Abstract

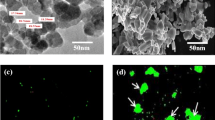

In this work, the free lipase Eversa® Transform 2.0 was used as a catalyst for enzymatic glycerolysis reaction in a solvent-free system. The product was evaluated by nuclear magnetic resonance (1H NMR) and showed high conversion related to hydroxyl groups. In sequence, the product of the glycerolysis was used as stabilizer and biopolyol for the synthesis of poly(urea–urethane) nanoparticles (PUU NPs) aqueous dispersion by the miniemulsion polymerization technique, without the use of a further surfactant in the system. Reactions resulted in stable dispersions of PUU NPs with an average diameter of 190 nm. After, the formation of the PUU NPs in the presence of concentrated lipase Eversa® Transform 2.0 was studied, aiming the lipase immobilization on the NP surface, and a stable enzymatic derivative with diameters around 231 nm was obtained. The hydrolytic enzymatic activity was determined using ρ-nitrophenyl palmitate (ρ-NPP) and the immobilization was confirmed by morphological analysis using transmission electron microscopy and fluorescence microscopy.

Similar content being viewed by others

References

Wilkerson JW, Yang SO, Funk PJ, Stanley SK, Bundy BC (2018) Nanoreactors: strategies to encapsulate enzyme biocatalysts in virus-like particles. New Biotechnol 44:59–63. https://doi.org/10.1016/j.nbt.2018.04.003

Carvalho F, Paradiso P, Saramago B, Ferraria AM, do Rego AMB, Fernandes P (2016) An integrated approach for the detailed characterization of an immobilized enzyme. J Mol Catal B Enzym 125:64–74. https://doi.org/10.1016/j.molcatb.2016.01.001

Pellis A, Cantone S, Ebert C, Gardossi L (2018) Evolving biocatalysis to meet bioeconomy challenges and opportunities. New Biotechnol 40:154–169. https://doi.org/10.1016/j.nbt.2017.07.005

Illanes A, Cauerhff A, Wilson L, Castro GR (2012) Recent trends in biocatalysis engineering. Bioresour Technol 115:48–57. https://doi.org/10.1016/j.biortech.2011.12.050

Price J, Nordblad M, Martel HH, Chrabas B, Wang H, Nielsen PM, Woodley JM (2016) Scale-up of industrial biodiesel production to 40 m3 using a liquid lipase formulation. Biotechnol Bioeng. https://doi.org/10.1002/bit.25936

Sasson A, Malpica C (2018) Bioeconomy in latin America. New Biotechnol 40:40–45. https://doi.org/10.1016/j.nbt.2017.07.007

Romera CDO, De Oliveira D, Henrique P, De Araújo H, Sayer C (2019) Enzymatic synthesis of a diene ester monomer derived from renewable resource. Appl Biochem Biotechnol 189:745–759

Shirke AN, White C, Englaender JA, Zwarycz A, Butterfoss GL, Linhardt RJ, Gross RA (2018) Stabilizing leaf and branch compost cutinase (LCC) with glycosylation: mechanism and effect on PET hydrolysis. Biochemistry 57:1190–1200. https://doi.org/10.1021/acs.biochem.7b01189

Sigurdardóttir SB, Lehmann J, Ovtar S, Grivel JC, Della Negra M, Kaiser A, Pinelo M (2018) Enzyme immobilization on inorganic surfaces for membrane reactor applications: mass transfer challenges, enzyme leakage and reuse of materials. Adv Synth Catal 360:2578–2607. https://doi.org/10.1002/adsc.201800307

Fernandez-Lafuente R (2010) Lipase from Thermomyces lanuginosus: uses and prospects as an industrial biocatalyst. J Mol Catal B Enzym 62:197–212. https://doi.org/10.1016/j.molcatb.2009.11.010

Javed S, Azeem F, Hussain S, Rasul I, Siddique MH, Riaz M, Afzal M, Kouser A, Nadeem H (2018) Bacterial lipases: a review on purification and characterization. Prog Biophys Mol Biol 132:23–34. https://doi.org/10.1016/j.pbiomolbio.2017.07.014

Salihu A, Alam MZ (2015) Solvent tolerant lipases: a review. Process Biochem 50:86–96. https://doi.org/10.1016/j.procbio.2014.10.019

de Miranda AS, Miranda LSM, de Souza ROMA (2015) Lipases: valuable catalysts for dynamic kinetic resolutions. Biotechnol Adv 33:372–393. https://doi.org/10.1016/j.biotechadv.2015.02.015

Cipolatti EP, Silva MJA, Klein M, Feddern V, Feltes MMC, Oliveira JV, Ninow JL, De Oliveira D (2014) Current status and trends in enzymatic nanoimmobilization. J Mol Catal B Enzym 99:56–67. https://doi.org/10.1016/j.molcatb.2013.10.019

Datta S, Christena LR, Rajaram YRS (2013) Enzyme immobilization: an overview on techniques and support materials. 3 Biotech. https://doi.org/10.1007/s13205-012-0071-7

