Abstract

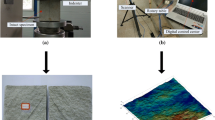

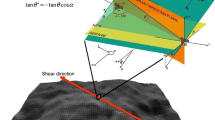

The three-dimensional (3D) morphology of joints is enormously important for the shear mechanical properties of rock. In this study, three-dimensional morphology scanning tests and direct shear tests are conducted to establish a new peak shear strength criterion. The test results show that (1) surface morphology and normal stress exert significant effects on peak shear strength and distribution of the damage area. (2) The damage area is located at the steepest zone facing the shear direction; as the normal stress increases, it extends from the steepest zone toward a less steep zone. Via mechanical analysis, a new formula for the apparent dip angle is developed. The influence of the apparent dip angle and the average joint height on the potential contact area is discussed, respectively. A new peak shear strength criterion, mainly applicable to specimens under compression, is established by using new roughness parameters and taking the effects of normal stress and the rock mechanical properties into account. A comparison of this newly established model with the JRC–JCS model and the Grasselli’s model shows that the new one could apparently improve the fitting effect. Compared with earlier models, the new model is simpler and more precise. All the parameters in the new model have clear physical meanings and can be directly determined from the scanned data. In addition, the indexes used in the new model are more rational.

Similar content being viewed by others

Abbreviations

- \(\sigma_{\text{t}}\) :

-

Tensile strength of the intact material (MPa)

- \(\sigma_{\text{c}}\) :

-

Uniaxial compressive strength of the intact material (MPa)

- \(\varphi_{\text{b}}\) :

-

Basic friction angle (°)

- n :

-

Outward normal vector of the triangle element

- n 1 :

-

The projection vector of n

- n 0 :

-

Outward normal vector of the shear plane

- S :

-

The shear vector

- \(\alpha\) :

-

The angle between n 1 and S (°)

- \(\theta\) :

-

Dip angle of the triangle element (°)

- \(\tau\) :

-

Shear stress applied by the testing machine (MPa)

- \(\tau^{\prime}\) :

-

Shear stress acting on asperity (MPa)

- \(\tau_{\text{p}}\) :

-

Peak shear strength (MPa)

- \(\sigma_{\text{n}}\) :

-

Normal stress (MPa)

- \(\sigma_{\text{j}}\) :

-

Normal stress acting on the joint plane (MPa)

- \(\tau_{\text{j}}\) :

-

Shear stress along the joint plane (MPa)

- A :

-

Total areas (mm2)

- A contact :

-

Total areas in contact before direct shear test (mm2)

- A shear :

-

Total areas facing the shear direction (mm2)

- \(A_{{\theta^{ * } }}^{ + }\) :

-

Ratio between A contact and A shear

- \(A_{{\theta^{ * } }}\) :

-

Ratio between A contact and A

- \(A_{0}\) :

-

Ratio between A shear and A

- \(\theta^{ * }\) :

-

Apparent dip angle (°)

- \(\bar{\theta }^{ * }\) :

-

Characteristics angle (°)

- \(\theta_{\rm max }^{ * }\) :

-

Maximum apparent dip angle (°)

- n :

-

Roughness parameter characterizing the distribution of apparent dip angles over the joint surface defined by this paper

- C :

-

Roughness parameter characterizing the distribution of apparent dip angles raised by Grasselli

- h :

-

Average joint height (mm)

- i :

-

Dilatancy angle (°)

- i p :

-

Peak dilatancy angle (°)

- i o :

-

Initial dilatancy angle (°)

- \(\delta\) :

-

Estimation error

- \(\delta_{\text{ave}}\) :

-

Average estimation error

- \(\tau_{\text{measured}}\) :

-

Measured peak shear strength (MPa)

- \(\tau_{\text{calculated}}\) :

-

Calculated peak shear strength (MPa)

- JRC:

-

Joint roughness coefficient

- JMC:

-

Joint matching coefficient

- JCS:

-

Joint wall compressive strength (MPa)

- \(L_{n}\) :

-

Real scale (mm)

- \(L_{o}\) :

-

Standard scale (mm)

- \({\text{JRC}}_{n}\) :

-

JRC value on real scale

- \({\text{JRC}}_{o}\) :

-

JRC value on standard scale

- \(j\) :

