Abstract

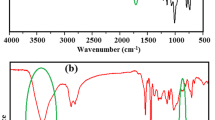

(2E,6E)2,6-Bis(4-amino benzylidene)cyclohexanone (BABC) was synthesized and used as a curing agent for tetrafunctional epoxy resin of bisphenol-C-formaldehyde (EBCF). Cured resin (EBCF–BABC) was characterized by FTIR, DSC and TGA techniques. No glass transition temperature was clearly detected due to overlapping of degradation steps with baseline shifting resulted distorted broad endothermic transition centered at about 236 °C and further was supplemented by TGA thermogram showing weight loss at that temperature. EBCF–BABC is thermally stable up to 175 °C and followed two-step degradation reactions. The first step has involved about 20% weight loss over 175–350 °C with temperature of maximum weight loss at about 217 °C. Similarly, the second step has involved about 52% weight loss over 350–500 °C with temperature of maximum weight loss at 412 °C. A 5.24-mm-thick glass fabric composite (G–EBCF–BABC) showed 140 MPa tensile strength, 192.3 MPa flexural strength, 7.524 GPa flexural modulus, 33.3 kJ m−2 impact strength, 38 Barcol hardness, 9 kV mm−1 electric strength, 3.6 × 1012 Ω cm volume resistivity and 12.4% equilibrium water absorption. Good thermomechanical, electrical and excellent hydrolytic stability of G–EBCF–BABC signified its usefulness for low load-bearing housing, electrical and electronic and marine applications.

Similar content being viewed by others

References

Faghihi K, Moghanian H (2010) Synthesis and characterization of new optically active poly(amide-imide)s based on N,N′-(pyromellitoyl)-bis-l-amino acids and 1,3,4-oxadiazole moieties. Des Monomers Polym 13:207–220

Faghihi K, Feyzi A, Isfahani HN (2010) Synthesis and characterization of new optically active poly(amide-imide)s based on N,N′-(bicyclo[2]oct-7-ene-2,3,5,6-tetra carboxylic)-bis-l-2-aminobutyric acid. Des Monomers Polym 13:131–142

Balakrishnan PS, Murugavel SC (2009) Spectral, thermal, and photoreactivity studies on epoxy resin containing benzylidene units in the main chain. J Appl Polym Sci 111:2340–2344

Faghihi K, Mozafari Z (2008) Synthesis and properties of novel photosensitive poly (amide-imide) s containing chalcone moiety and aromatic diamines in the main chain. Turk J Chem 32:673–683

Natansohn A, Rochon P (2002) Photoinduced motions in azo-containing polymers. Chem Rev 102:4139–4176

Gupta P, Trenor SR, Long TE, Wilkes GL (2004) In situ photo-cross-linking of cinnamate functionalized poly (methyl methacrylate-co-2-hydroxyethyl acrylate) fibers during electrospinning. Macromolecules 37:9211–9218

Hajibeygi M, Faghihi K, Shabanian M (2011) Synthesis and characterization of novel heat resistance poly(amide-imide)s from N,N′-[2,5-bis(4-aminobenzylidene)cyclopentanone] bistrimellitimide acid and various aromatic diamines. J Appl Polym Sci 121:2877–2885

Duvvuru D, Pinto N, Gomez C, Betzer J-F, Retailleau P, Voituriez A, Marinetti A (2012) Heterocyclic spiranes and dispiranes via enantioselective phosphine-catalyzed [3+2] annulations. Adv Synth Catal 354:408–414

Wu CC, Lee WJ (2010) Synthesis and properties of copolymer epoxy resins prepared from copolymerization of bisphenol-A, epichlorohydrin, and liquefied dendrocalamus latiflorus. J Appl Polym Sci 116:2065–2073

Lin CH, Huang JM, Wang CS (2002) Synthesis, characterization and properties of tetramethyl stilbene-based epoxy resins for electronic encapsulation. Polymer 43:2959–2967

Su WF, Lee YC, Pan WP (2002) Thermal properties of phthalic anhydride-and phenolic resin-cured rigid rod epoxy resins. Thermochim Acta 392:395–398

Huang X, Patham B (2013) Experimental characterization of a curing thermoset epoxy-anhydride system-Isothermal and nonisothermal cure kinetics. J Appl Polym Sci 127:1959–1966

Shokralla SA, Al-Muaikel NS (2010) Thermal properties of epoxy (DGEBA)/phenolic resin (novolac) blends. Arab J Sci Eng 35:7–14

Bajpai P, Bajpai M (2010) Development of a high performance hybrid epoxy silicone resin for coatings. Pigment Resin Technol 39:96–100

