Abstract

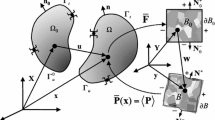

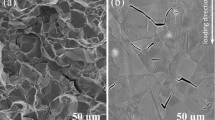

An enhanced three-dimensional (3D) framework for computational homogenization and intergranular cracking of polycrystalline materials is presented. The framework is aimed at reducing the computational cost of polycrystalline micro simulations, with an aim towards effective multiscale modelling. The scheme is based on a recently developed Voronoi cohesive-frictional grain-boundary formulation. A regularization scheme is used to avoid excessive mesh refinements often induced by the presence of small edges and surfaces in mathematically exact 3D Voronoi morphologies. For homogenization purposes, periodic boundary conditions are enforced on non-prismatic periodic micro representative volume elements (\(\mu \)RVEs), eliminating pathological grains generally induced by the procedures used to generate prismatic periodic \(\mu \)RVEs. An original meshing strategy is adopted to retain mesh effectiveness without inducing numerical complexities at grain edges and vertices. The proposed methodology offers remarkable computational savings and high robustness, both highly desirable in a multiscale perspective. The determination of the effective properties of several polycrystalline materials demonstrate the accuracy of the technique. Several microcracking simulations complete the study and confirm the performance of the method.

Similar content being viewed by others

References

Aliabadi MH (2002) The boundary element method: applications in solids and structures, vol 2. Wiley, England

de Araújo FC, d’Azevedo EF, Gray LJ (2010) Boundary-element parallel-computing algorithm for the microstructural analysis of general composites. Comput Struct 88:773–784

de Araújo FC, d’Azevedo EF, Gray LJ (2011) Constructing efficient substructure-based preconditioners for BEM systems of equations. Eng Anal Bound Elem 35:517–526

ASTM E112–10 (2010) Standard test methods for determining average grain size. ASTM Int. doi:10.1520/E0112-10

Aurenhammer F (1991) Voronoi diagrams-a survey of a fundamental geometric data structure. ACM Comput Surv (CSUR) 23(3):345–405

Banerjee P (1994) The boundary element methods in engineering. McGraw-Hill, London

Barbe F, Quey R (2011) A numerical modelling of 3d polycrystal-to-polycrystal diffusive phase transformations involving crystal plasticity. Int J Plast 27(6):823–840

Barthelat F, Tang H, Zavattieri PD, Li CM, Espinosa HD (2007) On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure. J Mech Phys Solids 55(2):306–337

Benedetti I, Aliabadi M (2015) Multiscale modelling of polycrystalline materials: a boundary element approach to material degradation and fracture. Comput Methods Appl Mech Eng 289:429–453

Benedetti I, Aliabadi MH (2013a) A three-dimensional grain boundary formulation for microstructural modelling of polycrystalline materials. Comput Mater Sci 67:249–260

Benedetti I, Aliabadi MH (2013b) A three-dimensional cohesive-frictional grain-boundary micromechanical model for intergranular degradation and failure in polycrystalline materials. Comput Methods Appl Mech Eng 265:36–62

Benedetti I, Barbe F (2013) Modelling polycrystalline materials: an overview of three-dimensional grain-scale mechanical models. J Multiscale Model 05(01):1350,002. doi:10.1142/S1756973713500029

Benedetti I, Aliabadi MH, Davì G (2008) A fast 3D dual boundary element method based on hierarchical matrices. Int J Solids Struct 45:2355–2376

Benedetti I, Milazzo A, Aliabadi MH (2009) A fast dual boundary element method for 3D anisotropic crack problems. Int J Numer Methods Eng 80:1356–1378

Berryman JG (2005) Bounds and self-consistent estimates for elastic constants of random polycrystals with hexagonal, trigonal, and tetragonal symmetries. J Mech Phys Solids 53(10):2141–2173

Böhlke T, Jöchen K, Kraft O, Löhe D, Schulze V (2010) Elastic properties of polycrystalline microcomponents. Mech Mater 42(1):11–23

CA Brebbia JT, Wrobel L (1984) Boundary element techniques. Springer, New York

Carnahan RD (1968) Elastic properties of silicon carbide. J Am Ceram Soc 51(4):223–224

Crisfield MA (1981) A fast incremental/iterative solution procedure that handles snap-through. Comput Struct 13(1–3):55–62. doi:10.1016/0045-7949(81)90108-5

