Abstract

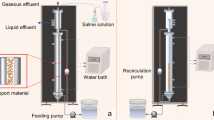

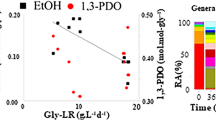

The production of 1,3-propanediol from crude glycerol and mixed anaerobic sludge was investigated in batch experiments and continuous reactors. Using a 23 complete factorial design, the effects of the concentration of glycerol (22–30 g L−1), KH2PO4 (1.50–2.00 g L−1), and vitamin B12 (7–8 mg L−1) were examined in batch reactors. As an evaluated response, the highest 1,3-PD yields occurred for high concentrations of vitamin B12 and low levels of KH2PO4, reaching 0.57 g g−1 glycerol consumed. The variable glycerol concentration was not significant in the studied range. In addition, the condition that provided the best 1,3-PD yield was applied to an anaerobic fluidized bed reactor fed with crude glycerol (26.0 g L−1), which was monitored as the hydraulic retention time (HRT) decreased from 36 to 12 h. The greatest 1,3-PD yield, of 0.31 g g−1 glycerol, was obtained with an HRT of 28 h.

Similar content being viewed by others

References

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industry microbiology. Biotechnol Adv 27(1):30–39

Zhang X, Yan S, Tyagi RD, Surampalli RY, Valéro JR (2016) Energy balance of biofuel production from biological conversion of crude glycerol. J Environ Manag 170:169–176

National Agency of Petroleum, Natural gas and biofuels (ANP, Brazil) (2017) Brazilian statistical yearbook of oil, natural gas and biofuels, 1st edn. National Agency of Oil, Natural Gas and Biofuels, Rio de Janeiro (in Portuguese)

Sittijunda S, Reungsang A (2017) Fermentation of hydrogen, 1,3-propanediol and ethanol from glycerol as affected by organic loading rate using up-flow anaerobic sludge blanket (UASB) reactor. Int J Hydrog Energy 42:27558–27569

Selembo PA, Perez JM, Lloyd WA, Logan BE (2009) Enhanced hydrogen and 1,3-propanediol production from glycerol by fermentation using mixed cultures. Biotechnol Bioeng 104(6):1098–1106

Kivistö A, Santala V, Karp M (2011) Closing the 1,3-propanediol route enhances hydrogen production from glycerol by Halanaerobium saccharolyticum subsp. Saccharolyticum. Int J Hydrog Energy 36(12):7074–7080

Moon C, Hwan Lee C, Sang BI, Um Y (2011) Optimization of medium compositions favoring butanol and 1,3-propanediol production from glycerol by Clostridium pasteurianum. Bioresour Technol 102(22):10561–10568

da Silva GP, de Lima CJB, Contiero J (2015) Production and productivity of 1,3-propanediol from glycerol by Klebsiella pneumoniae GLC29. Catal Today 257:259–266

Bauer R, Katsikis N, Varga S, Hekmat D (2005) Study of the inhibitory effect of the product dihydroxyacetone on Gluconobacter oxydans in a semi-continuous two-stage repeated-fed-batch process. Bioprocess Biosyst Eng 28(1):37–43

Song H, Lee SY (2006) Production of succinic acid by bacterial fermentation. Enzyme Microb Technol 39(3):352–361

Himmi EH, Bories A, Boussaid A, Hassani L (2000) Propionic acid fermentation of glycerol and glucose by Propionibacterium acidipropionici and Propionibacterium freudenreichii ssp Shermanii. Appl Microbiol Biotechnol 53(4):435–440

Dishisha T, Alvarez MT, Hatti-Kaul R (2012) Batch- and continuous propionic acid production from glycerol using free and immobilized cells of Propionibacterium acidipropionici. Bioresour Technol 118:553–562

Jarvis GN, Moore ERB, Thiele JH (1997) Formate and ethanol are the major products of glycerol fermentation produced by a Klebsiella planticola strain isolated from red deer. J Appl Microbiol 83(2):166–174

Ito T, Nakashimada Y, Senba K, Matsui T, Nishio N (2005) Hydrogen and ethanol production from glycerol-containing wastes discharged after biodiesel manufacturing process. J Biosci Bioeng 100(3):260–265

Imandi SB, Bandaru VR, Somalanka SR, Garapati HR (2007) Optimization of medium constituents for the production of citric acid from byproduct glycerol using Doehlert experimental design. Enzyme Microb Technol 40(5):1367–1372

Reungsang A, Sittijunda S, O-Thong S (2013) Bio-hydrogen production from glycerol by immobilized Enterobacter aerogenes ATCC 13048 on heat-treated UASB granules as affected by organic loading rate. Int J Hydrog Energy 38(17):6970–6979

