Abstract

The discrete element method (DEM) has been extensively used to capture the macroscopic and particulate response of granular materials. Although particle rolling (i.e. controlled by rolling resistance) has been acknowledged as a major contributing factor towards micro-mechanical behaviour of idealized spherical granular material, its influence on characteristic behaviour has not been thoroughly investigated within critical state soil mechanics (CSSM) framework. For instance, the influence of particle rolling on characteristic features of undrained and drained behaviour (e.g. phase transformation, characteristic state, instability, dilatancy, critical state) and the state parameter, (ψ) has not been captured. In this study, a series of constant volume (CV) and drained triaxial compression simulations were undertaken using a rolling resistance linear contact model, deployed within a DEM software. The CSSM framework was centrally used to assess the influence of particle rolling tendencies/resistance on CV and drained behaviours from both a macro- and micro-mechanical standpoint. The study advanced the current understanding of the influence of rolling resistance on CS-related behaviour.

Graphic abstract

Similar content being viewed by others

Abbreviations

- Δu :

-

Excess pore water pressure

- ε q :

-

Deviatoric strain

- ε v :

-

Volumetric strain

- η IS :

-

Stress ratio at instability state

- η ChS :

-

Stress ratio at instability state

- η PT :

-

Stress ratio at phase transformation

- μ :

-

Inter-particle friction coefficient

- μ r :

-

Rolling resistance coefficient

- σ 11 :

-

Maximum principal stress

- σ 33 :

-

Minor principal stress

- ϕ cv :

-

Constant volume friction angle

- ϕ p :

-

Peak friction angle

- ψ :

-

State parameter

- ψ 0 :

-

State parameter at the beginning of shearing

- ω avg :

-

Average angular velocity

- ω cs :

-

Average angular velocity at critical state

- CN :

-

Coordination number

- D 50 :

-

Median particle size

- e :

-

Void ratio

- e 0 :

-

POST-consolidation void ratio

- F :

-

Fabric tensor

- F vM :

-

Von Mises fabric

- I :

-

Inertial number

- k n :

-

Normal contact stiffness

- k s :

-

Tangential contact stiffness

- k r :

-

Rolling contact stiffness

- M :

-

Slope of CSL in q − p′ space

- N :

-

Total number of particles

- N c :

-

Total number of contacts

- p′:

-

Mean effective confining stress

- p′cs :

-

Mean effective confining stress at critical state

- p′0 :

-

Post-consolidation mean effective confining stress

- q :

-

Deviatoric stress

References

Aboul Hosn, R., Sibille, L., Benahmed, N., Chareyre, B.: Discrete numerical modeling of loose soil with spherical particles and interparticle rolling friction. Granular Matter 19(1), 1–12 (2017)

Ai, J., Chen, J., Rotter, M., Ooi, J.Y.: Assessment of rolling resistance models in discrete element simulations. Powder Technol. 206, 269–282 (2011)

Barnett, N., Rahman, M.M., Karim, M.R., Nguyen, H.B.K., Carraro, J.A.H.: Equivalent state theory for sand with non-plastic fine mixtures: a DEM investigation. In press, Geotechnique (2020)

Been, K., Jefferies, M.G.: A state parameter for sands. Geotechnique 35(2), 99–112 (1985)

Been, K., Jefferies, M.G., Hachey, J.: The critical state of sands. Geotechnique 41(3), 365–381 (1991)

Bobei, D.C., Wanatowski, D., Rahman, M.M., Lo, S.R., Gnanendran, C.T.: The effect of drained pre-shearing on the undrained behaviour of loose sand with a small amount of fines. Acta Geotech. 8(3), 311–322 (2013)

Calvetti, F., Emeriault, F.: Interparticle forces distribution in granular materials: link with the macroscopic behaviour. Mech. Cohes-Frict. Mat. 4(3), 247–279 (1999)

Carrera, A., Coop, M., Lancellotta, R.: Influence of grading on the mechanical behaviour of stava tailings. Geotechnique 61(11), 935–946 (2011)

