Abstract

Vitamin B6 comprises an important set of molecules tightly interwoven with the human amino acid, fatty acid, and carbohydrate metabolism. Analytical methods striving for the quantification of individual B6 vitamers so far mostly rely on methods based on HPLC in combination with fluorescence detection, but their application encounters multiple difficulties due to the chemical divergence of the single vitamers. The present study describes the development of a method based on LC-MS/MS and stable isotope dilution assay (SIDA) for the simultaneous quantification of five vitamers (PN, PL, PM, PMP, and PNG) of the B6 group in food samples. [13C3]-PN, [13C3]-PL, and [13C6]-PNG were applied as internal standards for the analysis of PN, PL, and PNG. PM and PMP were quantified via matrix-matched calibration referring to [13C3]-PN. The developed method was validated using starch matrix. The limits of detection and quantification ranged from 0.0028 to 0.02 mg/kg and from 0.0085 to 0.059 mg/kg, respectively, for all analytes. Calculated recoveries varied from 92 to 111%. Intra-injection precisions ranged from 0 to 9%, inter-day precisions from 4 to 10%, and intra-day precisions from 4 to 10%. A total of 14 plant-based food samples including fruits, vegetables, and cereals were examined for their content of vitamin B6 using the validated method. Furthermore, the first quantitation of PNG without enzymatic steps or divergent internal standards was undertaken utilizing LC-MS/MS and SIDA.

Similar content being viewed by others

Introduction

The group of vitamin B6 encompasses several water-soluble, essential, yet in vivo inter-convertible, vitamers, namely pyridoxine (PN), pyridoxal (PL), pyridoxamine (PM), and their respective phosphorylated compounds pyridoxine 5′-phosphate (PNP), pyridoxal 5′-phosphate (PLP), and pyridoxamine 5′-phosphate (PMP) [1]. In plants, the glycosylated derivative pyridoxine-5′-β-d-glucoside (5′-β-PNG) accounts for the major fraction of the total vitamin B6 content, additionally (Fig. 1) [2,3,4].

Vitamin B6 plays an important role in the human metabolism where it exhibits co-enzymatic characteristics in its metabolically active form, PLP, and is involved in an astonishing variety of over 150 biochemical reactions—an estimated 4% of all enzyme activities in the human metabolism show PLP dependency—within the amino acid, fatty acid, and carbohydrate metabolism [5, 6]. The diverse spectrum of enzymes furthermore increasingly awakens interest as potential targets in the field of drug development [7]. Additionally, vitamin B6 has been correlated to a number of physiological disorders, e.g., cardiovascular diseases [8], cancer development [9], oxidative stress [10], chromosomal instability [11], and inflammation [12].

The multifarious number of studies undertaken throughout medical subjects also illuminated analytical problems regarding this group of molecules. More precisely, the simultaneous quantification of the single vitamers presents a challenge to the analytical world to this day. The number and instability of the molecules, their high polarity, the similarity in structure, and connection to the examined matrices outline just some of the factors enriching the aggravating complexity of a specific individual determination [13,14,15,16]. Hence, a numerous variety of methods using several principles, e.g., microbiology [17,18,19], electrochemistry [20], spectrometry [21, 22], and chromatography [23,24,25,26,27,28,29,30,31,32,33,34], has been developed to quantify vitamin B6, either as part of a multivitamin method or in a selective screening of the B6 group. Many traditional methods pursue the detection of specifically selected vitamers or have to rely on the enzymatic transformation into PN beforehand [25, 32, 35]. Although the determination of individual B6 vitamers demands a higher analytical complexity, the benefits granted through this effort are of enormous nature to nutritional and medical fields. This is reflected in the aspect that, while the human body not being equipped with an ability to synthesize vitamin B6 itself, it possesses a fine-tuned mechanism of transforming individual vitamers of B6 into each other. The grave importance of this process with regard to the absorption, transport, and bioavailability inside the body is mirrored by the divergent utilization of the different forms of B6. While PLP and PL are the major forms present in the blood stream, phosphorylation and dephosphorylation present necessary steps for the transport and metabolic trapping processes inside the brain cells and choroid plexus. Hence, a method giving access to a more wide-ranging information via determination of individual quantities of the different forms of B6 compared with methods using multivitamin determination or transformation into one vitamer allows a deeper insight into the nutritional value of different foods and more detailed data when working with biological samples.

The increasing technological progress and involvement of liquid chromatography (LC) systems in the analytical field, mostly in combination with fluorescence detection due to the inherent sensitivity for B6, immensely facilitated aspects like simultaneous tracing of multiple substrates [36]. Nevertheless, issues like low fluorescence quantum yield, matrix interferences leading to signal-intensity manipulation, necessary pre-/post-column derivatization, and insufficient separation of the vitamers on the solid phase remained. Recent developments show interest in the application of systems based on liquid chromatography coupled to tandem mass spectrometry (LC-MS/MS). The involvement of isotopically labeled internal standards compensates for losses during sample workup and thus minimizes systematic errors [37]. Hereby, proposals arose for the quantitation of vitamin B6 in biological samples [38, 39], infant formula [40, 41], nutritional formula [42], and food [43,44,45]. Foodstuffs analyzed via LC-MS/MS comprise maize flour and green and golden kiwi as well as tomato pulp [43], Italian pasta [44], and beverages as well as dietary supplements [45].

So far, all studies revolving around LC-MS/MS analysis of foodstuff focus on simultaneous multivitamin analysis including some of the B6 vitamers and furthermore lack data on PNG. And [43] despite the rising implementation of LC-MS/MS into analytical chemistry with regard to the quantitation of vitamin B6, methods revolving around the simultaneous quantification of the individual vitamers in food utilizing SIDA remain still scarce. Hence, the aim of this study focused on the development of a LC-MS/MS method—including optimization of the sample workup and validation—capable of quantifying multiple vitamers of the B6 group in food samples [46, 47]. Hereby, special attention was given to PNG as a new substrate being included in an analytical method revolving around the analysis of vitamin B6.

Materials and methods

Chemicals and reagents

Pyridoxine hydrochloride (≥ 99%) was obtained from Alfa Aesar (Bellefonte, PA, USA) and pyridoxal hydrochloride (≥ 99.5%) from Alexis Biochemicals (Lausen, Switzerland). Pyridoxamine dihydrochloride (≥ 98%), pyridoxamine-5′-phosphate (≥ 98%), and pyridoxal-5′-phosphate monohydrate (≥ 97%) were purchased from Sigma-Aldrich (Bellefonte, PA, USA). 5′-β-Pyridoxine glycoside and the stable isotopically labeled standards [13C3]-PN, [13C3]-PL, and [13C6]-PNG were prepared in our laboratory, chromatographically purified, and characterized by NMR spectroscopy as published [48, 49]. Concentrations were determined by qNMR.

Formic acid (≥ 98%) was obtained from Sigma-Aldrich (Bellefonte, PA, USA), hydrochloric acid (32%) from VWR International GmbH (Darmstadt, Germany), and starch (high purity, order number: 101252) from Merck KGaA (Darmstadt, Germany). Acetonitrile (analytical grade), methanol (analytical grade), water (analytical and LC-MS grade), and isopropanol (LC-MS grade) were received from VWR International GmbH (Ismaning, Germany). Acetonitrile (LC-MS grade) was obtained from Carl Roth GmbH & Co., KG (Karlsruhe, Germany). Methanol (LC-MS grade) was purchased from Honeywell™ Riedel-de Häen™ (Seelze, Germany).

Preparation of stock solutions and calibration standards

Stock solutions of the unlabeled and labeled vitamers were prepared in concentrations of 0.1, 1, and 10 μg/mL in water (LC-MS grade) and stored at − 28 °C in the dark. The stock solutions were stable for the length of the study (6 months) under these conditions.