Chookaew T, O-Thong S, Prasertsan P (2014) Biohydrogen production from crude glycerol by immobilized by Klebsiella sp TR17 in a UASB reactor and bacterial quantification under non-sterile conditions. Int J Hydrog Energy 39(18):9580–9587

Biebl H, Menzel K, Zeng AP, Deckwer WD (1999) Microbial production of 1,3-propanediol. Appl Microbiol Biotechnol 52(3):289–297

Homann T, Tag CG, Biebl H, Deckwer W-D, Schink B (1990) Fermentation of glycerol to 1,3-propanediol by Klebsiella and Citrobacter strains. Appl Microbiol Biotechnol 33:121–126

Tee ZK, Jahim JM, Tan JP, Kim BH (2017) Preeminent productivity of 1,3-propanediol by Clostridium butyricum JKT37 and the role of using calcium carbonate as pH neutraliser in glycerol fermentation. Bioresour Technol 233:296–304

Khanna S, Goyal A, Moholkar VS (2013) Production of n-butanol from biodiesel derived crude glycerol using Clostridium pasteurianum immobilized on Amberlite. Fuel 112:557–561

Pflügl S, Marx H, Mattanovich D, Sauer M (2012) 1,3-Propanediol production from glycerol with Lactobacillus diolivorans. Bioresour Technol 119:133–140

Liu B, Christiansen K, Parnas R, Xu Z, Li B (2013) Optimizing the production of hydrogen and 1,3-propanediol in anaerobic fermentation of biodiesel glycerol. Int J Hydrog Energy 38(8):3196–3205

Gallardo R, Faria C, Rodrigues LR, Pereira MA, Alves MM (2014) Anaerobic granular sludge as a biocatalyst for 1,3-propanediol production from glycerol in continuous bioreactors. Bioresour Technol 155:28–33

Sun Y-Q, Shen J-T, Yan L, Zhou J-J, Jiang L-L, Chen Y, Yuanb J-L, Feng E, Xiu Z-L (2018) Advances in bioconversion of glycerol to 1,3-propanediol: prospects and challenges. Process Biochem. https://doi.org/10.1016/j.procbio.2018.05.009

Kanjilal B, Noshadi I, Bautista EJ, Srivastava R, Parnas RS (2015) Batch, design optimization, and DNA sequencing study for continuous 1,3-propanediol production from waste glycerol by a soil-based inoculum. Appl Microbiol Biotechnol 99(5):2105–2117

Jiang LL, Liu HF, Mu Y, Sun YQ, Xiu ZL (2017) High tolerance to glycerol and high production of 1,3-propanediol in batch fermentations by microbial consortium from marine sludge. Eng Life Sci 17(6):635–644

Varrone C, Floriotis G, Heggeset TMB, Le SB, Markussen S, Skiadas IV, Gavala HN (2017) Continuous fermentation and kinetic experiments for the conversion of crude glycerol derived from second-generation biodiesel into 1,3 propanediol and butyric acid. Biochem Eng J 128:149–161

Fuentes M, Mussati MC, Scenna NJ, Aguirre PA (2009) Global modeling and simulation of a three-phase fluidized bed bioreactor. Comput Chem Eng 33(1):359–370

Rosa PRF, Santos SC, Sakamoto IK, Varesche MBA, Silva EL (2014) Hydrogen production from cheese whey with ethanol-type fermentation: effect of hydraulic retention time on the microbial community composition. Bioresour Technol 161:10–19

Santos SC, Rosa PRF, Sakamoto IK, Varesche MBA, Silva EL (2014) Hydrogen production from diluted and raw sugarcane vinasse under thermophilic anaerobic conditions. Int J Hydrog Energy 39(18):9599–9610

Ottaviano LM, Ramos LR, Botta LS, Varesche MBA, Silva EL (2017) Continuous thermophilic hydrogen production from cheese whey powder solution in an anaerobic fluidized bed reactor: effect of hydraulic retention time and initial substrate concentration. Int J Hydrog Energy 42(8):4848–4860

Ramos LR, Silva EL (2016) Continuous hydrogen production from agricultural wastewaters at thermophilic and hyperthermophilic temperatures. Appl Biochem Biotechnol 182:846–869

Nazareth TC, de Oliveira Paranhos AG, Ramos LR, Silva EL (2018) Valorization of the crude glycerol for propionic acid production using an anaerobic fluidized bed reactor with grounded tires as support material. Appl Biochem Biotechnol. https://doi.org/10.1007/s12010-018-2754-y

Barbirato F, Grivet JP, Soucaille P, Bories A (1996) 3-Hydroxypropionaldehyde, an inhibitory metabolite of glycerol fermentation to 1,3-propanediol by enterobacterial species. Appl Environ Microb 62(4):3–7

