Abstract

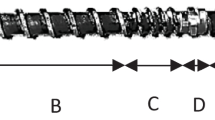

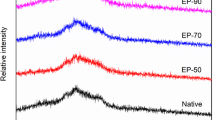

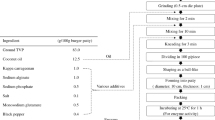

In this study, textured vegetable protein (TVP) based on soy protein isolate, wheat gluten, and corn starch was prepared at a 5:3:2 (w/w) ratio using a low-moisture extrusion process. To evaluate the effects of extrusion parameters, die temperature and screw rotation speed, on the properties of TVP, these two parameters were manipulated at a constant barrel temperature and moisture content. The results indicated that increasing the die temperature increased the expansion ratio while decreasing the density of the extrudates. Simultaneously, increasing the screw rotation speed clearly increased the specific mechanical energy of the TVP. Furthermore, mathematical modelling suggested that the expansion ratio increases exponentially to the die temperature. However, extreme process conditions bring about a decrease in water absorption capacity and expansion ratio, as well as undesirable texture and microstructure. The results suggested that the properties of SPI-based TVP are directly influenced by the extrusion process parameters, screw speed and die temperature.

Similar content being viewed by others

References

Akdogan H. High moisture food extrusion. International Journal of Food Science & Technology. 34: 195-207 (1999)

Asgar M, Fazilah A, Huda N, Bhat R, Karim A. Nonmeat protein alternatives as meat extenders and meat analogs. Comprehensive Reviews in Food Science and Food Safety. 9: 513-529 (2010)

Ataei F, Hojjatoleslamy M. Physicochemical and sensory characteristics of sponge cake made with olive leaf. Journal of Food Measurement and Characterization. 11: 2259-2264 (2017)

Beck SM, Knoerzer K, Arcot J. Effect of low moisture extrusion on a pea protein isolate’s expansion, solubility, molecular weight distribution and secondary structure as determined by Fourier Transform Infrared Spectroscopy (FTIR). Journal of Food Engineering. 214: 166-174 (2017)

Beck SM, d Knoerzer K, Foerster M, Mayo S, Philipp C, Arcot J. Low moisture extrusion of pea protein and pea fibre fortified rice starch blends. Journal of Food Engineering. 231: 61-71 (2018)

Bhattacharya S, CHOUDHURY GS. Twin‐screw extrusion of rice flour: Effect of extruder length‐to‐diameter ratio and barrel temperature on extrusion parameters and product characteristics. Journal of Food Processing and Preservation. 18: 389-406 (1994)

Branch S, Maria S. Evaluation of the functional properties of mung bean protein isolate for development of textured vegetable protein. International Food Research Journal. 24: 1595-1605 (2017)

Chen FL, Wei YM, Zhang B, Ojokoh AO. System parameters and product properties response of soybean protein extruded at wide moisture range. Journal of Food Engineering. 96: 208-213 (2010)

De Smet S, Vossen E. Meat: The balance between nutrition and health. A review. Meat Science. 120: 145-156 (2016)

do Carmo CS, Varela P, Poudroux C, Dessev T, Myhrer K, Rieder A, Zobel H, Sahlstrom S, Knutsen SH. The impact of extrusion parameters on physicochemical, nutritional and sensorial properties of expanded snacks from pea and oat fractions. LWT. 112: 108252 (2019)

Ferawati F, Zahari I, Barman M, Hefni M, Ahlström C, Witthöft C, Östbring K. High-moisture meat analogues produced from yellow pea and faba bean protein isolates/concentrate: Effect of raw material composition and extrusion parameters on texture properties. Foods. 10: 843 (2021)

Gu BY, Ryu GH. Effects of moisture content and screw speed on physical properties of extruded soy protein isolate. Journal of the Korean Society of Food Science and Nutrition. 46: 751-758 (2017)

Gu BY, Ryu GH. Influence of extrusion process parameters on specific mechanical energy and physical properties of high-moisture meat analog. International Journal of Food Engineering. 17: 149-157 (2021)

Guerrero P, Beatty E, Kerry J, De la Caba K. Extrusion of soy protein with gelatin and sugars at low moisture content. Journal of Food Engineering. 110: 53-59 (2012)

Guyony V, Fayolle F, Jury V. High moisture extrusion of vegetable proteins for making fibrous meat analogs: A review. Food Reviews International. 1-26 (2022)

Hoek AC, Luning PA, Weijzen P, Engels W, Kok FJ, De Graaf C. Replacement of meat by meat substitutes. A survey on person-and product-related factors in consumer acceptance. Appetite. 56: 662-673 (2011)

Krintiras GA, Göbel J, Van der Goot AJ, Stefanidis GD. Production of structured soy-based meat analogues using simple shear and heat in a Couette Cell. Journal of Food Engineering. 160: 34-41 (2015)