LC-MS/MS conditions

LC-MS/MS was carried out on a Shimadzu Nexera X2 UHPLC system (Shimadzu, Kyoto, Japan). A Shim-pack Velox PFPP column (2.1 × 100 mm, 2.7 μm, 90 Å, Shimadzu Corporation, Kyoto, Japan) protected by a Velox EXP Guard PFPP (2.1 × 5 mm, Shimadzu Corporation, Kyoto, Japan) was used as stationary phase and the temperature held at 30 °C. The flow rate was set to 0.3 mL/min. The binary gradient system comprised 0.1% formic acid in water (solvent A) and methanol (B). The mobile phase was held at 2% B for the first minute. The gradient raised linearly from 2 to 3.5% B during 1 min and remained at 3.5% B for 0.5 min. Afterwards, it raised to 5% B over the course of 0.5 min and was kept at 5% B for 4 min. Next, it raised to 50% B during 1 min and remained at 50% for 2 min. Finally, the mobile phase returned to 2% B over 1 min and the column was equilibrated for 3 min. The injection volume was 1 μL. As for the detection of the analytes, a triple quadrupole mass spectrometer (LCMS-8050, Shimadzu, Kyoto, Japan) was used that functioned in the positive electrospray ionization (ESI) mode for all analytes. Customization regarding the parameters of the interface proceeded as follows: nebulizing gas flow 3 L/min, heating gas flow 10 L/min, drying gas flow 10 L/min, heat block temperature 400 °C, interface temperature 300 °C, desolvation line temperature 250 °C, interface voltage 4 kV, and collision-induced dissociation gas pressure 270 kPa. MS/MS measurements were performed by the mass spectrometer in the scheduled multiple reaction monitoring (MRM) mode. The voltages for the fragmentation of the individual analytes were optimized by direct infusion of standard solutions of the vitamers at a concentration of 1 μg/mL. Confirmation of the analytes proceeded through two mass transitions, namely the quantifier and as qualifier. The mass transitions of the qualifiers and quantifiers of the analytes were checked for interfering matrix compounds from strawberry, banana, potato, and whole wheat flour extracts. Optimized voltages and collision energies, the retention time, and the quantifier/qualifier ratio of each analyte are listed in Table 1. Data acquisition was performed with LabSolutions software 5.80 (Shimadzu, Kyoto, Japan).

Food samples

Fourteen food samples—among them five vegetables, eight fruits, and one flour sample (for detailed information about the origin of each sample, see Table S1 in the Electronic Supplementary Material, ESM)—were purchased from various supermarkets in Germany in single units (except for strawberry, where five units were combined and homogenized) and analyzed for their vitamin B6 content with the optimized and validated method. The foodstuff was stored in the fridge after purchase and prepared as fast as possible. Stems were removed. No food was peeled, except for banana and melon, where only the pulp was used. Seeds were removed in all samples except for strawberry.

Optimization of the sample extraction

Generally, the blueprint for the sample workup followed a mild acidic extraction procedure including protein precipitation as well as centrifugation steps, subsequent reduction of the solvent, reconstitution of the sample, filtration, and measurement. Hereby, different aspects within the method optimization procedure such as sample weight and type as well as volume of extraction solvents, number and duration of extractions, and the composition of the uptake solvent were varied. All variations of the workup conditions used starch as matrix and were injected once after one single workup.

Optimized sample preparation

One gram of a well-ground and homogenized (standard mixer equipped with blades) sample was weighed into a 50-mL centrifuge tube and the isotopically labeled internal standards were added to the sample (200 μL of [13C3]-PN (1 μg/mL), 100 μL of [13C3]-PL (1 μg/mL), and 200 μL of [13C6]-PNG (1 μg/mL, solvent: water (LC-MS grade)). Extraction proceeded through addition of 20 mL of 5% formic acid (v/v in H2O) and shaking the mixture horizontally (350 rpm, Kombi Schüttler KL2, Edmund Bühler GmbH) for 5 min. The sample was centrifuged (1790×g, Centrifuge 5810 R, Eppendorf AG) for 15 min at 4 °C and the supernatant transferred into a new 50-mL centrifuge tube. A total of 15 mL ACN was added to the supernatant in order to initiate protein precipitation and centrifuged again (1790×g, 15 min). Another 15 mL ACN was added and the centrifugation repeated. The supernatant was transferred in a round flask (100 mL), the solvent rotary evaporated under reduced pressure (Rotationsverdampfer Hei-Vap Value, Heidolph Instruments GmbH & Co. KG), and the residue reconstituted in 10 mL of a mixture of 0.1% formic acid in water and methanol (v/v = 1/1). The sample was membrane-filtered (0.22 mm, polyvinylidene fluoride, Macherey-Nagel GmbH & Co. KG) and analyzed by LC-MS/MS.

Calibration and quantitation

PN, PL, and PNG were quantified using isotopically labeled internal standards, while PM and PMP were determined utilizing matrix-matched calibration in starch as matrix referring to isotopically labeled PN as internal standard. For PN and PL, the corresponding [13C3]-labeled compounds were used as internal standards, while PNG was analyzed with an [13C6]-labeled isotopologue.

Calibration functions of PN, PL, and PNG were established by mixing varying amounts of analyte (A) with constant amounts of internal standard (S). For PM and PMP, varying amounts of analyte (A) and constant amounts of internal standard (S) were spiked into vitamer-free starch and processed according to the procedure described above. The calibration was performed in molar ratios [n(A)/n(S)] between 0.01 and 100 (1:100, 1:75, 1:50, 1:10, 1:5, 1:2, 1:1, 2:1, 5:1, 10:1, 50:1, 100:1) for PN, PL, PM, and PNG and between 0.003 and 100 (1:300, 1:100, 1:50, 1:10, 1:5, 1:2, 1:1, 2:1, 5:1, 10:1, 50:1, 100:1) for PMP. The calibration functions were calculated from molar ratios [n(A)/n(S)] versus peak area ratios [A(A)/A(S)] after LC-MS/MS measurements using linear regression, which was verified using Mandel’s fitting test.

Method validation

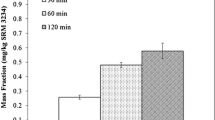

Determination of limits of detections (LODs) and limits of quantifications (LOQs) was performed as suggested by Vogelgesang and Hädrich [47] by spiking starch at four different spiking levels with PN (0.02, 0.1, 0.2, and 0.3 mg/kg), PL (0.07, 0.25, 0.5, and 0.7 mg/kg), PM (0.01, 0.035, 0.07, and 0.1 mg/kg), PMP (0.02, 0.08, 0.14, and 0.2 mg/kg), and PNG (0.01, 0.035, 0.07, and 0.1 mg/kg). Each level was worked up in triplicate and each extraction injected in triplicate. The extraction of vitamers and reduction of starch components were performed according to the procedure listed above followed by the measurement via LC-MS/MS.

The recoveries for each vitamer were determined by spiking the starch at three different spiking levels with PN (0.1, 0.2, and 0.3 mg/kg), PL (0.25, 0.5, and 0.7 mg/kg), PM (0.035, 0.07, and 0.1 mg/kg), PMP (0.08, 0.14, and 0.2 mg/kg), and PNG (0.035, 0.07, and 0.1 mg/kg), while each level was worked up in triplicate, and preparation according to the procedure described above followed by triple measurement via LC-MS/MS. The recovery rates of PN, PL, PM, PMP, and PNG were calculated as the ratio of detected and spiked amounts (R = found amount [mg/kg]/spiked amount [mg/kg]). Since the current study was of proof-of-principle and no reference material was available, recovery was taken for the assessment of trueness.

