Abstract

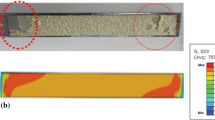

The design and validation of a new fixture for the shear testing of cellular solids are presented. The fixture is an extended version of a picture-frame shear fixture (EPF) and is suited for comparatively thick rectangular block specimens. The stress state in the specimen is analyzed using a detailed finite element model. The finite element model is based on a 3D CAD model and incorporates friction in the revolute joints. Using specimens with low stiffness, a nearly pure and uniform shear stress state is induced in the specimen. A correction factor for the shear stress is derived which takes into account the friction in the joints and the nonuniformity of the shear stress distribution in the gauge section. The shear response of the polymer foam Rohacell® 200 WF is determined in order to demonstrate the capabilities of the EPF. The strain state is analyzed by means of digital image correlation and is detected to be very pure and uniform on the specimen’s surface, as predicted by the numerical analysis. The shear modulus obtained with the EPF is in good agreement with the calculated shear modulus derived from tensile tests on the same material. In addition, there is only little scatter of the strength values over the tested specimens which further confirms the accuracy of the new fixture.

Similar content being viewed by others

References

Gibson L.J., Ashby M.F.: Cellular solids: structure and properties. Cambridge University Press, Cambridge (1997)

Shutov F.A.: Syntactic polymer foams. Adv. Polym. Sci. 73, 63–123 (1986)

Deshpande V.S., Fleck N.A.: Multi-axial yield behavior of polymer foams. Acta Mater. 49, 1859–1866 (2001)

Bartl F., Klaus H., Dallner R., Huber O.: Material behavior of a cellular composite undergoing large deformations. Int. J. Impact Eng. 36(5), 667–679 (2009)

Lee S., Munro M.: Evaluation of in-plane shear test methods for advanced composite materials by the decision analysis technique. Composites 17(1), 13–22 (1986)

Klaus H., Huber O., Kuhn G.: Lightweight potential of novel cellular spherical composites. Adv. Eng. Mater. 7(12), 1117–1124 (2005)

Huber O., Klaus H., Dallner R., Bartl F., Eigenfeld K., Kovacs B., Godehardt M.: Herstellung und Eigenschaften syntaktischer Metallschäume mit unterschiedlichen Matrix- und Füllmaterialien. Druckguss-Praxis 1, 9–24 (2006)

Diel S., Huber O., Saage H., Steinmann P., Winter W.: Mechanical behavior of a cellular composite under quasi-static, static, and cyclic compression loading. J. Mater. Sci. 47, 5635–5645 (2012)

Bastawros A.F., Bart-Smith H., Evans A.G.: Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J. Mech. Phys. Solids 48, 301–322 (2000)

Andrews E.W. et al.: Size effects in ductile cellular solids. Part II: experimental results. Int. J. Mech. Sci. 43, 701–713 (2001)

Gusev A.A.: Representative volume element size for elastic composites: a numerical study. J. Mech. Phys. Solids 45(9), 1449–1459 (1997)

Lachihab A., Sab K.: Does a representative volume element exist for fatigue life prediction? The case of aggregate composites. Int. J. Numer. Anal. Methods Geomech. 32, 1005–1021 (2008)

Sugimura Y., Rabiei A., Evans A.G., Harte A.M., Fleck N.A.: Compression fatigue of a cellular Al alloy. Mat. Sci. Eng. A 269, 38–48 (1999)

Clapper, R.B.: Shear and torsion testing of solid materials—a critical discussion. In: Symposium on shear and torsion testing, ASTM STP 289, American Society for Testing and Materials, pp. 111–120 (1960)

Farley G.L., Baker D.J.: In-plane shear test of thin panels. Exp. Mech. 23(1), 81–88 (1983)

O’Connor D.J.: An evaluation of test methods for shear modulus of sandwich cores. Int. J. Cem. Compos. Lightweight Concr. 6(1), 3–12 (1984)

Chatterjee, S.N., Adams, D.F., Oplinger, D.W.: Test methods for composites: a status report, volume III: shear test methods. Report DOT/FAA/CT-93/17, *III. Federal Aviation Administration, Atlantic City, NJ (1993)

American Society for Testing and Materials: Standard test method for shear properties of sandwich core materials: ASTM C 273, West Conshohocken, PA (2007)

Kelsey S., Gellatly R.A., Clark B.W.: The shear modulus of foil honeycomb cores: a theoretical and experimental investigation in cores used in sandwich construction. Aircr. Eng. Aero. Technol. 30(10), 294–302 (1958)

Iosipescu N.: New accurate procedure for single shear testing of metals. J. Mater. 2(3), 537–566 (1967)