Casagrande, A.: Liquefaction and cyclic deformation of sands. In: 5th Pan American conference on soil mechanics Buenos Aires, pp. 80–133 (1975)

Chang, X., Wang, Y., Zhou, W., Ma, G., Liu, J.: The influence of rotational resistance on critical state of granular materials. In: Proceedings of the 7th International Conference on Discrete Element Methods (2016)

Christoffersen, J., Mehrabadi, M.M., Nemat-Nasser, S.: A micromechanical description of granular material behavior. J. Appl. Mech. 48(2), 339–344 (1981)

Chu, J.: An experimental examination of the critical state and other similar concepts for granular soils. Can. Geotech. J. 32(6), 1065–1075 (1995)

Chu, J., Leong, W.K.: Effect of fines on instability behaviour of loose sand. Geotechnique 52(10), 751–755 (2002)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

da Cruz, F., Emam, S., Prochnow, M., Roux, J.-N., Chevoir, F.: Rheophysics of dense granular materials: discrete simulation of plane shear flows. Phys. Rev. E 72(2), 021309 (2005)

Dafalias, Y.F., Taiebat, M.: SANISAND-Z: zero elastic range sand plasticity model. Geotechnique, 1–15 (2016)

Estrada, N., Taboada, A., Radjaï, F.: Shear strength and force transmission in granular media with rolling resistance. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 78(2), 021301–021301 (2008)

Fonseca, J., O’Sullivan, C., Coop, M., Lee, P.D.: Quantifying the evolution of soil fabric during shearing using directional parameters. Geotechnique 63(6), 487–499 (2013)

Fonseca, J., O’sullivan, C., Coop, M.R., Lee, P.D.: Non-invasive characterization of particle morphology of natural sands. Soils Found. 52(4), 712–722 (2012)

Frossard, E.: Effect of sand grain shape on interparticle friction; indirect measurements by Rowe’s stress dilatancy theory. Geotechnique 29(3), 341–350 (1979)

Fu, P., Dafalias, Y.F.: Fabric evolution within shear bands of granular materials and its relation to critical state theory. Int. J. Numer. Anal. Meth. Geomech. 35(18), 1918–1948 (2011)

Gu, X., Huang, M., Qian, J.: DEM investigation on the evolution of microstructure in granular soils under shearing. Granular Matter 16(1), 91–106 (2014)

Guo, N., Zhao, J.: The signature of shear-induced anisotropy in granular media. Comput. Geotech. 47, 1–15 (2013)

Guo, P., Su, X.: Shear strength, interparticle locking, and dilatancy of granular materials. Can. Geotech. J. 44(5), 579–591 (2007)

Hasan, A., Alshibli, K.A.: Experimental assessment of 3D particle-to-particle interaction within sheared sand using synchrotron microtomography. Geotechnique 60(5), 369–379 (2012)

Huang, X., Hanley, K.J., O’Sullivan, C., Kwok, C.Y.: Exploring the influence of interparticle friction on critical state behaviour using DEM. Int. J. Numer. Anal. Meth. Geomech. 38(12), 1276–1297 (2014)

Huang, X., Hanley, K.J., O’sullivan, C., Kwok, C.-Y.: Implementation of rotational resistance models: a critical appraisal. Particuology 34, 14–23 (2017)

Huang, X., O’sullivan, C., Hanley, K.J., Kwok, C.Y.: Discrete-element method analysis of the state parameter. Geotechnique, 954–965 (2014)

Ishihara, K.: Liquefaction and flow failure during earthquakes. Geotechnique 43(3), 351–415 (1993)

Isomokos, A., Georgiannou, V.: Effect of grain shape and angularity on the undrained response of fine sands. Can. Geotech. J. 47(5), 539 (2010)

Itasca: Particle Flow Code in 3 Dimensions (PFC3D) Version 4. Minnesota, USA (2008)

Iwashita, K., Oda, M.: Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. 124, 285–292 (1998)

Iwashita, K., Oda, M.: Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol. 109(1), 192–205 (2000)

Jefferies, M.G.: Nor-Sand: a simple critical state model for sand. Geotechnique 43(1), 91–103 (1993)

