Abstract

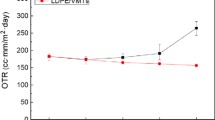

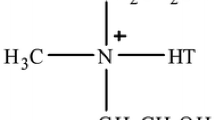

The effects of dicumyl peroxide/vinyltriethoxysilane treatment and nanoclay content were investigated for low-density polyethylene (LDPE)/clay nanocomposites. LDPE was treated with 0.1 phr of DCP with, respectively, 1 phr and 3 phr VTES (System A), and with 0.2 phr of DCP with the same amounts of VTES (System B), and then mixed with different contents (1, 3, and 5 wt%) of modified clay (Cloisite 15A). The morphology and extent of crosslinking, as well as the thermal, mechanical, and thermomechanical properties were studied. X-ray diffraction results of all the VTES-treated LDPE/clay nanocomposites showed an increase in interlayer spacing, which indicates that the polymer chains were intercalated between the clay layers. Transmission electron microscopy micrographs of System B showed some evidence of exfoliated clay layers, indicating that the system exhibited a mixed morphology. The clay-containing samples had better thermal stability than LDPE, but the thermal stability did not differ much for the two systems. VTES observably decreased the melting enthalpy of LDPE, while the presence of clay had little influence on this value. This is somewhat contrary to the gel content results that showed a decrease in the extent of crosslinking in the presence of and with increasing clay content. VTES/DCP treatment and the presence of clay observably changed the dynamic mechanical and tensile behaviour of the LDPE.

Similar content being viewed by others

References

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641. doi:10.1016/j.progpolymsci.2003.08.002

Grigoriadi K, Giannakas A, Ladavos A, Barkoula NM (2013) Thermomechanical behaviour of polymer/layered silicate clay nanocomposites based on unmodified low density polyethylene. Polym Eng Sci 53:301–308. doi:10.1002/pen.23264

Fermeglia M, Ferrone M, Pricl S (2003) Computer simulation of nylon-6/organoclay nanocomposites: prediction of the binding energy. Fluid Phase Equilib 212:315–329. doi:10.1016/S0378-3812(03)00273-5

Meneghetti P, Qutubuddin S (2006) Synthesis, thermal properties and applications of polymer-clay nanocomposites. Thermochim Acta 442:74–77. doi:10.1016/j.tca.2006.01.017

Ray S, Quek SY, Easteal A, Chen XD (2006) The potential use of polymer-clay nanocomposites in food packaging. Int J Food Eng 2:1–11. doi:10.2202/1556-3758.1149

Arunvisut S, Phummanee S, Somwangthanaroj A (2007) Effect of clay on mechanical and gas barrier properties of blown film LDPE/clay nanocomposites. J Appl Polym Sci 106:2210–2217. doi:10.1002/app.26839

Yeh JM, Chang KC (2008) Polymer/layered silicate nanocomposite anticorrosive coatings. J Ind Eng Chem 14:275–291. doi:10.1016/j.jiec.2008.01.011

Pavlidou S, Papaspyrides CD (2008) A review on polymer-layered silicate nanocomposites. Prog Polym Sci 33:1119–1198. doi:10.1016/j.progpolymsci.2008.07.008

Kim JK, Park HS, Rhee DK, Ham SJ, Lee KJ, Yoo PJ, Park JH (2012) Ultrathin nanoclay film with tunable thickness as barrier layers in organic light emitting devices. J Mater Chem 22:7718–7723. doi:10.1039/c2jm00047d

Tamboli SM, Mhaske ST, Kale DD (2004) Crosslinked polyethylene. Indian J Chem Technol 11:853–864

Barzin J, Azizi H, Morshedian J (2007) Preparation of silane-grafted and moisture crosslinked low density polyethylene. Part II: electrical, thermal and mechanical properties. Polymer-Plast Technol Eng 46:305–310. doi:10.1080/03602550601155815

Anbarasan R, Babot O, Maillard B (2004) Crosslinking of high-density polyethylene in the presence of organic peroxides. J Appl Polym Sci 93:75–81. doi:10.1002/app.20390

