Abstract

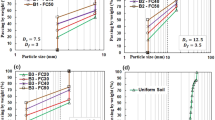

Mechanical behavior of granular soils is a classic research realm but still yet not completely understood as it can be influenced by a large number of factors, including confining pressure, soil density, loading conditions, and anisotropy of soil etc. Traditionally granular materials are macroscopically regarded as continua and their particulate and discrete nature has not been thoroughly considered although many researches indicate the macro mechanical behavior closely depends on the micro-scale characteristics of particles. This paper presents a DEM (discrete element method)-based micromechanical investigation of inter-particle friction effects on the behavior of granular materials. In this study, biaxial DEM simulations are carried out under both ‘drained’ and ‘undrained’ (constant volume) conditions. The numerical experiments employ samples having similar initial isotropic fabric and density, and the same confining pressure, but with different inter-particle friction coefficient. Test results show that the inter-particle friction has a substantial effect on the stress-strain curve, peak strength and dilatancy characteristics of the granular assembly. Clearly, it is noted that apart from the inter-particle friction, the shear resistance is also contributed to the dilation and the particle packing and arrangements. The corresponding microstructure evolutions and variations in contact properties in the particulate level are also elaborated, to interpret the origin of the different macro-scale response due to variations in the inter-particle friction.

Similar content being viewed by others

Abbreviations

- k n , k s :

-

Normal and tangential stiffness of contact model

- D 50 :

-

Mean particle diameter in a particle assemblage

- \({\sigma _x ,\sigma _y}\) :

-

Principal stresses along x and y directions respectively

- \({\sigma _1^{\prime} ,\sigma _2^{\prime}}\) :

-

Major and minor principal stresses respectively

- p, q :

-

Mean normal stress and deviatoric stress respectively

- \({\varepsilon _a ,\varepsilon _v}\) :

-

Axial strain along y direction and volumetric strain respectively

- \({\varepsilon _v^p ,\varepsilon _q^p}\) :

-

Plastic volumetric and deviatoric strains respectively

- CN :

-

Coordination number

- \({\varphi _\mu , \mu}\) :

-

Inter-particle friction angle and inter-particle friction coefficient

- \({d_{ij},\delta _{ij}}\) :

-

Second order deviatoric tensor and Kronecker delta

- n i :

-

Direction cosines of the unit vector with respective to the reference axes x i

- \({E(\varphi ), E_0}\) :

-

A density function and mean value of the density over direction respectively

- \({\Delta _d ,\varphi _d}\) :

-

Intensity and principal direction fabric tensor in general

- \({r(\varphi ), r_0}\) :

-

Spatial distribution of quantity r and its mean value over direction respectively

- \({\Delta _d^r , \varphi _d^r}\) :

-

Intensity and principal direction fabric tensor in term of quantity r

- \({f_n (\varphi ), f_0}\) :

-

Normal contact force distribution and mean value of normal contact force respectively

- \({f_t (\varphi )}\) :

-

Tangential contact force distribution

- \({\Delta _d^n , \varphi _d^n}\) :

-

Intensity and principal direction of fabric tensor in terms of contact normal force

- \({\Delta _d^t , \varphi _d^t}\) :

-

Intensity and principal direction of fabric tensor in terms of contact tangential force

- \({f_\mu (\varphi )}\) :

-

Mobilized inter-particle friction distribution

- \({\Delta _d^\mu , \varphi _d^\mu}\) :

-

Intensity and principal direction fabric tensor in terms of mobilized inter-particle friction

- \({\phi _{\rm mob}}\) :

-

Mobilized friction angle

- \({\eta ,\eta _{\rm res}}\) :

-

Mobilized stress ratio and stress ratio at residual state respectively

- A.R.:

-

Aspect ratio of particle characterizing the particle’s shape

References

Arthur J.R.F., Menzies B.K.: Inherent anisotropy in a sand. Géotechnique 22(1), 115–128 (1972)

Oda M.: Initial fabrics and their relations to mechanical properties of granular materials. Soils Found. 12(1), 17–36 (1972)

Bolton M.D.: The strength and dilatancy of sands. Géotechnique 36(1), 65–78 (1986)