Kumar P, Sharma B, Kumar R, Kumar A. Optimization of the level of wheat gluten in analogue meat nuggets. Indian Journal of Veterinary Research (The). 21: 54-59 (2012)

Lazou A, Krokida M. Structural and textural characterization of corn–lentil extruded snacks. Journal of Food Engineering. 100: 392-408 (2010)

Lee JS, Oh H, Choi I, Yoon CS, Han J. Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology. LWT. 113056 (2022)

Lin S, Huff H, Hsieh F. Texture and chemical characteristics of soy protein meat analog extruded at high moisture. Journal of Food Science. 65: 264-269 (2000)

Liu S, Peng M, Tu S, Li H, Cai L, Yu X. Development of a new meat analog through twin-screw extrusion of defatted soy flour-lean pork blend. Food Science and Technology International. 11: 463-470 (2005)

Maskus H, Arntfield S. Extrusion processing and evaluation of an expanded, puffed pea snack product. Journal of Nutrition & Food Sciences. 5: 1000378 (2015)

Mattice KD, Marangoni AG. Comparing methods to produce fibrous material from zein. Food Research International. 128: 108804 (2020)

Milani TMG, Menis MEC, Jordano A, Boscolo M, Conti-Silva AC. Pre-extrusion aromatization of a soy protein isolate using volatile compounds and flavor enhancers: Effects on physical characteristics, volatile retention and sensory characteristics of extrudates. Food Research International. 62: 375-381 (2014)

Omohimi C, Sobukola O, Sarafadeen K, Sanni L. Effect of thermo-extrusion process parameters on selected quality attributes of meat analogue from mucuna bean seed flour. Nigerian Food Journal. 32: 21-30 (2014)

Osen R, Toelstede S, Wild F, Eisner P, Schweiggert-Weisz U. High moisture extrusion cooking of pea protein isolates: Raw material characteristics, extruder responses, and texture properties. Journal of Food Engineering. 127: 67-74 (2014)

Osen R. Texturization of pea protein isolates using high moisture extrusion cooking. Technische Universität München. (2017)

Parada J, Aguilera JM, Brennan C. Effect of guar gum content on some physical and nutritional properties of extruded products. Journal of Food Engineering. 103: 324-332 (2011)

Park JH, Kang DI, Ryu GH. Effects of screw speed, moisture content, and die temperature on texturization of extruded soy protein isolate. Journal of the Korean Society of Food Science and Nutrition. 45: 1170-1176 (2016)

Rathod RP, Annapure US. Physicochemical properties, protein and starch digestibility of lentil based noodle prepared by using extrusion processing. LWT. 80: 121-130 (2017)

Rehrah D, Ahmedna M, Goktepe I, Yu J. Extrusion parameters and consumer acceptability of a peanut‐based meat analogue. International Journal of Food Science & Technology. 44: 2075-2084 (2009)

Samard S, Gu BY, Ryu GH. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. Journal of the Science of Food and Agriculture. 99: 4922-4931 (2019)

Samard S, Gu BY, Kim MH, Ryu GH. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Science and Biotechnology. 30: 395-403 (2021)

Schreuders FK, Dekkers BL, Bodnár I, Erni P, Boom RM, van der Goot AJ. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. Journal of Food Engineering. 261: 32-39 (2019)

Verbeek CJ, van den Berg LE. Extrusion processing and properties of protein‐based thermoplastics. Macromolecular Materials and Engineering. 295: 10-21 (2010)

Wittek P, Zeiler N, Karbstein HP, Emin MA. High moisture extrusion of soy protein: Investigations on the formation of anisotropic product structure. Foods. 10: 102 (2021)

Yeh AI, Jaw YM. Effects of feed rate and screw speed on operating characteristics and extrudate properties during single‐screw extrusion cooking of rice flour. Cereal Chemistry. 76: 236-242 (1999)

Yu L. Extrusion processing of protein rich food formulations: McGill University (Canada) (2011)

Yuliarti O, Kovis TJK, Yi NJ. Structuring the meat analogue by using plant-based derived composites. Journal of Food Engineering. 288: 110138 (2021)

Zhang J, Liu L, Liu H, Yoon A, Rizvi SS, Wang Q. Changes in conformation and quality of vegetable protein during texturization process by extrusion. Critical Reviews in Food Science and Nutrition. 59: 3267-3280 (2019)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lyu, J.S., Lee, JS., Chae, T.Y. et al. Effect of screw speed and die temperature on physicochemical, textural, and morphological properties of soy protein isolate-based textured vegetable protein produced via a low-moisture extrusion. Food Sci Biotechnol 32, 659–669 (2023). https://doi.org/10.1007/s10068-022-01207-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-022-01207-8