Abstract

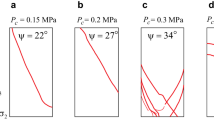

Deformation bands featuring localised material failure are ubiquitous in nature. They form important flow barriers and reduce/compartmentalise fluid flow in oil/gas/water reservoir rocks. Moderate temperature changes have been observed to play a fundamental role in the formation and style of these bands, but the mechanisms underpinning these changes are often obscure. Here, we show compaction experiments of highly porous limestone from Mt Gambier, Australia, with chemically non-reacting gaseous (helium) and fluid (kerosene) pore fluids. Gas-filled limestones showed a lower static elastic stiffness than fluid-filled specimens. The discrepancy in elastic modulus is particularly noted at high temperature. This indicates the important effect of temperature-sensitive compressibility of gas-filled pores versus nominally incompressible fluid-filled pores. A moderate temperature rise from 25 to 80 °C also led to a sharp transition in compaction band growth from dominantly ductile diffuse band growth at low temperatures to prevailing brittle growth at higher temperatures. We attribute this change to a temperature-sensitive change in micro-mechanism from rate-sensitive calcite twinning at room temperature to activation of a near-ideal plastic Peierls mechanism at 80 °C. The inverse-to-normal brittle–ductile transition is documented by time-lapse X-ray CT micro-tomographic images and associated digital image and volume image correlation techniques.

Highlights

-

4D time-lapse triaxial experiments on highly porous carbonates reveal thermomechanical and thermohydromechanical couplings.

-

Gas saturated specimens show higher yield stress and lower elastic modulus when compared to fluid-saturated specimens.

-

A changeover from ostensibly ductile to a dominantly brittle micro-deformation mechanisms is encountered when raising the temperature from 25 to 80 °C.

Similar content being viewed by others

Availability of Data and Materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Code Availability

Not applicable.

References

Abdallah Y, Sulem J, Bornert M, Ghabezloo S, Stefanou I (2021) Compaction banding in high-porosity carbonate rocks: 1. experimental observations. J Geophys Res Solid Earth 126:e2020JB020538. https://doi.org/10.1029/2020JB020538

Anderson GD (1981) Effects of friction on hydraulic fracture growth near unbonded interfaces in rocks. Soc Petrol Eng J 21:21–29. https://doi.org/10.2118/8347-PA

Arzilli F, Cilona A, Mancini L, Tondi E (2016) Using synchrotron X-ray microtomography to characterize the pore network of reservoir rocks: a case study on carbonates. Adv Water Resour 95:254–263. https://doi.org/10.1016/j.advwatres.2015.07.016

Atkinson BK (1984) Subcritical crack growth in geological materials. J Geophys Res Solid Earth 89:4077–4114. https://doi.org/10.1029/JB089iB06p04077

Aydin A, Borja RI, Eichhubl P (2006) Geological and mathematical framework for failure modes in granular rock. J Struct Geol 28:83–98

Baud P, Klein E, Wong T-F (2004) Compaction localization in porous sandstones: spatial evolution of damage and acoustic emission activity. J Struct Geol 26:603–624. https://doi.org/10.1016/j.jsg.2003.09.002

Baud P, Reuschlé T, Ji Y, Cheung CSN, Wong T-F (2015) Mechanical compaction and strain localization in Bleurswiller sandstone. J Geophys Res Solid Earth 120:6501–6522. https://doi.org/10.1002/2015JB012192

Baud P, Vinciguerra S, David C, Cavallo A, Walker E, Reuschlé T (2009) Compaction and failure in high porosity carbonates: mechanical data and microstructural observations. Pure Appl Geophys 166:869–898. https://doi.org/10.1007/s00024-009-0493-2

Baud P, Zhu W, Wong T-F (2000) Failure mode and weakening effect of water on sandstone. J Geophys Res Solid Earth 105:16371–16389. https://doi.org/10.1029/2000jb900087

Baxevanis T, Papamichos E, Flornes O, Larsen I (2006) Compaction bands and induced permeability reduction in Tuffeau de Maastricht calcarenite. Acta Geotech 1:123–135. https://doi.org/10.1007/s11440-006-0011-y

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: three-dimensional strain mapping using X-ray tomography. Exp Mech 39:217–226. https://doi.org/10.1007/BF02323555

Bésuelle P, Rudnicki JW (2004) Localization: shear bands and compaction bands. Int Geophys Ser 89:219–322

Bieniawski ZT (1967) Mechanism of brittle fracture of rock: Part II—experimental studies. Int J Rock Mech Min Sci Geomech Abstr 4:407–423. https://doi.org/10.1016/0148-9062(67)90031-9

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation matlab software. Exp Mech 55:1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Bourman RP, Murray-Wallace CV, Harvey N (2016) Coastal Landscapes of South Australia. University of Adelaide Press, Adelaide. https://doi.org/10.20851/coast-sa

Brantut N, Heap MJ, Meredith PG, Baud P (2013) Time-dependent cracking and brittle creep in crustal rocks: a review. J Struct Geol 52:17–43. https://doi.org/10.1016/j.jsg.2013.03.007

