Abstract

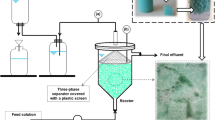

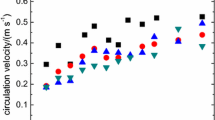

The continuous production of 1,3-propanediol (1,3-PDO) was investigated with Clostridium beijerinckii NRRL B-593 using raw glycerol without purification obtained from a biodiesel production process. Ceramic rings and pumice stones were used for cell immobilization in a packed-bed bioreactor. For comparison purpose, a control bioreactor with suspended culture was also run. The effect of hydraulic retention time (HRT) on the production of 1,3-PDO in both immobilized and suspended bioreactors were also investigated. The study revealed that HRT is an important factor for both immobilized and suspended systems and a HRT of 2 h is the best one in terms of volumetric production rate (g 1,3-PDO/L/h). Furthermore, cell immobilization had also obvious benefits especially for the robustness and the reliability of the production. The results indicated that cell immobilization achieved a 2.5-fold higher productivity in comparison to suspended cell system. Based on our results, continuous production of 1,3-PDO with immobilized cells is an efficient method, and raw glycerol can be utilized without any pretreatment.

Similar content being viewed by others

References

Mu Y, Xiu ZL, Zhang DJ (2008) A combined bioprocess of biodiesel production by lipase with microbial production of 1,3-propanediol by Klebsiella pneumoniae. Biochem Eng J 40:537–541

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 18:213–219

Hiremath A, Kannabiran M, Rangaswamy V (2010) 1,3 Propanediol production from crude glycerol from jathropa biodiesel process. New Biotechnol 28(1):19–23

Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27:895–913

Willke T, Vorlop K (2008) Biotransformation of glycerol into 1,3-propanediol. Eur J Lipid Sci Technol 110:831–840

Pflugmacher U, Gottschalk G (1994) Development of an immobilized cell reactor for the production of 1,3-propanediol by Citrobacter freundii. Appl Microbiol Biotechnol 41:313–316

Wittlich P, Capan E, Schlieker M, Vorlop KD, Jahnz U (2004) Entrapment in LentiKats®. In: Nedovic VA, Willaert R (eds) Fundamentals of cell ımmobilisation biotechnology. Kluwer Academic Publishers, Dordrecht

Gungormusler M, Gonen C, Ozdemir G, Azbar N (2010) 1,3 Propanediol production potential of Clostridium saccharobutylicum NRRL B-643. New Biotechnol 27(6):782–788

Gungormusler M, Gonen C, Ozdemir G, Azbar N (2010) Fermentation medium optimization for 1,3 propanediol production using Taguchi and Box-Behnken experimental designs. Fresenius Environ Bull 19(12):2840–2847

APHA, AWWA, WPCF (1995) Standard methods for the examination of water and wastewater, vol 19. American Public Health Association, Washington

Kourkoutas Y, Bekatorou A, Banat IM, Marchant R, Koutinas AA (2004) Immobilization technologies and support materials suitable in alcohol beverages production: a review. Food Microbiol 21:377–397

Demuyakor B, Ohta Y (1992) Promotive action of ceramics on yeast-ethanol production, and its relationship to pH, glycerol and alcohol dehydrogenase activity. Appl Microbiol Biotechnol 36:717–721

Biebl H (2001) Fermentation of glycerol by Clostridium pasteurianum—batch and continuous culture studies. J Ind Microbiol Biotechnol 27:18–26

Chen X, Xiu Z, Wang J, Zhang D, Xu P (2003) Stoichiometric analysis and experimental investigation of glycerol bioconversion to 1,3-propanediol by Klebsiella pneumoniae under microaerobic conditions. Enzyme Microb Technol 33:386–394

Sattayasamitsathit S, Prasertsan P, Methacanon P (2011) Statistical optimization for simultaneous production of 1,3-propanediol and 2,3-butanediol using crude glycerol by newly bacterial isolate. Process Biochem 46:608–614

Chen X, Zhang DJ, Qi WT, Gao SJ, Xiu ZL, Xu P (2003) Microbial fed-batch production of 1,3-propanediol by Klebsiella pneumoniae under micro-aerobic conditions. Appl Microbiol Biotechnol 63:143–146

Biebl H, Marten S, Hippe H, Deckwer WD (1992) Glycerol conversion to 1,3-propanediol by newly isolated Clostridia. Appl Microbiol Biotechnol 36:542–547

Saint-Amans S, Perlot P, Goma G, Soucaille P (1994) High production of 1,3-propanediol from glycerol by Clostridium butyricum VPI 3266 in a simply controlled fed-batch system. Biotechnol Lett 16:832–836

Zhao YN, Chen G, Yao SJ (2006) Microbial production of 1,3-propanediol from glycerol by encapsulated Klebsiella pneumoniae. Biochem Eng J 32:93–99

Menzel K, Zeng AP, Deckwer WD (1997) High concentration and productivity of 1,3-propanediol from continuous fermentation of glycerol by Klebsiella pneumoniae. Enzyme Microb Technol 20(2):82–86

Acknowledgments

The authors wish to thank TUBITAK-CAYDAG under the grant No 109Y150 and Ege University under the grant No 09MUH007 for the financial support of this study. The data presented in this article was produced within the projects above, however, it is only the authors of this article who are responsible for the results and discussions made herein.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gungormusler, M., Gonen, C. & Azbar, N. Continuous production of 1,3-propanediol using raw glycerol with immobilized Clostridium beijerinckii NRRL B-593 in comparison to suspended culture. Bioprocess Biosyst Eng 34, 727–733 (2011). https://doi.org/10.1007/s00449-011-0522-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-011-0522-2