-

Number of profiles

- \({\text{JRC}}_{\text{ave}}\) :

-

Average value of \({\text{JRC}}_{n}\)

- \(\beta\) :

-

Angle between schistosity plane and plane normal to the joint (°)

References

Akçin NA, Müeftüeouglu YV, Bacs N (1994) Prediction of drilling performance for electro-hydraulic percussive drills. In: International symposium, mine planning and equipment selection, pp 483–488

Bagde MN (2000) An investigation into strength and porous properties of metamorphic rocks in the Himalayas: a case study. Geotech Geol Eng 18(3):209–219

Bandis S, Lumsden AC, Barton NR (1983) Fundamentals of rock joint deformation. Int J Rock Mech Min Sci Geomech Abstr 20(6):249–268

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7:287–332

Barton N (1976) The shear strength of rock and rock joints. Int J Rock Mech Min Sci Geomech Abstr 13:255–279

Barton NR, Bandis S (1990) Review of predictive capabilities of JRC–JCS model in engineering practice. In: Rock joints; proceedings of the international symposium on rock joints, pp 603–610

Balci C, Bilgin N (2005) Mekanize Kazı Makinalarının Seçiminde Küçük ve tam boyutlu kazı deneylerinin Karşılaştırılması. İTÜ dergisi 4:76–86 (in Turkish)

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech Rock Eng 10:1–54

Barton N, Bandis S, Bakhtar K (1985) Strength, deformation and conductivity coupling of rock joints. Int J Rock Mech Min Sci Geomech Abstr 22:121–140

Belem T, Homand-Etienne F, Souley M (2000) Quantitative parameters for rock joint surface roughness. Rock Mech Rock Eng 33:217–242

Belem T, Souley M, Homand F (2009) Method for quantification of wear of sheared joint walls based on surface morphology. Rock Mech Rock Eng 42:883–910

Bell FG, Jermy CA (2000) The geotechnical character of some South African dolerites, especially their strength and durability. Q J Eng GeolHydrogeol 33:59–76

Bell FG, Jermy CA (2002) A geomechanical survey of some different facies in relation to stability at a mine in the Eastern Transvaal Coalfield. South Africa Eng Geol 64:19–39

Betournay MC, Gorski B, Labrie D, Jackson R, Gyenge M (1991) New considerations in the determination of Hoek and Brown material constants. In: Proceedings of the 7th ISRM Congress. Rotterdam: A. A. Balkema, Aachen, Germany, pp 195–200

Bilgin N, Copur H, Balci C (2012) Effect of replacing disc cutters with chisel tools on performance of a TBM in difficult ground conditions. Tunn Undergr Space Technol 27:41–51

Blanton TL (1981) Effect of strain rates from 10−2, to 10 sec−1, in triaxial compression tests on three rocks. Int J Rock Mech Min Sci Geomech Abstr 18(1):47–62

Börner K, Hill D (2010) Große Enzyklopädie der Steine: Die Naturstein-Datenbank. CD-ROM. Abraxas Verlag GmbH

Brace WF, Iii RJM (1968) A test of the law of effective stress for crystalline rocks of low porosity. Int J Rock Mech Min Sci Geomech Abstr 5(5):415–426

Buyuksagis IS, Goktan RM (2005) Investigation of marble machining performance using an instru-mented block-cutter. J Mater Process Technol 169:258–262

Carter BJ, Scott Duncan EJ, Lajtai EZ (1991) Fitting strength criteria to intact rock. Geotech Geol Eng 9:73–81

Cho JW, Kim H, Jeon S, Min KB (2012) Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int J Rock Mech Min Sci 50:158–169

Cottrell B (2009) Updates to the GG-shear strength criterion. Dissertation, University of Toronto

Cottrell B, Tatone BSA, Grasselli G (2010) Joint replica shear testing and roughness degradation measurement. In: Eurock 2010; rock mechanics in civil and environmental engineering, pp 207–210

Dayre M, Giraud A (1986) Mechanical properties of granodiorite from laboratory tests. Eng Geol 23:109–124

Demou SG, Olson RC, Wingquist CF (1983). Determination of bit forces encountered in hard rock cutting for application to continuous miner design. Minneapolis Mn U.S. Department of the Interior Bureau of Mines Ri

