Abstract

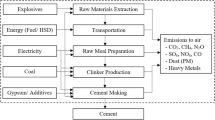

This study tries to find out the hotspots of the Spanish cement sector in 2010 by the life cycle assessment (LCA) and evaluates some improvement scenarios where best available technologies and substitution measures are taken into consideration. The document presents an environmental LCA of the cement production using the 2011 International Reference Life Cycle Data System method recommended by the European Commission. Attending to the clinker production by stage, fossil fuel combustion is the most important source in terms of impacts. Besides, limestone’s calcination is crucial attending to the climate change. Electricity consumption is also relevant both in human toxicity with cancer effects and freshwater eutrophication (FE). Accordingly, solutions deployed lead to reductions in different impact categories. Fossil fuel substitution scenario achieves to reduce 33 and 37 % photochemical ozone formation and acidification (A), while material substitution scenario leads to reduce 10–13 % each impact category. On the other hand, fossil fuel substitution scenario entails an increase of 10 % in FE. Considering the ideal case of applying all these improvements together, reductions go from 15 % in FE to 49 % in A, respectively. To face the problems derived from fossil fuel combustion, a fuel shift is needed to reach less contaminant options such as biomass and bio-waste. Material substitution is another good solution for the industry, but it requires a change in the demand and further research to ensure the properties of cement. Authors recommend taking into consideration the collateral increase of the FE due to the phosphates increase coming from the alternative fuels combustion.

Similar content being viewed by others

References

Benhelal E, Zahedi G, Shamsaei E, Bahadori A (2013) Global strategies and potentials to curb CO2 emissions in cement industry. J Clean Prod 51:142–161

Boesch ME, Hellweg S (2010) Identifying improvement potentials in cement production with life cycle assessment. Environ Sci Technol 44(23):9143–9149

Boesch ME, Meister R (2011) Manual for LCA 4 AFR. Module: cement kiln. ETH Zurich. Institute of Environmental Engineering Group for Ecological Systems Design. Zurich. www.ifu.ethz.ch/ESD/downloads/LCA4AFR/box_feeder/Manual_LCA4AFR_Cementkiln_v2.0.pdf. Accessed 03 Nov 2014

Brown D, Sadiq R, Hewage K (2014) An overview of air emission intensities and environmental performance of grey cement manufacturing in Canada. Clean Technol Environ Policy. doi:10.1007/s10098-014-0714-y

Cardim de Carvalho A (2001) Análisis de Ciclo de Vida (LCA) de Productos derivados del Cemento – Aportaciones al análisis de los inventarios del ciclo de vida del cemento. (In English: Life Cycle Assessment of the cement-derived products—Contributions to the study of the cement Life Cycle inventories). Thesis. Universidad Politécnica de Cataluña, Barcelona

CEMA (2009) Reciclado y Valorización de Residuos en la Industria Cementera en España (In English: Recycling and Valorization of waste in the Spanish cement industry). 2007–2009 update. Fundación Laboral del Cemento y el Medio Ambiente (CEMA). Instituto Cerdá for OFICEMEN, Madrid

CEMA (2010) Reciclado y Valorización de Residuos en la Industria Cementera en España. (In English: Recycling and Valorization of waste in the Spanish cement industry). 2010 update. Fundación Laboral del Cemento y el Medio Ambiente (CEMA). Instituto Cerdá for OFICEMEN, Madrid

CEMBUREAU (2009) Sustainable cement production. Co-processing of alternative fuels and raw materials in the European Cement Industry 2009. The European Cement Association, Brussels

CEMBUREAU (2011) Activity Report 2011. The European Cement Association, Brussels

CEMBUREAU (2012) Cements for a low-carbon Europe. A review of the diverse solutions applied by the European cement industry through clinker substitution to reducing the carbon footprint of cement and concrete in Europe. The European Cement Association, Brussels

CEN/TC-51 (2000) EN 197-1 Cement—part I: composition, specifications and conformity criteria for common cements; European Committee for Standardization

CORINAIR (2006) Combustion in manufacturing industry. Group 3. Cement. Table 8.2a. Emission factors for the production of cement (fuel related)

EC (2001) Directive 2001/81/EC. European Directive on national emission ceilings for certain atmospheric pollutants. Brussels

EC (2008) Directive 2008/98/EC. European Directive on wastes. Arts. 3–4. Brussels

EC (2009) Directive 2009/29/EC. European Directive amending Directive 2003/87/EC so as to improve and extend the greenhouse gas emission allowance trading scheme of the Community. Brussels

EC (2010) Directive 2010/75/EC. European Directive on industrial emission (integrated pollution prevention and control). Brussels

EC-JRC (2011) International Reference Life Cycle Data System (ILCD) Handbook Recommendations for Life Cycle Impact Assessment in the European context. 1st edition Nov 2011. European Commission—Joint Research Centre—Institute for Environment and Sustainability. Ispra

EC-JRC (2012) Characterisation factors of the ILCD Recommended Life Cycle Impact Assessment methods. Database and Supporting Information, First edn. European Commission, Joint Research Centre, Institute for Environment and Sustainability. Ispra

ECOINVENT (2010) Ecoinvent-center. Ecoinvent database v2.2 (2010); Swiss Centre for Life Cycle Inventories: 2010. www.ecoinvent.org/database/. Accessed 03 Nov 2014

EIPPCB (2013) Integrated Pollution Prevention and Control (IPPC): Reference Document on Best Available Techniques in the Cement and Lime Manufacturing Industries; European Integrated Pollution Prevention and Control Bureau: Joint Research Centre—Institute for Prospective Technological Studies. Seville

Fiksel J, Bakshi BR, Baral A, Guerra E, DeQuervain B (2011) Comparative life cycle assessment of beneficial applications for scrap tires. Clean Technol Environ Policy 13:19–35

