Abstract

The development of robust risk assessment procedures for offshore oil and gas operations is a major element for the assessment of the potential feedback between planned activities and the environment. We illustrate a methodological and computational framework conducive to (1) a quantitative risk analysis of deepwater well barrier failures and subsequent hydrocarbon release to the environment and (2) the analysis of the value of the deployment of conventional and/or innovative mitigation measures. Our methodological framework is grounded on historical records and combines the use of Dynamic Event Trees and Decision Trees from which we estimate probability of occurrence and impact of post-blowout events. Each sequence of response actions, which are undertaken immediately after the event or in the subsequent days, is considered within the context of appropriately structured event paths. This approach is conducive to an estimate of the expected value of key decisions and underlying technologies, with an emphasis on their potential to reduce the oil spill volume, which can critically impact the environment. Our study yields an original comparative analysis of diverse intervention strategies, and forms a basis to guiding future efforts towards the development and deployment of technologies and operating procedures yielding maximum benefit in terms of safety of operations and environmental protection.

Similar content being viewed by others

Abbreviations

- A:

-

Annulus

- BO:

-

Blow out

- BOEMRE:

-

Bureau of Ocean Energy Management, Regulation and Enforcement

- BOP:

-

Blow Out Preventer

- BOPD:

-

Barrel of Oil Per Day

- BP:

-

British Petroleum

- BS:

-

Blowstop

- BS-PI:

-

Blowstop (Primary Intervention)

- BS-SI:

-

Blowstop (Secondary Intervention)

- CS:

-

Capping Stack

- CUBE:

-

Containment of Underwater Blowout Events

- DNV:

-

Det Norske Veritas

- DPS:

-

Dynamic Positioning System

- DR:

-

Debris Removal

- DS:

-

Drill String

- DSL:

-

Damage to surface mud lines

- DT:

-

Decision Tree

- DTA:

-

Decision Tree Analysis

- EMV:

-

Expected Monetary Value

- ERA:

-

Environmental Risk Assessment

- ESP:

-

Electrical Submersible Pump

- ET:

-

Event Tree

- ETA:

-

Event Tree Analysis

- FLOAT:

-

Rig floating

- FMEA:

-

Failure Modes and Effects Analysis

- FTA:

-

Fault Tree Analysis

- HAWK:

-

Hampering Active Wellbore Kit

- IPR:

-

Inflow Performance Relationship

- LEP:

-

Loss of electric power

- LMRP:

-

Lower Marine Riser Package

- LMRP TH#4:

-

LMRP Top Hat #4

- NPV:

-

Net Present Value

- OA:

-

Outer Annulus

- OC:

-

Outside Casing

- OGP:

-

International Association of Oil and Gas Producers

- OLF:

-

Oljeindustriens Landsforening

- OSCAR:

-

Oil Spill Contingency And Response

- OSS:

-

Oil Spill Scenario

- OSV:

-

Oil Spill Volume

- PDF:

-

Probability Density Function

- PI:

-

Productivity Index

- PRA:

-

Probabilistic Risk Analysis

- PSA:

-

Probabilistic Safety Analysis

- QRA:

-

Quantitative Risk Analysis

- R&D:

-

Research & Development

- RC:

-

Rapid CUBE

- RIS:

-

Marine riser sinking

- RITT:

-

Riser Insertion Tube Tool

- ROV:

-

Remotely Operated Vehicle

- RW:

-

Relief Well

- SEP:

-

Start of evacuation of rig personnel

- SINK:

-

Rig sunk

- SINTEF:

-

Stiftelsen for INdustriell og TEknisk Forskning

- ST:

-

Stock Tank conditions

- TH:

-

Top Hat

- TOW:

-

Rig towed

- VEC:

-

Valued Ecosystem Component

- VoO:

-

Vessel of Opportunity

References

Abel LW (1993) Technology blowout risks cut with contingency plan. Oil Gas J 91(23):30–35

