Abstract

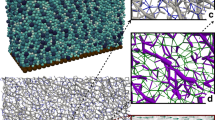

Deformable granular flows present complex kinematics. These materials can have various flow regimes: plastic, agglomerated, rigid-like granular flow, etc. In this paper, a multibody meshfree model is used to investigate the consequences of cohesion, stiffness, and viscosity of the particles on their collective sheared flows in tribological contacts. An approach derived from fluid mechanics postprocessing tools, based on vortex detection, is employed to understand the links between these parameters and the emerging friction coefficient of the sheared interface. These results pave the way to complete kinematic studies of third body simulations in tribological contacts.

Similar content being viewed by others

References

Dowson, D.: History of Tribology, 2nd edn. Wiley, Hoboken (1998)

Descartes, S., Courtieux, L., Berthier, Y., Peditto, F.: Tribological study of oral care silica. Tribol. Int. 82, 551–560 (2015). https://doi.org/10.1016/j.triboint.2014.02.023

Godet, M.: The third-body approach: a mechanical view of wear. Wear 100, 437–452 (1984). https://doi.org/10.1016/0043-1648(84)90025-5

Berthier, Y., Vincent, L., Godet, M.: Velocity accommodation in fretting. Wear 125, 25–38 (1988). https://doi.org/10.1016/0043-1648(88)90191-3

Berthier, Y., Vincent, L., Godet, M.: Fretting fatigue and fretting wear. Tribol. Int. 22, 235–242 (1989). https://doi.org/10.1016/0301-679X(89)90081-9

Kounoudji, K.A., Renouf, M., Mollon, G., Berthier, Y.: Role of third body on bolted joints’ self-loosening. Tribol. Lett. 61, 25 (2016). https://doi.org/10.1007/s11249-016-0640-8

Vingsbo, O., Söderberg, S.: On fretting maps. Wear 126, 131–147 (1988). https://doi.org/10.1016/0043-1648(88)90134-2

Vincent, L., Berthier, Y., Dubourg, M.-C., Godet, M.: Mechanics and materials in fretting. Wear 153, 135–148 (1992). https://doi.org/10.1016/0043-1648(92)90266-B

Collins, J.A.: Failure of Materials in Mechanical Design, 2nd edn. Wiley, Honoken (1993)

Arnaud, P., Baydoun, S., Fouvry, S.: Modeling adhesive and abrasive wear phenomena in fretting interfaces: a multiphysics approach coupling friction energy, third body and contact oxygenation concepts. Tribol. Int. 161, 107077 (2021). https://doi.org/10.1016/j.triboint.2021.107077

Baydoun, S., Fouvry, S., Descartes, S.: Modeling contact size effect on fretting wear: a combined contact oxygenation-third body approach. Wear (2021). https://doi.org/10.1016/j.wear.2021.204168

Wang, D., Dijksman, J.A., Barés, J., Zheng, H.: Strain dependent vorticity in sheared granular media. EPJ Web Conf. 249, 02010 (2021). https://doi.org/10.1051/epjconf/202124902010

Forterre, Y., Pouliquen, O.: Stability analysis of rapid granular chute flows: formation of longitudinal vortices. J. Fluid Mech. 467, 361–387 (2002). https://doi.org/10.1017/S0022112002001581

Abedi, S., Rechenmacher, A.L., Orlando, A.D.: Vortex formation and dissolution in sheared sands. Granul. Matter. 14, 695–705 (2012). https://doi.org/10.1007/s10035-012-0369-5

Rognon, P., Miller, T., Einav, I.: A circulation-based method for detecting vortices in granular materials. Granul. Matter. 17, 177–188 (2015). https://doi.org/10.1007/s10035-015-0549-1

Ding, J., Leen, S.B., McColl, I.R.: The effect of slip regime on fretting wear-induced stress evolution. Int. J. Fatigue 26, 521–531 (2004). https://doi.org/10.1016/j.ijfatigue.2003.09.001

Basseville, S., Cailletaud, G.: An evaluation of the competition between wear and crack initiation in fretting conditions for Ti–6Al–4V alloy. Wear 328–329, 443–455 (2015). https://doi.org/10.1016/j.wear.2015.03.010

Mary, C., Fouvry, S.: Numerical prediction of fretting contact durability using energy wear approach: optimisation of finite-element model. Wear 263, 444–450 (2007). https://doi.org/10.1016/j.wear.2007.01.116

