Abstract

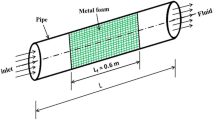

Metal foam heat exchangers have attracted a great deal of interest in numerous engineering fields due to their superior thermal capabilities. In the present study, the heat transfer characteristics of a double-pipe heat exchanger with metal foam insert are numerically investigated. The Forchheimer-extended Darcy equation and the local thermal non-equilibrium (LTNE) model are used to predict the fluid and energy transports, respectively. Thermal resistance of the interface solid wall is considered, while the porous-solid boundary follows the continuity principles. The commercial software FLUENT with specific user defined functions (UDFs) is adopted to implement the simulation. Configurations with uniform foam structure are firstly used to analyze the effects of flow arrangement, foam structural parameters (porosity and pore density) and thermal conductivity on the heat exchanger effectiveness and total pressure drop. Then, graded foam structure along the radius is proposed to further make use of the heat transfer potential of metal foam. The overall thermal performance with increasing and decreasing arrangements of porosity and pore density is assessed. The results indicate that the counter flow shows good performance, with 37.5% higher than the parallel flow in effectiveness. The effectiveness and total pressure drop present monotonic variation with the foam structural parameters for the uniform designs, while maximum performance factor occurs at 15 PPI. The effectiveness has a reduction after gradual increase to a peak 0.89 with the increasing of thermal conductivity of foam matrix. For the designs of graded foam structure, using lower porosity and small pore density at both side of the inner pipe wall shows better overall performance with the performance factors of 4.41 and 4.54.

Similar content being viewed by others

Abbreviations

- cf :

-

Specific heat, J kg−1 K−1

- CF :

-

Inertial coefficient

- d p :

-

Pore diameter, m

- h v :

-

Volumetric heat transfer coefficient, W m−3 K−1

- k :

-

Thermal conductivity, W m−1 K−1

- K :

-

Permeability, m2

- l :

-

Length of heat exchanger, m

- \( \dot{m} \) :

-

Mass flow rate, kg s−1

- p :

-

Pressure, Pa

- PP :

-

Pumping power, W

- Pr :

-

Prandtl number

- q :

-

Heat flux, W m−2

- Q :

-

Heat transfer rate, W

- Re d :

-

Reynolds number based on the pore diameter

- r 1, r 2, r 3 :

-

Radius of heat exchanger, m

- R :

-

Dimensionless r coordinate

- T :

-

Temperature, K

- U :

-

Velocity vector, m s−1

- U :

-

Dimensionless velocity

- \( \tilde{V} \) :

-

Volumetric flow rate, m3 s−1

- x, r :

-

Coordinates in flow region, m

- X :

-

Dimensionless x coordinate

- μ f :

-

Dynamic viscosity, kg m−1 s−1

- ρ :

-

Density, kg m−3

- ϕ :

-

Porosity

- ω :

-

Pore per inch, PPI

- θ :

-

Dimensionless temperature

- ε :

-

Heat exchanger effectiveness

- 1, 2:

-

Inner and annular pipes

- eff :

-

Effective

- f :

-

Fluid

- in:

-

Inlet

- out:

-

Outlet

- s :

-

Solid

- w :

-

Wall

References

Tan WC, Saw LH, Thiam HS, Xuan J, Cai Z, Yew MC (2018) Overview of porous media/metal foam application in fuel cells and solar power systems. Renew Sust Energ Rev 96:181–197

Gong L, Li Y, Bai Z, Xu M (2018) Thermal performance of micro-channel heat sink with metallic porous/solid compound fin design. Appl Therm Eng 137:288–295

Buonomo B, di Pasqua A, Ercole D, Manca O, Nardini S (2018) Numerical investigation on aluminum foam application in a tubular heat exchanger. Heat Mass Transf 54:2589–2597

Orihuela MP, Shikh Anuar F, Ashtiani Abdi I, Odabaee M, Hooman K (2018) Thermohydraulics of a metal foam-filled annulus. Int J Heat Mass Transf 117:95–106

Ouyang XL, Vafai K, Jiang PX (2013) Analysis of thermally developing flow in porous media under local thermal non-equilibrium conditions. Int J Heat Mass Transf 67:768–775

Dehghan M, Valipour MS, Saedodin S, Mahmoudi Y (2016) Thermally developing flow inside a porous-filled channel in the presence of internal heat generation under local thermal non-equilibrium condition: a perturbation analysis. Appl Therm Eng 98:827–834

Bağcı Ö, Arbak A, De Paepe M, Dukhan N (2018) Investigation of low-frequency-oscillating water flow in metal foam with 10 pores per inch. Heat Mass Transf 54:2343–2349

