Abstract

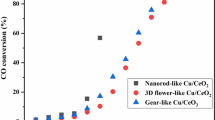

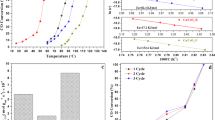

Surface morphology of Cu-based catalysts is considered as an important factor affecting both activity and product selectivity of electrochemical reduction of CO2. In this work, surface cavity effect on C2H4 formation was investigated using Cu2O cubes: solid cubes, cavity cubes, and broken cubes, typically representing smooth surface, cavity surface, and rough surface. With respect of C2H4 selectivity, cavity cubes show the significantly enhanced faradaic efficiency (FE) of C2H4, which is 2.7 and 1.7 times higher than those for solid cubes and broken cubes respectively. Moreover, a ratio of CO produced by CO2 reduction reaction (CO2RR) converted to CH4 and C2H4 was calculated to assess the extent of CO further reduction for a catalyst. As noted, cavity cubes exhibited a highest ratio of 29.5%, in contrast with the lower ratio of 13.0% on broken cubes and 14.9% on solid cubes. Consequently, the role of surface cavity is reflected in two effects, the increased CO formation due to higher electrochemical surface area as compared to the smooth surface, and meanwhile the increased ratio of CO converted to hydrocarbons and alcohols due to porous feature as compared to the rough surface with a comparable high electrochemical active surface area (ECSA). What’s more, when applied in a flow cell reactor with a gas diffusion electrode, cavity cubes also achieved much higher C2 selectivity of 37.7% FEC2 than solid cubes and broken cubes. Our work provides a facile strategy for improving the catalytic C2+ product selectivity of Cu2O-based catalysts for CO2RR through modifying surface morphology.

Graphical abstract

Similar content being viewed by others

References

Xu YX, Zhou ZF, Zou MC, Liu YQ, Zheng YP, Yang YY, Lan S, Lan JL, Nan CW, Lin YH (2022) Multi-field driven hybrid catalysts for CO2 reduction: progress, mechanism and perspective. Mater Today. https://doi.org/10.1016/j.mattod.2022.02.005

Ruiz-López E, Gandara-Loe J, Baena-Moreno F, Reina TR, Odriozola JA (2022) Electrocatalytic CO2 conversion to C2 products: catalysts design, market perspectives and techno-economic aspects. Renew Sustain Energy Rev 161:112329–112355

Yang C, Wang YH, Qian LQ, Al Enizi AM, Zhang LJ, Zheng GF (2021) Heterogeneous electrocatalysts for CO2 reduction. ACS Appl Energy Mater 4:1034–1044

Zhang LQ, Cao HZ, Lu YH, Zhang HB, Hou GY, Tang YP, Zheng GQ (2019) High-efficiency and sustainable photoelectric conversion of CO2 to methanol over CuxO/TNTs catalyst by pulse potential method. J Solid State Electrochem 24:447–459

Kortlever R, Tan KH, Kwon Y, Koper MTM (2013) Electrochemical carbon dioxide and bicarbonate reduction on copper in weakly alkaline media. J Solid State Electrochem 17:1843–1849

Zhong Y, Wang S, Li M, Ma J, Song S, Kumar A, Duan H, Kuang Y, Sun X (2021) Rational design of copper-based electrocatalysts and electrochemical systems for CO2 reduction: from active sites engineering to mass transfer dynamics. Mater Today Phys 18:100354–100381

Raciti D, Wang C (2018) Recent advances in CO2 reduction electrocatalysis on copper. ACS Energy Lett 3:1545–1556

Ye WX, Guo XL, Ma TL (2021) A review on electrochemical synthesized copper-based catalysts for electrochemical reduction of CO2 to C2+ products. Chem Eng J 414:128825–128841

Ma WC, Xie SJ, Liu TT, Fan QY, Ye JY, Sun FF, Jiang Z, Zhang QH, Cheng J, Wang Y (2020) Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen-assisted C-C coupling over fluorine-modified copper. Nat Catal 3:478–487

Zheng Y, Vasileff A, Zhou XL, Jiao Y, Jaroniec M, Qiao SZ (2019) Understanding the roadmap for electrochemical reduction of CO2 to multi-carbon oxygenates and hydrocarbons on copper-based catalysts. J Am Chem Soc 141:7646–7659

Xiao CL, Zhang J (2021) Architectural design for enhanced C2 product selectivity in electrochemical CO2 reduction using Cu-based catalysts: a review. ACS Nano 15:7975–8000

