Abstract

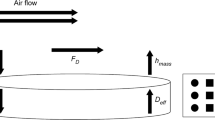

This paper presents an experimental and theoretical investigation of drying of moist slab, cylinder and spherical products to study dimensionless moisture content distributions and their comparisons. Experimental study includes the measurement of the moisture content distributions of slab and cylindrical carrot, slab and cylindrical pumpkin and spherical blueberry during drying at various temperatures (e.g., 30, 40, 50 and 60°C) at specific constant velocity (U = 1 m/s) and the relative humidity φ = 30%. In theoretical analysis, two moisture transfer models are used to determine drying process parameters (e.g., drying coefficient and lag factor) and moisture transfer parameters (e.g., moisture diffusivity and moisture transfer coefficient), and to calculate the dimensionless moisture content distributions. The calculated results are then compared with the experimental moisture data. A considerably high agreement is obtained between the calculations and experimental measurements for the cases considered. The effective diffusivity values were evaluated between 0.741 × 10−5 and 5.981 × 10−5 m2/h for slab products, 0.818 × 10−5 and 6.287 × 10−5 m2/h for cylindrical products and 1.213 × 10−7 and 7.589 × 10−7 m2/h spherical products using the Model-I and 0.316 × 10−5–5.072 × 10−5 m2/h for slab products, 0.580 × 10−5–9.587 × 10−5 m2/h for cylindrical products and 1.408 × 10−7–13.913 × 10−7 m2/h spherical products using the Model-II.

Similar content being viewed by others

Abbreviations

- A 1 :

-

Constant

- B 1 :

-

Constant

- Bi :

-

Biot number (dimensionless)

- D :

-

Moisture diffusivity (m2/h)

- Fo :

-

Fourier number (dimensionless)

- G :

-

Lag factor (dimensionless)

- k :

-

Moisture transfer coefficient (m/h)

- M :

-

Moisture content (kg H2O/kg d.m.)

- M e :

-

Equilibrium moisture content (kg H2O/kg d.m.)

- M i :

-

Initial moisture content (kg H2O/kg d.m.)

- μ 1 :

-

Root of the transcendental characteristic equation

- R 2 :

-

Correlation coefficient

- S :

-

Drying coefficient (1/h)

- t :

-

Drying time (h)

- T :

-

Air temperature (°C)

- U :

-

Air velocity (m/s)

- Y :

-

Characteristic dimension (m) (half thickness for slab, radius for sphere and cylinder)

- ϕ :

-

Dimensionless moisture content

- φ :

-

Relative humidity

References

Dincer I (1998) Moisture loss from wood products during drying—Part II: surface moisture content distributions. Energy Source 20(1):77–83

Mcminn WAM (2004) Prediction of moisture transfer parameters for microwave drying of lactose powder using Bi–G drying correlation. Food Res Int 37:1041–1047

Saravacos GS, Maroulis ZB (2001) Transport properties of food. Marcel Dekker Press, New York

Mrkic V, Ukrainczyk M, Tripalo B (2007) Applicability of moisture transfer Bi–Di correlation for convective drying of broccoli. J Food Eng 79:640–646

Mulet A, Sanjuan N, Bon J, Simal S (1999) Drying model for highly porous hemispherical bodies. Eur Food Res Technol 210:80–83

Dincer I, Dost S (1995) An analytical model for moisture diffusion in solid objects during drying. Dry Technol 13(1–2):425–435

Dincer I, Dost S (1996) A modeling study for moisture diffusivities and moisture transfer coefficients in drying of solid objects. Int J Energy Res 20:531–539

Dincer I, Hussain MM, Sahin AZ, Yilbas BS (2002) Development of a new moisture transfer (Bi–Re) correlation for food drying applications. Int J Heat Mass Transf 45:1749–1755

Dincer I, Hussain MM (2002) Development of a new Bi–Di correlation for solids drying. Int J Heat Mass Transf 45:3065–3069

Dincer I, Hussain MM (2004) Development of a new Biot number and lag factor correlation for drying applications. Int J Heat Mass Transf 47:653–658

Keey RB (1972) Drying principles and practice. Pergamon Press, Oxford

Holman JP (2001) Experimental methods for engineers. McGraw-Hill, New York

Kaya A, Aydin O, Dincer I (2008) Experimental and numerical investigation of heat and mass transfer during drying of Hayward Kiwi fruits (Actinidia Deliciosa Planch). J Food Eng 88:323–330

Kaya A, Aydin O, Demirtas C, Akgun M (2007) An experimental study on the drying kinetics of quince. Desalination 212:328–343

Kaya A, Aydin O, Demirtas C (2009) Experimental and theoretical analysis of drying characteristics of carrot. Desalination 237:285–295

Jamali A, Kouhila M, Mohamed LA, Idlimam A, Lamharrar A (2006) Moisture adsorption–desorption isotherms of Citrus reticulate leaves at three temperatures. J Food Eng 77:71–78

Corzo O, Bracho N, Alvarez C, Rivas V, Rojas Y (2008) Determining the moisture transfer parameters during the air-drying of mango slices using Biot–Dincer numbers correlation. J Food Process Eng 31:853–873

Acknowledgments

The authors acknowledge the financial support provided by Karadeniz Technical University Research Fund under Grant No 2004.112.003.01 and the Turkish Republic Prime Ministry State Planning Organization (DPT) under grant no 2003K120750. The second author of this article is also indebted to the Turkish Academy of Sciences (TUBA) for the financial support provided under the Programme to Reward Success Young Scientists (TUBA-GEBIT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaya, A., Aydın, O. & Dincer, I. Comparison of experimental data with results of some drying models for regularly shaped products. Heat Mass Transfer 46, 555–562 (2010). https://doi.org/10.1007/s00231-010-0600-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-010-0600-z