Adlercreutz P (2013) Immobilisation and application of lipases in organic media. Chem Soc Rev 42:6406–6436. https://doi.org/10.1039/c3cs35446f

Nisha S, Karthick SA, Gobi N (2012) A review on methods, application and properties of immobilized enzyme. Chem Sci Rev Lett 1:148–155. (ISSN 2278-6783)

DiCosimo R, McAuliffe J, Poulose AJ, Bohlmann G (2013) Industrial use of immobilized enzymes. Chem Soc Rev 42:6437. https://doi.org/10.1039/c3cs35506c

Mohamad NR, Marzuki NHC, Buang NA, Huyop F, Wahab RA (2015) An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnol Biotechnol Equip 29:205–220. https://doi.org/10.1080/13102818.2015.1008192

Mehta J, Bhardwaj N, Bhardwaj SK, Kim K-H, Deep A (2016) Recent advances in enzyme immobilization techniques: metal-organic frameworks as novel substrates. Coord Chem Rev 322:30–40. https://doi.org/10.1016/j.ccr.2016.05.007

Ahmad R, Sardar M (2015) Enzyme immobilization: an overview on nanoparticles as immobilization matrix. Biochem Anal Biochem. https://doi.org/10.4172/2161-1009.1000178

Shuai W, Das RK, Naghdi M, Brar SK, Verma M (2017) A review on the important aspects of lipase immobilization on nanomaterials. Biotechnol Appl Biochem 64:496–508. https://doi.org/10.1002/bab.1515

Min K, Yoo YJ (2014) Recent progress in nanobiocatalysis for enzyme immobilization and its application. Biotechnol Bioprocess Eng 19:553–567. https://doi.org/10.1007/s12257-014-0173-7

Bassi JJ, Todero LM, Lage FAP, Khedy GI, Ducas JD, Custódio AP, Pinto MA, Mendes AA (2016) Interfacial activation of lipases on hydrophobic support and application in the synthesis of a lubricant ester. Int J Biol Macromol 92:900–909. https://doi.org/10.1016/j.ijbiomac.2016.07.097

Manoel EA, dos Santos JCS, Freire DMG, Rueda N, Fernandez-Lafuente R (2015) Immobilization of lipases on hydrophobic supports involves the open form of the enzyme. Enzyme Microb Technol 71:53–57. https://doi.org/10.1016/j.enzmictec.2015.02.001

Cipolatti EP, Valério A, Nicoletti G, Theilacker E, Araújo PHH, Sayer C, Ninow JL, de Oliveira D (2014) Immobilization of Candida antarctica lipase B on PEGylated poly(urea-urethane) nanoparticles by step miniemulsion polymerization. J Mol Catal B Enzym 109:116–121. https://doi.org/10.1016/j.molcatb.2014.08.017

Cipolatti EP, Valério A, Ninow JL, de Oliveira D, Pessela BC (2016) Stabilization of lipase from Thermomyces lanuginosus by crosslinking in PEGylated polyurethane particles by polymerization: application on fish oil ethanolysis. Biochem Eng J 112:54–60. https://doi.org/10.1016/j.bej.2016.04.006

Chiaradia V, Valério A, de Oliveira D, Araújo PHH, Sayer C (2016) Simultaneous single-step immobilization of Candida antarctica lipase B and incorporation of magnetic nanoparticles on poly(urea-urethane) nanoparticles by interfacial miniemulsion polymerization. J Mol Catal B Enzym 131:31–35. https://doi.org/10.1016/j.molcatb.2016.06.004

Landfester K (2003) Miniemulsions for nanoparticle synthesis. Top Curr Chem 227:75–123. https://doi.org/10.1007/b10835

Bresolin D, Mazurek V, Valério A, Sayer C, de Araújo PHH, de Oliveira D (2018) Poly(urea-urethane) nanoparticles using mono- and diacylglycerol from glycerolysis of castor oil as biopolyol and stabilizer. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2018.09.044

Calle M, Lligadas G, Ronda JC, Galià M, Cádiz V (2016) Non-isocyanate route to biobased polyurethanes and polyureas via AB-type self-polycondensation. Eur Polym J. https://doi.org/10.1016/j.eurpolymj.2016.04.022

Cipolatti EP, Moreno-Pérez S, Souza LTDA, Valério A, Guisán JM, De Araújo PHH, Sayer C, Ninow JL, De Oliveira D, Pessela BC (2015) Synthesis and modification of polyurethane for immobilization of Thermomyces lanuginosus (TLL) lipase for ethanolysis of fish oil in solvent free system. J Mol Catal B Enzym 122:163–169. https://doi.org/10.1016/j.molcatb.2015.09.006

Chiaradia V, Soares NS, Valério A, de Oliveira D, Araújo PHH, Sayer C (2016) Immobilization of Candida antarctica lipase B on magnetic poly(urea-urethane) nanoparticles. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-016-2116-6

Mutlu H, Meier MAR (2010) Castor oil as a renewable resource for the chemical industry. Eur J Lipid Sci Technol 112:10–30. https://doi.org/10.1002/ejlt.200900138

