Abstract

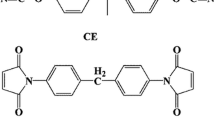

A novel kind of high performance composite of nano-Si3N4/epoxidized silane/cyanate ester (nano-Si3N4/ESi/BCE) has been developed. The mechanical, thermal and dielectric properties of the composite were investigated. The impact and flexural strength values of the nano-Si3N4/ESi/BCE system are 15.7 kJ/m2 and 114.2 MPa, respectively, which are increased by about 56 and 21 % compared with those of pure BCE resin, respectively. The glass transition temperature of the nano-Si3N4/ESi/BCE system is 278.7 °C, which is nearly 30 °C higher than that of pure BCE resin. In addition, nano-Si3N4/ESi/BCE system also exhibits lower and more stable dielectric loss than pure BCE resin over the testing frequency from 10 to 50 MHz. All these improvements of properties are closely correlated to the synergistic effects between nano-Si3N4 and ESi in the BCE matrix. The novel nano-Si3N4/ESi/BCE system with the outstanding integrated properties shows great potentialities to be applied in the field of electronic packaging.

Similar content being viewed by others

References

Lu SH, Zhou ZW, Fang L, Liang GZ, Wang JL (2007) Preparation and properties of cyanate ester modified by epoxy resin and phenolic resin. J Appl Polym Sci 103:3150–3156

Mondragón I, Solar L, Nohales A, Vallo CI, Gómez CM (2006) Properties and structure of cyanate ester/polysulfone/organoclay nanocomposites. Polymer 47:3401–3409

Zhang XY, Gu AJ, Liang GZ, Zhou DX, Li Y (2011) Liquid crystalline epoxy resin modified cyanate ester for high performance electronic packaging. J Polym Res 18:1441–1450

Chang HC, Lin HT, Lin CH (2012) Benzoxazine-based phosphinated bisphenols and their application in preparing flame-retardant, low dielectric cyanate ester thermosets. Polym Chem 3:970–978

Guan QB, Gu AJ, Liang GZ, Li Y, Fan L, Gong YW (2011) Curing kinetics and mechanism of novel high performance hyper branched polysiloxane/bismaleimide/cyanate ester resins for resin transfer molding. J Appl Polym Sci 122:304–312

Tao QS, Gan WJ, Yu YF, Wang MH, Tang XL, Li SJ (2004) Viscoelastic effects on the phase separation in thermoplastics modified cyanate ester resin. Polymer 45:3505–3510

Zeng MF, Sun XD, Yao XD, Wang Y, Zhang MZ, Wang BY, Qi CZ (2010) Modification of cyanate ester resin by hydroxyl-terminated liquid butadiene-acrylonitrile rubber and free volume properties of their composites. J Appl Polym Sci 115:338–345

Xia R, Zhang YC, Zhu QR, Qian JS, Dong QN (2008) Surface modification of nano-Sized silicon nitride with BA-MAA-AN tercopolymer. J Appl Polym Sci 107:562–570

Shi G, Zhang MQ, Rong MZ, Wetzelc B, Friedrich K (2003) Friction and wear of low nanometer Si3N4 filled epoxy composites. Wear 254:784–796

Luo Y, Yu XY, Dong XM, Rong MZ, Zhang MQ (2010) Effect of nano-Si3N4 surface treatment on the tribological performance of epoxy composite. Express Polym Lett 4:131–140

He H, Fu RL, Shen Y, Han YC, Song XF (2007) Preparation and properties of Si3N4/PS composites used for electronic packaging. Compos Sci Technol 67:2493–2499

Rangari VK, Shaik MY, Mahfuz H, Jeelani S (2009) Fabrication and characterization of high strength nylon-6/Si3N4 polymer nanocomposite fibers. Mat Sci Eng A-struct 500:92–97

Xu GC, Wang J, JI XL, Xiong JY, Li F (2007) Effect of nano-silicon nitride on the mechanical and electric properties of polypropylene nanocomposite. J Compos Mater 41:2213–2223

Tai YL, Qian JS, Miao JB, Xia R, Zhang YC, Yang ZJ (2012) Preparation and characterization of Si3N4/SBR nanocomposites with high performance. Mater Design 34:522–527

Yan HX, Li PB, Zhang JP, Ning RC (2010) Mechanical Properties of novel bismaleimide nanocomposites with Si3N4 nanoparticles. J Reinf Plast Comp 29:1515–1522

Vejayakumaran P, Rahma IA, Sipaut CS, Chee CK (2008) Structural and thermal characterizations of silica nanoparticles grafted with pendant maleimide and epoxide groups. J Colloid Interf Sci 328:81–91

Yan HX, Li PB, Ning RC, Ma XY, Zhang JP (2008) Tribological properties of bismaleimide composites with surface-modified SiO2 nanoparticles. J Appl Polym Sci 110:1375–1381

Xin F, Li L (2012) The role of a silane coupling agent in carbon nanotube/polypropylene composites. J Compos Mater 46:3267–3275

Heo GY, Park SJ (2012) Effect of coupling agents on thermal, flow, and adhesion properties of epoxy/silica compounds for capillary underfill applications. Powder Technol 230:145–150

Lin OH, Akil HM, Mohd Ishak ZA (2011) Surface-activated nanosilica treated with silane coupling agents/polypropylene composites: mechanical, morphological, and thermal studies. Polym composite 32:1568–1583

Jia QM, Zheng M, Xu CZ, Chen HX (2006) The mechanical properties and tribological behavior of epoxy resin composites modified by different shape nanofillers. Polym Adv Technol 17:168–173

Wei Q, Miao JB, Cheng GJ, Qian JS (2012) Surface modification of nano-sized silicon nitride with HFMA–MMA–VTMS tercopolymer and their dispersion in FKM composites. Asian J Chem 24:2487–2492

Yang CZ, Gu AJ, Song HW, Fang ZXZ (2007) Novel modification of cyanate ester by epoxidized polysiloxane. J Appl Polym Sci 105:2020–2026

Goertzen WK, Kessler MR (2008) Dynamic mechanical analysis of fumed silica/cyanate ester nanocomposites. Compos Part A Appl S 39:761–768

Rimdusit S, Ishida H (2000) Development of new class of electronic packaging materials based on ternary systems of benzoxazine, epoxy, and phenolic resins. Polymer 41:7941–7949

Miyagawa H, Misra M, Drzal LT, Mohanty AK (2005) Novel biobased nanocomposites from functionalized vegetable oil and organically-modified layered silicate clay. Polymer 46:445–453

Sun ZQ, Huang PZ, Gu AJ, Liang GZ, Yuan L, Dai SK (2012) Novel high-performance wave-transparent aluminum phosphate/cyanate ester composites. J Appl Polym Sci 123:1576–1583

Acknowledgments

This work was financially supported by the Aerospace Science Foundation of China (2011ZF53064) and the Program of Science and Technology Plan of Xi’an (YF07005) .

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, H., Zhang, M., Liu, C. et al. Nano-Si3N4/epoxidized silane/cyanate ester composites for electronic packaging. Polym. Bull. 70, 2923–2933 (2013). https://doi.org/10.1007/s00289-013-0997-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-013-0997-x