Brunauer S, Kantro D, Weise C (1956) The surface energies of amorphous silica and hydrous amorphous silica. Can J Chem 34:1483–1496

Burkhard M (1993) Calcite twins, their geometry, appearance and significance as stress–strain markers and indicators of tectonic regime: a review. J Struct Geol 15:351–368. https://doi.org/10.1016/0191-8141(93)90132-T

Butt H-J, Graf K, Kappl M (2013) Physics and chemistry of interfaces. Wiley

Cai X, Zhou Z, Liu K, Du X, Zang H (2019) Water-weakening effects on the mechanical behavior of different rock types: phenomena and mechanisms. Appl Sci 9:4450

Caselle C, Umili G, Bonetto S, Ferrero AM (2019) Application of DIC analysis method to the study of failure initiation in gypsum rocks. Géotech Lett 9:35–45. https://doi.org/10.1680/jgele.18.00156

Cerasi P, Walle LE (2016) Investigation of potential loss of injectivity and formation integrity due to pressure cycling. Energy Procedia 86:420–431. https://doi.org/10.1016/j.egypro.2016.01.043

Charalampidou E-M, Hall SA, Stanchits S, Lewis H, Viggiani G (2011) Characterization of shear and compaction bands in a porous sandstone deformed under triaxial compression. Tectonophysics 503:8–17. https://doi.org/10.1016/j.tecto.2010.09.032

Chen X, Regenauer-Lieb K, Lv A, Hu M, Roshan H (2020a) The dynamic evolution of permeability in compacting carbonates: phase transition and critical points. Transp Porous Media 135:687–711. https://doi.org/10.1007/s11242-020-01493-y

Chen X, Roshan H, Lv A, Hu M, Regenauer-Lieb K (2020b) The dynamic evolution of compaction bands in highly porous carbonates: the role of local heterogeneity for nucleation and propagation. Prog Earth Planet Sci 7:28. https://doi.org/10.1186/s40645-020-00344-0

Chu T, Ranson W, Sutton MA (1985) Applications of digital-image-correlation techniques to experimental mechanics. Exp Mech 25:232–244

Ciantia MO, Castellanza R, Di Prisco C (2015) Experimental study on the water-induced weakening of calcarenites. Rock Mech Rock Eng 48:441–461

Cilona A et al (2014) The effects of rock heterogeneity on compaction localization in porous carbonates. J Struct Geol 67:75–93. https://doi.org/10.1016/j.jsg.2014.07.008

Croize D, Renard F, Gratier J-P (2013) Compaction and porosity reduction in carbonates: a review of observations, theory, and experiments. In: Dmowska R (ed) Advances in geophysics, vol 54. Elsevier, San Diego, pp 181–238. https://doi.org/10.1016/B978-0-12-380940-7.00003-2

Das A, Nguyen GD, Einav I (2011) Compaction bands due to grain crushing in porous rocks: a theoretical approach based on breakage mechanics. J Geophys Res Solid Earth 116:B08203. https://doi.org/10.1029/2011JB008265

Das A, Nguyen GD, Einav I (2013) The propagation of compaction bands in porous rocks based on breakage mechanics. J Geophys Res Solid Earth 118:2049–2066. https://doi.org/10.1002/jgrb.50193

Eberhardt E, Stead D, Stimpson B (1999) Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int J Rock Mech Min Sci 36:361–380. https://doi.org/10.1016/S0148-9062(99)00019-4

Ferrill DA, Morris AP, Evans MA, Burkhard M, Groshong RH, Onasch CM (2004) Calcite twin morphology: a low-temperature deformation geothermometer. J Struct Geol 26:1521–1529. https://doi.org/10.1016/j.jsg.2003.11.028

Fortin J, Schubnel A, Guéguen Y (2005) Elastic wave velocities and permeability evolution during compaction of Bleurswiller sandstone. Int J Rock Mech Min Sci 42:873–889. https://doi.org/10.1016/j.ijrmms.2005.05.002

Fossen H, Schultz RA, Shipton ZK, Mair K (2007) Deformation bands in sandstone: a review. J Geol Soc 164:755–769. https://doi.org/10.1144/0016-76492006-036

Fossen H, Soliva R, Ballas G, Trzaskos B, Cavalcante C, Schultz RA (2018) A review of deformation bands in reservoir sandstones: geometries, mechanisms and distribution. Geol Soc Lond Spec Publ 459:9–33

Frangakis AS, Hegerl R (2001) Noise reduction in electron tomographic reconstructions using nonlinear anisotropic diffusion. J Struct Biol 135:239–250. https://doi.org/10.1006/jsbi.2001.4406

Friedman M, Heard HC (1974) Principal stress ratios in cretaceous limestones from Texas Gulf Coast 1. AAPG Bull 58:71–78. https://doi.org/10.1306/83D9137B-16C7-11D7-8645000102C1865D

Ghabezloo S, Sulem JJRM (2009) Stress dependent thermal pressurization of a fluid-saturated rock. Rock Mech Rock Eng 42:1

Griffith AA (1921) VI. The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A 221:163–198

