Abstract

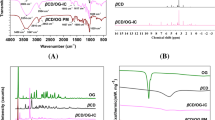

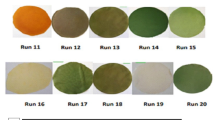

Polylactic acid (PLA)/starch acetate (SA) base film was prepared by scraping film method with PLA as the base film material, modified SA as the filling phase and polyethylene glycol (PEG) as plasticizer. Chitosan (CS)/tea polyphenol (TP) antibacterial agent was coated on the surface of PLA/SA base film by coating method. The morphology and structure of the composite film were characterized by FTIR, XRD, SEM and thermogravimetric analysis, and the mechanical, optical and antibacterial properties were tested and analyzed. The results showed that CS/TP compound antibacterial agent was well combined with PLA/SA base film. Compared with the PLA/SA base film, when the content of TP (based on the mass of PLA/SA base film, the same below) was 0.4%, the tensile strength of the composite film increased by 29.33%, had good mechanical strength (24.96 ± 0.65 MPa), and the elongation at break increased by 29.34%; There was no obvious change in transparency, the light transmittance decreased by 0.86%; At the same time, the antibacterial composite film had good antibacterial effect on Escherichia coli, Staphylococcus aureus and Bacillus subtilis. PLA/SA/CS/TP antibacterial composite film could be used in food packaging, especially those designed to protect food from light and microbial decay.

Similar content being viewed by others

References

Żołek-Tryznowska Z, Holica J (2020) Starch films as an environmentally friendly packaging material: printing performance. J Clean Prod, 276.

Wang B et al (2021) Antibacterial activity, optical, and functional properties of corn starch-based films impregnated with bamboo leaf volatile oil. Food Chem 357:129743

Pirsa S et al (2022) Nano-biocomposite based color sensors: Investigation of structure, function, and applications in intelligent food packaging. Food Packag Shelf Life. p. 31.

Ye J et al (2018) Preparation and properties of polylactic acid-tea polyphenol-chitosan composite membranes. Int J Biol Macromol 117:632–639

Rhim J-W et al (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38(10–11):1629–1652

Wang B et al (2021) Physicochemical properties and antibacterial activity of corn starch-based films incorporated with Zanthoxylum bungeanum essential oil. Carbohydr Polym 254:117314

Sani IK et al (2021) Composite film based on potato starch/apple peel pectin/ZrO2 nanoparticles/ microencapsulated Zataria multiflora essential oil; investigation of physicochemical properties and use in quail meat packaging. Food Hydrocolloids, p. 117.

Qin Y et al (2016) Effects of chitin nano-whiskers on the antibacterial and physicochemical properties of maize starch films. Carbohydr Polym 147:372–378

Wang X et al (2020) Research advances in chemical modifications of starch for hydrophobicity and its applications: a review. Carbohydr Polym 240:116292

Muller J et al (2017) Antimicrobial properties and release of cinnamaldehyde in bilayer films based on polylactic acid (PLA) and starch. Eur Polymer J 96:316–325

Ncube LK et al (2020) Environmental impact of food packaging materials: a review of contemporary development from conventional plastics to polylactic acid based materials. Materials (Basel) 13(21).

Kumar N et al (2017) Advances in bio-nanocomposite materials for food packaging: a review. Nutrition Food Sci 47(4):591–606

Siakeng R et al (2018) Natural fiber reinforced polylactic acid composites: a review. Polym Compos 40(2):446–463

Coltelli MB et al (2020) Properties and skin compatibility of films based on Poly(Lactic Acid) (PLA) bionanocomposites incorporating Chitin nanofibrils (CN). J Funct Biomater 11(2).

Ortega-Toro R et al (2015) Active bilayer films of thermoplastic starch and polycaprolactone obtained by compression molding. Carbohydr Polym 127:282–290

Muller J et al (2016) Influence of plasticizers on thermal properties and crystallization behaviour of poly(lactic acid) films obtained by compression moulding. Polym Int 65(8):970–978

Zhou X et al (2021) Biodegradable sandwich-architectured films derived from pea starch and polylactic acid with enhanced shelf-life for fruit preservation. Carbohydr Polym 251:117117

Li G et al. (2020) Synthesis and biological application of polylactic acid. Molecules 25 (21).

Meng L et al (2019) Preparation, microstructure and performance of poly (lactic acid)-Poly (butylene succinate-co-butyleneadipate)-starch hybrid composites. Composites Part B: Eng 177.

