and In-Use Nonroad Compression Ignition Engines Rule (40 CFR part 89 and 1039), but would nearly meet the Tier 4 PM emissions requirements of a similar but newer genset (0.02 g/kW•h).

As part of the PM emissions characterization, EC and BC were measured for all conditions from filter samples and continuous instrumentation, respectively. To better understand potential changes in particle composition, the ratios of EC/PM were considered (shown in Table 4 and Figure S1), and ranged from 0 to 0.79. Typically uncontrolled diesel engines would produce predominately carbon emissions with contributions from metals and inorganics such as sulfur (Subramanian et al. 2009; Kittelson 1998). All uncontrolled cases measured in the current study show similar composition, with EC/PM ratio being greater than 0.5. However, several instances of EC/PM ratio below 0.5 were measured with DPFs in use. EC/PM ratios for all conditions tested suggest a substantial portion of the PM measured consists of compounds other than EC, which could be attributed to OC and sulfur (Fujita et al. 2007). For all tests in the current study, non-highway ULSD was used, restricting the sulfur content to less than 15 ppm, and as such, sulfur produced solely from the fuel in the PM emissions was expected to be low. Although using a different control device design, Khalek et al. (2011) found sulfur content to comprise roughly 50 % of the PM when using DPFs for onroad diesel engines with ULSD. Therefore, XRF was performed on nine of the current PM filter samples spanning the entire test matrix and no quantifiable levels of any metals were detected, and only trace levels of sulfur were detected in two samples when a DOC was utilized. Previous research by Shah et al. (2004) with back-up generators showed EC dominating the particulate emissions for two different 4-stroke gensets tested from 10 to 100 % load, which is not seen in the particulate emissions measured from the uncontrolled gensets in the current study. As with PM, there was no consistent trend with load for EC or BC emission factors. However, a very consistent trend in the ratios EC/PM and EC/BC was seen, with EC measuring 33 % less than PM and BC emissions measuring nearly twice that of EC emissions for every genset, load, and control tested (shown Figure S1).

Removal efficiency

The main objective of the current study was to investigate the removal efficiency of PM using several aftermarket control devices. An important note for the discussion of PM removal efficiency is that sample duration varied by test day. This sampling duration was determined to ensure sufficient mass was collected on the filter samples and thus depended on the PM concentration. As mentioned previously, sampling did not stop or delay when the A-DPF went into a regeneration cycle, which means variability exists across this measurement. Furthermore, no regeneration cycles were carried out for the P-DPF during sampling. Therefore, the removal efficiency for either DPF under typical operation could be different than reported here. These reported removal efficiencies represent the average removal while sampling with the genset at steady state. Had the test duration been lengthened to 100 or 1,000 h, then multiple regeneration cycles could have occurred while sampling, potentially reducing the standard deviation across the average. However, lengthening the test duration by that many hours was not possible for the current study. Future research should focus on longer test cycles at steady-state genset conditions in order to ensure the samples taken incorporated at least one full regeneration of the DPFs.

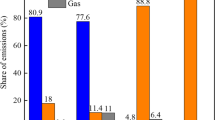

Table 5 shows the average percent removal and standard deviation for PM, BC, and EC across all gensets for each control device. A table with the average removal for PM broken down by genset is available in Table S2 in the supplemental material. For all gensets and loads, the P-DPF resulted in statistically significant reductions of PM, BC, and EC. Likewise, the A-DPF resulted in statistically significant reductions in all cases, with the exception of XQ600 at 90 % load. Conversely, with the exception of the XQ230 at 50 % load (which provided a statistically significant increase in EC), none of the tests performed with the DOC provided statistically significant PM, BC, or EC emission reductions. The statistical insignificance of the minimal PM removal (8–25 %) demonstrates that the DOC is not effective at reducing the PM, BC, and/or EC in these gensets with ULSD fuel. However, the DOC was effective at removing CO, with greater than 97 % removal. Therefore, it is clear that the DOC is functioning, and is sized, properly for the gensets tested.