Strawberry, banana, potato, and whole wheat flour were used for the determination of precisions (calculated as relative standard deviations) by spiking the absent vitamers and preparation according to the procedure described above followed by measurement via LC-MS/MS. Hereby, 300 μL PL (1 μg/mL) was spiked to banana, potato, and whole wheat flour and 300 μL PM (1 μg/mL) to whole wheat flour. Inter-injection precisions were determined by spiking and working up one of each food samples and injecting (1 μL) it in quintuplicate into the LC-MS/MS instrument (n = 5). The intra-day precisions were calculated after spiking and working up one of each food samples in triplicate followed by injecting (1 μL) it triply into the LC-MS/MS, all in 1 day (n = 9). The inter-day precisions were determined by spiking and working up one of each food samples in triplicate followed by injecting (1 μL) it triply (first day) or twice (second and third day) into the LC-MS/MS, all on three separate days distributed over 3 weeks (n = 21).

Results and discussion

This study revolved around the establishment of a method for the simultaneous quantification of the vitamers PN, PL, PM, PMP, and PNG in various food samples. The first steps started with the optimization of the sample workup and preparation. Next, the optimized method was validated, and lastly, various food samples were examined for their vitamin B6 content.

Optimization of the sample workup

The development of a suitable method started with the optimization of the sample workup. All variations of the workup conditions were analyzed in a single determination using starch to scope a multitude of possibilities with regard to workup parameters. Hereby, either an explicit trend was obtained when investigating an individual workup method within one optimization step—where a definite variation of the workup conditions showed better results than other variations, e.g., utilization of 5% formic acid compared with pure water—or the outcome of all individual variations within one optimization step was similar (e.g., time of extraction). Traditional extraction procedures rely on the utilization of heat in an acidic environment and use this treatment to their favor in order to transform all forms of B6 into PN while focusing on the measurement of one vitamer within a multivitamin method. Because the present study focused on conserving the individual forms of B6, a milder procedure was pursued. Additionally, the utilization of mild agents for protein denaturation such as SSA was neglected due to the necessary separation prior to measurement, although they have been successfully applied in former studies revolving around HPLC analysis. Hence, this study’s goal with regard to the optimization focused on the establishment of a mild procedure including both the complete extraction of the individual vitamers and a mild process avoiding vitamer degradation.

In a first survey, the weight of the test sample was optimized in order to assure a detectable amount of analyte and adequately reduce matrix effects. Thus, sample weights of 1.0, 1.5, and 2.0 g were examined. 1.0 g resulted in the best outcome, i.e., the highest specific concentration in the extract while worsening proportionally with increasing weight (Fig. 2).

When starting with 2.0 g, supernatants remained strongly turbid after the centrifugation, aggravating a separation of the matrix. Reported sample weights usually vary strongly depending on the analyzed matrix in the literature [27]. The sampling described with regard to food like whole wheat and refined wheat products [29, 50, 51], quinoa [34], potato, or various brans and soy flour [52] ranged roughly between 0.5 and 30 g.

The extraction of the B6 vitamers proceeded via acidic extraction and centrifugation procedures, since the application of cartridges for matrix reduction presents a difficult task due to the properties of the B6 group. Traditionally, sample workup involved the utilization of mineralic acids in combination with the application of heat, e.g., with the help of an autoclave, in order to release protein-bound B6 [53]. Depending on the reaction conditions, this procedure often also led to the degradation of phosphorylated and glycosylated derivatives and was combined with enzymatic methods to achieve a complete transformation of the vitamers into one substrate in order to analyze the total B6 content [19, 35, 54, 55]. Furthermore, milder procedures were applied for the determination of individual vitamers by addition of deproteinizing agents like perchloric acid, trichloroacetic acid (TCA), and sulfosalicylic acid (SSA) in order to keep the phosphorylated derivatives intact. These methods share the issue that the additive has to be removed before HPLC measurement [56, 57]. The establishment of a LC-MS/MS method including the application of internal standards in a SIDA allows the determination of the individual vitamers, thus making the hydrolysis and treatment with glycosidase dispensable.

In this study, extraction solvents consisting of various concentrations of formic acid (FA) in water (1, 3, 5, 10, and 15% vol in H2O) were studied (Fig. 3). Formic acid was chosen due to its simple incorporation into ESI-MS and overall increased stability of the vitamers in acidic environment. Furthermore, pure water and hydrochloric acid in water (pH = 4.0) were examined. Five percent FA showed on average the best results among the tested concentrations, since lower concentrations (1 and 3%) led to unsatisfying recoveries throughout all analytes and higher concentrations (10 and 15%) showed partially better (PM and PMP) or worse (PN, PL, and PNG) results. Hydrochloric acid was worse for the extraction of PM, while water showed overall bad extraction results for all vitamers. In the literature, hydrochloric or sulfuric acid is often used in combination with autoclaving to liberate the vitamers from the matrix. [19, 25,26,27]

In an additional set of experiments, mixtures of aqueous formic acid and organic solvents (acetonitrile/methanol) were tested as extraction media, but resulted in worse results compared with 5% FA in water.

The next variations focused on the number and duration of extractions. Single (á 10 or 20 mL), double (á 10 or 20 mL), and triple extractions (á 10 mL) with 5% FA were preliminarily performed to find the optimal volume (Fig. 4). Hereby, extractions with 10 mL showed worse results compared with extractions with 20 mL. Single extractions with 10 mL showed bad results for PL, double extractions for PM and PMP, and triple extraction for PM and PNG. Extracting twice with 20 mL resulted in a lower recovery for PNG; hence, a single extraction with 20 mL solvent was used, delivering the best results compared with the other methods.

With regard to the extraction time, not only different time frames (2.5, 5, 10, 20, and 30 min) were tested, but also the utilization of an ultrasonic bath (U-bath; 15 min) instead of a shaker (Fig. 5). Extraction times ranging from 5 to 30 min showed a similar outcome. 2.5 min showed slightly better results for PL and PMP, but worse for PN and PNG, making the method unsatisfying for the desired determination of all vitamers. Since a shorter extraction time generally is preferred, upcoming experiments were performed with an extraction time of 5 min.

Centrifugation is an important step in the separation of matrix components and finds its frequent application in the analytical quantification of vitamin B6 in methods using SSA extraction [58], while protein precipitation through addition of methanol or acetonitrile is seldom undertaken. In order to verify that the precipitate after centrifugation does not enclose any vitamer amounts, the residue was dissolved and checked via ESI-MS and no co-precipitated vitamers were detected. The separation of the proteins and the resulting increased sample volume required the removal of the solvent. Hence, the solvent was removed under reduced pressure at mild temperatures and the residue reconstituted with a defined volume.

As last part of the method development, the volume and composition of the uptake solvent were examined (Fig. 6). The residue was reconstituted with 1, 1.5, 5, or 10 mL of formic acid (0.1% vol in H2O). Hereby, 10 mL showed the best results in comparison with the other volumes.

Lastly, the composition of the uptake volume was optimized. Therefore, mixtures of 0.1% FA with ACN or MeOH (1:1 or 3:1, v/v) were used next to pure 0.1% FA. The different solvents showed similar results, but since the mixture of 0.1% FA in MeOH with a ratio of 1:1 (v/v) gave slightly better results, this composition was used as the uptake solvent [59].

Optimization of LC-MS/MS conditions

Preliminary experiments revolved around the separation of the vitamers on different solid phases and suitable eluent composition. The comparison of C8, C18, biphenyl, biphenylpropyl, phenyl-hexyl, HILIC, and PFPP materials showed that all columns had issues with the separation of the vitamers (for detailed information about the columns and HPLC conditions, see Tables S2 and S3 in the ESM). Furthermore, PM and PMP always dwelled near the dead volume. Among the tested columns, the PFPP phase resulted in the best peak shape and shortest overall run time, thus allowing a higher sample throughput. The dead volume was measured with acetone to 0.90 min.