Rogovina SZ et al (2018) Influence of PEG on mechanical properties and biodegradability of composites based on PLA and starch. Starch Stärke 70(7–8).

Meng L et al (2019) Improvement of interfacial interaction between hydrophilic starch film and hydrophobic biodegradable coating. ACS Sustain Chem Eng 7(10):9506–9514

Ortega-Toro R et al (2016) Improvement of properties of glycerol plasticized starch films by blending with a low ratio of polycaprolactone and/or polyethylene glycol. Food Hydrocolloids 56:9–19

Henise J et al (2015) Biodegradable tetra-PEG hydrogels as carriers for a releasable drug delivery system. Bioconjug Chem 26(2):270–278

Zhang K et al (2020) Effect of sodium citrate/polyethylene glycol on plasticization and retrogradation of maize starch. Int J Biol Macromol 154:1471–1477

Singh N et al (2004) Influence of acetic anhydride on physicochemical, morphological and thermal properties of corn and potato starch. Food Chem 86(4):601–608

Diop CI et al (2011) Effects of acetic acid/acetic anhydride ratios on the properties of corn starch acetates. Food Chem 126(4):1662–1669

Subaric D et al (2014) Modification of wheat starch with succinic acid/acetic anhydride and azelaic acid/acetic anhydride mixtures I. Thermophysical and pasting properties. J Food Sci Technol 51(10):2616–2623.

Ali TM, Hasnain A (2015) Physicochemical, morphological, thermal, pasting, and textural properties of starch acetates. Food Rev Intl 32(2):161–180

Nasseri R et al (2020) Poly(lactic acid)/acetylated starch blends: effect of starch acetylation on the material properties. Carbohydr Polym 229:115453

Soni B et al (2016) Transparent bionanocomposite films based on chitosan and TEMPO-oxidized cellulose nanofibers with enhanced mechanical and barrier properties. Carbohydr Polym 151:779–789

Srinivasa PC, Tharanathan RN (2007) Chitin/Chitosan—safe, ecofriendly packaging materials with multiple potential uses. Food Rev Intl 23(1):53–72

Raafat D, Sahl HG (2009) Chitosan and its antimicrobial potential—a critical literature survey. Microb Biotechnol 2(2):186–201

Liang J et al (2017) Applications of chitosan nanoparticles to enhance absorption and bioavailability of tea polyphenols: a review. Food Hydrocolloids 69:286–292

Bonilla J et al (2013) Effects of chitosan on the physicochemical and antimicrobial properties of PLA films. J Food Eng 119(2):236–243

Sani IK et al (2019) Preparation of chitosan/zinc oxide/Melissa officinalis essential oil nano-composite film and evaluation of physical, mechanical and antimicrobial properties by response surface method. Polymer Test 79.

Abdollahi M et al (2012) A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J Food Eng 111(2):343–350

Ojagh SM et al (2010) Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem 122(1):161–166

Wang Y et al (2021) Preparation, characterization, and 3D printing verification of chitosan/halloysite nanotubes/tea polyphenol nanocomposite films. Int J Biol Macromol 166:32–44

López de Dicastillo C et al (2013) Immobilization of green tea extract on polypropylene films to control the antioxidant activity in food packaging. Food Res Int 53(1):522–528

Gao HX et al (2019) A functional polysaccharide film forming by pectin, chitosan, and tea polyphenols. Carbohydr Polym 215:1–7

Zhang W, Jiang W (2020) Antioxidant and antibacterial chitosan film with tea polyphenols-mediated green synthesis silver nanoparticle via a novel one-pot method. Int J Biol Macromol 155:1252–1261

Lim SH, Hudson SM (2004) Synthesis and antimicrobial activity of a water-soluble chitosan derivative with a fiber-reactive group. Carbohydr Res 339(2):313–319

Kong M et al (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144(1):51–63

Wei D et al (2009) The synthesis of chitosan-based silver nanoparticles and their antibacterial activity. Carbohydr Res 344(17):2375–2382

Acknowledgements

This project was supported by “the Fundamental Research Funds for the Central Universities” (2572019BL01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Zhai, W., Cui, L. et al. Physicochemical properties and antibacterial activity of polylactic acid/starch acetate films incorporated with chitosan and tea polyphenols. Polym. Bull. 80, 13319–13341 (2023). https://doi.org/10.1007/s00289-023-04691-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-04691-y