Guéguen Y, Boutéca M (2004) Mechanics of fluid-saturated rocks. Elsevier, Amsterdam

Hadgu T, Zimmerman RW, Bodvarsson GS (1995) Coupled reservoir-wellbore simulation of geothermal reservoir behavior. Geothermics 24:145–166. https://doi.org/10.1016/0375-6505(95)91145-A

Han B, Shen WQ, Xie SY, Shao JF (2019) Influence of pore pressure on plastic deformation and strength of limestone under compressive stress. Acta Geotech 14:535–545. https://doi.org/10.1007/s11440-018-0658-1

Han G, Liu X, Wang E (2013) Experimental study on formation mechanism of compaction bands in weathered rocks with high porosity. Sci China Technol Sci 56:2563–2571. https://doi.org/10.1007/s11431-013-5322-2

Heap M, Baud P, Meredith P (2009) Influence of temperature on brittle creep in sandstones. Geophys Res Lett. https://doi.org/10.1029/2009GL039373

Hellmann R, Renders P, Gratier J, Guiguet R (2002) Experimental pressure solution of chalk in aqueous solutions. Part 2. Deformation examined by SEM, porosimetry, synthetic permeability, and X-ray computerized tomography. In: Roland HeUmann SAW (ed) Water–rock interactions, ore deposits, environmental geochemistry: a tribute to David A. Crerar, vol 7. Geochimical society, St. Louis, pp 153–176

Hill RE (1993) Analysis of deformation bands in the Aztec sandstone, Valley of Fire State Park, Nevada. MS thesis, University of Nevada

Hu M, Schrank C, Regenauer-Lieb K (2020) Cross-diffusion waves in hydro-poro-mechanics. J Mech Phys Solids 135:103632. https://doi.org/10.1016/j.jmps.2019.05.015

Issen K, Rudnicki J (2000) Conditions for compaction bands in porous rock. J Geophys Res Solid Earth 105:21529–21536. https://doi.org/10.1029/2000JB900185

Issen K, Rudnicki J (2001) Theory of compaction bands in porous rock. Phys Chem Earth A 26:95–100. https://doi.org/10.1016/S1464-1895(01)00031-X

Jasinski L, Sangaré D, Adler PM, Mourzenko VV, Thovert JF, Gland N, Békri S (2015) Transport properties of a Bentheim sandstone under deformation. Phys Rev E 91:013304. https://doi.org/10.1103/PhysRevE.91.013304

Karkush M, Zaboon A, Hussien H (2013) Studying the effects of contamination on the geotechnical properties of clayey soil. In: Manassero M, Dominijanni A, Foti S, Musso G (eds) Coupled phenomena in environmental geotechnics. Taylor & Francis, London, pp 599–607

Karner SL, Chester JS, Chester FM, Kronenberg AK, Hajash A Jr (2005) Laboratory deformation of granular quartz sand: implications for the burial of clastic rocks. AAPG Bull 89:603–625. https://doi.org/10.1306/12200404010

Ketcham RA, Hanna RDJC (2014) Beam hardening correction for X-ray computed tomography of heterogeneous natural materials. Comput Geosci 67:49–61

Kingston AM, Myers GR, Latham SJ, Li H, Veldkamp JP, Sheppard AP (2016) Optimized X-ray source scanning trajectories for iterative reconstruction in high cone-angle tomography. In: Stock SR, Müller B, Wang G (eds) Developments in X-ray tomography X. International Society for Optics and Photonics, Bellingham, p 996712. https://doi.org/10.1117/12.2238297

Kodama J, Goto T, Fujii Y, Hagan P (2013) The effects of water content, temperature and loading rate on strength and failure process of frozen rocks. Int J Rock Mech Min Sci 62:1–13. https://doi.org/10.1016/j.ijrmms.2013.03.006

Korsnes RI, Madland MV, Austad T, Haver S, Røsland G (2008) The effects of temperature on the water weakening of chalk by seawater. J Petrol Sci Eng 60:183–193. https://doi.org/10.1016/j.petrol.2007.06.001

Kuempel H-J, Chadha R, Ramana D, Ravi MJJotGSoI, (2017) In-situ pore pressure variations in Koyna–Warna—a promising key to understand triggered earthquakes. J Geol Soc India 90:678–683. https://doi.org/10.1007/s12594-017-0775-8

Kümpel H-J (2012) Thermo-hydro-mechanical coupling in fractured rock. Birkhäuser, Basel. https://doi.org/10.1007/978-3-0348-8083-1

Kümpel HJ (1991) Poroelasticity: parameters reviewed. Geophys J Int 105:783–799. https://doi.org/10.1111/j.1365-246X.1991.tb00813.x

Lackner KS (2002) Carbonate chemistry for sequestering fossil carbon. Ann Rev Energy Environ 27:193–232

Landry CJ, Karpyn ZT, Piri M (2011) Pore-scale analysis of trapped immiscible fluid structures and fluid interfacial areas in oil-wet and water-wet bead packs. Geofluids 11:209–227. https://doi.org/10.1111/j.1468-8123.2011.00333.x

Lange NA, Dean JA (1967) Lange’s handbook of chemistry. McGraw-Hill, New York

Latham S, Varslot T, Sheppard A (2008) Image registration: enhancing and calibrating X-ray micro-CT imaging. In: Proceedings of the international symposium of the Society of Core Analysts 2008, Abu Dhabi, UAE. Society of Core Analysts, pp 1–12.