Li PC, Zhong JL, Wang KY, Zhao CY (2018) Analysis of thermally developing forced convection heat transfer in a porous medium under local thermal non-equilibrium condition: a circular tube with asymmetric entrance temperature. Int J Heat Mass Transf 127:880–889

Alkam MK, Al-Nimr MA (1999) Improving the performance of double-pipe heat exchangers by using porous substrates. Int J Heat Mass Transf 42:3609–3618

Allouache N, Chikh S (2006) Second law analysis in a partly porous double pipe heat exchanger. J Appl Mech 73:60–65

Chikh S, Allouache N (2016) Optimal performance of an annular heat exchanger with a porous insert for a turbulent flow. Appl Therm Eng 104:222–230

Targui N, Kahalerras H (2008) Analysis of fluid flow and heat transfer in a double pipe heat exchanger with porous structures. Energy Convers Manag 49:3217–3229

Targui N, Kahalerras H (2013) Analysis of a double pipe heat exchanger performance by use of porous baffles and pulsating flow. Energy Convers Manag 76:43–54

Milani Shirvan K, Ellahi R, Mirzakhanlari S, Mamourian M (2016) Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: numerical simulation and sensitivity analysis of turbulent fluid flow. Appl Therm Eng 109:761–774

Milani Shirvan K, Mirzakhanlari S, Kalogirou SA, Öztop HF (2017) Heat transfer and sensitivity analysis in a double pipe heat exchanger filled with porous medium. Int J Therm Sci 121:124–137

Jamarani A, Maerefat M, Jouybari NF, Nimvari ME (2017) Thermal performance evaluation of a double-tube heat exchanger partially filled with porous media under turbulent flow regime. Transp Porous Media 120:449–471

Chen X, Tavakkoli F, Vafai K (2015) Analysis and characterization of metal foam-filled double-pipe heat exchangers. Numer Heat Transfer A 68:1031–1049

Yang K, Vafai K (2011) Transient aspects of heat flux bifurcation in porous media: an exact solution. J Heat Transf 133(5):052602

Chen X, Xia XL, Sun C, Yan XW (2017) Transient thermal analysis of the coupled radiative and convective heat transfer in a porous filled tube exchanger at high temperatures. Int J Heat Mass Transf 108:2472–2480

Chen X, Wang FQ, Han YF, Yu RT, Cheng ZM (2018) Thermochemical storage analysis of the dry reforming of methane in foam solar reactor. Energy Convers Manag 158:489–498

Gangapatnam P, Kurian R, Venkateshan SP (2018) Numerical simulation of heat transfer in metal foams. Heat Mass Transf 54:553–562

Zhao CY, Lu W, Tassou SA (2006) Thermal analysis on metal-foam filled heat exchangers. Part II: tube heat exchangers. Int J Heat Mass Transf 49:2762–2770

Du YP, Qu ZG, Zhao CY, Tao WQ (2010) Numerical study of conjugated heat transfer in metal foam filled double-pipe. Int J Heat Mass Transf 53:4899–4907

Xu HJ, Qu ZG, Tao WQ (2014) Numerical investigation on self-coupling heat transfer in a counter-flow double-pipe heat exchanger filled with metallic foams. Appl Therm Eng 66:43–54

Banerjee A, Bala Chandran R, Davidson JH (2015) Experimental investigation of a reticulated porous alumina heat exchanger for high temperature gas heat recovery. Appl Therm Eng 75:889–895

Bala Chandran R, De Smith RM, Davidson JH (2015) Model of an integrated solar thermochemical reactor/reticulated ceramic foam heat exchanger for gas-phase heat recovery. Int J Heat Mass Transf 81:404–414

Alhusseny A, Turan A, Nasser A (2017) Rotating metal foam structures for performance enhancement of double-pipe heat exchangers. Int J Heat Mass Transf 105:124–139

Zaragoza G, Goodall R (2013) Metal foams with graded pore size for heat transfer applications. Adv Eng Mater 15:123–128

Kuznetsov AV, Nield DA (2015) Local thermal non-equilibrium effects on the onset of convection in an internally heated layered porous medium with vertical throughflow. Int J Therm Sci 92:97–105

Xu ZG, Qin J, Zhou X, Xu HJ (2018) Forced convective heat transfer of tubes sintered with partially-filled gradient metal foams (GMFs) considering local thermal non-equilibrium effect. Appl Therm Eng 137:101–111

Xu ZG, Gong Q (2018) Numerical investigation on forced convection of tubes partially filled with composite metal foams under local thermal non-equilibrium condition. Int J Therm Sci 133:1–12