American Society for Testing and Materials: Standard test method for shear properties of composite materials by the V-notched beam method: ASTM D 5379–05. West Conshohocken, PA (2005)

American Society for Testing and Materials: Shear properties of composite materials by the V-notched rail shear method: ASTM D 7078–05. West Conshohocken, PA (2005)

Adams, D.O., Moriarty, J.M., Gallegos, A.M., Adams, D.F.: Development and evaluation of the V-notched rail shear test for composite laminates, NTIS, DOT/FAA/AR-03/63 (2003)

American Society for Testing and Materials: Standard test method for in-plane shear properties of polymer matrix composite materials by the rail shear method: ASTM D 4255, West Conshohocken, PA (1983)

Arcan M., Hashin Z., Voloshin A.: A method to produce uniform plane-stress states with applications to fiber-reinforced materials. Exp. Mech. 18, 141–146 (1978)

Hung S.C., Liechti K.M.: Finite element analysis of the Arcan specimen for fiber reinforced composites under pure shear and biaxial loading. J. Compos. Mater. 33, 1288–1316 (1999)

Mohr D., Doyoyo M.: A new method for the biaxial testing of cellular solids. Exp. Mech. 43(2), 173–182 (2003)

American Society for Testing and Materials: Standard test method for in-plane shear properties of hoop wound polymer matrix composite cylinders: ASTM D 5448. West Conshohocken, PA (1993)

Papka S.D., Kyriakides S.: Biaxial crushing of honeycombs—Part I: experiments. Int. J. Solids Struct. 36, 4367–4396 (1999)

American Society for Testing and Materials: Standard test methods for structural panels in shear through-the-thickness: ASTM D 2719–89. West Conshohocken, PA (2007)

Bryan, E.L.: Photoelastic investigation of the panel shear test for plywood. In: Symposium on shear and torsion testing, ASTM STP 289, American Society for Testing and Materials, pp. 90–94 (1961)

Dastin S., Lubin G., Munyak J., Slobodzinski A.: Mechanical properties and test techniques for reinforced plastic laminates. ASTM STP 460, 13–26 (1969)

Terry G.: A comparative investigation of some methods of unidirectional, in-plane shear characterization of composite materials. Composites 10(4), 233–237 (1979)

Kennedy, J.M., Farley, G.L., Barnett, T.: Analysis of the picture frame in-plane shear test for composite materials. In: Proceedings AIAA/ASME/ASCA/AHS 28th SDM Conference, pp. 402-407 (1987)

Lomov S.V., Willems A., Verpoest I., Zhu Y., Barburski M., Stoilova T.: Picture frame test of woven composite reinforcements with a full-field strain registration. Text. Res. J. 76(3), 243–252 (2006)

Basan, R., Trappe, V.: Bestimmung der Schubeigenschaften von Faserverbundwerkstoffen mittels eines Schubrahmens. In: Proceedings of Deutscher Luft- und Raumfahrtkongress, Aachen (2009)

Niu M.: Airframe structural design. Adasa Adastra Engineering Center, Granada Hills (1999)

Wiedemann J.: Leichtbau: Elemente und Konstruktion. Springer, Berlin (2006)

Ogden R.W.: Non-linear elastic deformations. Dover, New York (1984)

Diel, S., Huber, O.: Entwicklung und Evaluierung einer Schubversuchsvorrichtung auf Basis einer Schubfeldkonstruktion für statische und zyklische Beanspruchungen. In: Huber, O., Bicker, M. (eds.) Proceedings of the 5. Landshuter Leichtbau-Colloquium, Landshut, pp. 57–69 (2011)

Penzien J., Didriksson T.: Effective shear modulus of honeycomb cellular structure. AIAA J. 2(3), 531–535 (1964)

Niemann G., Winter H., Höhn B.R.: Maschinenelemente, vol. 1. Springer, Berlin (2005)

Kraatz, A.: Anwendung der Invariantentheorie zur Berechnung des dreidimensionalen Versagens- und Kriechverhaltens von geschlossenzelligen Schaumstoffen unter Einbeziehung der Mikrostruktur. Dissertation, University Halle-Wittenberg, Germany (2007)

Zenkert, D., Burman, M.: Tension, compression and shear fatigue of a closed cell foam. In: Kageyama, K., et al. (eds.) Proceedings of the 16th International Conference on Composite Materials (ICEM-16). Kyoto (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Diel, S., Huber, O., Steinmann, P. et al. Design and validation of a new fixture for the shear testing of cellular solids. Arch Appl Mech 84, 309–321 (2014). https://doi.org/10.1007/s00419-013-0801-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-013-0801-2