Ishihara K.: Liquefaction and follow failure during earthquakes. Géotechnique 43(3), 351–415 (1993)

Yang Z.X., Li X.S., Yang J.: Undrained anisotropy and rotational shear in granular soil. Géotechnique 57(4), 371–384 (2007)

Yang Z.X., Li X.S., Yang J.: Quantifying and modelling fabric anisotropy of granular soils. Géotechnique 58(4), 237–248 (2008)

Cabalar A.F., Clayton C.R.I.: Some observations of the effects of pore fluids on the triaxial behaviour of a sand. Granul. Matter 12(1), 87–95 (2010)

Santamarina, J.C., Cho, G.C.: Soil behaviour: the role of particle shape. In: Jardine, R.J., Potts, D.M., Higgins, K.G. (eds.) Advances in Geotechnical Engineering: The Skempton Conference, vol. 1, pp. 604–617. Thomas Telford, London (2004)

Mitchell J.K., Soga K.: Fundamentals of soil behaviour, 3rd edn. Wiley, NJ (2005)

Cavarretta, I.: The influence of particle characteristics on the engineering behaviour of granular materials. PhD Thesis, The University of London (2009)

Rowe P.W.: The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc. R. Soc. Lond. Ser. A 269(1339), 500–527 (1962)

Skinner A.E.: A note on the influence of interparticle friction on the shearing strength of a random assembly of spherical particles. Géotechnique 19(1), 150–157 (1969)

Haruyama M.: Effects of surface roughness on the shear characteristics of granular materials. Soils Found. 9(4), 48–67 (1969)

Procter D.C., Barton R.R.: Measurements of the angle of interparticle friction. Géotechnique 24(4), 581–604 (1974)

Cavarretta I., Coop M., O’Sullivan C.: The influence of particle characteristics on the behaviour of coarse grained soils. Géotechnique 60(6), 413–423 (2010)

Chan L.C.Y., Page N.W.: Particle fractal and load effects on internal friction in powders. Powder Technol. 90(3), 259–266 (1997)

Cho G.C., Dodds J., Santamarina J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132(5), 591–602 (2006)

Guo P., Su X.: Shear strength, interparticle locking, and dilatancy of granular materials. Can. Geotech. J. 44, 579–591 (2007)

Jensen R.P., Bosscher P.J., Plesha M.E., Edil T.B.: DEM simulation of granular media-structure interface: effects of surface roughness and particle shape. Int. J. Numer. Anal. Methods Geomech. 23, 531–547 (1999)

Nouguier-Lehon C., Cambou B., Vincens E.: Influnece of paricle shape and angularity on the behavior of granular materials : a numerical analysis. Int. J. Numer. Anal. Methods Geomech. 27, 1207–1226 (2003)

Peña A.A., García-Rojo G., Herrmann H.J.: Influence of particle shape on sheared dense granular media. Granul. Matter 9, 279–291 (2007)

Peña A.A., Lizcano A., Alonso-Marroquín F., Herrmann H.J.: Biaxial test simulations using a packing of polygonal particles. Int. J. Numer. Anal. Methods Geomech. 32, 143–160 (2008)

Thornton C.: Numerical simulations of deviatoric shear deformation of granular media. Géotechnique 50(1), 43–53 (2000)

Powrie W., Ni Q., Harkness R.M., Zhang X.: Numerical modelling of plane strain tests on sands using a particulate approach. Géotechnique 55(4), 297–306 (2005)

Alonso-Marroquín F., Luding S., Herrmann H.J., Vardoilakis I.: Role of anisotropy in the elastoplastic response of a polygonal packing. Phys. Rev. E 71, 051304 (2005)

Suiker A.S.J., Fleck N.A.: Frictional collapse of granular assemblies. J. Appl. Mech. Trans. ASME 71(3), 350–358 (2004)

Liu S., Matsuoka H.: Microscopic interpretation on a stress-dilatancy relationship of granular materials. Soils Found. 43(3), 73–84 (2003)