Wang YX, Zhu YC, Niu CL (2020) Surface and length effects for aqueous electrochemical reduction of CO2 as studied over copper nanowire arrays. J Phys Chem Solid 144:109507–109513

Spodaryk M, Zhao K, Zhang J, Oveisi E, Züttel A (2019) The role of malachite nanorods for the electrochemical reduction of CO2 to C2 hydrocarbons. Electrochim Acta 297:55–60

Zhu SQ, Shao MH (2015) Surface structure and composition effects on electrochemical reduction of carbon dioxide. J Solid State Electrochem 20:861–873

Altaf N, Liang SY, Huang L, Wang Q (2020) Electro-derived Cu-Cu2O nanocluster from LDH for stable and selective C2 hydrocarbons production from CO2 electrochemical reduction. J Energy Chem 48:169–180

Jung HJ, Lee SY, Lee CW, Cho MW, Won DH, Kim CH, Oh HS, Min BK, Hwang YJ (2019) Electrochemical fragmentation of Cu2O nanoparticles enhancing selective C-C coupling from CO2 reduction reaction. J Am Chem Soc 141:4624–4633

Ning H, Wang XS, Wang WH, Mao QH, Yang ZX, Zhao QS, Song Y, Wu MB (2019) Cubic Cu2O on nitrogen-doped carbon shells for electrocatalytic CO2 reduction to C2H4. Carbon 146:218–223

Chen Y, Fan ZX, Wang J, Ling CY, Niu WX, Huang ZQ, Liu GG, Chen B, Lai ZC, Liu XZ, Li B, Zong Y, Gu L, Wang JL, Wang X, Zhang H (2020) Ethylene selectivity in electrocatalytic CO2 reduction on Cu nanomaterials: a crystal phase-dependent study. J Am Chem Soc 142:12760–12766

Chen CS, Handoko AD, Wan JH, Ma L, Ren D, Yeo BS (2015) Stable and selective electrochemical reduction of carbon dioxide to ethylene on copper mesocrystals. Catal Sci Tech 5:161–168

Tsai YH, Chiu CY, Huang MH (2013) Fabrication of diverse Cu2O nanoframes through face-selective etching. J Phys Chem C 117:24611–24617

Fan MY, Garbarino S, Tavares AC, Guay D (2020) Progress in the electrochemical reduction of CO2 on hierarchical dendritic metal electrodes. Curr Opin Electrochem 23:145–153

Chou TC, Chang CC, Yu HL, Yu WY, Dong CL, Velasco-Vélez JJ, Chuang CH, Chen LC, Lee JF, Chen JM, Wu HL (2020) Controlling the oxidation state of the Cu electrode and reaction intermediates for electrochemical CO2 reduction to ethylene. J Am Chem Soc 142:2857–2867

Dutta A, Rahaman M, Luedi NC, Mohos M, Broekmann P (2016) Morphology matters: tuning the product distribution of CO2 electroreduction on oxide-derived Cu foam catalysts. ACS Catal 6:3804–3814

Rashid N, Bhat MA, Ingole PP (2020) Dendritic copper microstructured electrodeposits for efficient and selective electrochemical reduction of carbon dioxide into C1 and C2 hydrocarbons. J CO2 Util 38:385–397

Lv JJ, Jouny M, Luc W, Zhu WL, Zhu JJ, Jiao F (2018) A highly porous copper electrocatalyst for carbon dioxide reduction. Adv Mater 30:1803111–1803119

Yang KD, Ko WR, Lee JH, Kim SJ, Lee H, Lee MH, Nam KT (2017) Morphology-directed selective production of ethylene or ethane from CO2 on a Cu mesopore electrode. Angew Chem Int Edit 56:796–800

Wu M, Zhu C, Wang K, Li G, Dong X, Song Y, Xue J, Chen W, Wei W, Sun Y (2020) Promotion of CO2 electrochemical reduction via Cu nanodendrites. ACS Appl Mater Interface 12:11562–11569

Wu ZZ, Gao FY, Gao MR (2021) Regulating the oxidation state of nanomaterials for electrocatalytic CO2 reduction. Energy Environ Sci 14:1121–1139

Yu ZL, Wu SQ, Chen LW, Hao YC, Su X, Zhu Z, Gao WY, Wang B, Yin AX (2022) Promoting the electrocatalytic reduction of CO2 on ultrathin porous bismuth nanosheets with tunable surface-active sites and local pH environments. ACS Appl Mater Interface. https://doi.org/10.1021/acsami.1c16689

Giri SD, Mahajani SM, Suresh AK, Sarkar A (2020) Electrochemical reduction of CO2 on activated copper: influence of surface area. Mater Res Bull 123:110702–110733