Shah GB, Fuzail M, Anwar J (2004) Aspects of the crosslinking of polyethylene with vinyl silane. J Appl Polym Sci 92:3796–3803. doi:10.1002/app.20381

Shukri TM, Mosnacek J, Basfar AA, Bahattab MA, Noireaux P, Courdreuse A (2008) Flammability of blends of low-density polyethylene and ethylene vinyl acetate crosslinked by both dicumyl peroxide and ionizing radiation for wire and cable applications. J Appl Polym Sci 109:167–173. doi:10.1002/app.28080

Fabris FW, Stedile FC, Mauler RS, Nachtigall SMB (2004) Free radical modification of LDPE with vinyltriethoxysilane. Eur Polymer J 40:1119–1126. doi:10.1016/j.eurpolymj.2004.01.008

Rezanavaz R, Aghjeh R, Babaluo AA (2010) Rheology, morphology, and thermal behaviour of HDPE/clay nanocomposites. Polym Compos 31:1028–1036. doi:10.1002/pc.20889

Durmus A, Kasgoz A, Macosko CW (2008) Mechanical aspect of linear polyethylene (LLDPE)/clay nanocomposites: estimation of aspect ratio and interfacial strength by composites models. J Macromol Sci Part B Phys 47:608–619. doi:10.1080/00222340801957780

Hwang KJ, Park JW, Kim I, Ha CS, Kim GH (2006) Effect of a compatibilizer on the microstructure and properties of partially biodegradable LDPE/aliphatic polyester/organoclay nanocomposites. Macromol Res 14:179–186. doi:10.1007/BF03218506

Supri AG, Salmah H, Hazwan K (2008) Low density polyethylene-nanoclay composites: The effect of poly(acrylic acid) on mechanical properties, XRD, morphology properties and water absorption. Malays Polymer J 3:39–53

Teymouri Y, Nazockdast H (2011) The effect of process parameter on physical and mechanical properties of commercial low density polyethylene/ORG-MMT nanocomposites. J Mater Sci 46:6642–6647. doi:10.1007/s10853-011-5616-3

Stoeffler K, Lafleur PG, Sarazin FP, Bureau MN, Denault J (2011) Micro-mechanisms of deformation in polyethylene/clay micro- and nanocomposites. Compos A 42:916–927. doi:10.1016/j.compositesa.2011.03.020

Pakdaman AS, Morshedian J, Jahani Y (2012) Influence of the silane crafting of polyethylene on the morphology, barrier, thermal, and rheological properties of high- density polyethylene/organoclay nanocomposites. J Appl Polym Sci 125:E305–E313. doi:10.1002/app.36367

Wang H, Fang P, Chen Z, Wang S, Xu Y, Fang Z (2008) Effect of silane grafting on the microstructure of high-density polyethylene/organically modified montmorillonite nanocomposites. Polym Int 57:50–56. doi:10.1002/pi.2310

Lu H, Hu Y, Li M, Chen Z, Fan W (2006) Structure characteristics and thermal properties of silane-grafted-polyethylene/clay nanocomposite prepared by reactive extrusion. Compos Sci Technol 66:3035–3039. doi:10.1016/j.compscitech.2006.01.018

Azizi H, Morshedian J, Barikani M, Wagner MH (2010) Effect of layered silicate nanoclay on the properties of silane crosslinked linear low-density polyethylene (LLDPE). eXPRESS. Polymer Lett 4:252–262. doi:10.3144/expresspolymlett.2010.32

Rezanejad S, Kokabi M (2007) Shape memory and mechanical properties of cross-linked polyethylene/clay nanocomposites. Eur Polymer J 43:2856–2865. doi:10.1016/j.eurpolymj.2007.04.031

LU H, HU Y, Yang L, Wang Z, Chen Z, Fan W (2005) Preparation and thermal characteristics of silane-grafted polyethylene/montmorillonite nanocomposites. J Mat Sci 40:43–46. doi:10.1007/s10853-005-5685-2

Chen WC, Lai SM, Qiu RY, Tang SX (2012) Role of silane crosslinking on the properties of melt blended metallocene polyethylene-g-silane/clay nanocomposites at various clay contents. J Appl Polym Sci 124:2669–2681. doi:10.1002/app.35261