Zheng ZJ, Li MJ, He YL (2015) Optimization of porous insert configurations for heat transfer enhancement in tubes based on genetic algorithm and CFD. Int J Heat Mass Transf 87:376–379

Siavashi M, Talesh Bahrami HR, Aminian E (2018) Optimization of heat transfer enhancement and pumping power of a heat exchanger tube using nanofluid with gradient and multi-layered porous foams. Appl Therm Eng 138:465–474

Wang B, Hong Y, Hou X, Xu Z, Wang P, Fang X, Ruan X (2015) Numerical configuration design and investigation of heat transfer enhancement in pipes filled with gradient porous materials. Energy Convers Manag 105:206–215

Bai X, Kuwahara F, Mobedi M, Nakayama (2018) A forced convective heat transfer in a channel filled with a functionally graded metal foam matrix. J Heat Transf 140:111702

Fend T, Pitz-Paal R, Reutter O, Bauer J, Hoffschmidt B (2004) Two novel high-porosity materials as volumetric receivers for concentrated solar radiation. Sol Energy Mater Sol Cells 84:291–304

Chen X, Xia X, Meng X, Dong X (2015) Thermal performance analysis on a volumetric solar receiver with double-layer ceramic foam. Energy Convers Manag 97:282–289

Roldán MI, Smirnova O, Fend T, Casas JL, Zarza E (2014) Thermal analysis and design of a volumetric solar absorber depending on the porosity. Renew Energy 62:116–128

Zhu Q, Xuan Y (2019) Improving the performance of volumetric solar receivers with a spectrally selective gradual structure and swirling characteristics. Energy 172:467–476

Wang P, Vafai K (2017) Modeling and analysis of an efficient porous media for a solar porous absorber with a variable pore structure. J Sol Energy Eng 139:051005

Du S, Ren QL, He YL (2017) Optical and radiative properties analysis and optimization study of the gradually-varied volumetric solar receiver. Appl Energy 207:27–35

Zhu F, Zhang C, Gong XL (2017) Numerical analysis on the energy storage efficiency of phase change material embedded in finned metal foam with graded porosity. Appl Therm Eng 123:256–265

Kumar A, Saha SK (2018) Latent heat thermal storage with variable porosity metal matrix: a numerical study. Renew Energy 125:962–973

Xu ZG, Zhao CY (2015) Experimental study on pool boiling heat transfer in gradient metal foams. Int J Heat Mass Transf 85:824–829

Zhao CY, Xu ZG (2016) Enhanced boiling heat transfer by gradient porous metals in saturated pure water and surfactant solutions. Appl Therm Eng 100:68–77

Alhusseny ANM, Nasser AG, Al-zurf NMJ (2018) High porosity metal foams: potentials, applications, and formulations. In: Ghrib T (ed) Porosity: process, technologies and applications. InTechOpen, London

Boomsma K, Poulikakos D (2001) On the effective thermal conductivity of a threedimensionally structured fluid-saturated metal foam. Int J Heat Mass Transf 44:827–836

Calmidi VV, Mahajan RL (2000) Forced convection in high porosity metal foams. J Heat Transf 122:557–565

Calmidi VV (1998) Transport phenomena in high porosity metal foams. University of Colorado: UMI

Zukauskas AA (1987) Convective heat transfer in cross-flow. In: Kakac S, Shah RK, Aung W (eds) Handbook of single-phase convective heat transfer. Wiley, New York

Lu W, Zhao CY, Tassou SA (2006) Thermal analysis on metal-foam filled heat exchangers. Part I: metal-foam filled pipes. Int J Heat Mass Transf 49:2751–2761

Alazmi B, Vafai K (2002) Constant wall heat flux boundary conditions in porous media under local thermal non-equilibrium conditions. Int J Heat Mass Transf 45:3071–3087

Zhang HJ, Zou ZP, Li Y, Ye J (2011) Preconditioned density-based algorithm for conjugate porous/fluid/solid domains. Numer Heat Transfer A 60:129–153

Garrity PT, Klausner JF, Mei R (2010) Performance of aluminum and carbon foams for air side heat transfer augmentation. J Heat Transf 132:121901

Acknowledgments

This study is supported by the National Natural Science Foundation of China (No. 51806046, No. 51776053, No. 51536001) and the China Postdoctoral Science Foundation (No. 2018 M630350).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Xia, X., Sun, C. et al. Performance evaluation of a double-pipe heat exchanger with uniform and graded metal foams. Heat Mass Transfer 56, 291–302 (2020). https://doi.org/10.1007/s00231-019-02700-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-019-02700-3