Particle size distribution from SMPS

All distributions are essentially bimodal and in agreement with measurements from on-road diesels and small-scale gensets (Kittelson 1998; Lee et al. 2006). Figures S2 and S3 in the supplemental materials show particle size distributions for all three gensets, with each control configuration, at 50 and 90 % load, as well as uncontrolled cases compared at 50 and 90 % load. All particle size distributions represent averages over several tests for each condition and were corrected for dilution. Approximately 86–95 % of the particles exist in the accumulation mode (>20 nm), whereas the nuclei mode (<20 nm) accounts for roughly 5–14 % of total particle number. The nuclei fraction is biased low since particles smaller than 14.6 nm were not measured by the SMPS, but can still be used to identify trends in the particle size distribution with control technology.

All three gensets have very similar particle number size distributions and total number of particles emitted at the same load condition. In agreement with the PM emission factors, number concentrations (shown in Table 4) were significantly higher at 50 % load compared to 90 % load (nearly 1.9 times higher for the XQ400 genset). The peak diameters of the accumulation mode varied from approximately 40 nm (XQ230 genset at 90 % load) to approximately 70 nm (XQ600 genset at 90 % load), in agreement with the geometric mean number diameter of the accumulation mode for on-road diesel engines reported previously to be 50–80 nm diameter (Khalek et al. 1998; Kittelson et al. 2004).

Figures 2a–c show the influence of the aftermarket controls on the particle number (PN) size distributions at 50 % load for all three gensets. The highest average particle removal efficiency (>97 % for all three gensets) was measured with the P-DPF control device, with a total particle removal efficiency of more than 99 % measured for the XQ230 genset. Particle removal efficiency for the A-DPF was greater than 83 % for all three gensets, with the highest measured removal efficiency occurring on the XQ400 genset at 90 % load (>95 %).

While PN reduction with the DOC was significantly lower, a co-benefit of particle removal was observed with total PN removal between roughly 4 and 34 %. The only exception to this trend in PN removal was the XQ230 genset at 90 % load which had a (statistically insignificant) negative removal. The PN increase for this particular condition is in agreement with increases in PM mass and BC (also not statistically significant) for the same condition indicating increased particle formation with a DOC. A slight drop in EC/PM ratio coupled with an increase of PN in the nuclei mode could suggest the presence of semi-volatile compounds, and trace amount of sulfur measured by the XRF indicate formation of sulfate nanoparticles. A similar trend was seen by Shah et al. (2007) when testing with a 350 kW diesel genset at 100 % load with a DOC (exhaust temperature ~550 °C), and was attributed to the formation of sulfate nanoparticles, as the testing was conducted with 500 ppm sulfur diesel. However, these changes in EC/PM ratio and PN nuclei formation likely resulted in minimal change to the overall PM composition. For XQ400 and XQ600 gensets with each of the three controls, particles in the nuclei mode were removed more efficiently than those in the accumulation mode. The trend of decreasing particle removal efficiency with increasing particle size indicates that smaller particles may consist of more volatile OC compared to EC and thus more likely to be oxidized.

Optical properties

The average aerosol absorption at 781 nm, SSA at 532 nm, and α from 405 nm to 781 nm for each condition is shown in Table 4. The aerosol absorption had a similar trend to that observed for the PM, BC, and EC, i.e., large reductions in absorption with the A-DPF and P-DPF and minimal if any reduction with the DOC. Low particle concentrations during the P-DPF cases necessitated low dilution ratios to meet the detection limits of most of the instruments. Therefore, the diluted sample NO2 absorption was larger than the particle absorption. Although the PASS-3 accounts for gas-phase light absorption with periodic baseline adjustment with a filtered sample, fluctuations of the NO2 concentration in between adjustments caused larger light absorption than the particles at the 532 nm and 405 nm wavelengths for these P-DPF cases. The A-DPF case also had lower dilution ratios, but in general had lower NO2 concentrations and higher particle concentrations and was thus less affected by NO2 fluctuations in the diluted exhaust sample.

The SSA averaged over all conditions tested, with the exception of the P-DPF cases (likely impacted by NO2 absorption), for these gensets was 0.26 ± 0.03, which was slightly larger than similar measurements (at mid-visible wavelengths) from tunnel studies of on-road diesels at 0.2 (Strawa et al. 2010) and 0.14 (Dallman et al. 2012) and from a chamber experiment with a light-duty diesel engine at 0.2 (Schnaiter et al. 2003). The SSA exhibited statistically significant increases with engine load, except for the XQ400 genset, where the increase was not statistically significant. Generally, the SSA was decreased when the DOC or A-DPF was used, but the decrease was small (<20 %) and not statistically significant in most cases.