Lemos LJL (2003) Discussion: dynamic thermo-poro-mechanical analysis of catastrophic landslides. Géotechnique 53:523–524. https://doi.org/10.1680/geot.2003.53.5.523

Lenoir N, Andrade J, Sun W, Rudnicki J (2010) In situ permeability measurements inside compaction bands using X-ray CT and lattice Boltzmann calculations. In: Reed KAAAH (ed) Advances in computed tomography for geomaterials: GeoX2020. Wiley, Hoboken, pp 279–286. https://doi.org/10.1002/9781118557723.ch33

Leuthold J, Gerolymatou E, Vergara MR, Triantafyllidis T (2021) Effect of compaction banding on the hydraulic properties of porous rock: part I—experimental investigation. Rock Mech Rock Eng 54:2671–2683. https://doi.org/10.1007/s00603-021-02427-w

Levy M, Bass H, Stern R (2000) Handbook of elastic properties of solids, liquids, and gases, four-volume set. Academic Press, Cambridge

Link KC, Schlünder E-U (1996) A new method for the characterisation of the wettability of powders. Chem Eng Technol 19:432–437. https://doi.org/10.1002/ceat.270190508

Lisabeth HP, Zhu W (2015) Effect of temperature and pore fluid on the strength of porous limestone. J Geophys Res Solid Earth 120:6191–6208. https://doi.org/10.1002/2015JB012152

Liteanu E, Spiers C, De Bresser J (2013) The influence of water and supercritical CO2 on the failure behavior of chalk. Tectonophysics 599:157–169

Lock PA, Jing X, Zimmerman RW, Schlueter EM (2002) Predicting the permeability of sandstone from image analysis of pore structure. J Appl Phys 92:6311–6319. https://doi.org/10.1063/1.1516271

Louis L, Baud P, Wong T-F (2009) Microstructural inhomogeneity and mechanical anisotropy associated with bedding in rothbach sandstone. Pure Appl Geophys 166:1063–1087. https://doi.org/10.1007/s00024-009-0486-1

Louis L, Wong T-F, Baud P, Tembe S (2006) Imaging strain localization by X-ray computed tomography: discrete compaction bands in Diemelstadt sandstone. J Struct Geol 28:762–775. https://doi.org/10.1016/j.jsg.2006.02.006

Lv A, Ramandi HL, Masoumi H, Saadatfar M, Regenauer-Lieb K, Roshan H (2019) Analytical and experimental investigation of pore pressure induced strain softening around boreholes. Int J Rock Mech Min Sci 113:1–10. https://doi.org/10.1016/j.ijrmms.2018.11.001

Mahmutoglu Y (1998) Mechanical behaviour of cyclically heated fine grained rock. Rock Mech Rock Eng 31:169–179

Mavko G, Mukerji T, Dvorkin J (2020) The rock physics handbook. Cambridge University Press, Cambridge

McBeck J, Aiken JM, Ben-Zion Y, Renard F (2020) Predicting the proximity to macroscopic failure using local strain populations from dynamic in situ X-ray tomography triaxial compression experiments on rocks. Earth Planet Sci Lett 543:116344. https://doi.org/10.1016/j.epsl.2020.116344

Mollema P, Antonellini M (1996) Compaction bands: a structural analog for anti-mode I cracks in aeolian sandstone. Tectonophysics 267:209–228. https://doi.org/10.1016/S0040-1951(96)00098-4

Nagarajappa AK, Dwivedi N, Tiwari R (2015) Artifacts: the downturn of CBCT image. J Int Soc Prev Community Dent 5:440–445. https://doi.org/10.4103/2231-0762.170523

Newman GH (1983) The effect of water chemistry on the laboratory compression and permeability characteristics of some north sea chalks. J Petrol Technol 35:976–980. https://doi.org/10.2118/10203-PA

Nicolas A, Fortin J, Regnet J, Dimanov A, Guéguen Y (2016) Brittle and semi-brittle behaviours of a carbonate rock: influence of water and temperature. Geophys J Int 206:438–456. https://doi.org/10.1093/gji/ggw154

Oka F, Kitahara H, Ohta H (2006) Observation of compaction bands under triaxial conditions for diatomaceous mudstone. In: Geomechanics and geotechnics of particulate media: proceedings of the international symposium on geomechanics and geotechnics of particulate media, Ube, Japan, 12–14 September 2006. CRC Press, p 69.

