Abstract

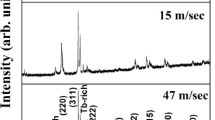

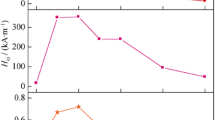

In the present work, Mn47Bi50Cr3 ribbons were synthesised employing melt spinning at different wheel speeds ranging from 16 to 28 m/s, to study the effect of quenching rate on the microstructure, morphology and magnetic properties of rapidly solidified alloy. X-ray diffraction studies indicate that the FWHM of diffraction peaks for MnBi increases with the increase in wheel speed, leading to a concurrent decrease in the mean grain size. This could be attributed to the high cooling rate causing homogeneous nucleation leading to refined grain size. The maximum value of coercivity of 11.9 kOe and saturation magnetisation of 54.2 emu/g was obtained for the alloy melt spun at 20 m/s, indicating dependence of coercivity on the grain size, and its orientation, which is largely controlled by the wheel speed. Also, XRD pattern confirms that the MnBi phase fraction is found to be maximum at this wheel speed. Therefore, high-performance nanocrystalline Mn47Bi50Cr3 magnetic material has been synthesised by adjusting the wheel speed and thereby tuning the quench rate. In addition, the phase transformation and variation with respect to temperature and time were studied using thermal analysis technique. Stability of magnetic properties of the alloy with respect to time was also studied after the ageing process.

Similar content being viewed by others

References

J.M.D. Coey, IEEE Trans. Magn. 47, 4671 (2011)

N.V.R. Rao, A.M. Gabay, W. Li, G.C. Hadjipanayis, J. Phys. D: Appl. Phys. 46, 265001 (2013)

N.V.R. Rao, A.M. Gabay, G.C. Hadjipanayis, J. Phys. D: Appl. Phys. 46, 062001 (2013)

X. Guo, X. Chen, Z. Altounian, J.O. Ström-Olsen, Phy. Rev. B 46, 14578 (1992)

H. Yoshida, T. Shima, T. Takahashi, H. Fujimori, Mater. Trans. JIM 40(5), 455–458 (1999)

X. Guo, A. Zaluska, Z. Altounian, J.O. Ström-Olsen, J. Mater. Res. 5, 2646 (1990)

S. Kim, H. Moon, H. Jung, S.M. Kim, H.S. Lee, H. Choi-Yim, W. Lee, J. Alloys Compd. 708, 1245 (2017)

E.J. Lavernia, T.S. Srivatsan, J. Mater. Sci. 45, 287–325 (2009)

S. Öztürk, K. Icin, B. Öztürk, U. Topal, H.K. Odabaşi, Int. J. Mater. Sci. Appl 6(5), 241–249 (2017)

S. Sarafrazian, A. Ghasemi, M. Tavoosi, J. Magn. Magn. Mater. 402, 115–123 (2016)

K. Simeonidis, C. Sarafidis, E. Papastergiadis, M. Angelakeris, I. Tsiaoussis, O. Kalogirou, Intermetallics 19, 589–595 (2011)

N.V. Rama Rao, G.C. Hadjipanayis, J. Alloys Compd. 616, 319–322 (2014)

N.V.R. Rao, G.C. Hadjipanayis, J. Alloys Compd. 629, 80–83 (2015)

P. Metall, M. Srinivas, B. Majumdar, G. Phanikumar, D. Akhtar, Metall. Mater. Trans. B: Process. Metall. Mater. Process. Sci. 42, 370–379 (2011)

K. Anand, N. Christopher, N. Singh, Appl. Phys. A 125, 12 (2019)

B.P. Bewlay, B. Cantor, Int. J. Rapid Solidif. 2, 107 (1986)

V.I. Tkatch, S.N. Denisenko, O.N. Beloshov, Acta Mater. 45, 2821 (1997)

V.I. Tkatch, A.I. Limanovskii, S.N. Denisenko, S.G. Rassolov, Mater. Sci. Eng. A 323, 91–96 (2002)

S. Saha, R.T. Obermyer, B.J. Zande, V.K. Chandhok, S. Simizu, S.G. Sankar, J.A. Horton, J. Appl. Phys. 91(10), 8525–8527 (2002)

K. Oikawa, Y. Mitsui, K. Koyama, K. Anzai, Mater. Trans. 52(11), 2032–2039 (2011)

M. Srinivas, B. Majumdar, D. Akhtar, A.P. Srivastava, D. Srivastava, J. Mater. Sci. 46, 616–622 (2011)

I. Janotová, P. Švec, I. Maťko, D. Janičkovič, P. Švec Sr, AIP Conf. Proc., 1996, 020021 (2018)

Z.M. Chen, Y. Zhang, G.C. Hadjipanayis, Q. Chen, B.M.J. Ma, J. Magn. Magn. Mater. 206, 8–16 (1999)

S. Muthiah, R.C. Singh, B.D. Pathak, P.K. Avasthi, R. Kumar, A. Kumar, A.K. Srivastava, A. Dhar, Nanoscale 10, 1970–1977 (2018)

G. Ouyang, B. Jensen, W. Tang, K. Dennis, C. Macziewski, S. Thimmaiah, Y. Liang, J. Cui, AIP Adv. 8, 056111 (2018)

A.L. Greer, Mater. Sci. Eng. A 133, 16 (1991)

T. Gheiratmand, H.R.M. Hosseini, P. Davami, M. Mansouri, in 4th International Conference on Ultrafine Grained and Nanostructure Matherials (2018)

D.A. Babu, A.P. Srivastava, B. Majumdar, D. Srivastava, D. Akhtar, Metall. Mater. Trans. A 41(5), 1313–1320 (2010)

Acknowledgements

This work was carried out under CSIR (India) Network Project PSC-0109. KA and NC acknowledge CSIR for financial assistance. Authors would like to thank Radhey Shyam and Naval Kishor for their technical support. The authors also acknowledge Mr. Jai Tawale for SEM measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anand, K., Christopher, N. & Singh, N. Influence of wheel speed and ageing on nanostructure and magnetic properties of Cr-doped MnBi magnetic material. Appl. Phys. A 126, 339 (2020). https://doi.org/10.1007/s00339-020-03528-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-03528-z