Abstract

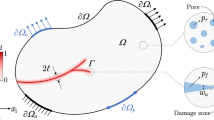

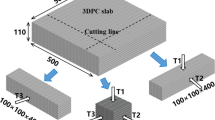

Early-age stiffness and strength evolution of cement paste is studied in the framework of continuum micromechanics. Based on the self-consistent scheme, elastic and strength properties are upscaled from the scale of several micrometers up to the scale of several hundreds or thousands of micrometers. Four material phases are considered: clinker, hydration products, water and air. We assign a spherical geometry to clinker grains and pores, while we investigate both spherical and acicular (needle-type) shapes as geometrical representation of the micrometer-sized hydration products. As regards macroscopic poromechanical boundary conditions, two extreme cases are considered: drained conditions and sealed conditions, respectively. These choices allow for studying the influence of (i) the morphological representation of hydrates, and of (ii) the bulk stiffness of water, on the micromechanical prediction of early-age behavior of cement paste, including setting and the hydration-dependent evolutions of both elastic stiffness and uniaxial compressive strength. The newly proposed strength model is based on a von Mises-type elastic limit criterion for individual hydrates. Corresponding deviatoric stress peaks within hydrates are estimated through quadratic stress averages. In this way, the micromechanical strength criterion is formulated in terms of macroscopic loading (stresses or strains, respectively). Model-predicted elasticity and strength evolutions are compared with data from experimental testing of cement pastes with water–cement ratios ranging from 0.35 to 0.60. Satisfactory agreement between model predictions and experiments allows for two conclusions: the morphology of hydrates significantly influences micromechanics-based elastic stiffness estimates of cement paste particularly at very early ages, whereas elastic properties of mature cement paste can be estimated reliably on the basis of both spherical or acicular shaped hydrates. The development of a reliable strength model, however, requires consideration of hydrates as non-spherical particles, no matter what age of cement paste is considered.

Similar content being viewed by others

Abbreviations

- C 2 S :

-

abbreviation for dicalcium silicate 2CaO · SiO2 2

- C 3 A :

-

abbreviation for tricalcium aluminate 3CaO · Al2O2 3

- C 4 FA :

-

abbreviation for calcium aluminoferrite 4CaO·Al2O3 · Fe2O3

- C 3 S :

-

abbreviation for tricalcium silicate 3CaO·SiO2

- C-S-H:

-

abbreviation for calcium silicate hydrates

- \({\mathbb {C}}\) :

-

elastic stiffness tensor (fourth-order tensor)

- \({\mathbb {C}_p}\) :

-

\({\mathbb {C}}\) of material phase p

- \({\mathbb {C}^{\rm hom}}\) :

-

macroscopic (homogenized) elastic stiffness tensor (fourth-order tensor), self-consistent estimate

- \({{C}^{\rm hom}_{ijrs}}\) :

-

ijrs-th component of \({\mathbb {C}^{\rm hom}}\)

- dV :

-

infinitesimal volume element

- E :

-

macroscopically prescribed, uniform strains (second-order tensor)

- E hom :

-

self-consistent estimate of macroscopic Young’s modulus

- f :

-

frequency of ultrasonic waves

- f air :

-

volume fraction of air

- f c :

-

uniaxial compressive strength

- f clin :

-

volume fraction of cement clinker

- f hyd :

-

volume fraction of hydration products

- fH2O:

-

volume fraction of water

- f p :

-

volume fraction of material phase p

- \({\mathbb {I}}\) :

-

symmetric fourth-order unity tensor

- i :

-

index

- \({\mathbb {J}}\) :

-

volumetric part of \({\mathbb {I}}\)

- j :

-

index

- k hom :

-

self-consistent estimate of macroscopic bulk modulus

- k air :

-

bulk modulus of air

- k clin :

-

bulk modulus of cement clinker

- k hyd :

-

bulk modulus of hydration products

- kH2O:

-

bulk modulus of water

- k p :

-

bulk modulus of material phase p

- \({\mathbb {K}}\) :

-

deviatoric part of \({\mathbb {I}}\)

- n :

-

number of summation terms

- \({\mathbb {P}_{\mathcal{S}_p}^{\rm scs}}\) :