Olsson WA (1999) Theoretical and experimental investigation of compaction bands in porous rock. J Geophys Res Solid Earth 104:7219–7228. https://doi.org/10.1029/1998JB900120

Paluszny A et al (2020) Caprock integrity and public perception studies of carbon storage in depleted hydrocarbon reservoirs. Int J Greenh Gas Control 98:103057. https://doi.org/10.1016/j.ijggc.2020.103057

Parlangeau C, Dimanov A, Lacombe O, Hallais S, Daniel JM (2019) Uniaxial compression of calcite single crystals at room temperature: insights into twinning activation and development. Solid Earth 10:307–316. https://doi.org/10.5194/se-10-307-2019

Plummer LN, Busenberg E (1982) The solubilities of calcite, aragonite and vaterite in CO2–H2O solutions between 0 and 90°C, and an evaluation of the aqueous model for the system CaCO3–CO2–H2O. Geochim Cosmochim Acta 46:1011–1040. https://doi.org/10.1016/0016-7037(82)90056-4

Pons A, David C, Fortin J, Stanchits S, Menéndez B, Mengus J (2011) X-ray imaging of water motion during capillary imbibition: a study on how compaction bands impact fluid flow in Bentheim sandstone. J Geophys Res Solid Earth. https://doi.org/10.1029/2010JB007972

Rashid F, Glover PWJ, Lorinczi P, Hussein D, Lawrence JA (2017) Microstructural controls on reservoir quality in tight oil carbonate reservoir rocks. J Petrol Sci Eng 156:814–826. https://doi.org/10.1016/j.petrol.2017.06.056

Regenauer-Lieb K et al (2020) Cross-diffusion waves as a trigger for multiscale, multiphysics Instabilities: application to earthquakes. Solid Earth Discuss 2020:1–44. https://doi.org/10.5194/se-2020-149

Renard F, Bernard D, Desrues J, Ougier-Simonin A (2009) 3D imaging of fracture propagation using synchrotron X-ray microtomography. Earth Planet Sci Lett 286:285–291. https://doi.org/10.1016/j.epsl.2009.06.040

Renner J, Rummel F (1996) The effect of experimental and microstructural parameters on the transition from brittle failure to cataclastic flow of carbonate rocks. Tectonophysics 258:151–169. https://doi.org/10.1016/0040-1951(95)00192-1

Rice JR (2006) Heating and weakening of faults during earthquake slip. J Geophys Res Solid Earth. https://doi.org/10.1029/2005JB004006

Risnes R, Haghighi H, Korsnes RI, Natvik O (2003) Chalk–fluid interactions with glycol and brines. Tectonophysics 370:213–226. https://doi.org/10.1016/S0040-1951(03)00187-2

Risnes R, Madland MV, Hole M, Kwabiah NK (2005) Water weakening of chalk—mechanical effects of water–glycol mixtures. J Petrol Sci Eng 48:21–36. https://doi.org/10.1016/j.petrol.2005.04.004

Robinson L (1959) Effects of pore and confining pressures on failure characteristics of sedimentary rocks. Transactions of the AIME 216:26–32

Roshan H, Aghighi MA (2012) Chemo-poroelastic analysis of pore pressure and stress distribution around a wellbore in swelling shale: effect of undrained response and horizontal permeability anisotropy. Geomech Geoeng 7:209–218. https://doi.org/10.1080/17486025.2011.616936

Roshan H, Chen X, Pirzada MA, Regenauer-Lieb K (2019) Permeability measurements during triaxial and direct shear loading using a novel X-ray transparent apparatus: fractured shale examples from Beetaloo basin, Australia. NDT&E Int 107:102129. https://doi.org/10.1016/j.ndteint.2019.102129

Roshan H, Rahman S (2011) A fully coupled chemo-poroelastic analysis of pore pressure and stress distribution around a wellbore in water active rocks. Rock Mech Rock Eng 44:199–210

Rostom F, Røyne A, Dysthe DK, Renard F (2013) Effect of fluid salinity on subcritical crack propagation in calcite. Tectonophysics 583:68–75. https://doi.org/10.1016/j.tecto.2012.10.023

Rowe K, Rutter E (1990) Palaeostress estimation using calcite twinning: experimental calibration and application to nature. J Struct Geol 12:1–17. https://doi.org/10.1016/0191-8141(90)90044-Y

Røyne A, Bisschop J, Dysthe DK (2011) Experimental investigation of surface energy and subcritical crack growth in calcite. J Geophys Res Solid Earth. https://doi.org/10.1029/2010JB008033

Rustichelli A, Tondi E, Agosta F, Cilona A, Giorgioni M (2012) Development and distribution of bed-parallel compaction bands and pressure solution seams in carbonates (Bolognano Formation, Majella Mountain, Italy). J Struct Geol 37:181–199. https://doi.org/10.1016/j.jsg.2012.01.007

Sayers CM (2008) The elastic properties of carbonates. Lead Edge 27:1020–1024. https://doi.org/10.1190/1.2967555

Sengun N (2014) Influence of thermal damage on the physical and mechanical properties of carbonate rocks. Arab J Geosci 7:5543–5551. https://doi.org/10.1007/s12517-013-1177-x

Shahin G, Viggiani G, Buscarnera G (2020) Simulating spatial heterogeneity through a CT-FE mapping scheme discloses boundary effects on emerging compaction bands. Int J Solids Struct 206:247–261. https://doi.org/10.1016/j.ijsolstr.2020.08.016

