Abstract

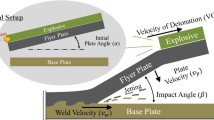

Explosive welding involves processes like the detonation of explosive, impact of metal structures and strong fluid–structure interaction, while the whole process of explosive welding has not been well modeled before. In this paper, a novel smoothed particle hydrodynamics (SPH) model is developed to simulate explosive welding. In the SPH model, a kernel gradient correction algorithm is used to achieve better computational accuracy. A density adapting technique which can effectively treat large density ratio is also proposed. The developed SPH model is firstly validated by simulating a benchmark problem of one-dimensional TNT detonation and an impact welding problem. The SPH model is then successfully applied to simulate the whole process of explosive welding. It is demonstrated that the presented SPH method can capture typical physics in explosive welding including explosion wave, welding surface morphology, jet flow and acceleration of the flyer plate. The welding angle obtained from the SPH simulation agrees well with that from a kinematic analysis.

Similar content being viewed by others

References

Cutler D (2006) What you can do with explosion welding. Weld J 5(4):177–199

Grignon F, Benson D, Vecchio KS, Meyers MA (2004) Explosive welding of aluminum to aluminum: analysis, computations and experiments. Int J Impact Eng 30:1333–1351

Kacar R, Acarer M (2004) An investigation on the explosive cladding of 316L stainless steel–din-P355GH steel. J Mater Process Technol 152(1):91–96

Kahraman N, Gülenç B, Findik F (2005) Joining of titanium/stainless steel by explosive welding and effect on interface. J Mater Process Technol 169(2):127–133

Bahrani AS, Crossland B (1967) The mechanics of wave formation in explosive welding. Proc R Soc Lond A 296:123–136

Stanyukovich K (2002) Explosion physics, 3rd edn. Nauka, Moscow

Salem SAL, Lazari LG, Al-Hassani STS (1984) Explosive welding of flat plates in free flight. Int J Impact Eng 2(1):85–101

Birnbaum NK, Cowler MS, Itoh M, Katayama M, Obata H (1987) AUTODYN—an interactive non-linear dynamic analysis program for microcomputers through supercomputers. In: Ninth international conference on structural mechanics in reactor technology, Lausanne, Switzerland

Hageman LJ, Walsh JM, Hageman LJ, Walsh JM (1971) HELP, a multi-material Eulerian program for compressible fluid and elastic–plastic flows in two space dimensions and time, vol 1. System, Science and Software Inc, La Jolla

Hallquist JO (1986) DYNA3D user’s manual (nonlinear dynamic analysis of structures in three dimensions). Lawrence Livermore National Laboratory, Livermore

Mousavi AAA, Burley SJ, Al-Hassani STS (2004) Simulation of explosive welding using the Williamsburg equation of state to model low detonation velocity explosives. Int J Impact Eng 31(6):719–734

Mousavi AAA, Al-Hassani STS (2008) Finite element simulation of explosively-driven plate impact with application to explosive welding. Mater Des 29(1):1–19

Sui GF, Li JS, Sun F, Ma B, Li HW (2011) 3D finite element simulation of explosive welding of three-layer plates. Sci China Phys Mech Astron 54(5):890–896

Zhang X, Chen Z, Liu Y (2016) The material point method—a continuum-based particle method for extreme loading cases. Elsevier, Amsterdam

Koshizuka S, Oka Y (1996) Moving-particle semi-implicit method for fragmentation of incompressible fluid. Nuclear Sci Eng 123(3):421–434

Li SF, Liu WK (2002) Meshfree and particle methods and their applications. Appl Mech Rev 55(1):1–34

Liu GR (2003) Mesh free methods moving beyond finite element method. Crc Press, Boca Raton

Liu WK, Chen Y, Jun S, Chen JS, Belytschko T, Pan C, Uras RA, Chang CT (1996) Overview and applications of the reproducing kernel particle methods. Arch Comput Methods Eng 3(1):3–80

Lian YP, Zhang X, Zhou X, Ma S, Zhao YL (2011) Numerical simulation of explosively driven metal by material point method. Int J Impact Eng 38(4):238–246

Wang Y, Beom HG, Sun M, Lin S (2011) Numerical simulation of explosive welding using the material point method. Int J Impact Eng 38(1):51–60

Gingold RA, Monaghan JJ (1977) Smoothed particle hydrodynamics: theory and application to non-spherical stars. Mon Not R Astron Soc 181(3):375–389

