Abstract

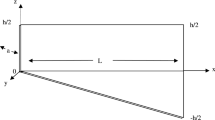

In this article, a passive mechanism for thermal stress regulation in micro-bridge structures is proposed. The mechanism is essentially a set of precisely designed parallel chevron beams that replace one of the fixed ends of the micro-bridge. The axial stress/force of the beam is determined by utilizing a sensing mechanism that makes use of two side-electrodes and the electromechanical buckling of the micro-bridge toward one of them. A combination of analytical and finite element methods has been employed for the modeling of the proposed mechanism. It has been demonstrated that the regulator mechanism has negligible dynamic effect on the sensing micro-beam. The model takes into account the effect of electric field fringes between the electrically charged bodies. It has been shown that there is a time delay between the moment that the pull-in occurs and the instant that the sensing beam rests on a side-electrode. The results of the modeling are verified by experiment on two devices fabricated using MetalMUMPs® fabrication technology. The thermal stress sensitivities of the devices are positive and their residual stresses are in excellent agreement.

Similar content being viewed by others

References

Abdel-Rahman EM, Younis MI, Nayfeh AH (2002) Characterization of the mechanical behavior of an electrically actuated microbeam. J Micromech Microeng 12(6):759–766

Abu-Salih S, Elata D (2006) Experimental validation of electromechanical buckling. J Microelectromech Syst 15(6):1656–1662

Andreykiv A, Rixen DJ (2009) Numerical modelling of electromechanical coupling using fictitious domain and level set methods. Int J Numer Methods Eng 80(4):478–506

Azevedo RG, Huang W, O’Reilly OM, Pisano AP (2008) Dual-mode temperature compensation for a comb-driven MEMS resonant strain gauge. Sens Actuators Phys A 144(2):374–380

Bendida S, Koning JJ, Bontemps JJM, van Beek JTM, Wu D, van Gils MAJ, Nath S (2008) Temperature stability of a piezoresistive MEMS resonator including self-heating. Microelectron Reliab 48(8-9):1227–1231

Boeloeni F, Benabou A, Tounzi A (2010) Comparison of pull-in voltages in MEMS using 3D FEM and analytical approaches. Int J Comput Math Electric Electron Eng 29(6):1653–1661

Chao PCP, Chiu CW, Liu TH (2008) Dc dynamic pull-in predictions for a generalized clamped–clamped micro-beam based on a continuous model and bifurcation analysis. J Micromech Microeng 18(11):14

Chen YC, Chang ICM, Chen RS, Hou MTK (2008) On the side instability of comb-fingers in MEMS electrostatic devices. Sens Actuators Phys A 148(1):201–210

Chyuan SW, Liao YS, Chen JT (2005) Computational study of the effect of finger width and aspect ratios for the electrostatic levitating force of MEMS combdrive. J Microelectromech Syst 14(2):305–312

Committee AIH (2000) Engineered materials handbook. ASM International, Novelty

Cowen A, Dudley B, Hill E, Walters M, Wood R, Johnson S, Wynands H, Hardy B (2002) MetalMUMPs design handbook. MEMSCAP Inc., Durham

Cretu E, Rocha LA, Wolffenbuttel RF (2001) Micromechanical voltage reference using the pull-in of a beam. IEEE Trans Instrum Meas 50(6):1504–1507

Das K, Batra RC (2009) Symmetry breaking, snap-through and pull-in instabilities under dynamic loading of microelectromechanical shallow arches. Smart Mater Struct 18(11):15

Elata D, Abu-Salih S (2005) Analysis of a novel method for measuring residual stress in micro-systems. J Micromech Microeng 15(5):921–927

Elata D, Bamberger H (2006) On the dynamic pull-in of electrostatic actuators with multiple degrees of freedom and multiple voltage sources. J Microelectromech Syst 15(1):131–140

Elata D, Leus V (2005) How slender can comb-drive fingers be? J Micromech Microeng 15(5):1055–1059

Fries TP, Belytschko T (2010) The extended/generalized finite element method: an overview of the method and its applications. Int J Numer Methods Eng 84(3):253–304

Fu YM, Zhang J (2010) Electromechanical dynamic buckling phenomenon in symmetric electric fields actuated microbeams considering material damping. Acta Mech 215(1–4):29–42

Guru BS, Hiziroglu HR (2004) Electromagnetic field theory fundamentals. Cambridge University Press, Cambridge

Hammer H (2010) Analytical model for comb-capacitance fringe fields. J Microelectromech Syst 19(1):175–182