Bresolin D, Valério A, de Oliveira D, Lenzi MK, Sayer C, de Araújo PHH (2018) Polyurethane foams based on biopolyols from castor oil and glycerol. J Polym Environ 26:2467–2475. https://doi.org/10.1007/s10924-017-1138-7

Fregolente PBL, Pinto GMF, Wolf-Maciel MR, Filho RM (2010) Monoglyceride and diglyceride production through lipase-catalyzed glycerolysis and molecular distillation. Appl Biochem Biotechnol 160:1879–1887. https://doi.org/10.1007/s12010-009-8822-6

Abdul Halim KA, Soloi S, Majid RA (2015) Synthesis of palm oil based polyol via glycerolysis and transamidation reactions for polyurethane foam production. Appl Mech Mater 735:226–229. https://doi.org/10.4028/www.scientific.net/AMM.735.226

da Silva JAP, Cardozo NSM, Petzhold CL (2018) Enzymatic synthesis of andiroba oil based polyol for the production of flexible polyurethane foams. Ind Crops Prod 113:55–63. https://doi.org/10.1016/j.indcrop.2018.01.020

Holmberg K (2018) Interactions between surfactants and hydrolytic enzymes. Colloids Surf B Biointerfaces 168:169–177. https://doi.org/10.1016/j.colsurfb.2017.12.002

Otzen DE (2015) Science proteins in a brave new surfactant world. Curr Opin Colloid Interface Sci 20:161–169. https://doi.org/10.1016/j.cocis.2015.07.003

Valério A, Rovani S, Treichel H, De Oliveira D, Oliveira JV (2010) Optimization of mono and diacylglycerols production from enzymatic glycerolysis in solvent-free systems. Bioprocess Biosyst Eng 33:805–812. https://doi.org/10.1007/s00449-009-0402-1

American Standard ASTM D4274-99 (2016) Standard test methods for testing polyurethane raw materials: determination of hydroxyl numbers of polyols, West Conshohocken, PA

Bresolin D, Estrella AS, Da Silva JRP, Valério A, Sayer C, De Araújo PHH, De Oliveira D (2018) Synthesis of a green polyurethane foam from a biopolyol obtained by enzymatic glycerolysis and its use for immobilization of lipase NS-40116. Bioprocess Biosyst Eng. https://doi.org/10.1007/s00449-018-2026-9

Chiou SH, Wu WT (2004) Immobilization of Candida rugosa lipase on chitosan with activation of the hydroxyl groups. Biomaterials 25:197–204. https://doi.org/10.1016/S0142-9612(03)00482-4

Remonatto D, Santin CM, Valerio A, Lerin L, Batistella L, Ninow JL, de Oliveira JV, de Oliveira D (2015) Lipase-catalyzed glycerolysis of soybean and canola oils in a free organic solvent system assisted by ultrasound. Appl Biochem Biotechnol 176:850–862. https://doi.org/10.1007/s12010-015-1615-1

Camino Feltes MM, Villeneuve P, Baréa B, de Oliveira D, Ninow JL (2012) Evaluation of the use of surfactants as additives in enzymatic glycerolysis reactions. Eur J Lipid Sci Technol 114:1352–1357. https://doi.org/10.1002/ejlt.201200065

Hu S, Wan C, Li Y (2012) Production and characterization of biopolyols and polyurethane foams from crude glycerol based liquefaction of soybean straw. Bioresour Technol 103:227–233. https://doi.org/10.1016/j.biortech.2011.09.125

Hejna A, Kosmela P, Formela K, Piszczyk L, Haponiuk JT (2016) Potential applications of crude glycerol in polymer technology-current state and perspectives. Renew Sustain Energy Rev 66:449–475. https://doi.org/10.1016/j.rser.2016.08.020

Rathod SSNVK (2017) Ultrasound assisted intensification of enzyme activity and its properties: a mini-review. World J Microbiol Biotechnol 170:131–144. https://doi.org/10.1007/s11274-017-2322-6

Şener N, Kiliç Apar D, Özbek B (2006) A modelling study on milk lactose hydrolysis and β-galactosidase stability under sonication. Process Biochem 41:1493–1500. https://doi.org/10.1016/j.procbio.2006.02.008

Feltes MMC, de Oliveira D, Block JM, Ninow JL (2013) The production, benefits, and applications of monoacylglycerols and diacylglycerols of nutritional interest. Food Bioprocess Technol 6:17–35. https://doi.org/10.1007/s11947-012-0836-3

Acknowledgements

The authors thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq—Process: 142143/2014-6) for the financial support; Novozymes® who kindly provided enzymes; Laboratório Central de Microscopia Eletrônica (LCME) of Universidade Federal de Santa Catarina (UFSC) for transmission electron microscopy images; and Laboratório Multiusuário de Estudos em Biologia (LAMEB) of UFSC for fluorescence microscopy analyses.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bresolin, D., Hawerroth, B., de Oliveira Romera, C. et al. Immobilization of lipase Eversa Transform 2.0 on poly(urea–urethane) nanoparticles obtained using a biopolyol from enzymatic glycerolysis. Bioprocess Biosyst Eng 43, 1279–1286 (2020). https://doi.org/10.1007/s00449-020-02324-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-020-02324-6