Abstract

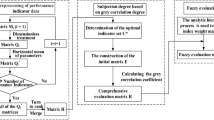

Although there are many types of cutting tool materials, no single cutting tool material meets all the needs of machining applications because of the complex and changeable cutting conditions. It is crucial to study the matching between tool materials and workpiece materials for improving productivity, obtaining good surface quality and reducing machining cost. In this paper, rule-based reasoning (RBR) method and gray complex proportional assessment (COPRAS-G) method are applied to solve the problem of cutting tool material selection. RBR is used for primary selection of tool materials to reduce the number of alternatives and the computational complexity in COPRAS-G method. Ten attributes of tool materials including physical, mechanical, chemical, and cost parameters are selected as criteria in the COPRAS-G method, and entropy method and analytic hierarchy process (AHP) are used to determine the objective weights and subjective weights of attributes, respectively. Finally, the ranking of several alternatives is obtained to select the most suitable cutting tool material. Taking the cutting tool material selection of machining CGI as an example to validate the method proposed in this paper. The research results revealed that the alumina ceramic has the best comprehensive performance, alumina ceramic cutting tools containing carbides to improve the flexural strength and fracture toughness, or cemented carbide cutting tools with alumina coating are preferred for machining CGI. High-speed milling experiments of CGI were carried out, and the results showed that the alumina-coated tungsten carbide tools had longer tool life than the silicon nitride ceramic tools, which confirmed the effectiveness of the proposed cutting tool material selection method. And this method can be extended to other engineering applications in material selection problems.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Zhou DC, Dai X (2015) A granulation analysis method for cutting tool material selection using granular computing. ARCHIVE Proc IMechE Part C: J Mech Eng Sci 230(13):2323–2336. https://doi.org/10.1177/0954406215593566

Klocke F, Kuchle A (2011). Manufacturing processes 1: cutting. Springer Berlin Heidelberg. DOI: https://doi.org/10.1007/978-3-642-11979-8

Yu QX (2002) On the historical development and future prospect of cutting tool material. Mech Eng 1:9–12 http://en.cnki.com.cn/Article_en/CJFDTOTAL-JXGU200201002.htm

Deng JX (2001) Study on matching of cutting tools with workpiece materials. Tool Eng. http://en.cnki.com.cn/Article_en/CJFDTOTAL-GJJS200110001.htm

An HP, Rui ZY, Wang RF, Guo JF (2011) A new method on choosing tool materials at high speed machining. Adv Mater Res 291-294:745–749

Zhou J, Deng JX, Liu LL, Liu ZQ, Ai X (2006) Intelligent matching of cutting tools with workpiece materials. Key Eng Mater 315-316:411–415

Edalew KO, Abdalla HS, Nash RJ (2001) A computer-based intelligent system for automatic tool selection. Mater Des 22(5):337–351

Rao RV, Patel BK (2010) A subjective and objective integrated multiple attribute decision making method for material selection. Mater Des 31(10):4738–4747

Mousavi-Nasab SH, Sotoudeh-Anvari A (2017) A comprehensive MCDM-based approach using TOPSIS, COPRAS and DEA as an auxiliary tool for material selection problems. Mater Des 121:237–253

Maity SR, Chatterjee P, Chakraborty S (2012) Cutting tool material selection using grey complex proportional assessment method. Mater Des 36:372–378

Çalışkan H (2013) Selection of boron based tribological hard coatings using multi-criteria decision-making methods. Mater Des 50(17):742–749

Li AH, Wu YM, Zhao J, Gong ZC (2016) Tool material selection based on analytic hierarchy process method in machining al-si piston alloy. Mater Sci Forum 836-837:277–282

Athawale VM, Kumar R, Chakraborty S (2011) Decision making for material selection using the UTA method. Int J Adv Manuf Technol 57(1–4):11–22

Guo P, Zou B, Huang CZ, Gao HB (2017) Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J Mater Process Technol 240:12–22

Wang YS, Zou B, Huang CZ (2019) Tool wear mechanisms and micro-channels quality in micro-machining of Ti-6Al-4V alloy using the Ti(C7N3)-based cermet micro-mills. Tribol Int 134:60–76

