Abstract

Measured damping coefficients of six different perforated micromechanical test structures are compared with damping coefficients given by published compact models. The motion of the perforated plates is almost translational, the surface shape is rectangular, and the perforation is uniform validating the assumptions made for compact models. In the structures, the perforation ratio varies from 24 to 59%. The study of the structure shows that the compressibility and inertia do not contribute to the damping at the frequencies used (130–220 kHz). The damping coefficients given by all four compact models underestimate the measured damping coefficient by approximately 20%. The reasons for this underestimation are discussed by studying the various flow components in the models.

Similar content being viewed by others

References

Bao M, Yang H, Sun Y, French PJ (2003) Modified Reynolds’ equation and analytical analysis of perforated structures. J Micromech Microeng 13:795–800. doi:10.1088/0960-1317/13/6/301

De Pasquale G, Veijola T (2008) Comparative numerical study of FEM methods solving gas damping in perforated MEMS structures. Microfluidics Nanofluidics 5:517–528. doi:10.1007/s10404-008-0264-x

Feng C, Zhao P, Liu DQ (2007) Squeeze-film effects in MEMS devices with perforated plates for small amplitude vibration. Microsyst Technol 13:623–633

Kim ES, Cho YH, Kim MU (1999) Effect of holes and edges on the squeeze film damping of perforated micromechanical structures. In: Proceedings of IEEE micro electro mechanical systems conference, pp 296–301

Kwok PY, Weinberger MS, Breuer KS (2005) Fluid effects in vibrating micromachined structures. J Microelectromech Syst 14:770–781. doi:10.1109/JMEMS.2005.845425

Mehner JE, Dötzel W, Schauwecker B, Ostergaard D (2003) Reduced order modeling of fluid structural interactions in mems based on modal projection techniques. In: Proceedings of transducers’03, Boston, pp 1840–1843

Mohite SS, Kesari H, Sonti VR, Pratap R (2005) Analytical solutions for the stiffness and damping coefficients of squeeze films in MEMS devices with perforated back plates. J Micromech Microeng 15:2083–2092. doi:10.1088/0960-1317/15/11/013

Morris CJ, Forster FK (2004) Oscillatory flow in microchannels. Exp Fluids 36:924–937. doi:10.1007/s00348-003-0776-9

Pandey AK, Pratap R (2008) A comparative study of analytical squeeze film damping models in rigid perforated MEMS structures with experimental results. Microfluidics Nanofluidics 4:205–218. doi:10.1007/s10404-007-0165-4

Sattler R, Wachutka G (2004) Compact models for squeeze-film damping in the slip flow regime. In Proceeidings of the 7th international conference on modeling and simulation of microsystems, MSM2004, Boston, pp 243–246

Schrag G, Wachutka G (2004) Accurate system-level damping model for highly perforated micromechanical devices. Sensors Actuator A Phys 111:222–228

Somà A, De Pasquale G (2007) Identification of test structures for reduced order modeling of the squeeze film damping in MEMS. In: Proceedings of DTIP symposium on design, test, integration and packaging of MEMS and MOEMS, Stresa, pp 230–239

Somà A, De Pasquale G (2008) Numerical and experimental comparison of MEMS suspended plates dynamic behaviour under Squeeze film damping effect. Analog Integr Circuits Signal Process 57:213–224

Veijola T (2006a) Analytic damping model for an MEM perforation cell. Microfluid Nanofluid 2:249–260. doi:10.1007/s10404-005-0072-5

Veijola T (2006b) Analytic damping model for a square perforation cell. In: Proceedings of the 9th international conference on modeling and simulation of microsystems, Boston, pp 554–557

Veijola T, Mattila T (2001) Compact squeezed-film damping model for perforated surface. In: Proceedings of transducers’01, Munich, pp 1506–1509

Veijola T, De Pasquale G, Somà A (2008) Comparison between damping coefficients of measured perforated structures and compact models. In: Proceedings of DTIP symposium on design, test, integration and packaging of MEMS and MOEMS, Nice, pp 236–241

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

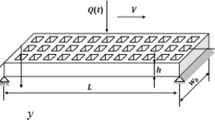

This Appendix contains equations for four compact models M1,…, M4. The dimensions and symbols in Fig. 1 are used: the length and width of the perforated plate are L and W. The side lengths of the square holes and the square perforation cells are s 0 and s X = s 0 + s 1, respectively. Figure 6 shows the structure of a perforation cell and the internal lumped flow resistances used in models M3,…, M6.

1.1 Model M1 equations

The equations for a narrow hole plate (L ≫ W) are given in (Bao et al. 2003). Note, in the following equations a = W/2 and b = L/2. The equivalent radii for the circular cell and hole are given in Eqs. 8 and 9. The damping coefficient c is

where

1.2 Model M2 equations

The equations for an arbitrary shaped rectangular plate are also included in (Bao et al. 2003). Also, in the following equations a = W/2 and b = L/2. The equivalent radii for the circular cell and hole are given in Eqs. 8 and 9. The damping coefficient c is

where

Above, l is the same as used in M1 equations.

1.3 Model M3 equations

A model for a circular perforation cell is derived in (Veijola 2006a), and the damping coefficient of a rectangular perforated plate is given in the paper. Note, in the following equations a = W and b = L. The equivalent radii for the circular cell and hole are given in Eqs. 8 and 9. The damping coefficient c is

Where the effective surface dimensions are

and

The flow resistance of a single perforation cell is

where the elongations are

where the functions are

The flow rate coefficients and Knudsen numbers for the air gap and the holes are

1.4 Model M4 equations

A model for a rectangular perforation cell has been given in (Veijola 2006b). Note, in the following equations a = W and b = L. The damping coefficient c is given by Eq. 11, where R P for a rectangular hole is

where the elongations are

where

The equation for ΔE includes a misprint in (Veijola 2006b). The corrected equation is shown above. The flow rate coefficients and Knudsen numbers for the square hole are

The effective radius is

Rights and permissions

About this article

Cite this article

Veijola, T., De Pasquale, G. & Somà, A. Experimental validation of compact damping models of perforated MEMS devices. Microsyst Technol 15, 1121–1128 (2009). https://doi.org/10.1007/s00542-009-0793-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-009-0793-6