The average α for all cases (except when the P-DPF was used) of 1.09 ± 0.07 was almost the same as the 1.1 measured by Schnaiter et al. (2003) on emissions from a light-duty diesel engine. Except for the XQ230 genset, α showed a slight decrease with increasing load that was not statistically significant. For the most part, α increased with the use of the A-DPF or DOC, but even the largest increase was less than 12 % and was not statistically significant.

Summary

The results presented here describe the gaseous and particulate emissions of three stationary diesel gensets ranging from 230 to 600 kW configured with and without A-DPF, P-DPF, and DOC aftermarket control technologies. The DPFs tested, both active and passive, were found to be viable means for mitigating PM emissions from large-scale diesel gensets with 4-cycle engines, across the entire submicron particle size range. However, no statistically significant PM removal was measured from any of the gensets while using the DOC. PM, EC, and BC emissions were reduced from those of the uncontrolled gensets in most conditions tested with either DPF. Low EC/PM values seen at some conditions suggest potential for compositional changes, and in all cases tested the BC measured was roughly twice that of EC. Increasing the load caused a small but statistically significant increase of the SSA. The addition of aftermarket controls caused a slight decrease in SSA and slight increase in α that was not entirely consistent over all conditions and was not statistically significant. Findings from this study would suggest that further investigation into changes in carbon emissions composition with the use of aftermarket PM control devices is needed.

Notes

40 CFR part 89 and 40 CFR part 1039. Control of Emissions from New and In-Use Nonroad Compression Ignition Engines

40 CFR part 63, subpart ZZZZ. National Emissions Standards for Hazardous Air Pollutants for Stationary Reciprocating Internal Combustion Engines (RICE)

References

Allansson R, Maloney C, Walker A, Warren J (2000) Sulphate production over the CRT™: What fuel sulphur level is required to enable the EU 4 and EU 5 PM standards to be met? SAE Technical Paper 2000-01-1875

Arnott WP, Hamasha K, Moosmüller H, Sheridan PJ, Ogren JA (2005) Towards aerosol light-absorption measurements with a 7-wavelength Aethalometer: evaluation with a photoacoustic instrument and 3-wavelength nephelometer. Aerosol Sci Technol 39(1):17–29. doi:10.1080/027868290901972

Bauner D, Laestadius S, Iida N (2009) Evolving technological systems for diesel engine emission control: balancing GHG and local emissions. Clean Technol Environ Policy 11:339–365. doi:10.1007/s10098-008-0151-x

Bond TC, Doherty SJ, Fahey DW, Forster PM, Berntsen T, DeAngelo BJ et al (2013) Bounding the role of black carbon in the climate system: a scientific assessment. J Geophys Res Atmos 118(11):5380–5552. doi:10.1002/jgrd.50171

Brito JM, Belotti L, Toledo AC, Antonangelo L, Silva FS, Alvim DS et al (2010) Acute cardiovascular and inflammatory toxicity induced by inhalation of diesel and biodiesel exhaust particles. Toxicol Sci 116(1):67–78. doi:10.1093/toxsci/kfq107

Chow JC, Watson JG, Doraiswamy P, Chen L-WA, Sodeman DA, Lowenthal DH et al (2009) Aerosol light absorption, black carbon, and elemental carbon at the Fresno Supersite California. Atmos Res 93(4):874–887. doi:10.1016/j.atmosres.2009.04.010

Dallman TR, DeMartini SJ, Kirchstetter TW, Herndon SC, Onasch TB, Wood EC, Harley RA (2012) On-road measurement of gas and particle phase pollutant emission factors for individual heavy-duty diesel trucks. Environ Sci Technol 46(15):8511–8518. doi:10.1021/es301936c

Eldering A, Cass GR (1996) Source-oriented model for air pollutant effects on visibility. J Geophys Res. doi:10.1029/95JD02928

Flowers BA, Dubey MK, Mazzoleni C, Stone EA, Schauer JJ, Kim S-W, Yoon SC (2010) Optical-chemical-microphysical relationships and closure studies for mixed carbonaceous aerosols observed at Jeju Island; 3-laser photoacoustic spectrometer, particle sizing, and filter analysis. Atmos Chem Phys 10:10387–10398. doi:10.5194/acp-10-10387-2010