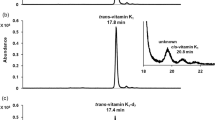

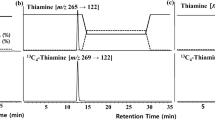

Since the B6 vitamers consist of different ionic forms depending on the pH of the eluent and show overall greater stability in acidic environment, various acid strengths were tested regarding their influence on the retention time while examining different mobile phases. Hence, mixtures of acetic acid (0.1% vol in H2O) and formic acid (0.01, 0.1, 0.5, and 1.0% vol in H2O) with acetonitrile/methanol were tested as eluents. For the HILIC columns, eluents consisting of ammonium formate buffers (5–10 mM) were used. In summary, only a binary gradient consisting of 0.1% formic acid in water and methanol resulted in the best separation and peak shapes. Figure 7 shows the LC-MS/MS chromatograms of an apple sample spiked with isotopically labeled standards in the positive ESI mode.

The B6 vitamers were measured in the positive ESI mode. Hereby, protonated molecules were used as precursor ions. Fragmentation patterns of the labeled standards resembled those of the respective unlabeled compounds (Fig. 8) [60,61,62,63,64].

LC-ESI(+)-MS/MS spectra of [13C3]-PN (a, CE = − 20 V), [13C3]-PL (b, CE = 13 V), and [13C6]-PNG (c, CE = − 22 V). Chromatogram (d) depicts [13C3]-PN, [13C3]-PL, and [13C6]-PNG from a spiked watermelon extract. Black and blue mass transitions refer to the quantifier and qualifier (for m/z transitions, see Table 1) of the spiked standards, respectively

Protonated [13C3]-PN (m/z 172.8) dissociated via loss of water (m/z 155.1), followed by an additional loss of water (m/z 137.1). The ESI-MS spectrum of protonated [13C3]-PL (m/z 170.8) also showed one loss of water (m/z 153.2), followed by other fragmentation steps [60]. Protonated [13C6]-PNG (m/z 337.9) fragmented via loss of glucose (m/z 152.2).

Method validation

Calibration

The quantitation of the vitamers in this study was undertaken by using either the respective calibration function (for the vitamers PN, PL, and PNG) or the matrix-matched calibration function (in the case of PM and PMP with labeled PN as internal standard). An important part of the method development, therefore, involved the assessment of whether a linear or quadratic regression should be chosen for this analytical method. In this regard, the Mandel test presents an efficient method by comparing the residual standard deviation of the linear model with that of the nonlinear model [59]. In this study, the linearity of the calibration functions of PN, PL, PM, and PNG was confirmed for molar ratios [n(A)/n(IS)] from 0.01 to 100 and of PMP between 0.003 and 100 with correlation coefficients close to 1.000 (Table 2).

LODs and LOQs

LODs and LOQs of the SIDAs were calculated according to Vogelgesang and Hädrich [47] and ranged from 0.0028 to 0.02 mg/kg (LOD) and from 0.0085 to 0.059 mg/kg (LOQ) (Table 2). Hereby, the set limit of 10% regarding the variation coefficients was fulfilled, except of PMP, where a coefficient of 21% was obtained when determining the LOD.

LODs and LOQs of B6 were reported for various food samples [26], e.g., Italian pasta [44], corn steep liquor [65], sea food [24, 66], cow milk [23], maize flour [43], green or golden kiwis [43], tomato pulp [43], cooked sausage [28], and vary between 0.000016 and 0.043 mg/kg (LOD) and between 0.000033 and 0.129 mg/kg (LOQ) depending on the vitamer and matrix. Data specifically regarding PNG are scarce in the literature because the vitamer is commonly determined as PN after enzymatic treatment. Gregory et al. noted a LOQ of 0.02 mg/kg and LOD of 0.0001 mg/kg in various foodstuffs utilizing HPLC in combination with fluorescence detection [52, 58].

In a survey regarding the separation of various substrates—among others PN, PL, and PLP—on different HILIC stationary phases, LOQs of 0.006 to 0.03 mg/kg for PN and 0.019 to 0.068 mg/kg for PL were determined using stock solutions [67].

The obtained LODs and LOQs aligned well with the respective range reported in the literature. A comparison with methods using LC-MS/MS shows that the results obtained in this study by using starch as matrix align well with the data of Leporati et al. using Italian pasta made from wheat [44]. The latter authors obtained LODs between 0.001 and 0.003 mg/kg and LOQs between 0.003 and 0.01 mg/kg according to a signal-to-noise ratio (S/N = 3 and 10). In comparison with that, Gentili et al. found for maize flour LODs ranging from 0.009 to 0.0144 mg/kg and LOQs ranging from 0.027 to 0.0432 mg/kg [43].

Since one aim of this study lied in the elaboration of the first LC-MS/MS method to detect and quantify PNG next to several B6 vitamers, this study granted data for a first general comparison of LODs and LOQs with other methods often chosen for the detection of B6 in foodstuff (e.g., fluorescence detection).

Recoveries

The recoveries of the SIDAs and matrix-matched calibrations were determined at three different levels by spiking vitamer-free starch with PN, PL, PM, PMP, and PNG. Hereby, the targeted range between 70 and 120% was met with values ranging between 92 and 111% for PN, PL, and PNG, which were determined by SIDA, and between 98 and 104% for PM and PMP, whose measurement was done via matrix-matched calibration. Both procedures had relative standard deviations (RSDs) below 9% (Table 3).

Recoveries described in various foods [24, 26], e.g., carrot [32], anchovy [32], garlic [32], chinoa [32], kiwi [43], tomato pulp [43], fish [66], cooked sausages [28], cow milk [23, 55, 68], Italian pasta [44], wheat [29], maize flour [43], and whole wheat flour [27], ranged between 15 and 118% depending on the matrix, extraction method, detection apparatus, and vitamer. Important factors when assessing the recoveries of B6 molecules refer to the extraction procedure and sample workup, since incomplete extraction or dephosphorylation/deglycosylation by enzymes has a crucial impact on the method. Differences in matrix composition play an additional role, thus complicating the determination. While utilizing 5% metaphosphoric acid during sample workup Sampson et al. measured recoveries between 57 and 101% of B6 vitamers in wheat, while Gentili et al. noted recoveries ranging from 40 to 96% in maize flour after matrix separation with C18 sorbent [29, 43]. Both did not include data on PNG. Thi Viet Do et al. received recoveries of 58 and 74% for PNG in carrot and garlic, respectively [32].

The recoveries measured during this study fit the expected values for a SIDA and matrix-matched calibration well. Losses during the workup were compensated for via reference to an internal standard. A comparison with literature data shows that the recoveries reported in this study with regard to similar food matrices (e.g., foods rich in starch) were better. This aspect can be traced back to the mild sample workup procedure in combination with application of SIDA during this study.

Precision

Calculation of inter-injection (n = 5), intra-day (n = 9), and inter-day (n = 21) precisions proceeded through spiking the missing vitamers (PL and PM) to whole wheat flour, potato, strawberry, or banana, subsequent preparation of the samples according to the procedure described above, and lastly injection into the LC-MS/MS instrument (Table 4) [46].

The relative standard deviation of the inter-injection precision ranged from 1 to 8% for whole wheat flour, 1 to 5% for potato, 2 to 9% for strawberry, and 3 to 9% for banana. Data for intra-day precisions ranged from 6 to 10% for whole wheat flour, 7 to 9% for potato, 5 to 9% for strawberry, and 4 to 10% for banana. Inter-day precisions ranged from 2 to 8% for whole wheat flour, 6 to 7% for potato, 4 to 10% for strawberry, and 4 to 10% for banana. All values met the targeted limit of 10%.