Biebl H, Pfennig N (1981) Isolation of members of the family Rhodosprillaceae. In: Starr MP, Stolp H, Trüper HG, Balows A, Schlegel HG (eds) The prokaryotes. Springer, Berlin, pp 267–273

Kim S, Han S, Shin H (2006) Effect of substrate concentration on hydrogen production and 16S rDNA-based analysis of the microbial community in a continuous fermenter. Process Biochem 41(1):199–207

Amorim ELC, Barros AR, Damianovic MHRZ, Silva EL (2009) Anaerobic fluidized bed reactor with expanded clay as support for hydrogen production through dark fermentation of glucose. Int J Hydrog Energy 34(2):783–790

American Public Health Association (2012) Standard methods for the examination for water and wastewater, 22nd edn. American Water Works Association, Water Environmental Federation, Washington

Walker M, Zhang Y, Heaven S, Banks C (2009) Potential errors in the quantitative evaluation of biogas production in anaerobic digestion process. Bioresour Technol 100(24):116–123

Bondioli P, Della Bella L (2005) An alternative spectrophotometric method for the determination of free glycerol in biodiesel. Eur J Lipid Sci Technol 107(3):153–157

Oh B-R, Seo J-W, Choi MH, Kim CH (2008) Optimization of culture conditions for 1,3-propanediol production from crude glycerol by Klebsiella pneumoniae using response surface methodology. Biotechnol Bioprocess Eng 13(6):666–670

Hong E, Yoon S, Kim J, Kim E, Kim D, Rhie S, Ryu Y-W (2013) Isolation of microorganisms able to produce 1,3-propanediol and optimization of medium constituents for Klebsiella pneumoniae. Bioprocess Biosyst Eng AJ4(6):835–843 36(

Kaur G, Srivastava AK, Chand S (2012) Determination of kinetic parameters of 1,3-propanediol fermentation by Clostridium diolis using statistically optimized medium. Bioprocess Biosyst Eng 35(7):1147–1156

Wang J, Wan W (2009) Factors influencing fermentative hydrogen production: a review. Int J Hydrog Energy 34:799–811

Angelidaki I, Sanders W (2004) Assessment of the anaerobic biodegradability of macropollutants. Rev Environ Sci Biotechnol 3:117–129

Gonen C, Gungormusler M, Azbar N (2013) Continuous production of 1,3-propanediol using waste glycerol with Clostridium beijerinckii NRRL B-593 immobilized on glass beads and glass rushing rings. Chem Biochem Eng 27(2):227–234

Edwards VH (1970) The influence of high substrate concentrations on microbial kinetics. Biotechnol Bioeng 12(5):679–712

Cheng KK, Zhang J-A, Liu D-H, Sun Y, Liu H-J, Yang M-D, Xu J-M (2007) Pilot-scale production of 1,3-propanediol using Klebsiella pneumoniae. Process Biochem 42(4):740–744

Gonen C, Gungormusler M, Azbar N (2012) Comparative evaluation of pumice stone as an alternative immobilization material for 1,3-propanodiol production from waste glycerol by immobilized Klebsiella pneumonia. Appl Biochem Biotechnol 168(8):2136–2147

Saint-Amans S, Girbal L, Andrade J, Ahrens K, Soucaille P (2001) Regulation of carbon and electron flow in Clostridium butyricum VPI 3266 grown on glucose–glycerol mixtures. J Bacteriol 183(5):1748–1754

Saint-Amans S, Perlot P, Goma G, Soucaille P (1994) High production of 1,3-propanediol from glycerol by Clostridium butyricum VPI 3266 in a simply controlled fed-batch system. Biotechnol Lett 16(8):831–836

Khanna S, Goyal A, Moholkar VS (2013) Effect of fermentation parameters on bio-alcohols production from glycerol using immobilized Clostridium pasteurianum: an optimization study. Prep Biochem Biotechnol 43(8):828–847

Huang H, Gong CS, Tsao GT (2002) Production of 1,3-propanediol by Klebsiella pneumoniae. Appl Biochem Biotechnol 98:687–698

Vivek N, Pandey A, Binod P (2016) Biological valorization of pure and crude glycerol into 1,3-propanediol using a novel isolate Lactobacillus brevis N1E9.3.3. Bioresour Technol 213:222–230

Acknowledgements

The authors gratefully acknowledge the financial support of the National Council for Scientific and Technological Development (CNPq), Coordination for the Improvement of Higher Education Personnel (CAPES), and São Paulo Research Foundation (FAPESP).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Edson Luiz Silva: Scopus ID: 24167115300.

Rights and permissions

About this article

Cite this article

Paranhos, A.G.d.O., Silva, E.L. Optimized 1,3-propanediol production from crude glycerol using mixed cultures in batch and continuous reactors. Bioprocess Biosyst Eng 41, 1807–1816 (2018). https://doi.org/10.1007/s00449-018-2003-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-018-2003-3