Agwa A, Leheta H, Salem A, Sadiq R (2013) Fate of drilling waste discharges and ecological risk assessment in the Egyptian Red Sea: an aquivalence-based fuzzy analysis. Stoch Environ Res Risk Assess 27:169. https://doi.org/10.1007/s00477-012-0574-0

Ahluwalia A, Ruochen L (2016) Managing blowout risk using a dynamic barrier approach. In: SPE international conference and exhibition on health, safety, security, environment, and social responsibility, Stavanger. https://doi.org/10.2118/179428-ms

Alzbutas R, Iešmantas T, Povilaitis M, Vitkutė J (2014) Risk and uncertainty analysis of gas pipeline failure and gas combustion consequence. Stoch Environ Res Risk Assess 28:1431. https://doi.org/10.1007/s00477-013-0845-4

Andreussi HP, De Ghetto G (2013) CUBE—a new technology for the containment of subsea blowouts. Soc Pet Eng. https://doi.org/10.2118/0113-0032-JPT

Benekos ID, Shoemaker CA, Stedinger JR (2007) Probabilistic risk and uncertainty analysis for bioremediation of four chlorinated ethenes in groundwater. Stoch Environ Res Risk Assess 21:375. https://doi.org/10.1007/s00477-006-0071-4

Blunt MJ (2013) Modelling Macondo: a calculation of the volume of oil released during the Deepwater Horizon incident. Exhibit 1, Case 2:10-md-02179-CJB-SS. Document 10533-2. In re: Oil spill by the oil rig “Deepwater Horizon” in the Gulf of Mexico, on April 20, 2010

BOEMRE (2011) Report regarding the causes of the April 20, 2010 Macondo well blowout. Bureau of Ocean Energy Management, Regulation and Enforcement, Washington

Brandt H, Chomatas A, Tangem K, Barry J, Rudberg A, Bergsli A, Kruuse-Meyer R, Brude OW, Marthinsen T, Aspholm O (2010) Environmental risk assessment of exploration drilling in Nordland VI. DNV Report no. 2010-04-20, Hovik

Brude OW (2007) Methodology for environmental risk analysis (MIRA) (Norwegian). Revision 2007. Det Norske Veritas, Oslo

Buchanan RT (2015) Judge rejects BP’s appeal to reduce billion-pound fine for 2010 oil spill. The Independent. http://www.independent.co.uk/news/business/news/judge-rejects-bps-appeal-to-reduce-billion-pound-fine-for-2010-oil-spill-10059898.html. Accessed 13 March 2016

Coopersmith E, Dean G, McVean J, Storaune E (2001) Making decisions in the oil and gas industry. Oilfield Rev J 12:2001

COWI A/S (2003) Ageing rigs—review of major accidents, causes and barriers. Report No. P-055481-B-32, Kongens Lyngby http://www.ptil.no/getfile.php/z%20Konvertert/Health,%20safety%20and%20environment/Safety%20and%20working%20environment/Dokumenter/2003cowiageingrigs_nov03.pdf. Accessed 27 Nov 2015

Dyb K, Thorsen L, Nielsen L (2012) Report: blowout risk evaluation, Labrador Sea south-west of Greenland. ACONA Flow Technology, Skien

Eni E&P (2016) Internal reports. Exploration & Production Division, San Donato Milanese

Ferrara P, De Marchi E, Pasquini M (2014) A new dual ROV assisted well killing system for deep water blowout recovery: development and testing. IPTC, 19-22 Jan, Doha. https://doi.org/10.2523/iptc-17630-ms

Fukutani Y, Suppasri A, Imamura F (2015) Stochastic analysis and uncertainty assessment of tsunami wave height using a random source parameter model that targets a Tohoku-type earthquake fault. Stoch Environ Res Risk Assess 29:1763. https://doi.org/10.1007/s00477-014-0966-4