Inter- and intra-day precisions for foodstuff reported in the literature vary between 2 and 12 and between 1 and 5% depending on the matrix, vitamer, and method, respectively [23, 24, 26, 28, 43, 58, 66, 68]. Hereby, Gentili et al. reported inter-day precisions < 12% for B6 vitamers in maize flour, while Kall et al. noted an internal reproducibility of 5.6% for PN in Graham flour [26]. Gregory et al. assessed precisions ranging from 2.5 to 5.0% using vitamer standard solutions, including PNG with 3.8% [58].

The precisions for PL in potato were not evaluable despite multiple measurements. Interestingly, precisions determined using whole wheat flour, which arguably can be seen as relatively similar with regard to the composition of constituents, were assessable. In general, PL—next to PLP—had, in accordance with the literature, the lowest intensity throughout this study when optimizing the method, which makes the analysis of the substrate vulnerable to factors such as matrix effects. Nevertheless, the implementation of whole wheat flour in this study allows the comparison with food samples rich in starch.

Overall, the good recoveries, the low relative standard deviations of the precision measurements, and LODs/LOQs coinciding with the literature affirmed the development of a robust method. Hence, sample workup/preparation and the LC-MS/MS method present a suitable tool for the analysis of plant-based food such as fruits, vegetables, and cereals.

Analysis of vegetables, fruits, and cereals

For the analysis of plant-based food, various vegetables (n = 5), fruits (n = 8), and a flour sample (n = 1) were purchased from local super markets and quantitatively analyzed for their content of the B6 vitamers PN, PL, PM, PMP, and PNG (Table 5).

Content of B6 in vegetables, fruits, and cereal

A first glance at the data reveals that all five vitamers were detected in broccoli, cauliflower, green pepper, strawberry, and watermelon. While green pepper (0.11 mg/100 g), nectarine (0.164 mg/100 g), and apricot (0.155 mg/100 g) stood out through high amounts of PM, cauliflower (0.075 mg/100 g), and strawberry (0.078 mg/100 g) contained large quantities of PL. Broccoli included large quantities of both PM (0.116 mg/100 g) and PL (0.075 mg/100 g). The highest content of PMP (0.086 mg/100 g) was found in banana. By contrast, watermelon surpassed other foods with regard to PNG (0.082 mg/100 g) in comparison with the other vitamers.

Although the numerous representations of B6 vitamers in broccoli being in accordance with the literature, elucidated data on the individual compounds vary significantly. While Gregory et al., Kabir et al., and Bognar and Ollilainen reported low quantities of PN (0.032–0.036 mg/100 g), PM (0.002–0.028 mg/100 g), PMP (0.041 mg/100 g), and PL (0.014–0.037 mg/100 g) after extraction with sulfosalicylic acid or autoclaving with 0.10 M HCl at 120 °C, the amount of PNG, on the one hand, was comparatively high (0.078–0.186 mg/100 g) [27, 58, 69]. Kall et al. also utilizing autoclaves for extraction purposes, on the other hand, noted high amounts of PL (0.118 mg/100 g) in comparison with the other vitamers (0.028–0.068 mg/100 g), taking treatment with phosphatases into calculation [26].

The comparatively high contents of PL (0.075 mg/100 g) and PN (0.047 mg/100 g) in cauliflower were in accordance with reported proportions (PL: 0.121 mg/100 g, PN: 0.052 mg/100 g) [26]. Although a higher quantity of PMP (0.019 mg/100 g) compared with PM (0.002 mg/100 g) was found in this study, the overall amount of the amine derivative of the B6 group matches with the literature (PM: 0.02 mg/100 g), considering the utilization of phosphatase during sample workup [26]. Comparing the data on raw cauliflower with reported results, the lower amount of PNG (0.019 mg/100 g) compared with those of the other vitamers is adequate.

Inspired by being an exceptional source of folates [70] and since no data on the individual content of B6 was reported in the literature, strawberries were implemented in this study. Hereby, vitamin B6 was strongly present as PL (0.078 mg/100 g) compared with the other vitamers (0.004–0.008 mg/100 g).

Kall et al. published data regarding PN (0.023 mg/100 g), PL (0.008 mg/100 g), and PM (0.005 mg/100 g) in apple after sample workup including an acid hydrolysis step (0.1 M HCl) in an autoclave [26]. The results for PN (0.018 mg/100 g), PL (0.003 mg/100 g), and PM (0.002 mg/100 g) from this study fit accurately with respect to the proportion of the vitamers. Furthermore, 0.005 mg/100 g PNG were detected with the presented method.

In this study, a high proportion of vitamin B6 in green pepper was present as PM (0.11 mg/100 g) and PNG (0.092 mg/100 g), while the other vitamers were detectable only in lower amounts (0.005–0.031 mg/100 g). Nishimura et al. examined red pepper (Japanese tougarashi) and converted all vitamers into the highly fluorescent 4-pyridoxolactone by enzymatic processes and acidic hydrolysis. Hereby, the large quantities of PN (0.91 mg/100 g) and PNP/PNG (0.546 mg/100 g, not differentiated) surpassed the remaining vitamers PL (0.089 mg/100 g), PM (0.067 mg/100 g), and PMP (0.242 mg/100 g) [25]. These values appear much higher than those measured by our method; however, lack of representativeness and biological variations have to be kept in mind and point to the fact that our study was just for proof-of-principle.

Literature data on the content of individual vitamers of B6 in oranges is not available. In orange juice, values on PNG (0.198 mg/100 g) exceeded the other vitamers (0.004–0.026 mg/100 g), indicating that the glycosylated form amounts up to 92% of the B6 content [58]. The orange analyzed in this study also contained comparatively high amounts of PNG (0.082 mg/100 g) to the other vitamers (0.004–0.039 mg/100 g).

Banana was the only food sample in this study, in which B6 vitamers were mostly represented by PN (0.105 mg/100 g). Besides, PMP (0.086 mg/100 g) and PM (0.043 mg/100 g) were present in high amounts, while the glycosylated derivative (0.027 mg/100 g) was found in comparatively lower amounts. This general distribution is also depicted in the literature, where PN (0.104–0.389 mg/100 g) and PM (0.067–0.482 mg/100 g) exceed the other vitamers (0.007–0.042 mg/100 g) [26, 58, 71]. In addition, according to previous literature, the ratio between PM and PMP is mostly shifted towards the free molecule due to involvement of enzymatic processes during sample preparation. Quantities of PMP, if reported, hereby remain low (0.007 mg/100 g) [58]. Contrarily, the mild extraction used in this study resulted in a twofold amount of PMP in comparison with PM, resulting in a similar trend to cauliflower, where more phosphorylated substrate was found.

In order to gain insight into the complete content of B6 vitamers in foods, and therefore compare the total B6 content without enzymatic steps during sample workup, the present method should be expanded by PLP and possibly PNP. PLP was not included due to lack of internal standard. PNP is not commercially available and, therefore, making the preparation of an internal standard via a tedious synthesis necessary. Nevertheless, to the best of our knowledge, no data is available on this substrate, making it an interesting focus for future studies.

Content of PNG in food

PN and 5′-β-PNG were present in all 14 samples. More precisely, approximately equivalent amounts were found in broccoli (PN, PNG = 0.042 mg/100 g, 0.053 mg/100 g), strawberry (0.004 mg/100 g, 0.008 mg/100 g), nectarine (0.008 mg/100 g, 0.005 mg/100 g), and apricot (0.031 mg/100 g, 0.019 mg/100 g). More PN was quantified in cauliflower (0.047 mg/100 g, 0.019 mg/100 g), banana (0.105 mg/100 g, 0.027 mg/100 g), and apple (0.018 mg/100 g, 0.005 mg/100 g), whereas higher amounts of PNG were obtained in carrot (0.006 mg/100 g, 0.157 mg/100 g), green pepper (0.005 mg/100 g, 0.092 mg/100 g), potato (0.015 mg/100 g, 0.305 mg/100 g), whole wheat flour (0.034 mg/100 g, 0.134 mg/100 g), Galia melon (0.002 mg/100 g, 0.027 mg/100 g), watermelon (0.006 mg/100 g, 0.082 mg/100 g), and orange (0.004 mg/100 g, 0.082 mg/100 g). Since plants use glycosylation for storage purposes, the abundant distribution of PNG throughout all samples is comprehensible [58]. Many quantifications of glycosylated derivatives of B6 in the literature result from enzymatic treatment and HPLC/fluorescence analysis. To the best of our knowledge, no data is available on the determination of PNG via LC-MS/MS and SIDA, making this the first study of this sort.