Jiang, M.J., Yu, H.-S., Harris, D.: A novel discrete model for granular material incorporating rolling resistance. Comput. Geotech. 32(5), 340–357 (2005)

Kuhn, M.R., Bagi, K.: Specimen size effect in discrete element simulations of granular assemblies. J. Eng. Mech. 109(1), 485–492 (2018)

Lade, P.V.: Static instability and liquefaction of loose fine sandy slopes. J Geotech. Eng.-Asce. 118(1), 51–71 (1992)

Lade, P.V., Ibsen, L.B.: A study of the phase transformation and characteristic lines of sand. In: Deformation and Progressive Failure in Geomechanics IS-NAGOYA, pp. 353–358 (1997)

Lashkari, A., Khodadadi, M., Binesh, S.M., Rahman, Md.M.: Instability of particulate assemblies under constant shear drained stress path: DEM approach. Int. J. Geomech. 19(6), 04019049 (2019)

Lee, K.L., Seed, H.B.: Dynamic strength of anisotropically consolidated sand. Proc. ASCE 93(SM5), 169–190 (1967)

Li, X., Dafalias, Y.: Anisotropic critical state theory: role of fabric. J. Eng. Mech. 138(3), 263–275 (2012)

Li, X.S.: A sand model with state-dependent dilatancy. Geotechnique 52(3), 173–186 (2002)

Li, X.S., Dafalias, Y.F.: Dilatancy for cohesionless soils. Geotechnique 50(4), 449–460 (2000)

Li, X.S., Dafalias, Y.F.: A constitutive framework for anisotropic sand including nonproportional loading. Geotechnique 54(1), 41–55 (2004)

Li, X.S., Dafalias, Y.F., Wang, Z.-L.: State-dependant dilatancy in critical-state constitutive modelling of sand. Can. Geotech. J. 36(4), 599–611 (1999)

Liu, Y., Liu, H., Mao, H.: The influence of rolling resistance on the stress-dilatancy and fabric anisotropy of granular materials. Granular Matter 20(1), 1–16 (2018)

Lopera Perez, J.C., Kwok, C.Y., O’Sullivan, C., Huang, X., Hanley, K.J.: Assessing the quasi-static conditions for shearing in granular media within the critical state soil mechanics framework. Soils Found. 56(1), 152–159 (2016)

Manzari, M.T., Dafalias, Y.F.: A critical state two-surface plasticity model for sands. Geotechnique 47(2), 255–272 (1997)

Marketos, G., Bolton, M.D.: Flat boundaries and their effect on sand testing. Int. J. Numer. Anal. Meth. Geomech. 34(8), 821–837 (2010)

MiDi, G.D.R.: On dense granular flows. Eur. Phys. J. E 14(4), 341–365 (2004)

Minh, N., Cheng, Y.: A DEM investigation of the effect of particle-size distribution on one-dimensional compression. Geotechnique 63(1), 44–53 (2013)

Minh, N., Cheng, Y., Thornton, C.: Strong force networks in granular mixtures. Granular Matter 16(1), 69–78 (2014)

Mizanur, R.M., Lo, S.R.: Predicting the onset of static liquefaction of loose sand with fines. J. Geotech. Geoenviron. Eng. 138(8), 1037–1041 (2012)

Mohamed, A., Gutierrez, M.: Comprehensive study of the effects of rolling resistance on the stress-strain and strain localization behavior of granular materials. Granular Matter 12(5), 527–541 (2010)

Murthy, T.G., Loukidis, D., Carraro, J.A.H., Prezzi, M., Salgado, R.: Undrained monotonic response of clean and silty sands. Geotechnique 57(3), 273–288 (2007)

Nakata, Y., Hyodo, M., Murata, H., Yasufuku, N.: Flow deformation of sands subjected to principal stress rotation. Soils Found. 38(2), 115–128 (1998)

Nguyen, H.B.K.: Critical State Behaviour of Granular Materials and Associated Micro-Mechanics: A DEM Study. University of South Australia, Adelaide (2017)