Tao Z, Yang S, Ge Z, Chen J, Fan L (2007) Synthesis and properties of novel fluorinated epoxy resins based on 1,1-bis(4-glycidylesterphenyl)-1-(3′-trifluoromethylphenyl)-2,2,2-trifluoro ethane. Eur Polym J 43:550–560

Samanta B, Maity T, Dalai S, Banthia A (2008) Influences of amine-terminated oligomers on glass fibre-epoxy composite. Pigment Resin Technol 37:3–8

Mishra G, Mohapatra S, Behera P, Dash B, Mohanty U, Ray B (2010) Environmental stability of GFRP laminated composites: an emphasis on mechanical behaviour. Aircr Eng Aerosp Technol 82:258–266

Thulasiraman V, Rakesh S, Sarojadevi M (2009) Synthesis and characterization of chlorinated soy oil based epoxy resin/glass fiber composites. Polym Compos 30:49–58

Patel JP, Parsania PH (2017) Fabrication and comparative mechanical, electrical and water absorption characteristic properties of multifunctional epoxy resin of bisphenol-C and commercial epoxy-treated and-untreated jute fiber-reinforced composites. Polym Bull 74(2):485–504

Wongajaiyen T, Brostow W, Chonkaew W (2018) Tensile properties and wear resistance of epoxy nanocomposites reinforced with cellulose nanofibers. Polym Bull 75:2039–2051

Bilyeu B, Brostow W, Menard KP (1999) Epoxy thermosets and their applications. I. Chemical structures. J Mater Educ 21:281–286

Bilyeu B, Brostow W, Menard KP (2000) Epoxy thermosets and their applications. II. Thermal analysis. J Mater Educ 22:107–129

Bilyeu B, Brostow W, Menard KP (2001) Epoxy thermosets and their applications. III. Kinetic equations and models. J Mater Educ 23:189–204

Bilyeu B, Brostow W, Menard KP (2002) Separation of gelation from vitrification in curing of a fiber-reinforced epoxy composite. Polym Compos 23:1111–1119

Tomuta AM, Ramis X, Ferrando F, Serra A (2012) The use of dihydrazides as latent curing agents in diglycidyl ether of bisphenol A coatings. Prog in Org Coat 74:59–66

Jens R, George GA, Frederich V (2013) Curing kinetics and thermomechanical behaviour of co-anhydride cured aminoglycidyl epoxy resins. Polym Int 52(2003):1758–1766

Musto P, Martuscelli E, Ragosta G, Mascia L (2001) Cure kinetics and ultimate properties of a tetrafunctional epoxy resin toughened by a perfluoro-ether oligomer. Polymer 42:5189–5198

Artner J, Ciesielski M, Walter O, Döring M, Perez RM, Sandler JKW, Altstädt V, Schartel B (2008) A Novel DOPO-based diamine as hardener and flame retardant for epoxy resin systems. Macromol Mater Eng 293(6):503–514

Liu W, Qiu Q, Wang J, Huo Z, Sun H (2008) Curing kinetics and properties of epoxy resin–fluorenyl diamine. Polymer 49:4399–4405

Xie MR, Wang ZG, Zhao YF (2001) Synthesis and properties of a novel, liquid, trifunctional, cycloaliphatic epoxide. J Polym Sci Part A Polym Chem 39:2799–2804

Lin LL, Ho TM, Wang CS (1997) Synthesis of novel trifunctional epoxy resins and their modification with polydimethylsiloxane for electronic application. Polymer 38:1997–2003

Wang CS, Li MC (1998) Synthesis and modification of a naphthalene-containing trifunctional epoxy resin for electronic applications. J Appl Polym Sci 70:1907–1921

Vogel AI, Tatchell AR, Funis BS, Hannaford AJ, Smith PWG (1998) Vogel’s textbook of practical organic chemistry, 5th edn. Addison Wesley Longman Ltd., London, p 395

Patel JP, Adroja PP, Parsania PH (2013) Synthesis and physico-chemical study of multifunctional cardo epoxy resin and its jute fiber reinforced silica filled and unfilled composites. J Polym Mater 30:53–64

Patel Jignesh P, Parsania PH (2019) Synthesis, spectral and thermal study of (2E,6E)-2,6-bis(4-amino benzylidene)cyclohexanone. World Sci News 124(2):312–318

Ellis B (1993) Chemistry and technology of epoxy resins. Springer, Berlin, pp 1–36

Hamerton I (1996) Recent developments in epoxy resins. Smithers Rapra Publishing, Akron