Among the tested samples, PNG accounted for a major part of the B6 content in whole wheat flour, potato, and carrot. Whole wheat flour contained 0.134 mg/100 g PNG next to 0.034 mg/100 g PN and 0.016 mg/100 g PMP. This is in accordance with reported data, where PNG (0.014–0.149 mg/100 g) accounts for the major part of B6 in various flour samples, e.g., wheat, whole wheat, Graham, rye, oat, maize, all-purpose, and soy flour. PN (0.006–0.41 mg/100 g), PM (0.010–0.044 mg/100 g), and PMP (0.01–0.024 mg/100 g) were found in lower amounts [26, 27, 30, 31, 43, 50, 51, 72].

In potato, PNG (3.05 mg/kg) also contributed mainly to the overall B6 content compared with the other vitamers (0.015–0.03 mg/100 g). Values reported in the literature also contained higher proportions of PNG (0.1 mg/100 g) next to PN (0.024–0.195 mg/100 g), PM (0.014–0.05 mg/100 g), and PL (0.009–0.089 mg/100 g) [26, 27, 73]. Investigating the impact of storage on the content of vitamin B6 in potato, Addo and Augustin found 0.439 mg/100 g PN, 0.321 mg/100 g PM, and 0.301 mg/100 g PNG after extraction with SSA and HPLC analysis. Furthermore, storage over 9 months led to a fourfold increase of PN glycoside, which was probably related to adjustments of the osmotic pressure at the given storage temperature [57].

Next to cereals and potatoes, carrots were also associated with increased quantities of PNG. Utilizing PNG isolated from alfalfa seeds and fluorescence detection, Gregory et al., on the one hand, determined 0.145 mg/100 g and 0.606 mg/100 g PNG in raw carrots [52, 58]. Thi Viet Do et al., on the other hand, chose the approach of converting all vitamers into 4-pyridoxolactone through enzymatic procedures and reported 0.242 mg/100 g [32]. In this survey, PNG (0.157 mg/100 g) constituted the highest represented vitamer, as well. The residual B6 molecules accounted for 0.006 to 0.019 mg/100 g, which aligns well with reported results (0.003–0.064 mg/100 g) [32, 52, 58].

In summary, the data regarding the commonly examined vitamers PN, PL, PM, and the phosphates thereof found during this study fit well with the literature values, affirming the validity of the developed method. Furthermore, utilizing LC-MS/MS and SIDA, more insight into the individual PNG content of plant-based food was presented. Here, the data aligns with reports from methods using enzymatic treatment and fluorescence detection.

Concluding remarks

LC-MS/MS in combination with SIDA presents a powerful tool for the determination of individual B6 vitamers in foodstuff. This study revolved around the development of a LC-MS/MS method including the optimization of the sample workup, the validation of the method validated, and lastly, its application in the analysis of various food samples. For the first time, the individual content of PNG in food was determined with ESI-MS/MS without enzymatic steps or divergent internal standards. Future applications of this method allow the accurate investigation of nutritional aspects of this group of vitamins such as effects of processing and bioavailability.

Abbreviations

- CE:

-

Collision energy

- PN:

-

Pyridoxine

- PL:

-

Pyridoxal

- PM:

-

Pyridoxamine

- PLP:

-

Pyridoxal phosphate

- PMP:

-

Pyridoxamine phosphate

- PNP:

-

Pyridoxine phosphate

- PNG:

-

Pyridoxine glycoside

- SSA:

-

Sulfosalicylic acid

References

IUPAC-IUB. Nomenclature for vitamins B-6 and related compounds. Eur J Biochem. 1973;40:325–7. https://doi.org/10.1111/j.1432-1033.1973.tb03200.x.

Siegel L, Melnick D, Oser BL. Bound pyridoxine (vitamin B6) in biological materials. J Biol Chem. 1943;149:361–7.

Rabinowitz JC, Snell EE. The vitamin B6 group, distribution of pyridoxal, pyridoxamine, and pyridoxine in some natural products. J Biol Chem. 1948;176(3):1157–67.

Tadera K, Yagi F, Kobayashi A. Specificity of a particulate glucosyltransferase in seedlings of Pisum sativum L. which catalyzes the formation of 5'-O-(β-D-glucopyranosyl)pyridoxine. J Nutr Sci Vitaminol. 1982;28(4):359–66. https://doi.org/10.3177/jnsv.28.359.

Schneider G. The manifold of vitamin B6 dependent enzymes. Structure. 2000;8(1):R1–6.

Percudani R, Peracchi A. The B6 database: a tool for the description and classification of vitamin B6-dependent enzymatic activities and of the corresponding protein families. BMC Bioinformatics. 2009;10:273. https://doi.org/10.1186/1471-2105-10-273.

Mueller IB, Wu F, Bergmann B, Knockel J, Walter RD, Gehring H, et al. Poisoning pyridoxal 5-phosphate-dependent enzymes: a new strategy to target the malaria parasite Plasmodium falciparum. PLoS One. 2009;4(2):e4406. https://doi.org/10.1371/journal.pone.0004406.

Page JH, Ma J, Chiuve SE, Stampfer MJ, Selhub J, Manson JE, et al. Plasma vitamin B6 and risk of myocardial infarction in women. Circulation. 2009;120(8):649–55. https://doi.org/10.1161/CIRCULATIONAHA.108.809038.

Zitvogel L, Pietrocola F, Kroemer G. Nutrition, inflammation and cancer. Nat Immunol. 2017;18(8):843–50. https://doi.org/10.1038/ni.3754.

Lee MS, Su TC, Huang YC, Yang RC, Kao JK, Lee CH, et al. Effects of vitamin B-6 supplementation on oxidative stress and inflammatory response in neonatal rats receiving hyperoxia therapy. J Food Drug Anal. 2018;26(3):1086–96. https://doi.org/10.1016/j.jfda.2018.01.004.

Marzio A, Merigliano C, Gatti M, Verni F. Sugar and chromosome stability: clastogenic effects of sugars in vitamin B6-deficient cells. PLoS Genet. 2014;10(3):e1004199. https://doi.org/10.1371/journal.pgen.1004199.

Ueland PM, McCann A, Midttun O, Ulvik A. Inflammation, vitamin B6 and related pathways. Mol Asp Med. 2017;53:10–27. https://doi.org/10.1016/j.mam.2016.08.001.

Fennema RO. Food chemistry. Third edition ed. New York, Basel, Hong-Kong: Marcel Dekker, Inc.; 1996.

Leenheer APD, Lambert W. Modern chromatographic analysis of vitamins. Boca Raton CRC Press 2000.

Ball GFM. Vitamins in foods: analysis, bioavailability, and stability. 1st Edition ed. Food Science and Technology. Boca Raton CRC Press; 2005.

Eitenmiller RR, W. O. Landen J, Ye L. Vitamin analysis for the health and food sciences. 2nd Edition ed. Boca Raton: CRC Press; 2007.

Leonard SW, Hardin K, Leklem JE. Vitamin B-6 content of spices. J Food Compos Anal. 2001;14(2):163–7. https://doi.org/10.1006/jfca.2000.0946.