Ghasemi S, Mahmoudvand R, Yavari K (2016) Application of the FMEA in insurance of high-risk industries: a case study of Iran’s gas refineries. Stoch Environ Res Risk Assess 30:737. https://doi.org/10.1007/s00477-015-1104-7

Gill SD, Bonke CA, Carter J (1985) Management of the Uniacke G-72 incident. IOSC Proc. https://doi.org/10.7901/2169-3358-1985-1-311

Hickman SH, Hsieh PA, Mooney WD, Enomoto CB, Nelson PH, Mayer LA, Weber TC, Moran K, Flemings PB, McNutt MK (2012) Scientific basis for safely shutting in the Macondo well after the April 20, 2010 Deepwater Horizon blowout. P Natl Acad Sci USA. https://doi.org/10.1073/pnas.1115847109

Holand P (1997) Offshore blowouts, causes and control. Gulf Publishing Company, Houston

Holand P (2014) Blowout and well release characteristics and frequencies. SINTEF Technology and Society, Trondheim

Ji ZG, Johnson WR, Li Z, Green RE, O’Reilly SE, Gravois MP (2012) Oil spill risk analysis: Gulf of Mexico Outer Continental Shelf (OCS) lease sales, central and western planning areas, 2012–2017, and gulfwide OCS program, 2012–2051. BOEM OCS Report, Herndon

Johnsen S (2012) Probabilistic blowout risk in former disputed area southeast in the Norwegian part of the Barents Sea. Dissertation, University of Stavanger

Jouravel V (2013) Blowout quantitative risk assessment and mitigation of consequences (Russian). Oil Gas J Russia, No, p 12

Karlsen HC, Ford EP (2014) BlowFlow—next generation software for calculating blowout rates. Soc Pet Eng. https://doi.org/10.2118/169226-MS

Klassen W (2013) Secondary intervention of blow out preventers. Soc Pet Eng. https://doi.org/10.2118/166551-MS

Kruuse-Meyer R, Bergsli A, Rudberg A, Østbøll H (2011) Operational risk analysis tool OPERAto for oil and gas activities. Int Oil Spill Conf Proc. https://doi.org/10.7901/2169-3358-2011-1-259

Lehr B, Bristol S, Possolo A (2010) Oil budget calculator, Deepwater Horizon—technical documentation. The Federal Interagency Solutions Group, Oil Budget Calculator Science and Engineering Team

Marquin S (2014) Oil rig disasters—rig incident list. http://home.versatel.nl/the_sims/rig/losses.htm. Accessed 5 Oct 2015

Miller M (2001) Blowout recovery operations. In: Petroleum History Society Archives. Newsletter of the Petroleum History Society, vol XII, No. 8, Calgary

Mumford KG, Mustafa N, Gerhard JI (2016) Probabilistic risk assessment of contaminant transport in groundwater and vapour intrusion following remediation of a contaminant source. Stoch Environ Res Risk Assess 30:1017. https://doi.org/10.1007/s00477-015-1156-8

Myer PG (1984) IXTOC I: case study of a major oil spill. Theses and major papers, Paper 133

National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling (2011a) Deep water, The Gulf oil disaster and the future for offshore drilling, report to the president. UNT Libraries Government Documents Department, Washington

National Commission on the BP Deepwater Horizon Oil Spill and Offshore Drilling (2011b) Macondo: the Gulf oil disaster: Chief Counsel’s report, Washington

Nilsen T, Jacobsen NEB, Myhrvold A, Nilsen EF, Roald T (2004) Guidelines for calculation of flow rates and duration for use in environmental risk assessment, 2nd edn. Norwegian Oil Industry Association, Sandnes

OGP (2011) Capping and Containment. Global Industry Response Group Recommendations. Report No. 464, London

Petersen FC, Miura K, Fonseca TC, Pelaquim Mendes JR, Rizzo Guilherme I, Kazuyuki Morooka C (2011) Operational safety on subsea wells. In: SPE Americas E&P health, safety, security and environmental conference, Houston. https://doi.org/10.2118/142204-ms