Dong HK, Gratchev I, Hein M et al (2016) The application of normal stress reduction function in tilt tests for different block shapes. Rock Mech Rock Eng 49(8):1–14

Efimov VP (2009) The rock strength in different tension conditions. J Min Sci 45:569–575

Ersoy A, Waller MD (1995) Prediction of drill-bit performance using multi-variable linear regression analysis. Transactions of the Institution of Mining & Metallurgy

Ersoy A, Atıcı U (2004) Performance characteristics of circular diamond saws in cutting different types of rocks. Diam Relat Mater 13:22–37

Fereshtenejad S, Song JJ (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49(6):2065–2074

Fjær E, Holt RM, Raaen AM, Risnes R, Horsrud P (2008) Petroleum related rock mechanics, vol 53, 2nd edn. Developments in Petroleum Science. Elsevier, Amsterdam, p 491

Friedman M, Perkins RD, Green SJ (1970) Observation of brittle-deformation features at the maximum stress of westerly granite and solenhofen limestone. Int J Rock Mech Min Sci Geomech Abstr 7(3):297–302

Gadelmawla ES, Koura MM, Maksoud TMA, Elewa IM, Soliman HH (2002) Roughness parameters. J Mater Process Technol 123:133–145

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in Colorado Red Granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44:238–246

Ghazvinian E (2010) Modelling and testing strategies for brittle fracture simulation in crystalline rock samples. Dissertation, Queen’s University

Gnirk PF, Cheatham JB (1963) Indentation experiments on dry rocks under pressure. J Petrol Technol 15:1031–1039

Gnirk PF, Cheatham JB (1965) An experimental study of single bit-tooth penetration into dry rock at confining pressures 0 to 5,000 psi. Soc Petrol Eng J 5(2):117–130

Goodman RE, Taylor RL, Brekke TL (1968) A model for the mechanics of jointed rocks. J Soil Mech Found Div 94:637–659

Grasselli G (2001) Shear strength of rock joints based on quantified surface description. Dissertation, Swiss Federal Institute of Technology

Grasselli G, Egger P (2003) Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int J Rock Mech Min Sci 40:25–40

Howarth DF, Rowlands JC (1987) Quantitative assessment of rock texture and correlation with drillability and strength properties. Rock Mech Rock Eng 20:57–85

Huang SL, Wang ZW (1997) The mechanics of diamond core drilling of rocks. Int J Rock Mech Min Sci 34:134.e1–134.e14

Hungr O, Coates DF (1978) Deformability of joints and its relation to rock foundation settlement. Can Geotech J 15(2):239–249

Janach W (1976) The role of bulking in brittle failure of rocks under rapid compression. Int J Rock Mech Min Sci Geomech Abstr 13(6):177–186

Jang HS, Kang SS, Jang BA (2014) Determination of joint roughness coefficients using roughness parameters. Rock Mech Rock Eng 47:2061–2073

Jennings M, Wright D (1989) Guidelines for sawing stone. Ind Diamond Rev 49:70–75

Jiang C, Zhao GF (2015) A preliminary study of 3D printing on rock mechanics. Rock Mech Rock Eng 48(3):1041–1050

Jiang C, Zhao GF, Zhu J et al (2016a) Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech Rock Eng 49(10):1–16

Jiang Q, Feng X, Gong Y et al (2016b) Reverse modelling of natural rock joints using 3D scanning and 3D printing. Comput Geotech 73:210–220

Jing L (1990) Numerical modeling of jointed rock masses by distinct element method for two, and three dimensional problems. Dissertation, Lulea University of Technology

Ju Y, Xie H, Zheng Z et al (2014) Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin Sci Bull 59(36):5354–5365

Ju Y, Wang L, Xie H et al (2017) Visualization and transparentization of the structure and stress field of aggregated geomaterials through 3D printing and photoelastic techniques. Rock Mech Rock Eng 50(6):1383–1407

Kahraman S, Balcı C, Yazıcı S, Bilgin N (2000) Prediction of the penetration rate of rotary blast hole drills using a new drillability index. Int J Rock Mech Min Sci 37:729–743

Kahraman S, Bilgin N, Feridunoglu C (2003) Dominant rock properties affecting the penetration rate of percussive drills. Int J Rock Mech Min Sci 40:711–723