Paulin, C., Fouvry, S., Meunier, C.: Finite element modelling of fretting wear surface evolution: application to a Ti–6A1–4V contact. Wear 264, 26–36 (2008). https://doi.org/10.1016/j.wear.2007.01.037

Ding, J., McColl, I.R., Leen, S.B., Shipway, P.H.: A finite element based approach to simulating the effects of debris on fretting wear. Wear 263, 481–491 (2007). https://doi.org/10.1016/j.wear.2006.12.056

Gallego, L., Nélias, D., Deyber, S.: A fast and efficient contact algorithm for fretting problems applied to fretting modes I, II and III. Wear 268, 208–222 (2010). https://doi.org/10.1016/j.wear.2009.07.019

Gallego, L., Fulleringer, B., Deyber, S., Nélias, D.: Multiscale computation of fretting wear at the blade/disk interface. Tribol. Int. 43, 708–718 (2010). https://doi.org/10.1016/j.triboint.2009.10.011

Renouf, M., Massi, F., Fillot, N., Saulot, A.: Numerical tribology of a dry contact. Tribol. Int. 44, 834–844 (2011). https://doi.org/10.1016/j.triboint.2011.02.008

Cundall, P.A., Hart, R.D.: Numerical modelling of dicontinua. Eng. Comput. 9, 101–113 (1992). https://doi.org/10.1108/eb023851

Chapteuil, É., Renouf, M., Zeng, C., Berthier, Y.: Influence of copper/graphite properties on the tribological and electrical behavior of copper-graphite third body layer. Lubricants 6, 109 (2018). https://doi.org/10.3390/lubricants6040109

Rivière, J., Renouf, M., Berthier, Y.: Thermo-mechanical investigations of a tribological interface. Tribol. Lett. 58, 48 (2015). https://doi.org/10.1007/s11249-015-0523-4

Champagne, M., Renouf, M., Berthier, Y.: Modeling wear for heterogeneous bi-phasic materials using discrete elements approach. J. Tribol. 136, 1–11 (2014). https://doi.org/10.1115/1.4026053

Renouf, M., Fillot, N.: Coupling electrical and mechanical effects in discrete element simulations. Int. J. Numer. Methods Eng. 74, 238–254 (2008). https://doi.org/10.1002/nme.2157

Descartes, S., Renouf, M., Fillot, N., Gautier, B., Descamps, A., Berthier, Y., Demanche, P.: A new mechanical–electrical approach to the wheel-rail contact. Wear 265, 1408–1416 (2008). https://doi.org/10.1016/j.wear.2008.02.040

Renouf, M., Nhu, V.-H., Saulot, A., Massi, F.: First-body versus third-nody: dialogue between an experiment and a combined discrete and finite element approach. J. Tribol. 136, 1–9 (2014). https://doi.org/10.1115/1.4026062

Li, W., Huang, Y., Fu, B., Cui, Y., Dong, S.: Fretting damage modeling of liner-bearing interaction by combined finite element–discrete element method. Tribol. Int. 61, 19–31 (2013). https://doi.org/10.1016/j.triboint.2012.11.019

Leonard, B.D., Ghosh, A., Sadeghi, F., Shinde, S., Mittelbach, M.: Third body modeling in fretting using the combined finite-discrete element method. Int. J. Solids Struct. 51, 1375–1389 (2014). https://doi.org/10.1016/j.ijsolstr.2013.12.036

Dijksman, J.A., Brodu, N., Behringer, R.P.: Refractive index matched scanning and detection of soft particles. Rev. Sci. Instrum. 88, 051807 (2017). https://doi.org/10.1063/1.4983047

Vu, T.-L., Barés, J.: Soft-grain compression: beyond the jamming point. Phys. Rev. E. 100, 042907 (2019). https://doi.org/10.1103/PhysRevE.100.042907

Cantor, D., Cárdenas-Barrantes, M., Preechawuttipong, I., Renouf, M., Azéma, E.: Compaction model for highly deformable particle assemblies. Phys. Rev. Lett. 124, 208003 (2020). https://doi.org/10.1103/PhysRevLett.124.208003

Nguyen, T.H., Nezamabadi, S., Delenne, J.-Y., Radjai, F.: Compaction of granular materials composed of deformable particles. EPJ Web Conf. 140, 05013 (2017). https://doi.org/10.1051/epjconf/201714005013

Harthong, B., Jérier, J.-F., Richefeu, V., Chareyre, B., Dorémus, P., Imbault, D., Donzé, F.-V.: Contact impingement in packings of elastic–plastic spheres, application to powder compaction. Int. J. Mech. Sci. 61, 32–43 (2012). https://doi.org/10.1016/j.ijmecsci.2012.04.013