Pooladi-Darvish M (2013) Estimate of cumulative volume of oil released from the MC252 Macondo Well. In; Macondo/Deep Water Horizon court proceeding, New Orleans

PSA (2007) Shallow gas events 1984–2006 in the Norwegian sector. Shallow Gas Project, Report by AGR-Triangle, Stavanger

Qin XS (2012) Assessing environmental risks through fuzzy parameterized probabilistic analysis. Stoch Environ Res Risk Assess 26:43. https://doi.org/10.1007/s00477-010-0454-4

Rasmussen SE (2011) Environmental consequences associated with a large-scale blowout of oil in the former disputed area between Norway and Russia in the Barents Sea (a case study). Dissertation, University of Stavanger

Roald TH (2000) New risk assessment approach shows significant reduction in oil blowout risk. In: SPE international conference on health, safety and environment in oil and gas exploration and production, Stavanger. https://doi.org/10.2118/61255-ms

Rojas FE, Slocum AH (2016) A complementary safety tool for blowout preventers. Offshore Tech Conf. https://doi.org/10.4043/27139-MS

Ruochen L, Hasan AR, Ahluwalia A, Sam Mannan M (2016) Well specific oil discharge risk assessment by a dynamic blowout simulation tool. Process Saf Environ. https://doi.org/10.1016/j.psep.2016.06.037

Rygg OB, Smestad P, Wright JW (1992) Dynamic two-phase flow simulator: a powerful tool for blowout and relief well kill analysis. Soc Pet Eng. https://doi.org/10.2118/24578-MS

Shahriar A, Sadiq R, Tesfamariam S (2014) Life cycle greenhouse gas footprint of shale gas: a probabilistic approach. Stoch Environ Res Risk Assess 28:2185. https://doi.org/10.1007/s00477-014-0874-7

Shan X, Liu K, Sun PL (2017) Risk analysis on leakage failure of natural gas pipelines by fuzzy Bayesian network with a Bow–Tie model. Sci Program 2017:5. https://doi.org/10.1155/2017/3639524

SINTEF, DNV (2009) Oil spill modelling and oil spill response modelling, Oil Spill Contingency and Response (OSCAR)/Oil Spill 3D (OS3D)

Tartakovsky DM (2012) Assessment and management of risk in subsurface hydrology: a review and perspective. Adv Water Resour 51:247–260. https://doi.org/10.1016/j.advwatres.2012.04.007

Thompson B (2013) Feds eye billions in fines in Deepwater Horizon trial. American Thinker. http://www.americanthinker.com/articles/2013/09/deepwater_horizon_how_much_oil.html. Accessed 30 March 2016

Thorogood JL, Hogg TW, Williamson HS (1991) Application of risk analysis methods to subsurface well collisions. SPE Drill Eng J. https://doi.org/10.2118/23941-PA

Transocean (2015) Jim Cunningham—loss of well control and emergency response. MDL 2179 Trial Docs—Phase Tree, Exhibit No. 11583, Worldwide Court Reporters, Inc

United States District Court (2015) Findings of Fact and Conclusions of Law, Phase 2 Trial. In re: oil spill by the oil rig Deepwater Horizon in the Gulf of Mexico, on April 20, 2010. MDL No. 2179, ECF No. 14021

Vandenbussche V, Bergsli A, Brandt H, Nissen-Lie TR, Brude OW (2012) Well-specific blowout risk assessment. In: SPE/APPEA international conference on health, safety and environment in oil and gas exploration and production. https://doi.org/10.2118/157319-ms

Vandenbussche V, Brude OW, Tvedt H (2014) Effect of well capping as a blowout risk reduction measure. Int Oil Spill Conf Proc. https://doi.org/10.7901/2169-3358-2014.1.878