Lee SY, Jung H, Kim NK, Oh HS, Min BK, Hwang YJ (2018) Mixed copper states in anodized cu electrocatalyst for stable and selective ethylene production from CO2 reduction. J Am Chem Soc 140:8681–8689

Arán-Ais RM, Scholten F, Kunze S, Rizo R, Cuenya BR (2020) The role of in situ generated morphological motifs and Cu(i) species in C2+ product selectivity during CO2 pulsed electroreduction. Nat Energy 5:317–325

Yano J, Morita T, Shimano K, Nagami Y, Yamasaki S (2006) Selective ethylene formation by pulse-mode electrochemical reduction of carbon dioxide using copper and copper-oxide electrodes. J Solid State Electrochem 11:554–557

Cao XR, Cao GW, Li M, Zhu XL, Han JY, Ge QF, Wang H (2021) Enhanced ethylene formation from carbon dioxide reduction through sequential catalysis on Au decorated cubic Cu2O electrocatalyst. Eur J Inorg Chem 24:2353–2364

Garza AJ, Bell AT, Head-Gordon M (2018) Mechanism of CO2 reduction at copper surfaces: pathways to C2 products. ACS Catal 8:1490–1499

Shang LM, Lv XM, Shen H, Shao ZZ, Zheng GF (2019) Selective carbon dioxide electroreduction to ethylene and ethanol by core-shell copper/cuprous oxide. J Colloid Interface Sci 552:426–431

Tan W, Cao B, Xiao WQ, Zhang M, Wang SS, Xie SL, Xie D, Cheng FL, Guo QQ, Liu P (2019) Electrochemical reduction of CO2 on hollow cubic Cu2O@Au nanocomposites. Nanoscale Res Lett 14:63–70

Zhang LJ, Li M, Zhang SB, Cao XR, Bo JX, Zhu XL, Han JY, Ge QF, Wang H (2021) Promoting carbon dioxide electroreduction toward ethanol through loading Au nanoparticles on hollow Cu2O nanospheres. Catal Today 365:348–356

Li QW, Li M, Zhang SB, Liu X, Zhu XL, Ge QF, Wang H (2019) Tuning Sn-Cu catalysis for electrochemical reduction of CO2 on partially reduced oxides SnOx-CuOx-modified Cu electrodes. Catal 9:476–489

Montoya JH, Peterson AA, Nørskov JK (2013) Insights into C-C coupling in CO2 electroreduction on copper electrodes. ChemCatChem 5:737–742

Shen SB, He J, Peng XY, Xi W, Zhang LH, Xi DS, Wang L, Liu XJ, Luo J (2018) Stepped surface-rich copper fiber felt as an efficient electrocatalyst for the CO2RR to formate. J Mater Chem A 6:18960–18966

Kim D, Lee SH, Ocon JD, Jeong BY, Lee JK, Lee JY (2015) Insights into an autonomously formed oxygen-evacuated Cu2O electrode for the selective production of C2H4 from CO2. Phys Chem Chem Phys 17:824–830

Kuang SY, Li ML, Xia R, Xing L, Su YQ, Fan Q, Liu JP, Hensen EJM, Ma XB, Zhang S (2020) Stable surface-anchored Cu nanocubes for CO2 electroreduction to ethylene. ACS Appl Nano Mater 3:8328–8334

Simon GH, Kley CS, Cuenya BR (2021) Potential-dependent morphology of copper catalysts during CO2 electroreduction revealed by in situ atomic force microscopy. Angew Chem Int Edit 60:2561–2568

Mistry H, Varela AS, Bonifacio CS, Zegkinoglou I, Sinev I, Choi YW, Kisslinger K, Stach EA, Yang JC, Strasser P, Cuenya BR (2016) Highly selective plasma-activated copper catalysts for carbon dioxide reduction to ethylene. Nat Commun 7:12123–12132

Wei C, Sun SN, Mandler D, Wang X, Qiao SZ, Xu ZCJ (2019) Approaches for measuring the surface areas of metal oxide electrocatalysts for determining their intrinsic electrocatalytic activity. Chem Soc Rev 48:2518–2534

Liu B, Cai C, Yang BP, Chen KJ, Long Y, Wang QY, Wang SD, Chen GZ, Li HM, Hu JH, Fu JW, Liu M (2021) Intermediate enrichment effect of porous Cu catalyst for CO2 electroreduction to C2 fuels. Electrochim Acta 388:138552–138559