Nguyen, H.B.K., Rahman, M.M., Cameron, D.A., Fourie, A.B.: The effect of consolidation path on undrained behaviour of sand - A DEM approach. In: A. M. Fusao Oka, Ryosuke Uzuoka, Sayuri Kimoto (eds.) Computer Methods and Recent Advances in Geomechanics. CRC Press: Taylor & Francis Group, pp. 175–180 (2015)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Undrained behaviour of granular material and the role of fabric in isotropic and K0 consolidations: DEM approach. Geotechnique 67(2), 153–167 (2017)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Characteristic behavior of drained and undrained triaxial compression tests: DEM study. J. Geotech. Geoenviron. Eng. 144(9), 1–13 (2018)

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: How particle shape affects the critical state, triggering of instability and dilatancy of granular materials – results from a DEM study. Géotechnique (2020). https://doi.org/10.1680/jgeot.18.P.211

Nguyen, H.B.K., Rahman, M.M., Fourie, A.B.: Effect of Particle Shape on Constitutive Relation: DEM Study. J. Geotech. Geoenviron. Eng. 146(7), 04020058 (2020)

O’sullivan, C., Wadee, M.A., Hanley, K.J., Barreto, D.: Use of DEM and elastic stability analysis to explain the influence of the intermediate principal stress on shear strength. Geotechnique, 1298–1309 (2013)

Oda, M.: Fabric tensor for discontinuous geological materials. Soils Found. 22(4), 96–108 (1982)

Oda, M., Kazama, M.: Microstructure of shear bands and its relation to the mechanisms of dilatancy and failure of dense granular soils. Geotechnique 48(4), 465–481 (1998)

Oda, M., Konishi, J., Nemat-Nasser, S.: Experimental micromechanical evaluation of strength of granular materials: effect of particle rolling. Mech. Mater. 1, 269–283 (1982)

Perez, J.C.L., Kwok, C.Y., O’Sullivan, C., Huang, X., Hanley, K.J.: Exploring the micro-mechanics of triaxial instability in granular materials. Geotechnique, 1–16 (2016)

Plassiard, J., Belheine, N., Donzé, F.: A spherical discrete element model: calibration procedure and incremental response. Granular Matter 11(5), 293–306 (2009)

Qadimi, A., Coop, M.R.: The undrained cyclic behaviour of a carbonate sand. Geotechnique 57(9), 739–750 (2007)

Rabbi, A.T.M.Z., Rahman, M.M., Cameron, D.A.: Undrained behavior of silty sand and the role of isotropic and K0 consolidation. J. Geotech. Geoenviron. Eng. 144(4), 1–11 (2018)

Rabbi, A.T.M.Z., Rahman, M.M., Cameron, D.A.: Critical state study of natural silty sand instability under undrained and constant shear drained path. Int. J. Geomech. 19(8), 04019083 (2019)

Radjai, F., Wolf, D.E., Jean, M., Moreau, J.: Bimodal character of stress transmission in granular packings. Phys. Rev. Lett. 80(1), 61–64 (1998)

Rahman, M., Baki, M., Lo, S.: Prediction of undrained monotonic and cyclic liquefaction behavior of sand with fines based on the equivalent granular state parameter. Int. J. Geomech. 14(2), 254–266 (2014)

Rahman, M.M., Lo, S.-C.R., Dafalias, Y.F.: Modelling the static liquefaction of sand with low-plasticity fines. Geotechnique 64(11), 881–894 (2014)

Rahman, M.M., Lo, S.R.: Undrained behaviour of sand-fines mixtures and their state parameters. J. Geotech. Geoenviron. Eng. 140(7) (2014)

Rahman, M.M., Nguyen, H.B.K., Rabbi, A.T.M.Z.: The effect of consolidation on undrained behaviour of granular materials: experiment and DEM simulation. Geotech. Res. 5(4), 199–217 (2018). https://doi.org/10.1680/jgere.17.00019

Rahman, M.M., Nguyen, H.B.K., Fourie, A.B., Kuhn, M.: Critical state soil mechanics for cyclic liquefaction and post-liquefaction behaviour: a DEM study. J. Geotech. Geoenviron. Eng. (2020). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002453