Ball GFM. Water-soluble vitamin assays in human nutrition. Microbiological methods for the determination of the B-group vitamins. Springer, Boston, MA; 1994. p. 317–64.

Gregory JF. Methods for determination of vitamin B6 foods and other biological materials: a critical review. J Food Compos Anal. 1988;1(2):105–23. https://doi.org/10.1016/0889-1575(88)90014-2.

Wei X, Qi L, Qiao J, Yao C, Wang F, Chen Y. Assay of vitamin B in urine by capillary electrochromatography with methacrylate-based monolithic column. Electrophoresis. 2010;31(19):3227–32. https://doi.org/10.1002/elps.201000147.

Zhang Y, Zhou WE, Yan JQ, Liu M, Zhou Y, Shen X, et al. A review of the extraction and determination methods of thirteen essential vitamins to the human body: an update from 2010. Molecules. 2018;23(6). https://doi.org/10.3390/molecules23061484.

Ahmad I, Mirza T, Qadeer K, Nazim U, Vaid FH. Vitamin B6: deficiency diseases and methods of analysis. Pak J Pharm Sci. 2013;26(5):1057–69.

Schmidt A, Schreiner MG, Mayer HK. Rapid determination of the various native forms of vitamin B6 and B2 in cow’s milk using ultra-high performance liquid chromatography. J Chromatogr A. 2017;1500:89–95. https://doi.org/10.1016/j.chroma.2017.04.009.

Lebiedzinska A, Marszall ML, Kuta J, Szefer P. Reversed-phase high-performance liquid chromatography method with coulometric electrochemical and ultraviolet detection for the quantification of vitamins B1 (thiamine), B6 (pyridoxamine, pyridoxal and pyridoxine) and B12 in animal and plant foods. J Chromatogr A. 2007;1173(1–2):71–80. https://doi.org/10.1016/j.chroma.2007.09.072.

Nishimura S, Nagano S, Crai AC, Yokochi N, Yoshikane Y, Ge F, et al. Determination of individual vitamin B6 compounds based on enzymatic conversion to 4-pyridoxolactone. J Nutr Sci Vitaminol. 2008;54(1):18–24. https://doi.org/10.3177/jnsv.54.18.

Kall MA. Determination of total vitamin B6 in foods by isocratic HPLC: a comparison with microbiological analysis. Food Chem. 2003;82(2):315–27. https://doi.org/10.1016/S0308-8146(02)00568-X.

Bognår A, Ollilainen V. Influence of extraction on the determination of vitamin B6 in food by HPLC. Z Lebensm Unters Forch. 1997;204:327–35. https://doi.org/10.1007/s002170050085.

Valls F, Sancho MT, Fernández-Muiño MA, Checa MA. Determination of vitamin B6 in cooked sausages. J Agric Food Chem. 2001;49(1):38–41. https://doi.org/10.1021/jf0003202.

Sampson DA, Eoff LA, Yan XL, Lorenz K. Analysis of free and glycosylated vitamin B6 in wheat by high-performance liquid chromatography. Cereal Chem. 1995;72(2):217–21.

Batifoulier F, Verny MA, Chanliaud E, Rémésy C, Demigné C. Effect of different breadmaking methods on thiamine, riboflavin and pyridoxine contents of wheat bread. J Cereal Sci. 2005;42(1):101–8. https://doi.org/10.1016/j.jcs.2005.03.003.

Batifoulier F, Verny MA, Chanliaud E, Rémésy C, Demigné C. Variability of B vitamin concentrations in wheat grain, milling fractions and bread products. Eur J Agron. 2006;25(2):163–9. https://doi.org/10.1016/j.eja.2006.04.009.

Do HTV, Ide Y, Mugo AN, Yagi T. All-enzymatic HPLC method for determination of individual and total contents of vitamin B6 in foods. Food Nutr Res. 2012;56:5409. https://doi.org/10.3402/fnr.v56i0.5409.

Goldschmidt RJ, Wolf WR. Simultaneous determination of water-soluble vitamins in SRM 1849 infant/adult nutritional formula powder by liquid chromatography-isotope dilution mass spectrometry. Anal Bioanal Chem. 2010;397(2):471–81. https://doi.org/10.1007/s00216-009-3373-9.

Halvin K, Nisamedtinov I, Paalme T. Comparison of different extraction methods to determine free and bound forms of B-group vitamins in quinoa. Anal Bioanal Chem. 2014;406(28):7355–66. https://doi.org/10.1007/s00216-014-8122-z.

Yagi T, Murayama R, Do HTV, Ide Y, Mugo AN, Yoshikane Y. Development of simultaneous enzymatic assay method for all six individual vitamin B6 forms and pyridoxine-β-glucoside. J Nutr Sci Vitaminol. 2010;56(3):157–63. https://doi.org/10.3177/jnsv.56.157.

Argoudelis CJ. Simple high-performance liquid chromatographic method for the determination of all seven vitamin B6-related compounds. J Chromatogr A. 1997;790(1–2):83–91. https://doi.org/10.1016/S0021-9673(97)00740-1.

Rychlik M, Asam S. Stabilisotopenverdünnungsanalysen zur Quantifizierung organischer Spurenkomponenten in der Lebensmittelanalytik. UWSF-Z. 2009;21(5):470–82. https://doi.org/10.1007/s12302-009-0082-0.

Asante I, Pei H, Zhou E, Liu S, Chui D, Yoo E, et al. Simultaneous quantitation of folates, flavins and B6 metabolites in human plasma by LC-MS/MS assay: applications in colorectal cancer. J Pharm Biomed Anal. 2018;158:66–73. https://doi.org/10.1016/j.jpba.2018.05.030.

Zhang M, Liu H, Huang X, Shao L, Xie X, Wang F, et al. A novel LC-MS/MS assay for vitamin B1, B2 and B6 determination in dried blood spots and its application in children. J Chromatogr B. 2019;1112:33–40. https://doi.org/10.1016/j.jchromb.2019.02.028.

Cellar NA, McClure SC, Salvati LM, Reddy TM. A new sample preparation and separation combination for precise, accurate, rapid, and simultaneous determination of vitamins B1, B2, B3, B5, B6, B7, and B9 in infant formula and related nutritionals by LC-MS/MS. Anal Chim Acta. 2016;934:180–5. https://doi.org/10.1016/j.aca.2016.05.058.

Salvati LM, McClure SC, Reddy TM, Cellar NA. Simultaneous determination of total vitamins B1, B2, B3, and B6 in infant formula and related nutritionals by enzymatic digestion and LC-MS/MS: single-laboratory validation, first action 2015.14. J AOAC Int. 2016;99(3):776–85. https://doi.org/10.5740/jaoacint.15-0315.

Phinney KW, Rimmer CA, Thomas JB, Sander LC, Sharpless KE, Wise SA. Isotope dilution liquid chromatography - mass spectrometry methods for fat- and water-soluble vitamins in nutritional formulations. Anal Chem. 2011;83(1):92–8. https://doi.org/10.1021/ac101950r.

Gentili A, Caretti F, D'Ascenzo G, Marchese S, Perret D, Di Corcia D, et al. Simultaneous determination of water-soluble vitamins in selected food matrices by liquid chromatography/electrospray ionization tandem mass spectrometry. Rapid Commun Mass Spectrom. 2008;22(13):2029–43. https://doi.org/10.1002/rcm.3583.

Leporati A, Catellani D, Suman M, Andreoli R, Manini P, Niessen WMA. Application of a liquid chromatography tandem mass spectrometry method to the analysis of water-soluble vitamins in Italian pasta. Anal Chim Acta. 2005;531(1):87–95. https://doi.org/10.1016/j.aca.2004.10.006.