Fontaras G, Franco V, Dilara P, Martini G, Manfredi U (2014) Development and review of Euro 5 passenger car emission factors based on experimental results over various driving cycles. Sci Total Environ. doi:10.1016/j.scitotenv.2013.09.043

Fujita EM, Campbell DE, Arnott WP, Chow JC, Zielinska B (2007) Evaluations of the chemical mass balance method for determining contributions of gasoline and diesel exhaust to ambient carbonaceous aerosols. JAPCA J Air Waste Manag 57(6):721–740. doi:10.3155/1047-3289.57.6.721

Hansen ADA, Rosen H, Novakov SM (1984) The Aethalometer—an instrument for the real-time measurement of optical absorption by aerosol particles. Sci Total Environ 36:191

International Agency for Research on Cancer (IARC) (2012) Diesel engine exhaust carcinogenic, Media Release, IARC and World Health Organization (WHO), Lyon, France: 12 June

Jacobson MZ (2002) Control of fossil-fuel particulate black carbon and organic matter, possibly the most effective method of slowing global warming. J Geophys Res 107(D19):4410. doi:10.1029/2001JD001376

Khalek IS, Kittelson DB, Graskow BR, Wei Q, Brear F (1998) Diesel exhaust particle size: Measurement issues and trends. SAE Technical Paper, 980525

Khalek IA, Bougher TL, Merritt PM, Zielinska B (2011) Regulated and unregulated emissions from highway heavy-duty diesel engines complying with U.S. Environmental Protection Agency 2007 emissions standards. JAPCA J Air Waste Manag 61(4):427–442. doi:10.3155/1047-3289.61.4.427

Khan B, Hays MD, Geron C, Jetter J (2012) Differences in the OC/EC ratios that characterize ambient and source aerosols due to thermal-optical analysis. Aerosol Sci Technol 46(2):127–137. doi:10.1080/02786826.2011.609194

Kittelson DB (1998) Engines and nanoparticles : a review. J Aerosol Sci 29(5):575–588

Kittelson DB, Watts WF, Johnson JP, Remerowki ML, Ische EE, Oberdörster G et al (2004) On-road exposure to highway aerosols. 1 Aerosol and gas measurements. Inhal Toxicol 1(16 Suppl):31–39. doi:10.1080/08958370490443024

Konstandopoulos AG (2000) Fundamental studies of diesel particulate filters: Transient loading, regeneration and aging. SAE Technical Paper 2000-01-1016

Lack DA, Cappa CD (2010) Impact of brown and clear carbon on light absorption enhancement, single scatter albedo and absorption wavelength dependence of black carbon. Atmos Chem Phys 10(9):4207–4220. doi:10.5194/acp-10-4207-2010

Lee D, Miller A, Kittelson D, Zachariah MR (2006) Characterization of metal-bearing diesel nanoparticles using single-particle mass spectrometry. J Aerosol Sci 37(1):88–110. doi:10.1016/j.jaerosci.2005.04.006

Liu ZG, Ford DC, Vasys VN, Chen D-R, Johnson TR (2007) Influence of engine operating conditions on diesel particulate matter emissions in relation to transient and steady-state conditions. Environ Sci Technol 41(13):4593–4599. doi:10.1021/es0616229

Mayer A, Egli H, Burtscher H, Czerwinski J, et al (1995) Particle size distribution downstream traps of different design, SAE Technical Paper 950373

Mayer A, Czerwinski J, Scheidegger P (1996) Trapping efficiency depending on particulate size, SAE Technical Paper 960472

Nash DG, Swanson NB, Preston WT, Yelverton TLB, Roberts WL, Wendt JOL, Linak WP (2013) Environmental implications of iron fuel borne catalysts and their effects on diesel particulate formation and composition. J Aerosol Sci 58:50–61. doi:10.1016/j.jaerosci.2013.01.001

Park SS, Hansen ADA, Cho SY (2010) Measurement of real time black carbon for investigating spot loading effects of Aethalometer data. Atmos Environ 44(11):1449–1455. doi:10.1016/j.atmosenv.2010.01.025