Deng Q, Li CG, Wang SL, Tang H, Zheng H (2013) A new method to the treatment of corners in the bem. Eng Anal Bound Elem 37(1):182–186

Döbrich KM, Rau C, Krill CE III (2004) Quantitative characterization of the three-dimensional microstructure of polycrystalline Al-Sn using X-ray microtomography. Metall Mater Trans A 35A:1953–1961

Espinosa HD, Zavattieri PD (2003) A grain level model for the study of failure initiation and evolution in polycrystalline brittle materials. Part I: theory and numerical implementation. Mech Mater 35:333–364

Fan Z, Wu Y, Zhao X, Lu Y (2004) Simulation of polycrystalline structure with voronoi diagram in laguerre geometry based on random closed packing of spheres. Comput Mater Sci 29(3): 301–308

Fritzen F, Böhlke T, Schnack E (2009) Periodic three-dimensional mesh generation for crystalline aggregates based on Voronoi tessellations. Comput Mech 43:701–713

Geers MGD, Kouznetsova VG, Brekelmans WAM (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234(7):2175–2182

Gérard C, Cailletaud G, Bacroix B (2013) Modeling of latent hardening produced by complex loading paths in fcc alloys. Int J Plast 42:194–212

Geuzaine C, Remacle JF (2009) Gmsh: a 3-d finite element mesh generator with built-in pre-and post-processing facilities. Int J Numer Methods Eng 79(11):1309–1331

Gray L, Lutz E (1990) On the treatment of corners in the boundary element method. J Comput Appl Math 32(3):369–386

Groeber M, Ghosh S, Uchic MD, Dimiduk DM (2008) A framework for automated analysis and simulation of 3D polycrystalline microstructures. Part 1: statistical characterization. Acta Mater 56:1257–1273

Han TS, Dawson PR (2007) A two-scale deformation model for polycrystalline solids using a strongly-coupled finite element methodology. Comput Methods Appl Mech Eng 196(1316):2029–2043

Hashin Z (1983) Analysis of composite materials: a survey. ASME J Appl Mech 50:481–505

Hashin Z, Shtrikman S (1962a) On some variational principles in anisotropic and nonhomogeneous elasticity. J Mech Phys Solids 10(4):335–342

Hashin Z, Shtrikman S (1962b) A variational approach to the theory of the elastic behaviour of polycrystals. J Mech Phys Solids 10(4):343–352

Hlilou A, Naceur IB, Sai K, Gérard C, Forest S, Cailletaud G (2009) Generalization of the polycrystalline \(\beta \)-model: finite element assessment and application to softening material behavior. Comput Mater Sci 45(4):1104–1112

Jia N, Peng RL, Wang Y, Johansson S, Liaw P (2008) Micromechanical behavior and texture evolution of duplex stainless steel studied by neutron diffraction and self-consistent modeling. Acta Mater 56(4):782–793

Kamaya M, Itakura M (2009) Simulation for intergranular stress corrosion cracking based on a three-dimensional polycrystalline model. Eng Fract Mech 76(3):386–401

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40:3647–3679

Kumar S, Kurtz SK (1994) Simulation of material microstructure using a 3D Voronoi tessellation: calculation of effective thermal expansion coefficient of polycrystalline materials. Acta Met 42:3917–3927

Kumar S, Kurtz SK, Agarwala VK (1996) Micro-stress distribution within polycrystalline aggregate. Acta Mech 114:203–216

Kuramae H, Ikeya Y, Sakamoto H, Morimoto H, Nakamachi E (2010) Multi-scale parallel finite element analyses of LDH sheet formability tests based on crystallographic homogenization method. Int J Mech Sci 52(2):183–197

Kuzmin A, Luisier M, Schenk O (2013) Fast methods for computing selected elements of the greens function in massively parallel nanoelectronic device simulations. In: Wolf F, Mohr B, Mey D (eds) Euro-Par 2013 Parallel Processing, Lecture notes in computer science, vol 8097. Springer, Berlin Heidelberg, pp 533–544

Lamari H, Ammar A, Cartraud P, Legrain G, Chinesta F, Jacquemin F (2010) Routes for efficient computational homogenization of nonlinear materials using the proper generalized decompositions. Arch Comput Methods Eng 17(4):373–391

Lautensack C (2008) Fitting three-dimensional laguerre tessellations to foam structures. J Appl Stat 35(9):985–995

Lautensack C, Zuyev S (2008) Random laguerre tessellations. Adv Appl Probab 40:630–650