Sheppard A et al (2014) Techniques in helical scanning, dynamic imaging and image segmentation for improved quantitative analysis with X-ray micro-CT. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 324:49–56. https://doi.org/10.1016/j.nimb.2013.08.072

Sheppard AP, Sok RM, Averdunk H (2004) Techniques for image enhancement and segmentation of tomographic images of porous materials. Phys A Stat Mech Appl 339:145–151. https://doi.org/10.1016/j.physa.2004.03.057

Siddiqui MAQ, Chen X, Iglauer S, Roshan H (2019) A multiscale study on shale wettability: spontaneous imbibition versus contact angle. Water Resour Res 55:5012–5032. https://doi.org/10.1029/2019WR024893

Siddiqui MAQ, Salvemini F, Ramandi HL, Fitzgerald P, Roshan H (2021) Configurational diffusion transport of water and oil in dual continuum shales. Sci Rep 11:2152. https://doi.org/10.1038/s41598-021-81004-1

Skoczylas N (2015) Determining the gas permeability coefficient of a porous medium by means of the bubble-counting flow meter. Meas Sci Technol 26:085004. https://doi.org/10.1088/0957-0233/26/8/085004

Sly MK, Thind AS, Mishra R, Flores KM, Skemer P (2020) Low-temperature rheology of calcite. Geophys J Int 221:129–141. https://doi.org/10.1093/gji/ggz577

Somerton WH (1992) Thermal properties and temperature-related behavior of rock/fluid systems. Elsevier, Amsterdam

Stanier SA, Blaber J, Take WA, White D (2016) Improved image-based deformation measurement for geotechnical applications. Can Geotech J 53:727–739

Sternlof KR, Karimi-Fard M, Pollard DD, Durlofsky LJ (2006) Flow and transport effects of compaction bands in sandstone at scales relevant to aquifer and reservoir management. Water Resour Res. https://doi.org/10.1029/2005WR004664

Sternlof KR, Rudnicki JW, Pollard DD (2005) Anticrack inclusion model for compaction bands in sandstone. J Geophys Res Solid Earth 110:B11403. https://doi.org/10.1029/2005JB003764

Sulem J, Lazar P, Vardoulakis I (2007) Thermo-poro-mechanical properties of clayey gouge and application to rapid fault shearing. Int J Numer Anal Methods Geomech 31:523–540

Sulem J, Stefanou I (2016) Thermal and chemical effects in shear and compaction bands. Geomech Energy Environ 6:4–21

Takano D, Lenoir N, Otani J, Hall SA (2015) Localised deformation in a wide-grained sand under triaxial compression revealed by X-ray tomography and digital image correlation. Soils Found 55:906–915. https://doi.org/10.1016/j.sandf.2015.06.020

Tanikawa W, Shimamoto T (2006) Klinkenberg effect for gas permeability and its comparison to water permeability for porous sedimentary rocks. Hydrol Earth Syst Sci Discuss 3:1315–1338. https://doi.org/10.5194/hessd-3-1315-2006

Tembe S, Baud P, Wong TF (2008) Stress conditions for the propagation of discrete compaction bands in porous sandstone. J Geophys Res Solid Earth 113:B09409. https://doi.org/10.1029/2007JB005439

Tembe S, Vajdova V, Wong TF, Zhu W (2006) Initiation and propagation of strain localization in circumferentially notched samples of two porous sandstones. J Geophys Res Solid Earth 111:B02409. https://doi.org/10.1029/2005JB003611

Tondi E, Antonellini M, Aydin A, Marchegiani L, Cello G (2006) The role of deformation bands, stylolites and sheared stylolites in fault development in carbonate grainstones of Majella Mountain, Italy. J Struct Geol 28:376–391. https://doi.org/10.1016/j.jsg.2005.12.001

Turner FJ, Griggs DT, Heard H (1954) Experimental deformation of calcite crystals. Geol Soc Am Bull 65:883–934

Vajdova V, Wong TF (2003) Incremental propagation of discrete compaction bands: acoustic emission and microstructural observations on circumferentially notched samples of Bentheim. Geophys Res Lett. https://doi.org/10.1029/2003GL017750

Varslot T, Kingston A, Sheppard A, Sakellariou A (2010) Fast high-resolution micro-CT with exact reconstruction methods. In: The SPIE—progress in biomedical optics and imaging, San Diego, California, USA, 2010. International Society for Optics and Photonics, p 780413. https://doi.org/10.1117/12.860298

Vendroux G, Knauss W (1998) Submicron deformation field measurements: part 2 improved digital image correlation. Exp Mech 38:86–92

Viggiani G, Tengattini A (2019) Recent developments in laboratory testing of geomaterials with emphasis on imaging. In: Proceedings of the XVII ECSMGE-2019. The Icelandic Geotechnical Society, Reykjavik

Violay M, Di Toro G, Nielsen S, Spagnuolo E, Burg JP (2015) Thermo-mechanical pressurization of experimental faults in cohesive rocks during seismic slip. Earth Planet Sci Lett 429:1–10. https://doi.org/10.1016/j.epsl.2015.07.054