Hassanpour PA, Cleghorn WL, Esmailzadeh E, Mills JK (2007) Vibration analysis of micro-machined beam-type resonators. J Sound Vib 308(1-2):287–301

Hassanpour PA, Wong CT, Nieva PM, Khajepour A (2009) Axial force regulation in MEMS resonant sensors. In: Proceedings of the ASME 2009 international mechanical engineering congress and exposition

Hassanpour PA, Nieva PM, Khajepour A (2010) Stochastic analysis of a nonlinear MEMS force sensor. In: Proceedings of the ASME 2010 international design engineering technical conferences

Hassanpour PA, Nieva PM, Khajepour A (2011) Stochastic analysis of a novel force sensor based on bifurcation of a micro-structure. J Sound Vib (accepted)

Hibbeler RC (2005) Mechanics of materials. Pearson Prentice Hall, Upper Saddle River

Hopcroft MA, Kim B, Chandorkar S, Melamud R, Agarwal M, Jha CM, Bahl G, Salvia J, Mehta H, Lee HK, Candler RN, Kenny TW (2007) Using the temperature dependence of resonator quality factor as a thermometer. Appl Phys Lett 91(1):013,505

Huang JM, Liu AQ, Lu C, Ahn J (2003) Mechanical characterization of micromachined capacitive switches: design consideration and experimental verification. Sens Actuators Phys A 108(1–3):36–48

Jha CM, Hopcroft MA, Chandorkar SA, Salvia JC, Agarwal M, Candler RN, Melamud R, Kim B, Kenny TW (2008) Thermal isolation of encapsulated MEMS resonators. J Microelectromech Syst 17(1):175–184

Joglekar MM, Pawaskar DN (2011a) Closed-form empirical relations to predict the static pull-in parameters of electrostatically actuated microcantilevers having linear width variation. Microsyst Technol Micro- Nano-Syst Inf Storage Process Syst 17(1):35–45

Joglekar MM, Pawaskar DN (2011b) Estimation of oscillation period/switching time for electrostatically actuated microbeam type switches. Int J Mech Sci 53(2):116–125

Karnovsky I, Lebed O (2004) Nonclassical vibrations of arches and beams: eigenvalues and eigenfunctions. McGraw-Hill, New York

Kenig E, Malomed BA, Cross MC, Lifshitz R (2009) Intrinsic localized modes in parametrically driven arrays of nonlinear resonators. Phys Rev E 80(4):14

Kim B, Hopcroft MA, Candler RN, Jha CM, Agarwal M, Melamud R, Chandorkar SA, Yama G, Kenny TW (2008) Temperature dependence of quality factor in MEMS resonators. J Microelectromech Syst 17(3):755–766

Koskenvuori M, Kaajakari V, Mattila T, Tittonen I (2008) Temperature measurement and compensation based on two vibrating modes of a bulk acoustic mode microresonator. In: 21st IEEE international conference on micro electro mechanical systems (MEMS 2008), pp 78–81

Krylov S (2008) Parametric excitation and stabilization of electrostatically actuated microstructures. Int J Multiscale Comput Eng 6(6):563–584

Krylov S, Maimon R (2004) Pull-in dynamics of an elastic beam actuated by continuously distributed electrostatic force. J Vib Acoust Trans ASME 126(3):332–342

Krylov S, Harari I, Cohen Y (2005) Stabilization of electrostatically actuated microstructures using parametric excitation. J Micromech Microeng 15(6):1188–1204

Krylov S, Gerson Y, Nachmias T, Keren U (2010) Excitation of large-amplitude parametric resonance by the mechanical stiffness modulation of a microstructure. J Micromech Microeng 20(1):12

Lian W, Middelhoek S (1986) Flip-flop sensors: a new class of silicon sensors. Sens Actuators 9(3):259–268

Liao YS, Chyuan SW, Chen JT (2004) An alternatively efficient method (DBEM) for simulating the electrostatic field and levitating force of a MEMS combdrive. J Micromech Microeng 14(8):1258–1269

Lin CM, Yen TT, Felmetsger VV, Hopcroft MA, Kuypers JH, Pisano AP (2010a) Thermally compensated aluminum nitride lamb wave resonators for high temperature applications. Appl Phys Lett 97(8):1258–1263

Lin CM, Yen TT, Lai YJ, Felmetsger VV, Hopcroft MA, Kuypers JH, Pisano AP (2010b) Temperature-compensated aluminum nitride lamb wave resonators. IEEE Trans Ultrasonics Ferroelectrics Frequency Control 57(3):524–532

Lobontiu N, Garcia E (2005) Mechanics of microelectromechanical systems. Kluwer, New York