Lee SW, Lee HK (2009) Rule-based cutting condition recommendation system for intelligent machine tools. J Mech Sci Technol 23(4):1202–1210

Novák V, Lehmke S (2006) Logical structure of fuzzy if-then rules. Fuzzy Sets Syst 157(15):2003–2029

Wang R, Zhao W, Luo CJ, Wang ZY, Luo T (2014) An intelligent tool selection system based on CRB and RBR. Open Mech Eng J 8(1):795–802

Wang YS, Zou B, Huang CZ, Qi H, Song JP (2019) Feasibility study of the Ti(C7N3)-based cermet micro-mill based on dynamic fatigue behavior and modeling of the contact stress distribution on the round cutting edge. Int J Mech Sci 155:143–158

Xing HY, Zou B, Liu XY, Wang XF, Chen QH, Fu XS, Li YS (2020) Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technol 359:314–322

Liu XY, Zou B, Xing HY, Huang CZ (2019) The preparation of ZrO2-Al2O3 composite ceramic by SLA-3D printing and sintering processing. Ceram Int, 46(1)

Saha A, Majumder H (2016) Multi criteria selection of optimal machining parameter in turning operation using comprehensive grey complex proportional assessment method for ASTM A36. Int J Eng Res Afr 23:24–32

Zavadskas EK, Kaklauskas A, Turskis Z, Tamošaitienė J (2009) Multi-attribute decision-making model by applying grey numbers. Informatica 20(2):305–320

Rao RV (2013) Decision making in the manufacturing environment: using graph theory and fuzzy multiple attribute decision making methods. Springer Series in Advanced Manufacturing https://doi.org/10.1007/978-1-4471-4375-8

Sen P, Yang JB (1998) Multiple criteria decision support in engineering design. Springer Science & Business Media https://doi.org/10.1007/978-1-4471-3020-8

Rao RV, Davim JP (2008) A decision-making framework model for material selection using a combined multiple attribute decision-making method. Int J Adv Manuf Technol 35(7–8):751–760

Rao RV (2006) Machinability evaluation of work materials using a combined multiple attribute decision-making method. Int J Adv Manuf Technol 28(3–4):221–227

Liu LH, Wang YC, Bai FX, Wang DS (2018) Optimization of tool material selection based on analytic hierarchy process and TOPSIS. Modular Machine Tool & Automatic Manufacturing Technique, 4, 043. http://en.cnki.com.cn/Article_en/CJFDTotal-ZHJC201804043.htm

Saaty TL (2000) Fundamentals of decision making and priority theory with the analytical ierarchy process. Analytic hierarchy process

Klocke F, Kuchle A (2011) Cutting tool materials and tools. Manufacturing processes 1. Springer Berlin Heidelberg, 95–196. https://doi.org/10.1007/978-3-642-11979-8_4

Huang WJ (2010) Quick search manual for tool materials. China Machine Press

Wong T, Kim W, Kwon P (2004) Experimental support for a model-based prediction of tool wear. Wear 257(7):790–798

Chen ZY (2005) Chemical thermodynamics of refractories. Metallurgical industry press, Beijing

Zhou Z (1992) Metal cutting theory. Mechanical Industry Press, Beijing

Shao F, Liu ZQ, Wan Y (2010) Thermo dynamical matching of alumina-based composite ceramic tools with typical workpiece materials. Int J Adv Manuf Technol 49(5–8):567–578

Wang YS, Zou B, Wang JC, Wu Y, Huang CH (2020) Effect of the progressive tool wear on surface topography and chip formation in micro-milling of Ti–6Al–4V using Ti(C7N3)-based cermet micro-mill. Tribol Int 141:105900

Niu JH, Huang CZ, Su R, Zou B, Wang J, Liu ZQ, Li CW (2019) Study on surface integrity of compacted graphite iron milled by cemented carbide tools and ceramic tools. Int J Adv Manuf Technol 103:4123–4134. https://doi.org/10.1007/s00170-019-03592-7

Funding

This work is financially supported by Major Program of Shandong Province Natural Science Foundation (ZR2018ZA0401).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niu, J., Huang, C., Li, C. et al. A comprehensive method for selecting cutting tool materials. Int J Adv Manuf Technol 110, 229–240 (2020). https://doi.org/10.1007/s00170-020-05534-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05534-0