Abstract

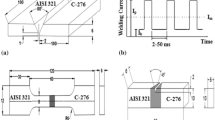

In this research, mechanical and corrosion properties of dissimilar joint between duplex stainless steel UNS S32750 duplex stainless steel and AISI 321 austenite stainless steel welded by pulsed current gas tungsten arc welding (PCGTAW) and continuous current gas tungsten arc welding (CCGTAW) were compared. The welding parameters and the filler metal were the same in both methods. Microstructural characterization of joint was determined by optical and scanning electron microscope. The pitting potential was evaluated by potentiodynamic polarization test in 3.5 wt.% NaCl solution at room temperature. Mechanical properties of optimal joint were investigated by impact test and vickers microhardness. Microstructural evaluation shows that the equal amounts of ferrite and austenite were obtained in PCGTAW weldment, while in CCGTAW weldment fraction of phases changed to 40% ferrite and 60% austenite. TiN precipitations were formed in fusion line of CCGTAW weldment on the side of AISI 321 austenite stainless steel. The average values of hardness in PCGTAW and CCGTAW weld zone were 241 and 225 HV0.2, respectively. The higher amount of ferrite in PCGTAW weldment in comparison with CCGTAW weldment was the reason of higher hardness average. The toughness of PCGTAW and CCGTAW was 106 and 102 J, respectively. Based on cyclic polarization test, pitting potential of weldment welded with PCGTAW and CCGTAW was 1.03 and 0.8 V, respectively, which is a proof of better pitting corrosion resistance of the weld zone in PCGTAW method.

Similar content being viewed by others

References

Xu D, Xia J, Zhou E, Zhang D, Li H, Yang C, Li Q, Lin H, Li X, Yang K (2017) Accelerated corrosion of 2205 duplex stainless steel caused by marine aerobic Pseudomonas aeruginosa biofilm. Bioelectrochemistry 113:1–8

Zhang Z, Jing H, Xu L, Han Y, Zhao L, Zhang J (2017) Influence of microstructure and elemental partitioning on pitting corrosion resistance of duplex stainless steel welding joints. Appl Surf Sci 394:297–314

Moteshakker A, Danaee I, Moeinifar S, Ashrafi A (2016) Hardness and tensile properties of dissimilar welds joints between SAF 2205 and AISI 316L. Sci Technol Weld Join 21(1):1–10

Shockley JM, Horton DJ, Wahl KJ (2017) Effect of aging of 2507 super duplex stainless steel on sliding tribocorrosion in chloride solution. Wear 380-381:251–259

Zhang Z, Zhao H, Zhang H, Hu J, Jin J (2017) Microstructure evolution and pitting corrosion behavior of UNS S32750 super duplex stainless steel welds after short-time heat treatment. Corros Sci 121:22–31

Hongyun L, Yubo Z, Hongdou L, Jinlong L, Yue M (2017) Characterization of the oxide films formed on low temperature sensitized AISI 321 stainless steel with different strain levels in elevated temperature borate buffer solution. J Alloys Compd 696:1235–1243

Sharma S, Taiwade RV, Vashishtha H (2017) Effect of continuous and pulsed current gas tungsten arc welding on dissimilar weldments between hastelloy C-276/AISI 321 austenitic stainless steel. J Mater Eng Perform 26(3):1146–1157

Tiamiyu A, Eskandari M, Sanayei M, Odeshi A, Szpunar J (2016) Mechanical behavior and high-resolution EBSD investigation of the microstructural evolution in AISI 321 stainless steel under dynamic loading condition. Mater Sci Eng A 673:400–416

Padmanaban G, Balasubramanian V (2011) Metallurgical characterization of pulsed current gas tungsten arc, friction stir and laser beam welded AZ31B magnesium alloy joints. Mater Chem Phys 125(3):686–697