Kruyt, N.P., Rothenburg, L.: Strength, dilatancy, energy and dissipation in quasi-static deformation of granular materials. In: García-Rojo, R., Herrmann, H.J., McNamara, S. (eds.) Powders and Grains, pp. 251. A.A. Balkema, Rotterdam (2005)

Cundall P.A., Strack O.D.L.: A discrete numerical model for granular assemblies. Géotechnique 29(1), 47–65 (1979)

Jiang M.J., Konrad J.M., Leroueil S.: An efficient technique for generating homogeneous specimens for DEM studies. Comput. Geotech. 30(7), 579–597 (2003)

Feng Y.T., Han K., Owen D.R.J.: Filling domains with disks: an advancing front approach. Int. J. Numer. Methods Eng. 56(5), 699–713 (2003)

Bagi K.: An algorithm to generate random dense arrangements for discrete element simulations of granular assemblies. Granul. Matter 7(1), 31–43 (2005)

Cui L., O’Sullivan C.: Analysis of a triangulation based approach for specimen generation for discrete element simulations. Granul. Matter 5(3), 135–145 (2003)

Li, X.: Micro-scale investigation on the quasi-static behavior of granular material. PhD Thesis, The Hong Kong University of Science and Technology (2006)

Huang Z.Y., Yang Z.X., Wang Z.Y.: Discrete element modeling of sand behavior in a biaxial shear test. J. Zhejiang Univ. Sci. A 9(9), 1176–1183 (2008)

Iwashita K., Oda M.: Rotational resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. ASCE 124, 285–292 (1998)

Mahmood Z., Iwashita K.: Influence of inherent anisotropy on mechanical behavior of granular materials based on DEM simulations. Int. J. Numer. Anal. Methods Geomech. 34(8), 795–819 (2010)

Fu P., Dafalias Y.F.: Study of anisotropy shear strength of granular materials using DEM simulation. Int. J. Numer. Anal. Methods Geomech. 35(10), 1098–1126 (2011)

PFC2D User’s manual, Itasca Consulting group, Inc., Minneapolis, USA (2005)

Ng T.T.: Fabric evolution of ellipsoidal arrays with different particle shapes. ASCE J. Eng. Mech. 127, 994–999 (2001)

Shodja H.M., Nezami E.G.: A micromechanical study of rolling and sliding contacts in assemblies of oval granules. Int. J. Numer. Anal. Methods Geomech. 27, 403–424 (2003)

Oda M., Konishi J., Nemat-Nasser S.: Experimental micromechanical evolution of strength of granular materials: effects of particle rolling. Mech. Mater. 1(4), 269–283 (1982)

Horne M.R.: The behaviour of an assembly of rotund, rigid, cohesionless particles III. Proc. R. Soc. Lond. Ser. A 310(1500), 21–34 (1969)

Alonso-Marroquín F., Vardoulakis I., Herrmann H.J., Weatherley D., Mora P.: Effects of rolling on dissipation in fault gouges. Phys. Rev. E 74, 031306 (2006)

Cambou B.: From Global to Local Variables in Granular Materials, Thorton, Editor, Powders & Grains, pp. 73–86. Balkema, Rotterdam (1993)

Drescher A.: An experimental investigation of flow rule for granular assemblies. Géotechnique 26(4), 49–65 (1976)

Oda M., Konishi J., Nemat-Nasser S.: Some experimentally based fundamental results on the mechanical behaviour of granular materials. Géotechnique 30(4), 479–495 (1980)

Oda M., Kazama H.: Microstructure of shear bands and its relation to the mechanisms of dilatancy and failure of dense granular soils. Géotechnique 48(4), 465–481 (1998)

Oda M.: The mechanism of fabric changes during compressional deformation of sand. Soils Found. 12(2), 1–18 (1972)

Bathurst R.J., Rothenburg L.: Investigation of micromechanical features of idealized granular assemblies using DEM. Eng. Comput. 9, 199–210 (1992)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Z.X., Yang, J. & Wang, L.Z. On the influence of inter-particle friction and dilatancy in granular materials: a numerical analysis. Granular Matter 14, 433–447 (2012). https://doi.org/10.1007/s10035-012-0348-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-012-0348-x