Rothenburg, L., Bathurst, R.J.: Analytical study of induced anisotropy in idealized granular materials. Geotechnique 39(4), 601–614 (1989)

Rowe, P.W.: The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci., 269(1339), 500–527 (1962)

Satake, M.: Fabric tensor in granular materials. In: Proceedings of the IUTAM Symposium on Deformations and Failure of Granular Materials, pp. 93–96 (1982)

Sitharam, T.G., Vinod, J.S., Ravishankar, B.V.: Evaluation of undrained response from drained triaxial shear tests: DEM simulations and experiments. Geotechnique 58(7), 605–608 (2008)

Sladen, J.A., D’Hollander, R.D., Krahn, J.: The liquefaction of sands, a collapse surface approach. Can. Geotech. J. 22(4), 564–578 (1985)

Sukumaran, B., Leonards, G.A., Fox, J.P.: Discussion: liquefaction and postliquefaction behaviour of sand. J. Geotech. Geoenviron. Eng. 122(6), 502–503 (1996)

Tang, H., Dong, Y., Chu, X., Zhang, X.: The influence of particle rolling and imperfections on the formation of shear bands in granular material. Granular Matter 18(1), 1–12 (2016)

Vaid, Y.P., Sivathayalan, S., Stedman, D.: Influence of specimen-reconstituting method on the undrained response of sand. Geotech. Test. J. 22(3), 187–195 (1999)

Yan, W., Dong, J.: Effect of particle grading on the response of an idealized granular assemblage. Int. J. Geomech. 11(4), 276–285 (2011)

Yang, J.: Non-uniqueness of flow liquefaction line for loose sand. Geotechnique 52(10), 757–760 (2002)

Yang, J., Dai, B.B.: Is the quasi-steady state a real behaviour? A micromechanical perspective. Geotechnique 61(2), 175–183 (2011)

Yang, Z.X., Li, X.S., Yang, J.: Quantifying and modelling fabric anisotropy of granular soils. Geotechnique 58(4), 237–248 (2008)

Yoshimine, M., Ishihara, K.: Flow potential of sand during liquefaction. Soils Found. 38(3), 189–198 (1998)

Yoshimine, M., Ishihara, K., Vargas, W.: Effects of principal stress direction and intermediate principal stress on undrained shear behaviour of sand. Soils Found. 38(3), 179–188 (1998)

Zhang, J., Lo, S.C.R., Rahman, M.M., Yan, J.: “Characterizing monotonic behaviour of pond ash within critical state approach. J. Geotech. Geoenviron. Eng., 144(1) (2018)

Zhao, J., Guo, N.: Unique critical state characteristics in granular media considering fabric anisotropy. Geotechnique, 695–704 (2013)

Zhao, J., Guo, N.: Rotational resistance and shear-induced anisotropy in granular media. Acta Mech. Solida Sin. 27(1), 1–14 (2014)

Zhao, S., Evans, T.M., Zhou, X.: Shear-induced anisotropy of granular materials with rolling resistance and particle shape effects. Int. J. Solids Struct. 150, 268–281 (2018)

Zhou, W., Liu, J., Ma, G., Chang, X.: Three-dimensional DEM investigation of critical state and dilatancy behaviors of granular materials. Acta Geotech. 12(3), 527–540 (2017)

Zhou, W., Xu, K., Ma, G., Yang, L., Chang, X.: Effects of particle size ratio on the macro- and microscopic behaviors of binary mixtures at the maximum packing efficiency state. Granular Matter 18(4), 1–13 (2016)

Zhou, Y.C., Wright, B.D., Yang, R.Y., Xu, B.H., Yu, A.B.: Rolling friction in the dynamic simulation of sandpile formation. Physica Stat. Mech. Appl. 269(2), 536–553 (1999)

Zhou, Y.C., Xu, B.H., Yu, A.B., Zulli, P.: Numerical investigation of the angle of repose of monosized spheres. Phys. Rev. E 64, 213011 (2001)