Liu CX, Zhang ML, Li JW, Xue WQ, Zheng TT, Xia C, Zeng J (2022) Nanoconfinement engineering over hollow multi-shell structured copper towards efficient electrocatalytical C-C coupling. Angew Chem Int Edit 61:202113498–202113504

Huang Y, Handoko AD, Hirunsit P, Yeo BS (2017) Electrochemical reduction of CO2 using copper single-crystal surfaces: effects of CO* coverage on the selective formation of ethylene. ACS Catal 7:1749–1756

Jiang K, Yf H, Gs Z, Toma FM, Goddard WA, Bell AT (2020) Effects of surface roughness on the electrochemical reduction of CO2 over Cu. ACS Energy Lett 5:1206–1214

Resasco J, Bell AT (2020) Electrocatalytic CO2 reduction to fuels: progress and opportunities. Trends Chem 2:825–836

Kim C, Weng LC, Bell AT (2020) Impact of pulsed electrochemical reduction of CO2 on the formation of C2+ products over Cu. ACS Catal 10:12403–12413

Luo MC, Wang ZY, Li Yg C, Li J, Li FW, Lum YW, Nam DH, Chen B, Wicks J, Xu AN, Zhuang TT, Leow WR, Wang X, Dinh CT, Wang Y, Wang YH, Sinton D, Sargent EH (2019) Hydroxide promotes carbon dioxide electroreduction to ethanol on copper via tuning of adsorbed hydrogen. Nat Commun 10:5814–5821

Zhang ZS, Melo L, Jansonius RP, Habibzadeh F, Grant ER, Berlinguette CP (2020) pH matters when reducing CO2 in an electrochemical flow cell. ACS Energy Lett 5:3101–3107

Lu X, Zhu CQ, Wu ZS, Xuan J, Francisco JS, Wang HL (2020) In situ observation of the pH gradient near the gas diffusion electrode of CO2 reduction in alkaline electrolyte. J Am Chem Soc 142:15438–15444

Li CL, Ciston J, Kanan MW (2014) Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nat 508:504–507

Dinh CT, Burdyny T, Kibria MG, Seifitokaldani A, Gabardo CM, Arquer F, Kiani A, Edwards JP, Luna PD, Bushuyev OS, Zou CQ, Quintero-Bermudez R, Pang YJ, Sinton D, Sargent DH (2018) CO2 electroreduction to ethylene via hydroxide-mediated copper catalysis at an abrupt interface. Sci 360:783–787

Cheng T, Xiao H, Goddard WA III (2016) Reaction mechanisms for the electrochemical reduction of CO2 to CO and formate on the Cu(100) surface at 298 K from quantum mechanics free energy calculations with explicit water. J Am Chem Soc 138:13802–13805

Li HF, Liu TF, Wei PF, Lin L, Gao DF, Wang GX, Bao XH (2021) High-rate CO2 electroreduction to C2+ products over a copper-copper iodide catalyst. Angew Chem Int Edit 60:14329–14333

Lyu ZH, Zhu SQ, Xie MH, Zhang Y, Chen ZT, Chen RH, Tian MK, Chi MF, Shao MH, Xia YN (2021) Controlling the surface oxidation of Cu nanowires improves their catalytic selectivity and stability toward C2+ products in CO2 reduction. Angew Chem Int Edit 60:1909–1915

Gao DF, Zegkinoglou I, Divins NJ, Scholten F, Sinev I, Grosse P, Cuenya BR (2017) Plasma-activated copper nanocube catalysts for efficient carbon dioxide electroreduction to hydrocarbons and alcohols. ACS Nano 11:4825–4831

Zhao YR, Chang XX, Malkani AS, Yang X, Thompson L, Jiao F, Xu BJ (2020) Speciation of Cu surfaces during the electrochemical CO reduction reaction. J Am Chem Soc 142:9735–9743

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 22178266). We are grateful to the analysis and test center of Tianjin University for providing test characterizations.

Author information

Authors and Affiliations

Contributions

Guangwei Cao: methodology, investigation, validation, data analysis, writing — original draft. Xuerui Cao: methodology, investigation. Mengqing Shan: investigation, data analysis. Mei Li: data analysis. Xinli Zhu: methodology. Jinyu Han: methodology. Qingfeng Ge: methodology. Hua Wang: conceptualization, supervision, validation, writing — review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cao, G., Cao, X., Shan, M. et al. Surface cavity effect on C2H4 formation from electrochemical reduction of CO2 as studied using Cu2O cubes. J Solid State Electrochem 26, 1527–1540 (2022). https://doi.org/10.1007/s10008-022-05190-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-022-05190-2