Ludwig W, King A, Reischig P, Herbig M, Lauridsen EM, Schmidt S, Proudhon H, Forest S, Cloetens P, du Roscoat SR, Buffiére JY, Marrow TJ, Poulsen HF (2009) New opportunities for 3d materials science of polycrystalline materials at the micrometre lengthscale by combined use of x-ray diffraction and x-ray imaging. Mater Sci Eng A 524(12):69–76

Mallardo V, Alessandri C (2004) Arc-length procedures with bem in physically nonlinear problems. Eng Anal Bound Elem 28(6):547–559. doi:10.1016/j.enganabound.2003.11.002

Mura T (1987) Micromechanics of defects in solids, 2nd edn., Mechanics of elastic and inelastic solidsKluwer Academic Publishers, Dordrecht

Musienko A, Cailletaud G (2009) Simulation of inter- and transgranular crack propagation in polycrystalline aggregates due to stress corrosion cracking. Acta Mater 57(13):3840–3855

Nakamachi E, Tam N, Morimoto H (2007) Multi-scale finite element analyses of sheet metals by using SEM-EBSD measured crystallographic RVE models. Int J Plast 23(3):450–489

Needleman A (2000) Computational mechanics at the mesoscale. Acta Mater 48(1):105–124

Nemat-Nasser S, Hori M (1999) Micromechanics: overall properties of heterogeneous materials, 2nd edn. North-Holland, Elsevier, Amsterdam

Nguyen VP, Stroeven M, Sluys LJ (2011) Multiscale continuous and discontinuous modeling of heterogeneous materials: a review on recent developments. J Multiscale Model 03(04):229–270. doi:10.1142/S1756973711000509

Persson PO, Strang G (2004) A simple mesh generator in matlab. SIAM Rev 46(2):329–345

Quey R, Dawson PR, Barbe F (2011) Large scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Methods Appl Mech Eng 200:1729–1745

Rowenhorst DJ, Lewis AC, Spanos G (2010) Three-dimensional analysis of grain topology and interface curvature in a \(\beta \)-titanium alloy. Acta Mater 58:5511–5519

Schclar NA (1994) Anisotropic analysis using boundary elements, Topics in Engineering, vol 20. Computational Mechanics Publications

Schenk O, Wchter A, Hagemann M (2007) Matching-based preprocessing algorithms to the solution of saddle-point problems in large-scale nonconvex interior-point optimization. Comput Optim Appl 36(2–3):321–341

Schenk O, Bollhöfer M, Römer RA (2008) On large-scale diagonalization techniques for the anderson model of localization. SIAM Rev 50(1):91–112

Schöberl J (1997) Netgen an advancing front 2d/3d-mesh generator based on abstract rules. Comput Vis Sci 1(1):41–52

Sfantos GK, Aliabadi MH (2007) A boundary cohesive grain element formulation for modelling intergranular microfracture in polycrystalline brittle materials. Int J Numer Methods Eng 69:1590–1626

Shewchuk JR (1996) Triangle: engineering a 2D quality mesh generator and Delaunay triangulator. In: Lin M, Manocha D (eds) Applied computational geometry: towards geometric engineering. Lecture notes in computer science, vol 1148. Springer, Berlin, pp 203–222. (From the First ACM Workshop on Applied Computational Geometry)

Simonovski I, Cizelj L (2012) Towards modeling intergranular stress corrosion cracks on grain size scales. Nucl Eng Des 246:107–114

Sukumar N, Srolovitz DJ, Baker TJ, Prévost JH (2003) Brittle fracture in polycrystalline microstructures with the extended finite element method. Int J Numer Methods Eng 56:2015–2037

Terada K, Hori M, Kyoya T, Kikuchi N (2000) Simulation of the multi-scale convergence in computational homogenization approaches. Int J Solids Struct 37(16):2285–2311

Watanabe T, Tsurekawa S (1999) The control of brittleness and development of desirable mechanical properties in polycrystalline systems by grain boundary engineering. Acta Mater 47(1516):4171–4185

Yvonnet J, He QC (2007) The reduced model multiscale method (r3m) for the non-linear homogenization of hyperelastic media at finite strains. J Comput Phys 223(1):341–368

Zhang C, Suzuki A, Ishimaru T, Enomoto M (2004) Characterization of three-dimensional grain structure in polycrystalline iron by serial sectioning. Metall Mater Trans A 35A:1927–1933

