Abstract

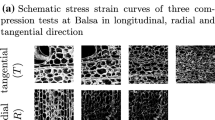

Transverse compression of wood is a process that induces large deformations. The process is dominated by elastic and plastic cell wall buckling. This work reports a numerical study of the transverse compression and densification of wood using a large-deformation, elastic–plastic constitutive law. The model is isotropic, formulated within the framework of hyperelasticity, and implemented in explicit material point method (MPM) software. The model was first validated for modeling of cellular materials by compression of an isotropic cellular model specimen. Next, it was used to model compression of wood by first validating use of isotropic, transverse plane properties for tangential compression of hardwood, and then by investigating both tangential and radial compression of softwood. Importantly, the discretization of wood specimens used MPM methods to reproduce accurately the complex morphology of wood anatomy for different species. The simulations have reproduced observations of stress–strain response during wood compression including details of inhomogeneous deformation caused by variations in wood anatomy.

Similar content being viewed by others

References

Astley RJ, Stol KA, Harrington JJ (1998) Modeling the elastic properties of softwood—part II: the cellular microstructure. Holz Roh Werkst 56:43–50

Bardenhagen SG, Kober EM (2004) The generalized interpolation material point method. Comput Model Eng Sci 5(6):477–495

Bardenhagen SG, Guilkey JE, Roessig KM, Brackbill JU, Witzel WM, Foster JC (2001) An improved contact algorithm for the material point method and application to stress propagation in granular materials. Comput Model Eng Sci 2:509–522

Bodig J (1963) The peculiarity of compression of conifers in radial direction. For Prod J 13(10):438

Bodig J (1965) The effect of anatomy on the initial stress–strain relationship in transverse compression. For Prod J 15:197–202

Bodig J (1966) Stress–strain relationship for wood in transverse compression. J Mater 1:645–666

Davids WG, Landis EN, Vasic S (2003) Lattice models for the prediction of load-induced failure and damage in wood. Wood Fiber Sci 35:120–134

Dinh AT (2011) Comportement élastique linéaire et non-linéaire du bois en relation avec sa structure (in French). Dissertation, AgroParisTech, France

Easterling KER, Harrysson LJ, Gibson LJ, Ashby MF (1982) On the mechanics of balsa and other woods. Proc R Soc Lond A 383:31–41

Gibson LJ, Ashby MF (1997) Cellular solids. Structure and properties. Cambridge University Press, Cambridge

Gibson LJ, Ashby MF, Schajer GS, Robertso CI (1982) The mechanics of two-dimensional cellular materials. Proc R Soc Lond A 382:25–42

Guitard D (1987) Mechanics of wood and composite materials (Mécanique du matériau bois et composites) (in French) In: Coll Nabla. Cépadues éditions, Toulouse. 228p

Harrington JJ, Booker R, Astley RJ (1998) Modeling the elastic properties of softwood—part I: the cell-wall lamellae. Holz Roh Werkst 56:37–41

Holmberg SA (1998) A numerical and experimental study of initial defibration of wood. Technical report, Lund University—Lund Institute of Technology—Division of structural Mechanics, Sweden

Koponen S, Toratti T, Kanerva P (1989) Modeling longitudinal elastic and shrinkage properties of wood. Wood Sci Technol 23:55–63

Kultikova EV (1999) Structure and properties relationships of densified wood. MS Thesis, Virginia Polytechnic Institute and State University

Landis EN, Vasic S, Davids WG, Parrod P (2002) Coupled experiments and simulations of micro-structural damage in wood. Exp Mech 42:389–394

Nairn JA (2003) Material point method calculations with explicit cracks. Comput Model Eng Sci 4:649–664

Nairn JA (2006) Numerical simulations of transverse compression and densification in wood. Wood Fiber Sci 38:576–591

Nairn JA (2007) Numerical implementation of imperfect interfaces. Comput Mater Sci 40:525–536

Nairn JA (2013) Modeling imperfect interfaces in the material point method using multimaterial methods. Comput Model Eng Sci 92:271–299

Oudjene M, Khelifa M (2009a) Finite element modeling of wooden structures at large deformations and brittle failure prediction. Constr Build Mater 30:408–4087

Oudjene M, Khelifa M (2009b) Elasto–plastic constitutive law for wood behavior under compression loadings. Constr Build Mater 23:3359–3366

Persson K (2000) Micromechanical modeling of wood fiber properties. Dissertation, Department of Mechanics and Materials, Lund University, Sweden

Qing H, Mishnaevsky L Jr (2009) 3D hierarchical computational model of wood as a cellular material with fibril reinforced, heterogeneous multiple layers. Mech Mater 41:1034–1049

Rangsri W (2004) Experimental and numerical study wood indentation test (Etude expérimentale et numérique de l’essai d’indentation du bois) (in French), Dissertation, Université de Montpellier II, France

Sadeghirad A, Brannon RM, Burghardt J (2011) A convected particle domain interpolation technique to extend applicability of the material point method for problems involving massive deformations. Int J Numer Methods Eng 86(12):1435–1456

Shiari B, Wild PM (2004) Finite element analysis of individual wood-pulp fibers subjected to transverse compression. Wood Fiber Sci 36:135–142

Sidoroff F (1974) Nonlinear viscoelastic model with an intermediate configuration (Un modele viscoélastique non linéaire avec configuration intermédiaire) (in French). J Mech 13:679–713

Simo JC (1988a) A framework for finite strain elastoplasticity based on maximum plastic dissipation and the multiplicative decomposition. part I: continuum formulation. Comput Methods Appl Mech Eng 66:199–219

Simo JC (1988b) A framework for finite elastoplasticity based on maximum plastic dissipation and the multiplicative decomposition. part II: computational aspects. Comput Methods Appl Mech Eng 68:1–31

Simo JC, Hughes TJR (1997) Computational inelasticity. Springer, New York

Smith I, Landis E, Gong E (2003) Fracture and fatigue in wood. Wiley, New York

Sulsky D, Chen Z, Schreyer HL (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118:179–196

Tabarsa T (1999) Compression perpendicular-to-grain behavior of wood. Dissertation, University of New Brunswick, Canada

Tabarsa T, Chui YH (2000) Stress–strain response of wood under radial compression. Part I. Test method and influences of cellular properties. Wood Fiber Sci 32:144–152

Tabarsa T, Chui YH (2001) Characterizing microscopic behavior of wood under transverse compression, Part II. Effect of species and loading direction. Wood Fiber Sci 33:223–232

Zhou S (1998) The numerical prediction of material failure based on the material point method. Dissertation, University of New Mexico

Zhu HX, Mills NJ, Knott JF (1997) Analysis of the higher strain compression of open cell foams. J Mech Phys Solids 45:1875–1904

Acknowledgments

The authors would like to thank Joseph Gril, CNRS Research Director at University of Montpellier II France, for providing some experimental data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aimene, Y.E., Nairn, J.A. Simulation of transverse wood compression using a large-deformation, hyperelastic–plastic material model. Wood Sci Technol 49, 21–39 (2015). https://doi.org/10.1007/s00226-014-0676-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0676-6