Vinnem EV (2007) Offshore risk assessment: principles, modelling and applications of QRA Studies, 2nd edn. Springer series in reliability engineering, London

Westergaard RH (1987) All about blowout. Norwegian Oil Review, Oslo

Williams LW (1972) Blowout at Petrel no. 1 well and subsequent events. Bureau of Mineral Resources, Geology and Geophysics—Department of National Development—Commonwealth of Australia—Record 1972/34 c.3

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Duration of activities and interventions (Part 1)

Interventions and activities | Mean ≡ Mode [d] | Min [d] | Max [d] |

|---|---|---|---|

Site Preparation | 11 | 5 | 17 |

Mobilize Intervention Workover Control System Hardware | 3 | 1 | 5 |

Mobilize IWOCS Vessel | 3 | 1 | 5 |

IWOCS System and Vessel in Field | 8 | 4 | 12 |

Debris Removal | 16 | 8.5 | 23.5 |

Mobilize Debris Removal Hardware | 5 | 3 | 7 |

Transport Debris Removal Hardware to Field | 8 | 4 | 12 |

Mobilize Vessel with ROV and Construction Support | 3 | 1 | 5 |

Vessels in Field | 8 | 4 | 12 |

Debris Removal Plan developed | 2 | 2 | 2 |

Debris Removal Activities | 5 | 3.5 | 6.5 |

Rapid CUBE | 17 | 11 | 23 |

Mobilize CUBE and Necessary Equipment | 3 | 1 | 5 |

Transport CUBE by Airplane | 1 | 1 | 1 |

Mobilize Support Vessels and Well Testing Equipment | 5 | 3 | 7 |

Preparation for Offshore Transportation | 1 | 1 | 1 |

Transport CUBE on Site | 8 | 4 | 12 |

Mobilize required consumables (chemicals) | 2 | 0 | 4 |

Mobilize MODU and arrival to Location | 11 | 5 | 17 |

Make Up and Run CUBE on Riser | 1 | 1 | 1 |

Position Acquisition and Flow Rate Adjustment | 1 | 1 | 1 |

Early Capture to the Intervention Vessel (Drilling Rig) | 1 | 1 | 1 |

Duration of activities and interventions (Part 2)

