Abstract

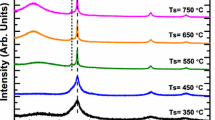

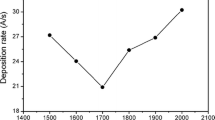

The effect of DC negative bias (− Vs) on microstructure and surface morphology of amorphous silicon carbide thin films prepared by helicon wave plasma chemical vapor deposition is reported. Microstructure and surface morphology were obtained by scanning electron microscope (SEM) and atomic force microscope (AFM). The results show that the increase of − Vs on the substrate make a more compact film and lower surface roughness, which can reach 0.56 nm. The XRD analysis reveals that the SiC thin films are of an amorphous structure. Percentages of carbon and silicon atoms (C/Si) were measured by energy dispersive spectrometer (EDS), and the C/Si ratio can reach 1.45. The structural properties of the films were studied by Raman spectroscopy techniques and Fourier transform infrared (FTIR). It is found that the films contain not only Si–C bonds but also Si–CHx bonds. Raman spectra results show that the proportion of disordered carbon in the films decreases with the increase of − Vs. The results of ultra-microhardness tester show that the hardness of the films increases with the increase of − Vs and the maximum mechanical hardness can reach 18.5 GPa at − Vs = − 60 V.

Similar content being viewed by others

References

H. Harikrishna, W.A. Lanford et al., J. Nucl. Mater. 514, 154–160 (2018)

G. Wen, X. Zeng et al., J. Appl. Phys. 115(16), 164303 (2014)

M. Li, L. Jiang, Y. Sun et al., J. Non-Cryst. Solids 503, 252259 (2018)

E. Chen, G. Du, Y. Zhang et al., Ceram. Int. 40(7), 9791–9797 (2014)

K.E. Bae, K.W. Chae et al., Adv. Eng. Mater. 18(7), 1123–1126 (2016)

J.Y. Fan, X.L. Wu, P.K. Chu, Prog. Mater. Sci. 51(8), 983–1031 (2006)

J. Xu, L. Yang, Y. Rui et al., Solid State Commun. 133(9), 565–568 (2005)

I.A. Yunaz, K. Hashizume, S. Miyajima et al., Sol. Energy Mater. Sol. Cells 93(6–7), 1056–1061 (2009)

S.Y. Lien, K.W. Weng, J.J. Huang et al., Curr. Appl. Phys. 11(1), 2 (2011)

A.R. Oliveira, I. Pereyra et al., Mater. Sci. Eng. B 112(2–3), 144–146 (2004)

L.F. Marsal, J. Pallarès et al., Semicond. Sci. Technol. 13(10), 1148 (1999)

Y. Ji, D. Shan, M. Qian et al., AIP Adv. 6(10), 211103–211662 (2016)

M.M. Rahman et al., J. Appl. Phys. 67(11), 7065 (1990)

T. Jeong, J.G. Zhu, S. Mao et al., Int J Thermo Phys 33(6), 1000–1012 (2012)

C.G. Jin, T. Yu, Y. Zhao et al., Phys. E 43(10), 1863–1866 (2011)

Y. Awad, M.A.E. Khakani, D. Brassard et al., Thin Solid Films 518(10), 2738–2744 (2010)

Y. Qin, T. Feng, Z. Li et al., Appl. Surf. Sci. 257(18), 7993–7996 (2011)

Y. Cheng, X. Huang, Z. Du et al., Opt. Mater. 73, 723–728 (2017)

M. Li, L. Jiang, Y. Sun et al., J. Alloy Compd. 753, 320–328 (2018)

G. Wen, X. Zeng, X. Li, J. Non-Cryst. Solids 441, 10–15 (2016)

T.Y. Huang, C.G. Jin, J. Yu et al., Sci. China Phys. Mech. Astronomy 59(4), 645201 (2016)

S. Logothetidis, I. Alexandrou et al., Surf. Coat. Technol. 80(1–2), 66–71 (1996)

H. Yokoyama, M. Okamoto et al., Jpn. J. Appl. Phys. 30(2), 344–348 (1991)

D.M. Mattox et al., J. Vacuum Sci. Technol. A Vacuum Surf. Films 7(3), 1105 (1989)

W. Dai, H.E. Zheng, W.U. Guosong et al., Vacuum 85(2), 231–235 (2010)

Z. Chen, W. Tian, X. Zhang et al., J Micromech Microeng 27, 11 (2017)

T. Welzel, I. Dani, F. Richter, Plasma Sourc. Sci. Technol. 11(3), 351 (2002)

J.L. Andújar, E. Pascual, G. Viera et al., Thin Solid Films 317(1–2), 120–123 (1998)

Motohashi M, Ashibu K et al., Electron. Commun. Jpn. Part 2 Electron. 90(2), 9–16 (2007)

M. Li, L. Jiang et al., Optik-Int. J. Light Electron Opt. 176, 401–409 (2019)

E. Ermakova, Y. Rumyantsev, A. Shugurov et al., Appl. Surf. Sci. 339, 102–108 (2015)

L. Jiang, X. Tan, T. Xiao et al., Thin Solid Films 622, 71–77 (2017)

Y. Sun, Miyasato T 37(10), 5485–5489 (1998)

C. Casiraghi, A.C. Ferrari et al., Phys. Rev. B Condensed Matter 72(8), 85401 (2005)

F. Tuinstra, J. Chem. Phys. 53(3), 1126 (1970)

A. Nawaz, W.G. Mao, C. Lu et al., Ceram. Int. 43(1), 385–391 (2017)

V. Kulikovsky, V. Vorlicek et al., Surf. Coat. Technol. 205(11), 3372–3377 (2011)

O.K. Porada, V.I. Ivashchenko et al., Surf. Coat. Technol. 2004, 122–126 (2004)

J.E. Krzanowski et al., J. Am. Ceram. Soc. 84(3), 672–674 (2001)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (nos. 11435009, 11975163), a Project funded by China Postdoctoral Science Foundation (no. 156455), a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and a Project Funded by the Postgraduate Research & Practice Innovation Program of Jiangsu Province (no. KYCX19_1966).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ji, P., Chen, J., Huang, T. et al. Effect of DC negative bias on microstructure and surface morphology of amorphous silicon carbide films prepared by HWP-CVD. Appl. Phys. A 126, 247 (2020). https://doi.org/10.1007/s00339-020-3349-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-3349-3