Kakitani A, Inoue T, Matsumoto K, Watanabe J, Nagatomi Y, Mochizuki N. Simultaneous determination of water-soluble vitamins in beverages and dietary supplements by LC-MS/MS. Food Addit Contam. 2014;31(12):1939–48. https://doi.org/10.1080/19440049.2014.977965.

Thompson M, Ellison SLR, Wood R. Harmonized guidelines for single laboratory validation of methods of analysis. Pure Appl Chem. 2002;74(5):835–55.

Vogelgesang J, Hädrich J. Limits of detection, identification and determination: a statistical approach for practitioners. Accred Qual Assur. 1998;3:242–55. https://doi.org/10.1007/s007690050234.

Bachmann T, Rychlik M. Synthesis of [13C3]-B6 vitamers labelled at three consecutive positions starting from [13C3]-propionic acid. Molecules. 2018;23:2117. https://doi.org/10.3390/molecules23092117.

Bachmann T, Schnurr C, Zainer L, Rychlik M. Chemical synthesis of 5′-β-glycoconjugates of vitamin B6. Carbohydr Res. 2020;489:107940. https://doi.org/10.1016/j.carres.2020.107940.

Polansky MM, Toepfer EW. Nutrient composition of selected wheats and wheat products. IV. Vitamin B-6 components. Cereal Chem. 1969;46(6):664–74.

Sampson DA, Wen Q-B, Lorenz K. Vitamin B6 and pyridoxine glucoside content of wheat and wheat flours. Cereal Chem. 1996;73(6):770–4.

Gregory JF, Sartain DB. Improved chromatographic determination of free and glycosylated forms of vitamin B6 in foods. J Agric Food Chem. 1991;39(5):899–905. https://doi.org/10.1021/jf00005a019.

Rabinowitz JC, Snell EE. Vitamin B6 group. Extraction procedures for the microbiological determination of vitamin B6. Anal Chem. 1947;19(4):277–80. https://doi.org/10.1021/ac60004a020.

Ollilainen V. HPLC analysis of vitamin B6 in foods. Agric Food Sci. 1999;8(6):515–619. https://doi.org/10.23986/afsci.5632.

Bitsch R, Möller J. Analysis of B6 vitamers in foods using a modified high-performance liquid chromatographic method. J Chromatogr. 1989;463(1):207–11. https://doi.org/10.1016/s0021-9673(01)84472-1.

Rizzolo A, Polesello S. Chromatographic determination of vitamins in foods. J Chromatogr. 1992;624(1–2):103–52. https://doi.org/10.1016/0021-9673(92)85676-k.

Addo C, Augustin J. Changes in the vitamin B-6 content in potatoes during storage. J Food Sci. 1988;53(3):749–52. https://doi.org/10.1111/j.1365-2621.1988.tb08947.x.

Gregory JF, Ink SL. Identification and quantification of pyridoxine-β-glucoside as a major form of vitamin B6 in plant-derived foods. J Agric Food Chem. 1987;35(1):76–82. https://doi.org/10.1021/jf00073a018.

Andrade J, Gómez Carracedo MP. Notes on the use of Mandel's test to check for nonlinearity in laboratory calibrations. Anal Methods. 2013;5:1145–9. https://doi.org/10.1039/C2AY26400E.

Dejongh DC, Korytnyk W. Mass spectrometry of vitamin B6. Methods Enzymol. 1970;18:483–8. https://doi.org/10.1016/0076-6879(71)18348-6.

Dejongh DC, Perricone SC, Gay ML, Korytnyk W. Mass spectrometry of vitamin B6: different forms of the vitamin, its metabolites, antimetabolites, and analogs. J Mass Spectrom. 1968;1(1):151–66. https://doi.org/10.1002/oms.1210010114.

DeJongh DC, Perricone SC, Korytnyk W. A mass spectrometric investigation of pyridoxol, its C-5 analogs, and O-isopropylidene derivatives. J Am Chem Soc. 1966;88(6):1233–7. https://doi.org/10.1021/ja00958a027.

Khaksari M, Mazzoleni LR, Ruan C, Kennedy RT, Minerick AR. Data representing two separate LC-MS methods for detection and quantification of water-soluble and fat-soluble vitamins in tears and blood serum. Data in Brief. 2017;11:316–30. https://doi.org/10.1016/j.dib.2017.02.033.

Juhasz M, Takahashi S, Kitahara Y, Fujii T. Thermal decomposition of pyridoxine: an evolved gas analysis-ion attachment mass spectrometry study. Rapid Commun Mass Spectrom. 2012;26(7):759–64. https://doi.org/10.1002/rcm.6161.

Hofer A, Herwig C. Quantitative determination of nine water-soluble vitamins in the complex matrix of corn steep liquor for raw material quality assessment. J Chem Technol Biotechnol. 2017;92(8):2106–13. https://doi.org/10.1002/jctb.5211.

Chatterjee NS, Kumar KA, Ajeeshkumar KK, Kumari KRR, Vishnu KV, Anandan R, et al. Screening natural content of water-soluble B vitamins in fish: enzymatic extraction, HILIC separation, and tandem mass spectrometric determination. J AOAC Int. 2017;100(3):579–85. https://doi.org/10.5740/jaoacint.17-0056.

Pasakova I, Gladziszova M, Charvatova J, Stariat J, Klimes J, Kovarikova P. Use of different stationary phases for separation of isoniazid, its metabolites and vitamin B6 forms. J Sep Sci. 2011;34(12):1357–65. https://doi.org/10.1002/jssc.201100081.

Gatti R, Gioia MG. Liquid chromatographic determination with fluorescence detection of B6 vitamers and riboflavin in milk and pharmaceuticals. Anal Chim Acta. 2005;538(1–2):135–41. https://doi.org/10.1016/j.aca.2005.02.025.

Kabir H, Leklem J, Miller LT. Measurement of glycosylated vitamin B6 in foods. J Food Sci. 1983;48(5):1422–5. https://doi.org/10.1111/j.1365-2621.1983.tb03506.x.

Striegel L, Chebib S, Netzel ME, Rychlik M. Improved stable isotope dilution assay for dietary folates using LC-MS/MS and its application to strawberries. Front Chem. 2018;6(11). https://doi.org/10.3389/fchem.2018.00011.

Roth-Maier DA, Kettler SI, Kirchgessner M. Availability of vitamin B6 from different food sources. Int J Food Sci Nutr. 2002;53(2):171–9. https://doi.org/10.1080/09637480220132184.

Toepfer EW, Polansky MM. Comparison of vitamin B6 values of selected food samples by bioassay and microbiological assay. J Agric Food Chem. 1963;11(6):523–5.

Bognar A. Bestimmung von Vitamin B6 in Lebensmitteln mit Hilfe der Hochdruckfluessig-Chromatographie (HPLC). Z Lebensm Unters Forsch. 1985;181(3):200–5. https://doi.org/10.1007/BF02425578.

Acknowledgments

The authors gratefully acknowledge the support by the Chair of Food Chemistry and Molecular Science, Technical University Munich, Germany, for the NMR measurements.

Funding

Open Access funding provided by Projekt DEAL. The study was supported by a grant from the Deutsche Forschungsgemeinschaft (RY 19/17–1).

Author information

Authors and Affiliations

Contributions

T. Bachmann and M. Rychlik conceived and designed the experiments; T.B. and A. Maurer performed the experiments and analyzed the data; T. Bachmann and M. Rychlik wrote the manuscript. All authors contributed to the revision of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 393 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bachmann, T., Maurer, A. & Rychlik, M. Development of a LC-MS/MS method using stable isotope dilution for the quantification of individual B6 vitamers in fruits, vegetables, and cereals. Anal Bioanal Chem 412, 7237–7252 (2020). https://doi.org/10.1007/s00216-020-02857-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-020-02857-5