Kahraman S, Fener M, Kozman E (2012) Predicting the compressive and tensile strength of rocks from indentation hardness index. J South Afr Inst Min Metall 112:331–339

Kılıç A, Teymen A (2008) Determination of mechanical properties of rocks using simple methods. Bull Eng Geol Env 67:237–244

Kim SJ (2010) An experimental investigation of the effect of blasting on the impact breakage of rocks. Dissertation, Queen’s University

Kimura T, Esaki T (1995) A new model for the shear strength of rock joints with irregular surfaces. Mech Jt Faulted Rock Rossmanith: Vienna: 133–8

Kwasniewski M (1983) Deformational and strength properties of the three structual varieties of carboniferous sandstones. In: Proceedings of the 5th ISRM Congress, Melbourne, Australia, pp A105–A115

Ladanyi B, Archambault G (1969) Simulation of shear behavior of a jointed rock mass. Ussymp Rock Mech 20:2359–2365

Lawi K (1976) Fundamental studies of fluid flow through a single fracture. Dissertation, University of California

Li Y, Zhang Y, Li Y, Zhang Y (2015) Quantitative estimation of joint roughness coefficient using statistical parameters. Int J Rock Mech Min Sci 77:27–35

Maerz NH, Franklin JA, Bennett CP (1990) Joint roughness measurement using shadow profilometry. Int J Rock Mech Min Sci Geomech Abstr 27:329–343

Mahabadi OK (2012) Investigating the influence of micro-scale heterogeneity and microstructure on the failure and mechanical behaviour of geomaterials. Dissertation, University of Toronto

Maksimović M (1992) New description of the shear strength for rock joints. Rock Mech Rock Eng 25:275–284

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. Dissertation, University of Manitoba

Martin CD (1993) The strength of massive Lac du Bonnet granite around underground openings. Dissertation, University of Manitoba

Masuda K, Mizutani H, Yamada I (1987) Experimental study of strain-rate dependence and pressure dependence of failure properties of granite. J Phys Earth 35(1):37–66

McFeat-Smith I, Fowell RJ (1977) Correlation of rock properties and tunnel machine performance. In: Proceedings of a conference on rock engineering, University of Newcastle Upon Tyne, pp 581–602

Morales Demarco M, Oyhantçabal P, Stein KJ, Siegesmund S (2011) Black dimensional stones: geology, technical properties and deposit characterization of the dolerites from Uruguay. Environ Earth Sci 63:1879–1909

Nuri TM, Ali ANY, Ali ANY (2012) Correlation study between point load test and uniaxial compressive strength and tensile strength of some sedimentary rocks in Mosul City. Eng Technol J 30:155–166

Olsson WA (1991) The compressive strength of tuff as a function of strain rate from 10−6, to 103/s. Int J Rock Mech Min Sci Geomech Abstr 28(1):115–118

Patton FD (1966) Multiple modes of shear failure in rock. In: Proceeding of the congress of international society of rock mechanics, pp 509–513

Reddish DJ, Yasar E (1996) A new portable rock strength index test based on specific energy of drilling. Int J Rock Mech Min Sci Geomech Abstr 33:543–548

Rostami J (1992) Design optimization, performance prediction and economic analysis of tunnel boring machines for the construction of the proposed yucca mountain nuclear waste repository. Dissertation, Colorado School of Mines

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12:361–366

Schmidt RL (1972) Drillability studies: percussive drilling in the field. Report of investigations 7684, U.S. Dept. of Interior, Bureau of Mines

Schneider HJ (1976) The friction and deformation behaviour of rock joints. Rock Mech Rock Eng 8:169–184

Schwartz AE (1964) Failure of rock in the triaxial shear test. In: Proceedings of the 6th U.S symposium on rock mechanics, american rock mechanics association, Rolla, Missouri, pp 109–151

Sheorey PR (1997) Empirical rock failure criteria. A. A. Balkema, Rotterdam, p 176

Snowdon RA, Ryley MD, Temporal J, Crabb GI (1983) The effect of hydraulic stiffness on tunnel boring machine performance. Int J Rock Mech Min Sci Geomech Abstr 20:203–214