Violay M et al (2014) Effect of water on the frictional behavior of cohesive rocks during earthquakes. Geology 42:27–30. https://doi.org/10.1130/G34916.1

Walsh JB (1965) The effect of cracks on the compressibility of rock. J Geophys Res Solid Earth 70:381–389. https://doi.org/10.1029/JZ070i002p00381

Wang B, Chen Y, Wong T-F (2008) A discrete element model for the development of compaction localization in granular rock. J Geophys Res Atmos. https://doi.org/10.1029/2006JB004501

Wawersik WR et al (2001) Terrestrial sequestration of CO2: an assessment of research needs. In: Dmowska R, Saltzman B (eds) Advances in Geophysics, vol 43. Elsevier, Amsterdam, pp 97–IX. https://doi.org/10.1016/S0065-2687(01)80003-0

Wiederhorn SM (1967) Influence of water vapor on crack propagation in soda-lime glass. J Am Ceram Soc 50:407–414. https://doi.org/10.1111/j.1151-2916.1967.tb15145.x

Wong LNY, Zhang Y, Wu Z (2020) Rock strengthening or weakening upon heating in the mild temperature range? Eng Geol 272:105619. https://doi.org/10.1016/j.enggeo.2020.105619

Wong TF, David C, Zhu W (1997) The transition from brittle faulting to cataclastic flow in porous sandstones: mechanical deformation. J Geophys Res Solid Earth 102:3009–3025. https://doi.org/10.1029/96JB03281

Xue L, Qin S, Sun Q, Wang Y, Lee LM, Li W (2014) A study on crack damage stress thresholds of different rock types based on uniaxial compression tests. Rock Mech Rock Eng 47:1183–1195. https://doi.org/10.1007/s00603-013-0479-3

Yavuz H, Demirdag S, Caran S (2010) Thermal effect on the physical properties of carbonate rocks. Int J Rock Mech Min Sci 47:94–103. https://doi.org/10.1016/j.ijrmms.2009.09.014

Zeng L, Chen Y, Lu Y, Hossain MM, Saeedi A, Xie Q (2020) Role of brine composition on rock surface energy and its implications for subcritical crack growth in calcite. J Mol Liq 303:112638. https://doi.org/10.1016/j.molliq.2020.112638

Zhou S, Xia C, Zhou Y (2018) A theoretical approach to quantify the effect of random cracks on rock deformation in uniaxial compression. J Geophys Eng 15:627–637. https://doi.org/10.1088/1742-2140/aaa1ad

Zimmerman RW (2000) Coupling in poroelasticity and thermoelasticity. Int J Rock Mech Min Sci 37:79–87. https://doi.org/10.1016/S1365-1609(99)00094-5

Acknowledgements

We would like to thank the Tyree X-Ray Laboratory at the School of Mineral and Energy Resources, UNSW for their assistance in imaging and image reconstruction. The project was financially supported by the Australian Research Council (ARC DP170104550, DP170104557, DP200102517, and LP170100233). The first author would like to acknowledge the fellowship from the UNSW Tuition Fee Scholarship (TFS) and the China Scholarship Council (CSC).

Funding

The project was financially supported by the Australian Research Council (ARC DP170104550, DP170104557, DP200102517, LE200100209, and LP170100233).

Author information

Authors and Affiliations

Contributions

HR and KRL are project coordinators, proposed the topic, conceived the study, and reviewed the final manuscript. XC conducted the experiments, analysed the data, and composed the draft of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

A series of pre-tests were conducted at a constant water flow rate to warm up the specimen to the desired temperature. The temperature of the specimen was measured with a thermocouple probe made of Cu–CuNi wires which was placed inside the specimen. The thermocouple was connected to ALMEMO 2590 data logger, which has a resolution of 0.1 °C. Figure 15 shows the desired temperature of 80 °C requiring circulating hot water (95 °C) at 90 ml/min for 60 min and temperature of 50 °C requiring circulating hot water (95 °C) at 90 ml/min for 8 min and then reduced to 24 ml/min for another 30 min until the temperature stabilises. The temperature fluctuation is ± 0.5 °C throughout.

Appendix 2

2.1 Digital Image Processing

Each scan might have slightly different greyscale intensity because of the filament lifetime changes. Differences in greyscale intensity can result in bias when obtaining the accurate registration and thresholding segmentation process across all the images. The greyscale intensity was carefully calibrated according to selected homogeneous regions: air, kerosene, triaxial cell body, top and bottom platens, and rubber sleeve. All differences were corrected using an obtained linear function.

When the X-ray beam passes through a cylindrical specimen, the outer regions absorb and scatter the lower energies in the X-ray spectrum, which results in the exterior regions being brighter than the inner regions. Beam-hardening correlation thus applied a Gaussian smoothing kernel on specified regions of the data to reduce the beam hardening effect (Ketcham and Hanna 2014). Noise is another artifact that makes it challenging to differentiate low-density areas, thereby reducing the ability to segment effectively (Nagarajappa et al. 2015). A nonlinear anisotropic diffusion filter denoising the images and preserving the edges using a similar method by Frangakis and Hegerl (2001) was used in our study.