Madou MJ (2002) Fundamentals of microfabrication. CRC Press, New York

Melamud R, Kim B, Chandorkar SA, Hopcroft MA, Agarwal M, Jha CM, Kenny TW (2007) Temperature-compensated high-stability silicon resonators. Appl Phys Lett 90(24):244,107

Melamud R, Chandorkar SA, Kim B, Lee HK, Salvia JC, Bahl G, Hopcroft MA, Kenny TW (2009) Temperature-insensitive composite micromechanical resonators. J Microelectromech Syst 18(6):1409–1419

Naeli K, Brand O (2009) Cancellation of environmental effects in resonant mass sensors based on resonance mode and effective mass. Rev Sci Instrum 80(6):063,903

Nayfeh AH (2000) Nonlinear interactions: analytical, computational, and experimental methods. Wiley, New York

Nayfeh AH, Mook DT (1979) Nonlinear oscillations. Wiley, New York

Nayfeh AH, Younis MI, Abdel-Rahman EM (2005) Reduced-order models for MEMS applications. Nonlinear Dyn 41(1–3):211–236

Nayfeh AH, Younis MI, Abdel-Rahman EM (2007) Dynamic pull-in phenomenon in MEMS resonators. Nonlinear Dyn 48(1–2):153–163

Osterberg PM, Senturia SD (1997) M-test: a test chip for MEMS material property measurement using electrostatically actuated test structures. J Microelectromech Syst 6(2):107–118

Rao SS (2007) Vibration of continuous systems. Wiley, New York

Rhoads JF, Shaw SW, Turner KL (2006) The nonlinear response of resonant microbeam systems with purely-parametric electrostatic actuation. J Micromech Microeng 16(5):890–899

Salvia J, Messana M, Ohline M, Hopcroft M, Melamud R, Chandorkar S, Lee H, Bahl G, Murmann B, Kenny T (2008) Exploring the limits and practicality of q-based temperature compensation for silicon resonators. In: Electron Devices Meeting, 2008. IEDM 2008. IEEE International, pp 1–4

Seo JH, Demirci KS, Byun A, Truax S, Brand O (2008) Temperature compensation method for resonant microsensors based on a controlled stiffness modulation. J Appl Phys 104(1):014911-9

Singamaneni S, LeMieux MC, Lang HP, Gerber C, Lam Y, Zauscher S, Datskos PG, Lavrik NV, Jiang H, Naik RR, Bunning TJ, Tsukruk VV (2008) Bimaterial microcantilevers as a hybrid sensing platform. Adv Mater 20(4):653–680

Sun X, Horowitz R, Komvopoulos K (2002) Stability and resolution analysis of a phase-locked loop natural frequency tracking system for MEMS fatigue testing. J Dyn Syst Meas Control Trans ASME 124(4):599–605

Sundaresan K, Ho GK, Pourkamali S, Ayazi F (2007) Electronically temperature compensated silicon bulk acoustic resonator reference oscillators. IEEE J Solid-State Circ 42(6):1425–1434

Tilmans HA, Elwenspoek M, Fluitman JH (1992) Micro resonant force gauges. Sens Actuators Phys A 30(1–2):35–53

Towfighian S, Heppler GR, Abdel-Rahman EM (2011) Analysis of a chaotic electrostatic micro-oscillator. J Comput Nonlinear Dyn 6(1):011,001

Wilcox B, Dankowicz H (2011) Limit-switch sensor functionality based on discontinuity-induced nonlinearities. J Comput Nonlinear Dyn 6(3):8

Wong CL, Palaniapan M (2009) Phonon detection technique for the study of the temperature coefficient of resonance frequency in clampedclamped beam resonators. J Micromech Microeng 19(6):065,021

Younis MI, Abdel-Rahman EM, Nayfeh A (2003) A reduced-order model for electrically actuated microbeam-based MEMS. J Microelectromech Syst 12(5):672–680

Zhanshe G, Zhou F, Le C, Shangchun F (2011) Theoretical and experimental study of capacitance considering fabrication process and edge effect for MEMS comb actuator. Microsyst Technol 17(1):71–76

Zhao Y, Wang L, Yu T (2003) Mechanics of adhesion in MEMS: a review. J Adhes Sci Technol 17(4):519–546

Acknowledgments

The authors would like to acknowledge CMC Microsystems and its staff for providing subsidized fabrication, design software, and technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hassanpour, P.A., Nieva, P.M. & Khajepour, A. A passive mechanism for thermal stress regulation in micro-machined beam-type structures. Microsyst Technol 18, 543–556 (2012). https://doi.org/10.1007/s00542-012-1491-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-012-1491-3