-

self-consistent expression of Hill tensor for material phase p with phase particles of morphological shape \({\mathcal{S}_p}\) (fourth-order tensor)

- \({\mathbb {P}_{\rm sph}^{\rm scs}}\) :

-

\({\mathbb {P}_{\mathcal{S}_p}^{\rm scs}}\) for a material phase p constituted by spherical particles

- \({\mathbb {P}_{\rm cyl}^{\rm scs}}\) :

-

\({\mathbb {P}_{\mathcal{S}_p}^{\rm scs}}\) for a material phase p constituted by acicular particles

- RVE:

-

abbreviation for representative volume element

- p :

-

index denoting a specific material phase

- q :

-

index denoting a specific material phase

- r :

-

index, scalar parameter

- s :

-

index, scalar parameter

- t :

-

scalar parameter

- \({\underline {u}}\) :

-

displacement vector

- V L :

-

compressive (longitudinal) wave velocity

- \({V^{\rm hom}_{L}}\) :

-

self-consistent estimate of V L

- V T :

-

shear (transverse) wave velocity

- \({V^{\rm hom}_{T}}\) :

-

self-consistent estimate of V T

- W :

-

elastic energy stored in the RVE

- w/c :

-

water-cement ratio

- \({\underline {x}}\) :

-

position vector labeling locations within the RVE and on its boundary

- z :

-

substitution for cos \({\vartheta}\)

- α :

-

parameter depending on both k hom and μ hom, defined in Eq. (25)

- β :

-

parameter depending on both k hom and μ hom, defined in Eq. (25)

- δ ij :

-

Kronecker delta

- ∂Ω :

-

surface of the RVE

- ε :

-

linearized strain tensor

- ε dev :

-

deviatoric part of ε

- \({\epsilon^{\rm dev}}\) :

-

deviatoric strain measure, defined in Eq. (9)

- \({\underline{\zeta}}\) :

-

direction vector

- ζ i :

-

component of \({\underline{\zeta}}\)

- \({\overline{\overline{\epsilon}}^{\rm dev}_p}\) :

-

quadratic average of \({\epsilon^{\rm dev}}\) over material phase p

- \({\vartheta}\) :

-

Euler angle (spherical coordinate)

- λ :

-

wave length of ultrasonic waves

- μ hom :

-

self-consistent estimate of macroscopic shear modulus

- μ air :

-

shear modulus of air

- μ clin :

-

shear modulus of cement clinker

- μ hyd :

-

shear modulus of hydration products

- μH2O:

-

shear modulus of water

- μ p :

-

shear modulus of material phase p

- ξ :

-

degree of hydration

- ρ air :

-

mass density of air

- ρ clin :

-

mass density of cement clinker

- ρ cp :

-

macroscopic mass density of cement paste

- ρ hyd :

-

mass density of hydration products

- ρH2O:

-

mass density of water

- Σ :

-

macroscopically prescribed, uniform stresses (second-order tensor)

- σ hyd :

-

second-order stress tensor of hydrates

- \({\sigma_{\rm hyd}^{\rm dev}}\) :

-

deviatoric part of σ hyd

- \({\sigma_{\rm hyd}^{\rm dev}}\) :

-

deviatoric stress measure for hydrates, defined in Eq. (28)

- \({\overline{\overline{\sigma}}^{\rm dev}_{\rm hyd}}\) :

-

quadratic average of \({\sigma_{\rm hyd}^{\rm dev}}\)

- \({\sigma_{\rm crit}^{\rm dev}}\) :

-

critical value of \({\sigma_{\rm hyd}^{\rm dev}}\)

- φ :

-

Euler angle (spherical coordinate)

- Ω :

-

volume of the RVE

- Ω hyd :

-

subvolume of Ω, occupied by hydrates

- \({\Omega_{\rm hyd}^{\vartheta,\varphi}}\) :

-

subvolume of Ωhyd, occupied by acicular hydrates with orientation defined by \({\vartheta}\); and φ

- Ω p :

-

subvolume of Ω, occupied by material phase p

- ω :

-

scalar weight

References

Acker, P.: Comportement mécanique du béton: Apports de l’approche physico-chimique [Mechanical behavior of concrete: contributions of a physicochemical approach]. PhD thesis, Ecole Nationale des Ponts et Chaussées (in French), Paris, France (1987)