Favier de Coulomb, A., Bouzid, M., Claudin, P., Clément, E., Andreotti, B.: Rheology of granular flows across the transition from soft to rigid particles. Phys. Rev. Fluids. 2, 102301 (2017). https://doi.org/10.1103/PhysRevFluids.2.102301

Doucet, J.-P., Weber, J.: Computer-Aided Molecular Design: Theory and Applications. Academic Press, Cambridge (1996)

Aghababaei, R., Warner, D.H., Molinari, J.-F.: Critical length scale controls adhesive wear mechanisms. Nat. Commun. 7, 11816 (2016). https://doi.org/10.1038/ncomms11816

Molinari, J.-F., Aghababaei, R., Brink, T., Frérot, L., Milanese, E.: Adhesive wear mechanisms uncovered by atomistic simulations. Friction. 6, 245–259 (2018). https://doi.org/10.1007/s40544-018-0234-6

Robbins, M.O., Müser, M.H.: Computer simulations of friction, lubrication, and wear. In: Modern Tribology Handbook, Two Volume Set, pp. 717–765 (2000). https://doi.org/10.1201/9780849377877.ch20

Mollon, G.: Solid flow regimes within dry sliding contacts. Tribol. Lett. 67, 120 (2019). https://doi.org/10.1007/s11249-019-1233-0

Mollon, G.: A multibody meshfree strategy for the simulation of highly deformable granular materials. Int. J. Numer. Methods Eng. 108, 1477–1497 (2016). https://doi.org/10.1002/nme.5258

Mollon, G.: A unified numerical framework for rigid and compliant granular materials. Comput. Part. Mech. 5, 517–527 (2018). https://doi.org/10.1007/s40571-018-0187-6

Zhang, Y., Mollon, G., Descartes, S.: Significance of third body rheology in friction at a dry sliding interface observed by a multibody meshfree model: influence of cohesion between particles. Tribol. Int. 145, 106188 (2020). https://doi.org/10.1016/j.triboint.2020.106188

Quacquarelli, A., Mollon, G., Commeau, T., Fillot, N.: A dual numerical-experimental approach for modeling wear of Diamond Impregnated Tools. Wear 478–479, 203763 (2021). https://doi.org/10.1016/j.wear.2021.203763

Casas, N., Mollon, G., Daouadji, A.: DEM analyses of cemented granular fault gouges at the onset of seismic sliding: peak strength, development of shear zones and kinematics. Earth Sp. Sci. Open Arch. (2021). https://doi.org/10.1002/essoar.10507128.1

Jaza, R., Mollon, G., Descartes, S., Paquet, A., Berthier, Y.: Lessons learned using machine learning to link third body particles morphology to interface rheology. Tribol. Int. 153, 106630 (2021). https://doi.org/10.1016/j.triboint.2020.106630

Graftieaux, L., Michard, M., Grosjean, N.: Combining PIV, POD and vortex identification algorithms for the study of unsteady turbulent swirling flows. Meas. Sci. Technol. 12, 1422–1429 (2001). https://doi.org/10.1088/0957-0233/12/9/307

Berson, A., Michard, M., Blanc-Benon, P.: Vortex identification and tracking in unsteady flows. C. R. Mec. 337, 61–67 (2009). https://doi.org/10.1016/j.crme.2009.03.006

Macaulay, M., Rognon, P.: Viscosity of cohesive granular flows. Soft Matter 17, 165–173 (2021). https://doi.org/10.1039/D0SM01456G

Mandal, S., Nicolas, M., Pouliquen, O.: Rheology of cohesive granular media: shear banding, hysteresis, and nonlocal effects. Phys. Rev. X 11, 021017 (2021). https://doi.org/10.1103/PhysRevX.11.021017

Mollon, G.: The soft discrete element method. Granul. Matter. 24, 11 (2022). https://doi.org/10.1007/s10035-021-01172-9

Acknowledgements

The authors gratefully acknowledge Safran Aircraft Engines and the French National Research and Technology Agency (ANRT) for financially supporting this research project. The authors acknowledge that this study contains original material. Its publication has been approved tacitly by the responsible authorities at the institutes where the work has been carried out.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bouillanne, O., Mollon, G., Saulot, A. et al. How vorticity and agglomeration control shear strength in soft cohesive granular flows. Granular Matter 24, 55 (2022). https://doi.org/10.1007/s10035-022-01216-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01216-8