García-Gusano D, Garraín D, Herrera I, Cabal H, Lechón Y (2013) Life Cycle Assessment of applying CO2 post-combustion capture to the Spanish cement production. J Clean Prod. doi:10.1016/j.jclepro.2013.11.056 (in press, corrected proof)

Habert G (2013) A method for allocation according to the economic behaviour in the EU-ETS for by-products used in cement industry. Int J LCA 18(1):113–126

Huntzinger DN, Eatmon TD (2009) A life-cycle assessment of Portland cement manufacturing: comparing the traditional process with alternative technologies. J Clean Prod 17(7):668–675

IEA (2007) Tracking industrial energy efficiency and CO2 emissions. International Energy Agency, Paris

IEA (2009a) Energy technology transitions for industry: strategies for the next industrial revolution. International Energy Agency, Paris

IEA (2009b) Cement technology roadmap: carbon emissions reductions up to 2050. International Energy Agency—The World Business Council for Sustainable Development, Paris

IEA GHG (2008) CO2 capture in the cement industry: international energy agency. Greenhouse Gas R&D Programme, Cheltenham

Ioannou S, Reig L, Paine K, Quillin K (2014) Properties of ternary calcium sulfoaluminate–calcium sulfate–fly ash cement. Cem Concr Res 56:75–83

ISO (2006) International Standard ISO 14040: Environmental Management. Life Cycle Assessment. Principles and Framework; International Organisation for Standardization, Geneva

Josa A, Aguado A, Cardim A, Byars E (2007) Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem Concr Res 37:781–788

Junta de Andalucía (2011) Guía de apoyo para la notificación de la industria de fabricación de elementos cerámicos de construcción. Notificación de datos PRTR. Epígrafe 3.g. Servicio de Prevención y Control Ambiental. Consejería de Medio Ambiente. Junta de Andalucía. (In English: Support guide for the notification of the emissions of the ceramic building production industry), Seville

Law 16 (2002) National Law 16/2002 on integrated pollution control. BOE-A-2007-8352. Madrid

Law 22 (2011) National Law 22/2011 on wastes and contaminated soils. BOE-A-2011-13046. Madrid

MAGRAMA (2012) Inventario de Gases de Efecto Invernadero de España. Edición 2012. Serie 1990–2010. Sumario de resultados (In English: Spanish GHG inventory 2012. Serie 1990–2010. Summary of results). Ministerio de Agricultura, Alimentación y Medio Ambiente (Ministry of Agricultura, Food and the Environment), Madrid

Masanet E, Stadel A, Gursel P (2012) Life-cycle evaluation of concrete building construction as a strategy for sustainable cities, SN3119, Portland Cement Association. Skokie, Illinois

MMA (2004) Guía de Mejores Técnicas Disponibles en España de Fabricación de Cemento (In English: Best Available Techniques Referente Document for the Spanish cement industry). Ministerio de Medio Ambiente (Ministry of Environment). Dirección General de Calidad y Evaluación Medioambiental, Madrid

Moya JA, Pardo N, Mercier A (2010) Energy efficiency and CO2 emissions: prospective scenarios for the cement industry. European Commission. Joint Research Centre—Institute for Energy, Petten

OFICEMEN (2010a) Anuario de 2010 (In English: Annual report 2010). Agrupación de Fabricantes de Cemento de España (Spanish Cement Association), Madrid

OFICEMEN (2010b) Informe CO2 de 2010 (In English: CO2 report 2010). Agrupación de Fabricantes de Cemento de España (Spanish Cement Association), Madrid

PRé Consultants (2012) SimaPro Life Cycle Assessment Software Package. V. 7.3.3. PRé Consultants. Amersfoort

PRTR-ES (2010) Spanish pollutant release and transfer registry. (E-PRTR Regulation and Royal Decree 58/2007). 2010 data. Accessed 03 Nov 2014

RD (2003) Royal Decree 653/2003 on waste incineration in Spain. BOE-A-2003-11946. Madrid

REE (2011) El sistema eléctrico español 2011 (In English: The Spanish electricity system in 2011). Red Eléctrica de España (Spanish electricity system, network operador). Alcobendas

Shi C, Fernández AV, Palomo A (2011) New cements for the 21st century: the pursuit of an alternative to Portland cement. Cem Concr Res 41(7):750–763

Valderrama C, Granados R, Cortina JL, Gasol CM, Guillem M, Josa A (2012) Implementation of best available techniques in cement manufacturing: a life-cycle assessment study. J Clean Prod 25:60–67

Valderrama C, Granados R, Cortina JL, Gasol CM, Guillem M, Josa A (2013) Comparative LCA of sewage sludge valorisation as both fuel and raw material substitute in clinker production. J Clena Prod 51:205–213

Van Oss HG, Padovani AC (2003) Cement manufacture and the environment part II: environmental challenges and opportunities. J Ind Ecol 7(1):93–126

Volkart K, Bauer C, Boulet C (2013) Life cycle assessment of carbon capture and storage in power generation and industry in Europe. Int J Greenhouse Gas Control 16:91–106

WBCSD (2009) The cement sustainability initiative. cement industry energy and CO2 performance. “Getting the Numbers Right”. World Business Council for Sustainable Development. Cement Sustainability Initiative (CSI), Conches-Geneva

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

See Table 9.

Appendix 2

See Table 10.

Appendix 3

See Table 11.

Appendix 4

See Fig. 4.

Rights and permissions

About this article

Cite this article

García-Gusano, D., Herrera, I., Garraín, D. et al. Life cycle assessment of the Spanish cement industry: implementation of environmental-friendly solutions. Clean Techn Environ Policy 17, 59–73 (2015). https://doi.org/10.1007/s10098-014-0757-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-014-0757-0