Acker P. (2001) Micromechanical analysis of creep and shrinkage mechanisms. In: Ulm F.-J., Bažant Z., Wittmann F. (eds). Creep, shrinkage and durability mechanics of concrete and other quasi-brittle materials, 6th International Conference CONCREEP@MIT. Elsevier, Amsterdam, pp. 15–26

ASTM C 109 / C 109M. Standard test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens). ASTM International, West Conshohocken (1995)

ASTM C 215. Standard test method for fundamental transverse, longitudinal, and torsional frequencies of concrete specimens. ASTM International, West Conshohocken (1997)

ASTM C 305. Standard practice for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency. ASTM International, West Conshohocken (1982)

Baroghel-Bouny, V.: Caractérisation des pâtes de ciment et des bétons—méthodes, analyse, interprétation [Characterization of cement pastes and concretes—methods, analysis, interpretations]. Technical report, Laboratoire Central des Ponts et Chaussées (in French), Paris, France (1994)

Barthélémy J.-F., Dormieux L.: Détermination du critère de rupture macroscopique d’un milieu poreux par homogénéisation non linèaire [Determination of the macroscopic strength criterion of a porous medium by nonlinear homogenization] (in French). Comptes Rendus Mécanique 331(4), 271–276 (2003)

Barthélémy J.F., Dormieux L.: A micromechanical approach to the strength criterion of Drucker-Prager materials reinforced by rigid inclusions. Int. J. Numer. Anal. Methods Geomech. 28(7–8), 565–582 (2004)

Barthélémy J.-F., Dormieux L., Maghous S.: Micromechanical approach to the modelling of compaction at large strains. Computers and Geotechnics 30(4), 321–338 (2003)

Benveniste Y.: A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech. Mater. 6, 147–157 (1987)

Bernard O., Ulm F.J., Lemarchand E.: A multiscale micromechanics-hydration model for the early-age elastic properties of cement-based materials. Cement Concrete Res. 33(9), 1293–1309 (2003)

Bilaniuk N., Wong G.: Speed of sound in pure water as a function of temperature. J. Acoust. Soc. Am. 93(3), 1609–1612 (1993)

Biot M.: Theory of elasticity and consolidation for a porous anisotropic solid. J. Appl. Phys. 26(2), 182–185 (1955)

Boumiz A., Vernet C., Cohen-Tenoudji F.: Mechanical properties of cement pastes and mortars at early ages. Adv. Cement Based Mater. 3(3-4), 94–106 (1996)

Cast3M. Finite Element Package “Cast3M”. Commissariat à l’Energie Atomique (CEA), 25, rue Leblanc, 75015 Paris, France. Download from: http://www-cast3m.cea.fr (last visit of website: December 22, 2007) (2003)

CEN EN 197.1. Cement—Part 1: Composition, specifications and conformity criteria for common cements. European Committee for Standardization, Brussels (2000)

Constantinides G., Ulm F.-J.: The effect of two types of C-S-H on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cement Concrete Res. 34(1), 67–80 (2004)

Dormieux L., Kondo D., Ulm F.-J.: Microporomechanics. Wiley, London (2006)

Dormieux L., Lemarchand E., Kondo D., Fairbairn E.: Elements of poro-micromechanics applied to concrete. Mater. Struct. 37(1), 31–42 (2004)

Dormieux L., Molinari A., Kondo D.: Micromechanical approach to the behavior of poroelastic materials. J. Mech. Phys. Solids 50(10), 2203–2231 (2002)

Eshelby, J.: The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. A 241, 376–396 (1957) Reprinted in [45]

Feenstra P., de Borst R.: A composite plasticity model for concrete. Int. J. Solids Struct. 33(5), 707–730 (1996)

Fritsch A., Dormieux L., Hellmich C.: Porous polycrystals built up by uniformly and axisymmetrically oriented needles: homogenization of elastic properties. Comptes Rendus Mécanique. 334(3), 151–157 (2006)