Liu GR, Liu MB (2003) Smoothed particle hydrodynamics: a meshfree particle method. World Scientific, Singapore

Lucy LB (1977) A numerical approach to the testing of the fission hypothesis. Astron J 82:1013–1024

Feng DL, Liu MB, Li HQ, Liu GR (2013) Smoothed particle hydrodynamics modeling of linear shaped charge with jet formation and penetration effects. Comput Fluids 86(7):77–85

Liu MB, Liu GR, Lam KY (2006) Adaptive smoothed particle hydrodynamics for high strain hydrodynamics with material strength. Shock Waves 15(1):21–29

Liu MB, Liu GR, Lam KY, Zong Z (2003) Smoothed particle hydrodynamics for numerical simulation of underwater explosion. Comput Mech 30(2):106–118

Liu MB, Liu GR, Zong Z, Lam KY (2003) Computer simulation of high explosive explosion using smoothed particle hydrodynamics methodology. Comput Fluids 32(3):305–322

Randles PW, Libersky LD (1996) Smoothed particle hydrodynamics: some recent improvements and applications. Comput Methods Appl Mech Eng 139:375–408

Swegle JW, Attaway SW (1995) On the feasibility of using smoothed particle hydrodynamics for underwater explosion calculations. Comput Mech 17(3):151–168

Li XJ, Mo F, Wang XH, Wang B, Liu KX (2012) Numerical study on mechanism of explosive welding. Sci Technol Weld Join 17(1):36–41

Nassiri A, Kinsey B (2016) Numerical studies on high-velocity impact welding: smoothed particle hydrodynamics (SPH) and arbitrary Lagrangian–Eulerian (ALE). J Manuf Process 24

Shao JR, Li HQ, Liu GR, Liu MB (2012) An improved SPH method for modeling liquid sloshing dynamics. Comput Struct 100–101(6):18–26

Liu MB, Li SM (2016) On the modeling of viscous incompressible flows with smoothed particle hydrodynamics. J Hydrodyn 28(5):731–745

Zukas JA (1990) High velocity impact dynamics. Wiley, London

Lee EL, Hornig HC, Kury JW (1967) Adiabatic expansion of high explosive detonation products. Livermore Lawrence Radiation Lab, California University, Livermore

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of seventh international symposium on ballistics, The Hague, Netherlands

Zhou CE, Liu GR, Lou KY (2007) Three-dimensional penetration simulation using smoothed particle hydrodynamics. Int J Comput Methods 4:671–691

Liu MB, Liu GR (2006) Restoring particle consistency in smoothed particle hydrodynamics. Appl Numer Math 56(1):19–36

Ren B, Fan H, Bergel GL, Regueiro RA, Lai X, Li S (2015) A peridynamics–SPH coupling approach to simulate soil fragmentation induced by shock waves. Comput Mech 55(2):287–302

Chen JK, Beraun JE (2000) A generalized smoothed particle hydrodynamics method for nonlinear dynamic problems. Comput Methods Appl Mech Eng 190(1–2):225–239

Liu MB, Xie WP, Liu GR (2005) Modeling incompressible flows using a finite particle method. Appl Math Model 29(12):1252–1270

Hu XY, Adams NA (2007) An incompressible multi-phase SPH method. J Comput Phys 227(1):264–278

Zhang MY, Deng XL (2015) A sharp interface method for SPH. J Comput Phys 302:469–484

Colagrossi A (2003) A meshless Lagrangian method for free-surface and interface flows with fragmentation. Universita di Roma, La Sapienza

Monaghan JJ (2005) Smoothed particle hydrodynamics. World Scientific, Singapore

Benz W (1990) Smooth particle hydrodynamics—a review. In: Buchler JR (ed) Numerical modelling of nonlinear stellar pulsations: problems and prospects. Kluwer Academic, Boston

Mader CL (1979) Numerical modeling of detonation. University of California Press, Berkeley

Carpenter SH, Wittman RH (1967) Relationships of explosive welding parameters to material properties and geometry factors. University of Denver, Denver

Acknowledgements

This work has been supported by the National Natural Science Foundation of China (Grant Nos. U1530110 and 11172306).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, M.B., Zhang, Z.L. & Feng, D.L. A density-adaptive SPH method with kernel gradient correction for modeling explosive welding. Comput Mech 60, 513–529 (2017). https://doi.org/10.1007/s00466-017-1420-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-017-1420-5