Interventions and activities | Mean ≡ Mode [d] | Min [d] | Max [d] |

|---|---|---|---|

Well Capping (Shut Only Scenario) | 24 | 18 | 30 |

Mobilize Tested Well Cap System | 7 | 5 | 9 |

Transport Well Cap System by Airplane | 1 | 1 | 1 |

Transport Well Cap System to Dock | 2 | 2 | 2 |

Mobilize Intervention Vessel | 5 | 3 | 7 |

Preparation for Offshore Transportation | 1 | 1 | 1 |

Transport Well Cap to Site | 8 | 4 | 12 |

Offload Well Cap and Prepare for Deployment | 1 | 1 | 1 |

Deploy Well Cap in Safe Zone | 2 | 2 | 2 |

Position, Land and Test Well Cap | 1 | 1 | 1 |

Shut In Well | 1 | 1 | 1 |

Monitor Well for Stability | 1 | 1 | 1 |

Preparatory activities for Well Kill (BSSI, CS) | 18 | 10 | 26 |

Mobilize Pumping Services and Equipment | 3 | 1 | 5 |

Mobilize MODU and arrival to Location | 11 | 5 | 17 |

Mobilize Test package to the drilling rig and Test | 4 | 2 | 6 |

Approach the well head with the auxiliary line | 2 | 2 | 2 |

Debris Removal (BOP choke/kill line inlet) | 2 | 2 | 2 |

Connect the Auxiliary Line with Pumping Unit | 1 | 1 | 1 |

Blowstop (Secondary Intervention) | 21 | 13 | 29 |

Wait for the auxiliary line | 0 | 0 | 0 |

Debris Removal (BOP choke/kill line inlet) | 2 | 2 | 2 |

Mobilize Blowstop Equipment | 5 | 3 | 7 |

Mobilize Blowstop equipment to dock | 5 | 3 | 7 |

Mobilize Blowstop equipment on site | 8 | 4 | 12 |

Prepare the Injection System on MODU | 1 | 1 | 1 |

Bullets Injection | 0 | 0 | 0 |

Coating Swelling | 1 | 1 | 1 |

Static Well Killing (Well Capped) | 28 | 22 | 34 |

Mobilize Pumping Services and Equipment | 3 | 1 | 5 |

Mobilize MODU and arrival to Location | 11 | 5 | 17 |

Mobilize Test package to the drilling rig and Test | 4 | 2 | 6 |

Perform Well Kill after Capping Stuck Shut In | 4 | 4 | 4 |

Relief Well and Dynamic Killing | 71 | 49.5 | 92.5 |

Mobilize Drilling Equipment | 9 | 7 | 11 |

Mobilize MODUs and arrival to Location | 13 | 7 | 19 |

Drilling Relief Well | 45 | 31.5 | 58.5 |

Perform Well Kill and Abandonment Scope | 4 | 4 | 4 |

Appendix 2

2.1 Flow chart for risk evaluation methodology and factors contributing to expected blowout risk

We illustrate here the main steps leading to expected blowout risk evaluation with the aim of evidencing the contribution of the various model components.

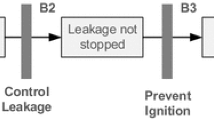

We do so by considering in Fig. 11 an exemplary setting corresponding to the decision of deploying all intervention techniques in case of occurrence of the top event (well blowout). We illustrate the example of the Event Tree for the Annulus flow-path in case of dynamically positioned rigs. We consider one given path inside the event tree for which the applicability of all techniques (at the moment of their application) is consistent with the actual conditions of the spill and the rig. Note that probability values shown in the grey circles of Fig. 11 are solely to be considered as representative of the actual statistics associated with given events.

All of the events, each with its probability of occurrence, are listed on the left hand side of the chart in Fig. 11. Cause-effect relationships between events, applicability of interventions and their success are displayed following the assumptions considered in Sects. 2.3.1 and 2.3.2.

The right hand side of the diagram is devoted to the calculation of the impact in terms of blowout flow rates, their duration and of their final product, leading to quantifiable Oil Spill Volumes (OSV). Figure 11 only shows the events that cause a modification of blowout flow rate, either increasing or decreasing it (i.e., post blowout interventions). Oil spill volumes are then summed up to obtain an overall final spill volume for the considered branch of the Event Tree. The resulting value of the expected blowout risk for the considered decision is hence calculated as a sum of probabilities associated with each branch, multiplied by the corresponding oil spill impact. Note that the value included in the diagram necessarily coincides with the expected value for Long Term Future scenario shown in Fig. 9a with a blue bar.

Appendix 3

Assumptions considered on mode, minimum and maximum values of times of activities

Interventions and activities | Mean ≡ Mode [d] | Min [d] | Max [d] |

|---|---|---|---|

Mobilization of equipment or VoO (fast) | 1 | 3 | 5 |

Mobilization of equipment or VoO (medium) | 3 | 5 | 7 |

Mobilization of equipment or VoO (slow) | 5 | 7 | 9 |

Arrival of VoO to incident site | 4 | 8 | 12 |

Debris removal activities on site | 3.5 | 5 | 6.5 |

Relief well drilling activities | 31.5 | 45 | 58.5 |

Rights and permissions

About this article

Cite this article

Caia, A., Di Lullo, A.G., De Ghetto, G. et al. Probabilistic analysis of risk and mitigation of deepwater well blowouts and oil spills. Stoch Environ Res Risk Assess 32, 2647–2666 (2018). https://doi.org/10.1007/s00477-017-1509-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00477-017-1509-6