Mirabella FM, Bafna A (2002) Determination of the crystallinity of polyethylene/α-olefin copolymers by thermal analysis: Relationship of the heat of fusion of 100% polyethylene crystal and the density. J Polym Sci Part B Polym Phys 40:1637–1643

Singh B, Sharma N (2008) Mechanistic implications of plastic degradation. Polym Degrad Stab 93:561–584. doi:10.1016/j.polymdegradstab.2007.11.008

Abdelwahad M, Agag T, Akelah A, Takeichi T (2012) Synthesis and characterization of methyl methacrylate modified vinylester resin-clay nanocomposites. Open Macromol J 6:20–27

Alagar M, Abdul Majeed SM, Nagendiran S (2005) Preparation and characterization of vinyltriethoxysilane grafted ethylene propylene diene terpolymer/linear low density polyethylene (EPDM-g-VTES/LLDPE) blends. Polymer Adv Technol 16:582–591. doi:10.1002/pat.626

Kusmono ZA, Mohd Ishak, Chow WS, Rochmadi TT (2010) Effect of clay modification on the morphology, mechanical, and thermal properties of polyamide 6/polypropylene/montmorillonite nanocomposites. Polym Compos 31:1156–1167. doi:10.1002/pc.20902

Zhao C, Qin H, Gong F, Feng M, Zhang S, Yang M (2005) Mechanical, thermal and flammability of polyethylene/clay nanocomposites. Polym Degrad Stab 87:183–189. doi:10.1016/j.polymdegradstad.2004.08.005

Onischuk AA, Panfilov VN (2001) Mechanism of thermal decomposition of silanes. Russ Chem Rev 70:321–332. doi:10.1070/RC2001v070n04ABEH000603

Zanetti M, Bracco P, Costa L (2004) Thermal degradation behaviour of PE/clay nanocomposites. Polym Degrad Stab 85:657–665. doi:10.1016/j.polymdegradstab.2004.03.005

Nese A, Sen S, Tasdelen MA, Nugay N, Yagci Y (2006) Clay-PMMA nanocomposites by radical polymerization using intercalated phenacyl pyridinium salt initiators. Macromol Chem Phys 207:820–826. doi:10.1002/macp.200500511

Wang L, Wang K, Chen L, Zhang Y, He C (2006) Preparation, morphology and thermal/mechanical properties of epoxy/nanoclay composite. Compos A 37:1890–1896. doi:10.1016/j.compsitesa.2005.12.020

Molefi JA, Luyt AS (2010) Comparison of the influence of copper micro- and nano-particles on the mechanical properties of polyethylene/copper composites. J Mat Sci 45:82–88. doi:10.1007/s10853-009-3894-9

Mark J, Ngai K, Graessley W, Mandelkern L, Samulski E, Koenig J, Wignall G (2003) Physical properties of polymers, 3rd edn. Cambridge University Press, Cambridge

Nouri MR (2005) Thermal and dynamic mechanical properties of a polypropylene random copolymer. Iran Polym J 14:485–493

Mohanty S, Nayak SK (2007) Melt blended polystyrene/layered silicates nanocomposites: Effect of clay modification on the mechanical, thermal, morphological and viscoelastic behaviour. J Thermoplast Compos Mat 20:175–193. doi:10.1177/0892705707073180

Morawiec J, Pawlak A, Slouf M, Galeski A, Piorkowska E, Krasnikowa N (2005) Preparation and properties of compatibilized LDPE/organo-modified montmorillonite nanocomposites. Eur Polymer J 41:1115–1122. doi:10.1016/j.eurpolymj.2004.11.011

Hidalgo M, Beltran MI, Reinecke H, Mijango C (1998) Thermal and mechanical properties of silane-crosslinked poly (vinylchloride). J Appl Polym Sci 70:865–872

Acknowledgments

The National Research Foundation in South Africa and the University of the Free State are acknowledged for financial support of this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sibeko, M.A., Luyt, A.S. Preparation and characterisation of vinylsilane crosslinked low-density polyethylene composites filled with nano clays. Polym. Bull. 71, 637–657 (2014). https://doi.org/10.1007/s00289-013-1083-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-1083-0