Pope CA, Dockery DW (2006) Health effects of fine particulate air pollution: lines that connect. JAPCA J Air Waste Manag 56(6):709–742. doi:10.1080/10473289.2006.10464485

Ramanathan V, Carmichael G (2008) Global and regional climate changes due to black carbon. Nat Geo Sci 1:221–227. doi:10.1038/ngeo156

Reşitoğlu IA, Altinisik K, Keskin A (2014) The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technol Environ Policy. doi:10.1007/s10098-014-0793-9

Ryan NE, Larsen KM, Black PC (2002) Smaller, closer, dirtier: Diesel backup generators in California. Environmental Defense Report: New York

Schnaiter M, Horvath H, Mohler O, Naumann KH, Saathoff H, Schock OW (2003) UV-vis-NIR spectral optical properties of soot and soot-containing aerosols. J Aerosol Sci 34(10):1421–1444. doi:10.1016/S0021-8502(03)00361-6

Shah SD, Cocker DR, Miller JW, Norbeck JM (2004) Emission rates of particulate matter and elemental and organic carbon from in-use diesel engines. Environ Sci Technol 38(9):2544–2550. doi:10.1021/es0350583

Shah SD, Cocker DR, Johnson KC, Lee JM, Soriano BL, Miller JW (2007) Reduction of particulate matter emissions from diesel backup generators equipped with four different exhaust aftertreatment devices. Environ Sci Technol 41(14):5070–5076. doi:10.1021/es0614161

Strawa AW, Kirchstetter TW, Hallar AG, Ban-Weiss GA, McLaughlin JP, Harley RA, Lunden MM (2010) Optical and physical properties of primary on-road vehicle particle emissions and their implications for climate change. J Aerosol Sci 41(1):36–50. doi:10.1016/j.jaerosci.2009.08.010

Subramanian R, Winijkul E, Bond TC, Thiansathit W, Oanh NTK, Paw-armart I, Duleep KG (2009) Climate-relevant properties of diesel particulate emissions: results from a piggyback study in Bangkok Thailand. Environ Sci Technol 43(11):4213–4218. doi:10.1021/es8032296

U.S. DOE. (2000) Diesel Emission Control Sulfur Effects (DECSE) Program - Phase I Interim Data Report No. 4: Diesel Particulate Filters—Final Report January 2000

U.S. Environmental Protection Agency (2010). Diesel oxidation catalyst general information EPA Technical Bulletin420-F-10-031. http://www.epa.gov/cleandiesel/documents/420f10031.pdf. Accessed 11 Dec 2014

Virkkula A, Mäkelä T, Hillamo R, Yli-Tuomi T, Hirsikko A, Hämeri K, Koponen IK (2007) A Simple Procedure for Correcting Loading Effects of Aethalometer Data. JAPCA J Air Waste Manag 57(10):1214–1222. doi:10.3155/1047-3289.57.10.1214

Wang SC, Flagan RC (1990) Scanning electrical mobility spectrometer. Aerosol Sci Technol 13:230–240. doi:10.1080/02786829008959441

Wien S, England GC, Chang OMC (2004) Development of fine particulate emission factors and speciation profiles for oil and gas-fired combustion systems, topical report: test results for a diesel fuel-fired compression ignition reciprocating engine with a diesel particulate filter at site Foxtrot

Acknowledgments

The authors are grateful to Carl Singer (ARCADIS International) for aiding in system design and data reduction, Daniel Janek (ARCADIS International) for genset operation and data collection, Melanie King (U.S. EPA) for regulatory guidance and support, and the members of Manufacturers of Emission Controls Association (MECA) for use of PM control devices for testing. The research described in this article has been reviewed by the U.S. EPA National Risk Management Research Laboratory and approved for publication. The contents of this article should not be construed to represent Agency policy nor does mention of trade names or commercial products constitute endorsement or recommendation for use.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jelica Pavlovic was a ORISE postdoctoral fellow at the U.S. Environmental Protection Agency Research Triangle Park, NC at the time the research and analysis were completed.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yelverton, T.L.B., Holder, A.L. & Pavlovic, J. Emissions removal efficiency from diesel gensets using aftermarket PM controls. Clean Techn Environ Policy 17, 1861–1871 (2015). https://doi.org/10.1007/s10098-015-0900-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0900-6