Zohdi TI, Wriggers P (2005) An introduction to computational micromechanics. Lecture notes in applied and computational mechanics. vol 20, Springer, Berlin

Acknowledgments

The authors gratefully acknowledge the support of CINECA’s staff for the use of CINECA’s HPC facilities. Moreover, they express their gratitude to Romain Quey of the École des Mines de Saint-Étienne, France, for his support in the use of Neper: short but focused communications provided inspiration for some of the ideas expressed in the paper.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Anisotropic Green’s functions

The 3D Green’s functions for the anisotropic problem are the solutions of the following problem

where \(\mathbf {\xi }\) and \(\mathbf {\eta }\) denote generic collocation and field points, \(C_{ijkl}\) is the anisotropic fourth-order elasticity tensor, the commas followed by letters in the subscripts denote derivation with respect to the related components of \(\eta \), \(\delta _{iq}\) is the Kronecker delta and \(\delta \left( \mathbf {\xi }-\mathbf {\eta }\right) \) is the Dirac delta function.

Defined the unit vector \(\mathbf b =(\mathbf {\xi }-\mathbf {\eta })/\Vert \mathbf {\xi }-\mathbf {\eta }\Vert \) in the direction connecting \(\mathbf {\xi }\) and \(\mathbf {\eta }\), the anisotropic Green’s function can be written

with

where \(r=\Vert \mathbf {\xi }-\mathbf {\eta }\Vert \), \(\mathbf {z}\) is a unit vector lying on the plane \(\Pi \) perpendicular to \(\mathbf {b}\), \(\mathbf {z}\cdot \mathbf {b}=0\), whose position is given in terms of the angle \(\varphi \) with respect to a reference axis on \(\Pi \), and \(C_{ipjq}\) are the components of the stiffness tensor. The integration in Eq. (13) is the performed along a unit circle lying on the plane \(\Pi \).

The kernels appearing in the formulation can all be expressed in terms of the Green’s functions \(G_{ij}\) and their first derivatives, which are given by

where the integration is still performed on the plane \(\Pi \) and

For a more detailed introduction to the boundary element method for anisotropic elastic problems, the interested readers are referred to [56] and references therein.

Appendix 2: Interface micro-cracking modelling

The intergranular model used in the present study allows to analyze initiation, evolution and coalescence of microcracks within the aggregate. For the sake of completeness, the interface equations are briefly recalled here. For further details, the interested readers are referred to [11, 60].

When an interface is pristine, displacement continuity and traction equilibrium are enforced on it:

where all the quantities are expressed in local coordinates over each grain face (which motivates the signs in the above equations), see [10, 11].

Microcracking initiation and evolution is modelled replacing the traction equilibrium equations with cohesive laws embodying an irreversible damage parameter, upon fulfilment of the following intergranular threshold condition

where \(t_e\) is an effective traction, \(T_\mathrm {max}\) is the interface cohesive strength, and \(\widetilde{t}_n\) and \(\widetilde{t}_s\) are the normal and tangential traction components, respectively. In Eq. (18), \(\langle \ \rangle \) are the McCauley’s brackets, and \(\alpha \) and \(\beta \) are suitable constants entering the cohesive law. When damage is introduced, the following irreversible extrinsic cohesive traction-separation laws are introduced

being

where \(\delta u_s^\mathrm {cr}\) and \(\delta u_n^\mathrm {cr}\) are the critical displacement jumps in sliding mode and opening mode, respectively. \(d^*\) is the irreversible damage parameter

which is given by the maximum value reached by the effective displacement d during the loading history \(\mathscr {H}_d\). It is worth noting that the above equations, in the case of very low levels of damage \(d^*\), still provide consistent interface conditions: this can be realized considering that multiplying \(\varPsi _j^{\,ab}\), \(j=1,2,3\) by \(d^*\approx 0\), in Eq. (10), corresponds to enforce \(\delta u_j=0\), i.e. pristine interface conditions. The interested readers are refereed to [11] for further details, including a visual representation of the traction separation laws.

Finally, when the critical condition \(d^*=1\) is reached, the interface fails and the cohesive laws are replaced by equations of separation, contact slip or contact stick [11].

Rights and permissions

About this article

Cite this article

Gulizzi, V., Milazzo, A. & Benedetti, I. An enhanced grain-boundary framework for computational homogenization and micro-cracking simulations of polycrystalline materials. Comput Mech 56, 631–651 (2015). https://doi.org/10.1007/s00466-015-1192-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-015-1192-8