Image registration is a crucial step in time-lapse experiments. A 3D registration algorithm developed by Latham et al. (2008) was used for image registration. This technique brings two or more images into geometric alignment for further digital image correlation analysis. In our study, each scan was carefully registered to a previous scan to ensure that undeformed parts are overlapped.

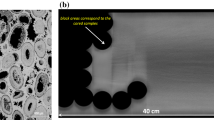

The histogram of all the image slices can be exported before image segmentation (Fig. 1). The greyscale values of the tomographs correspond to the X-ray attenuation produced by material, i.e., for example, lower for air than kerosene and the calcite grains. The histogram shows two peaks corresponding to the pores (air, low X-ray attenuation) and matrix (mainly calcite, high X-ray attenuation). With compression of the specimen, the volume of the pore phase reduces, and the matrix phase increases. Two dashed lines indicate the greyscale value of the pore phase and the matrix phase. The converging active contours’ (CAC) method was used for the segmentation of these images (Sheppard et al. 2014; Sheppard et al. 2004). This method uses a combination of the watershed and active contour methods to segment the greyscale data. The real boundary of the pore and matrix can be determined by this method. Later on, the layer-by-layer porosity profile can be extracted from the segmented images along with Z-axis.

2.2 Digital Image Correlation (DIC) and Digital Volume Correlation (DVC) Analysis

Since the 1980s, the 2D digital image correlation (DIC) technique has been widely used to measure real-time full-field data of displacements and strains (Chu et al. 1985; Vendroux and Knauss 1998). This non-destructive testing method can measure the deformation behaviour of a material over a wide area in exceptional detail. DIC uses image registration algorithms to track the relative displacement of material points between a reference image and a deformed image. Our study uses an open-source 2D subset-based DIC software package: Ncorr (Blaber et al. 2015). Ncorr uses the reliability guided (RG-DIC) method to obtain displacement values for a subset. The shear and compressive strain field can be extracted based on the displacement field using the Green–Lagrangian strain tensor, which can be used to determine the nucleation and propagation of the compaction bands. This DIC code has been shown to work well for tracking the materials displacements (Caselle et al. 2019; Lv et al. 2019; Siddiqui et al. 2021; Stanier et al. 2016). With the wide use of X-ray CT and synchrotron 3D images, the digital volume correlation (DVC) technique has become popular (Bay et al. 1999). This technique can be considered as the extended version of the 2D-DIC method to the 3D-DVC domain in conjunction with 3D images, which effectively determines the internal volumetric deformation behaviours of solid materials. Avizo (Thermofisher Scientific) digital volume correlation (DVC) was used for 3D-DVC analysis in our study. A subset-based (local) approach is used to capture the large displacements on a coarse, regular grid.

Appendix 3

The radial deformations for both helium and kerosene saturated specimens at low and high temperatures were extracted from every X-ray CT scan. The radial and axial strain versus axial stress is plotted in Fig. 16.

Appendix 4

The contact angles of kerosene–calcite–air and water–calcite–air were measured by viewing the drop profile (Link and Schlünder 1996; Siddiqui et al. 2019) and are shown in Fig. 17.

Contact angle measurement using distilled water and purified kerosene with crushed powder of Mt Gambier limestone. Because of the highly permeable sample powder, the contact angle of two different fluids was measured using a high-speed camera. The results were plotted by contact angle versus time. Two dashed lines show the power-law fit of the kerosene and water contact angles, respectively

The equilibrium contact angle (\({\theta }_{\mathrm{C}}\)) is determined from Young equation (Butt et al. 2013)

where, \(\gamma\) is the surface energy, and SG, SL, and LG represent the solid–gas, solid–liquid, and liquid–gas, respectively. We write the contact angle equations for water–calcite–air and kerosene–calcite–air system as

where Sa, Sw, wa, and w represent calcite–air, calcite–water, water–air, and water, and Sk, ka, and k represent calcite–kerosene, kerosene–air, and kerosene, respectively. The difference between \({\gamma }_{\mathrm{Sw}}\) and \({\gamma }_{\mathrm{Sk}}\) is

where \({\gamma }_{\mathrm{wa}}\) is 0.0728 N/m at 25 °C (Lange and Dean 1967) and \({\gamma }_{\mathrm{ka}}\) is 0.0267 N/m at 25 °C (Landry et al. 2011). Also, \({\theta }_{\mathrm{k}}\) and \({\theta }_{\mathrm{w}}\) are 5° and 20°, respectively, leading to

Rights and permissions

About this article

Cite this article

Chen, X., Regenauer-Lieb, K. & Roshan, H. Temperature-Induced Ductile–Brittle Transition in Porous Carbonates and Change in Compaction Band Growth Revealed by 4-D X-Ray Tomography. Rock Mech Rock Eng 55, 1087–1110 (2022). https://doi.org/10.1007/s00603-021-02736-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-021-02736-0