Stowe RL (1969) Strength and deformation properties of granite, basalt, limestone and tuff at various loading rates. Miscellaneous paper C-69-1. United States Army Engineer Waterways Experiment Station, USACE. Vicksburg, Mississippi

Sun Futing (2015) Experimental research on three-dimensional joint morphology quantification and shear strength property of tensile hard rock joints with and without cement grouting. Dissertation, Wuhan University

Tahir M, Mohammad N, Din F (2011) Strength parameters and their inter-relationship for limestone of Cherat and Kohat areas of Khyber Pakhtunkhwa. J Himal Earth Sci 44:45–51

Tang H, Ge Y, Wang L, Yuan Y, Huang L, Sun M (2012) Study on estimation method of rock mass discontinuity shear strength based on three-dimensional laser scanning and image technique. J Earth Sci 23:908–913

Tatone B (2014) Investigating the evolution of rock discontinuity asperity degradation and void space morphology under direct shear. Dissertation, University of Toronto

Tatone BS, Grasselli G (2009) A method to evaluate the three-dimensional roughness of fracture surfaces in brittle geomaterials. Rev Sci Instrum 80:125110–125110–125110

Tatone BSA, Grasselli G (2010) A new 2D discontinuity roughness parameter and its correlation with JRC. Int J Rock Mech Min Sci 47:1391–1400

Tecen O, Fowell RJ (1983) Hybrid rock cutting: fundamental investigations and practical applications. In: Summer DA, Haston FF (eds) Proceedings of the 2nd U.S. water jet conference, Rolla, Missouri

Tiryaki B, Dikmen AC (2006) Effects of rock properties on specific cutting energy in linear cutting of sandstones by picks. Rock Mech Rock Eng 39:89–120

Tse R, Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16:303–307

Tumac D, Bilgin N, Feridunoglu C, Ergin H (2007) Estimation of rock cuttability from shore hardness and compressive strength properties. Rock Mech Rock Eng 40:477–490

Xia CC, Tang ZC, Xiao WM, Song YL (2014) New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech Rock Eng 47:387–400

Xing HZ, Zhang QB, Braithwaite CH et al (2017) High-speed photography and digital optical measurement techniques for geomaterials: fundamentals and applications. Rock Mech Rock Eng 2017:1–49

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Undergr Space Technol 24:66–74

Yang ZY, Lo SC, Di CC (2001) Reassessing the joint roughness coefficient (JRC) estimation using Z2. Rock Mech Rock Eng 34:243–251

Yang ZY, Taghichian A, Huang GD (2011) On the applicability of self-affinity concept in scale of three-dimensional rock joints. Int J Rock Mech Min Sci 48:1173–1187

Yang J, Rong G, Hou D, Peng J, Zhou C (2016) Experimental study on peak shear strength criterion for rock joints. Rock Mech Rock Eng 49:821–835

Yarali O, Soyer E (2013) Assessment of relationships between drilling rate index and mechanical properties of rocks. Tunn Undergr Space Technol 33:46–53

Yu X, Vayssade B (1991) Joint profiles and their roughness parameters. Int J Rock Mech Min Sci Geomech Abstr 28:333–336

Zhang QB, Zhao J (2014) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47(4):1411–1478

Zhang XP, Wong LNY, Wang SJ, Han GY (2011) Engineering properties of quartz mica schist. Eng Geol 121:135–149

Zhang X, Jiang Q, Chen N, Wei W, Feng X (2016) Laboratory investigation on shear behavior of rock joints and a new peak shear strength criterion. Rock Mech Rock Eng 49:3495–3512

Zhao J (1996) Joint surface matching and shear strength part A: joint matching coefficient (JMC). Int J Rock Mech Min Sci 34:173–178

Zhao J (1997) Joint surface matching and shear strength part B: JRC-JMC shear strength criterion. Int J Rock Mech Min Sci 34:179–185

Acknowledgements

The authors would like to acknowledge the consistent support of the National Basic Research Program of China (973 Program) (Grant No. 2014CB046904) and the National Natural Science Foundation China (Grant No. 41130742).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Tian, Y., Ji, P. et al. Experimental Investigation of the Peak Shear Strength Criterion Based on Three-Dimensional Surface Description. Rock Mech Rock Eng 51, 1005–1025 (2018). https://doi.org/10.1007/s00603-017-1390-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1390-0