Fritsch, A., Dormieux, L., Hellmich, C., Sanahuja, J.: Mechanical behaviour of hydroxyapatite biomaterials: an experimentally validated micromechanical model for elasticity and strength. J. Biomed. Mater. Res. Part A. Accepted for publication, avaiable online in advance of print at doi:10.1002/jbm.a.31727 (2007a)

Fritsch A., Dormieux L., Hellmich C., Sanahuja J.: Micromechanics of crystal interfaces in polycrystalline solid phases of porous media: fundamentals and application to strength of hydroxyapatite biomaterials. J. Mater. Sci. 42(21), 8824–8837 (2007b)

Garrault S., Finot E., Lesniewska E., Nonat A.: Study of C-S-H growth on C3S surface during its early. Mater. Struct. 38(4), 435–442 (2005)

Gawin D., Majorana C., Schrefler B.: Numerical analysis of hygro-thermal behaviour and damage of concrete at high temperature. Mech. Cohesive-Friction. Mater. 4(1), 37–74 (1999)

Gawin D., Pesavento F., Schrefler B.: Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. Part I: hydration and hygro-thermal phenomena. Int. J. Numer. Methods Eng. 67(3), 299–331 (2006)

Granju J., Grandet J.: Relation between the hydration state and the compressive strength of hardened portland cement pastes. Cement Concrete Res. 19(4), 579–585 (1989)

Granju J., Maso J.: Hardened portland cement pastes, modelisation of the micro-structure and evolution laws of mechanical properties II—compressive strength law. Cement Concrete Res. 14(3), 303–310 (1984)

Haecker C.J., Garboczi E., Bullard J., Bohn R., Sun Z., Shah S., Voigt T.: Modeling the linear elastic properties of portland cement paste. Cement Concrete Res. 35(10), 1948–1960 (2005)

Harsh S., Shen Z., Darwin D.: Strain-rate sensitive behavior of cement paste and mortar in compression. ACI Mater J. 87(5), 508–516 (1990)

Hashin Z.: Analysis of composite materials—a survey. J. Appl. Mech. 50, 481–505 (1983)

Hellmich C., Barthélémy J.-F., Dormieux L.: Mineral–collagen interactions in elasticity of bone ultrastructure—a continuum micromechanics approach. Eur. J. Mech. A/Solids 23(5), 783–810 (2004)

Hellmich C., Mang H.: Shotcrete elasticity revisited in the framework of continuum micromechanics: From submicron to meter level. J. Mater. Civil Eng. (ASCE) 17(3), 246–256 (2005)

Hellmich C., Ulm F.-J.: Drained and undrained poroelastic properties of healthy and pathological bone: a poro-micromechanical investigation. Transport Porous Media 58(3), 243–268 (2005)

Hershey A.: The elasticity of an isotropic aggregate of anisotropic cubic crystals. J. Appl. Mech. (ASME) 21, 226–240 (1954)

Hill R.: Elastic properties of reinforced solids. J. Mech. Phys. Solids 11(5), 357–372 (1963)

Hofstetter, K., Hellmich, C., Eberhardsteiner, J.: Predicting wood strength from composition and microstructure: development and experimental verification of a continuum micromechanics model. In: Dormieux, L., Kondo, D., Sab, K., (eds) Colloque en l’honneur du Professor Jean-Louis Auriault: microstructure et Propriétés des Matériaux, pp. 217–222. Presses de l’Ecole Nationale des Ponts et Chaussées (2005)

Kreher W.: Residual stresses and stored elastic energy of composites and polycrystals. J. Mech. Phys. Solids 38(1), 115–128 (1990)

Kreher W., Molinari A.: Residual stresses in polycrystals as influenced by grain shape and texture. J. Mech. Phys. Solids 41(12), 1955–1977 (1993)

Kröner E.: Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls [Computation of the elastic constants of a polycrystal based on the constants of the single crystal] (in German). Zeitschrift für Physik A Hadrons and Nuclei 151(4), 504–518 (1958)

Laws N.: The determination of stress and strain concentrations at an ellipsoidal inclusion in an anisotropic material. J. Elast. 7(1), 91–97 (1977)

Lemarchand E., Ulm F.-J., Dormieux L.: Effect of inclusions on friction coefficient of highly filled composite materials. J. Eng. Mech. (ASCE) 128(8), 876–884 (2002)