Zhu, Y., Nie, Z., Gong, J.: Influence of the rolling-resistance-based shape of coarse particles on the shear responses of granular mixtures. Particuology (2020)

Acknowledgements

The first author acknowledges the support provided by the Research Training Program domestic (RTPd) scholarship, awarded by The School of Natural and Built Environments, University of South Australia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix A: Method of deformability

1.1 Computation of stiffness parameters

Through the method of deformability:

here A = πr2 represents the contact area. Depending on the type of entities in contact r is computed:

where \(R^{\left( 1 \right)}\) denotes the radius of contact entity 1. In similar nature the contact length (L) is computed based on contact type:

E* and k* = kn/ks are input parameters in the study and are discussed and presented in Table 1 in the manuscript. The rolling radius, Rr and its formulation is also presented in the manuscript.

Appendix B: Rolling resistance linear contact model

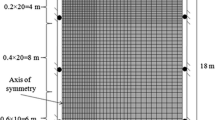

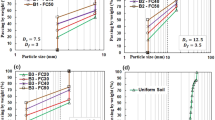

The rolling resistance linear contact model (RRLCM) utilised in this study adds to the conventional linear contact model commonly used in DEM through the installation of a rolling spring and dashpot at the contact (Fig. 21).

Rolling resistance linear contact model. After Iwashita and Oda [32]

In a rheological sense, the rolling spring signifies the presence of an elastic resisting moment between contacting pieces (\(M_{r}^{k} )\), whilst the dashpot signifies the presence of a viscous moment at the contact \((M_{r}^{d} )\). The overall rolling resistance moment (Mr) may be mathematically defined as:

to effectively utilize the RRLCM in a numerical modelling environment, Mr must be updated incrementally with respect to the time step. At time t + Δt, \(M_{r}^{k}\) may be computed via:

here M* represents the maximum (limiting) resisting torque (\(M^{ *} = \mu_{r} \bar{R}F_{n}\)) and \(\bar{R} = \left( {r_{i} r_{j} } \right)/\left( {r_{i} + r_{j} } \right)\); where Fn is the normal contact force, \(\bar{R}\) represents the effective radius of the contact, \(r_{i}\) and \(r_{j}\) are the radii of contacting entities. When a boundary or wall element is the contacting entity, r → ∞. Notice, when \(\mu_{r} = 0\), \(M^{ *} = 0\) and therefore a free-rolling environment is created. \(M_{r}^{k}\) is the incremental rolling resistance torque observed at time, t + Δt and is computed through consideration of the rolling stiffness, kr and the relative rotation between two contacting particles, θr,

where kr = ksRr. A limitation of the model is defining a kr which has strong physical basis. kr is related to ks based on an idealized consideration that the moment generated at a contact due to shear displacement is equivalent to the moment generated due to rolling displacement. \(M_{r}^{d}\) in Equation 17 is also updated with respect to the time step, t + Δt:

where \(C_{r} = 2_{r} \sqrt {I_{r} k_{r} }\) is the viscous damping rolling coefficient, ηr is the critical viscous damping ratio and Ir is the equivalent moment of inertia about the contact point between two contacting entities. Instead of an oscillating resisting moment applied at the contact, as applied in some rolling resistance contact models [2], the applied resisting moment at the contact within a quasi-static system is stable and therefore the packing behaviour of the assembly is stabilized. For such reasons, this model is often used in DEM simulation of quasi-static systems. Using various modified versions of this model in DEM along with the tuning of μr, some have captured the influence of particle rolling on the behaviour of granular material in triaxial compression. In particular some observed that with the addition of rolling resistance, shear strength and dilatancy increases [32, 46, 54, 94], shear banding and strain localization intensifies [32, 33, 54, 84] and fabric anisotropy intensifies [46].

Rights and permissions

About this article

Cite this article

Barnett, N., Rahman, M.M., Karim, M.R. et al. Evaluating the particle rolling effect on the characteristic features of granular material under the critical state soil mechanics framework. Granular Matter 22, 89 (2020). https://doi.org/10.1007/s10035-020-01055-5

Received:

Published:

DOI: https://doi.org/10.1007/s10035-020-01055-5