May CA (1987) Epoxy resins: chemistry and technology. CRC Press, Boca Raton, FL, USA

Lee H, Neville K (1972) Handbook of epoxy resin. McGraw Hill, New York

Patel Jignesh P, Parsania PH (2014) Spectral and thermal behavior of aromatic and aliphatic amines cured cardo group containing multifunctional epoxy Resin. Adv Polym Technol 33:1–5

Patel JP, Bhatt RD, Parsania PH (2014) Studies on bismaleamic acids cured tetrafunctional epoxy resin of bisphenol-C and glass-epoxy composites. Adv Polym Technol 33:S1. https://doi.org/10.1002/adv.21457(E1-9)

Anderson DA, Freeman ES (1961) Kinetics of the thermal degradation of polystyrene and polyethylene. J Polym Sci 54:253–260

Grassie N, Guy MI, Tennent NH (1986) Degradation of epoxy polymers: part 4-thermal degradation of bisphenol-A diglycidyl ether cured with ethylene diamine. Polym Degrad Stab 14:125–137

Levchik SV, Camino GM, Luda PL, Costa B, Costes Y, Henry Y, Morel E, Muller G (1995) Mechanistic study of thermal behavior and combustion performance of epoxy resins: I homopolymerized TGDDM. Polym for Adv Technol 6:53–62

Kagathara VM, Parsania PH (2002) Thermal analysis of cured chloro epoxy resins and epoxy–acrylate–styrene copolymers. Polym Test 21:659–663

Adroja PP, Koradiya SB, Parsania PH (2011) Synthesis, curing behavior and characterization of epoxyacrylate and triethylamine cured epoxy resin of 1,1′-bis(3-methyl-4-hydroxy phenyl) cyclohexane. Polym Plast Technol Eng 50:52–58

Mer PK, Parsania PH (2011) Synthesis and thermal study of cured epoxy-acrylate-maleate, unsaturated polyester and their interpenetrating networks of varying compositions. Polym Plast Technol Eng 50:282–287

Dutta S, Karak N, Baruah S (2010) Jute-fiber-reinforced polyurethane green composites based on Mesua ferrea L. seed oil. J App Polym Sci 115:843–850

Ray D, Sarkar BK, Das S, Rana AK (2002) Dynamic mechanical and thermal analysis of vinylester-resin-matrix composites reinforced with untreated and alkali-treated jute fibres. Compos Sci Technol 62:911–917

Mavani SI, Mehta NM, Parsania PH (2006) Synthesis and physicochemical study of bisphenol-C-formaldehyde-toluene diisocyanate polyurethane–jute and jute–rice husk/wheat husk composites. J Appl Polym Sci 101:2363–2370

Biro DA, McLean P, Deslandes Y (1991) Application of the microbond technique: characterization of carbon fiber-epoxy interfaces. Polym Eng Sci 31:1250–1260

International Cast Polymer Alliance (2003) Solid surface properties and applications. Arlington, ICPA, p 8

Brostow W, Hagg Lobland HE (2010) Brittleness of materials: implications for composites and relation to impact strength. J Mater Sci 45:242–250

Bao LR, Yee AF (2008) Effect of temperature on moisture absorption in a bismalimide resin and its carbon fiber composites. Polymer 43:3987–3997

Espert A, Vilaplana F, Karlsson S (2004) Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos Part A Appl Sci Manuf 35:1267–1276

Gassan J, Bledzki AK (1997) The influence of fiber-surface treatment on mechanical properties of jute-polypropylene composites. Compos Part A Appl Sci Manuf 28:1001–1005

Collings TA (1994) Moisture absorption–Fickian diffusion kinetics and moisture profiles. In: Jones FR (ed) Handbook of polymer fibre composites. Longman Scientific and Technical, UK, pp 366–371

Crank J, Park GS (1968) Diffusion in polymers. Academic Press, New York

Tyberg CS, Bergeron K, Sankarapandian M, Shih P, Loos AC, Dillard DA, McGrath J, Riffle J, Sorathia U (2000) Structure property relationships of void-free phenolic–epoxy matrix materials. Polymer 41:5053–5062

Acknowledgements

Authors are thankful to Director TIPCO industries Ltd., Valsad—Gujarat, India, for testing facilities and UGC—New Delhi and DST—New Delhi for instrumentation grants.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Parsania, P.H., Patel, J.P. Fabrication and physicochemical properties of glass fabric–multifunctional epoxy resin composite. Polym. Bull. 77, 1667–1679 (2020). https://doi.org/10.1007/s00289-019-02809-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02809-9