Markenscoff, X., Gupta, A., (eds.): Collected Works of J. D. Eshelby—The Mechanics of Defects and Inhomogeneities, vol. 133. Solid Mechanics and Its Applications. Springer, Heidelberg (2006)

Mori T., Tanaka K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metallurgica. 21, 571–574 (1973)

Pichler, B., Scheiner, S., Hellmich, C.: From micron-sized needle-shaped hydrates to meter-sized shotcrete tunnel shells. Micromechanical upscaling of stiffness and strength of hydrating shotcrete. Acta Geotechnica. Accepted for Publication

Ponte Castañeda P., Willis J.: The effect of spatial distribution on the effective behavior of composite materials and cracked media. J. Mech. Phys. Solids 43(12), 1919–1951 (1995)

Psakhie S., Horie Y., Ostermeyer G., Korostelev S., Smolin A., Shilko E., Dmitriev A., Blatnik S., Špegel M., Zavšek S.: Movable cellular automata method for simulating materials with mesostructure. Theor. Appl. Fract. Mech. 37(1–3), 311–334 (2001)

Salençon J.: Handbook of Continuum Mechanics. Springer, Berlin (2001)

Sanahuja J., Dormieux L., Chanvillard G.: Modelling elasticity of a hydrating cement paste. Cement Concrete Res. 37(10), 1427–1439 (2007)

Sevostianov I., Levin V., Kachanov M.: On the modeling and design of piezocomposites with prescribed properties. Arch. Appl. Mech. (Ingenieur Arch.) 71(11), 733–747 (2001)

Sevostianov I., Yilmaz N., Kushch V., Levin V.: Effective elastic properties of matrix composites with transversely-isotropic phases. Int. J. Solids Struct. 42(2), 455–476 (2005)

Stora E., He Q.-C., Bary B.: Influence of inclusion shapes on the effective linear elastic properties of hardened cement pastes. Cement Concrete Res. 36(7), 1330–1344 (2006)

Stroud A.: Approximate Calculation of Multiple Integrals. Prentice-Hall, Englewood Cliffs (1971)

Sun Z., Ye G., Shah S.: Microstructure and early-age properties of portland cement paste—effects of connectivity of solid phases. ACI Mater. J. 102(2), 122–129 (2005)

S˘breve;milauer V., Bittnar Z.: Microstructure-based micromechanical prediction of elastic properties in hydrating cement paste. Cement Concrete Res. 36(9), 1708–1718 (2006)

Taylor, H.: Cement Chemistry. Thomas Telford Ltd, 2nd edn. (2007)

Tennis P., Jennings H.: A model for two types of calcium silicate hydrate in the microstructure of portland cement pastes. Cement Concrete Res. 30(6), 855–863 (2000)

Tritthart J., Häußler F.: Pore solution analysis of cement pastes and nanostructural investigations of hydrated C3S. Cement Concrete Res. 33(7), 1063–1070 (2003)

Ulm F.-J., Constantinides G., Heukamp F.: Is concrete a poromechanics material? – A multiscale investigation of poroelastic properties. Mater. Struct. Materiaux et Construct. 37(1), 43–58 (2004)

Ulm F.-J., Coussy O.: Strength growth as chemo-plastic hardening in early age concrete. J. Eng. Mech. (ASCE) 122(12), 1123–1132 (1996)

Zaoui, A.: Matériaux hétérogènes et composites [Heterogeneous materials and composites] (in French). Lecture Notes. Ecole Polytechnique, Paris, France (1997a)

Zaoui, A.: Structural morphology and constitutive behavior of microheterogeneous materials. In: Suquet, P. (ed.) Continuum Micromechanics, pp. 291–347, Vienna. Springer, Heidelberg (1997b)

Zaoui A.: Continuum micromechanics: Survey. J. Eng. Mech. (ASCE) 128(8), 808–816 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pichler, B., Hellmich, C. & Eberhardsteiner, J. Spherical and acicular representation of hydrates in a micromechanical model for cement paste: prediction of early-age elasticity and strength. Acta Mech 203, 137–162 (2009). https://doi.org/10.1007/s00707-008-0007-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-008-0007-9