Ramkumar KD, Chandrasekhar A, Srivastava A, Preyas H, Chandra S, Dev S, Arivazhagan N (2016) Effects of filler metals on the segregation, mechanical properties and hot corrosion behaviour of pulsed current gas tungsten arc welded super-austenitic stainless steel. J Manuf Process 24:46–61

Ramkumar KD, Thiruvengatam G, Sudharsan S, Mishra D, Arivazhagan N, Sridhar R (2014) Characterization of weld strength and impact toughness in the multi-pass welding of super-duplex stainless steel UNS 32750. Mater Des 60:125–135

Kang D, Lee H (2013) Study of the correlation between pitting corrosion and the component ratio of the dual phase in duplex stainless steel welds. Corros Sci 74:396–407

Kangazian J, Shamanian M, Ashrafi A (2017) Dissimilar welding between SAF 2507 stainless steel and Incoloy 825 Ni-based alloy: the role of microstructure on corrosion behavior of the weld metals. J Manuf Process 29:376–388

Abdollahi A, Shamanian M, Golozar MA (2018) Parametric optimization of pulsed current gas arc welding of dissimilar welding between UNS32750 and AISI 321 based on Taguchi method. Trans Indian Inst Metals 71(3):597–603

Atlas Steels Australia, Stainless Steel - Grade 310 (UNSS31000) http://www.azom.com/article.aspx?ArticleID=966.

Outokumpu Stainless A (2013) Handbook of stainless steel. Outokumpu Stainless AB, Avesta

Neissi R, Shamanian M, Hajihashemi M (2016) The effect of constant and pulsed current gas tungsten arc welding on joint properties of 2205 duplex stainless steel to 316L austenitic stainless steel. J Mater Eng Perform 25(5):2017–2028

Yousefieh M, Shamanian M, Saatchi A (2011) Optimization of the pulsed current gas tungsten arc welding (PCGTAW) parameters for corrosion resistance of super duplex stainless steel (UNS S32760) welds using the Taguchi method. J Alloys Compd 509(3):782–788

ASTM E (2007) Standard test methods for notched bar impact testing of metallic materials. E23-07a, Pennsylvania, PA, USA

ASTM G (2003) “48-03.” Pitting and crevice corrosion resistance of stainless steels, USA

Sun Y, Wu X, Wu X, Li J, Jiang Y (2016) Influence of multi-pass welding on the microstructure evolution and corrosion resistance of a super duplex stainless steel. Int J Electrochem Sci 11(11):9666–9675

Muthupandi V, Srinivasan PB, Seshadri S, Sundaresan S (2003) Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater Sci Eng A 358(1):9–16

Kotecki D, Lippold J (2005) Welding metallurgy and weldability of stainless steels. Wiley, Hoboken

Barbero B, Ureta E (2011) Comparative study of different digitization techniques and their accuracy. Comput Aided Des 43:188–206

Leban MB, Tisu R (2013) The effect of TiN inclusions and deformation-induced martensite on the corrosion properties of AISI 321 stainless steel. Eng Fail Anal 33:430–438

Chawla KK, Meyers M (1999) Mechanical behavior of materials. Prentice Hall, Upper Saddle River

Verma J, Taiwade RV (2016) Effect of austenitic and austeno-ferritic electrodes on 2205 duplex and 316L austenitic stainless steel dissimilar welds. J Mater Eng Perform 25(11):4706–4717

Pardo A, Merino M, Coy A, Viejo F, Arrabal R, Matykina E (2008) Pitting corrosion behaviour of austenitic stainless steels–combining effects of Mn and Mo additions. Corros Sci 50(6):1796–1806

Kelly RG, Scully JR, Shoesmith D, Buchheit RG (2002) Electrochemical techniques in corrosion science and engineering. CRC Press, Boca Raton

Liou H-Y, Hsieh R-I, Tsai W-T (2002) Microstructure and pitting corrosion in simulated heat-affected zones of duplex stainless steels. Mater Chem Phys 74(1):33–42

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdollahi, A., Shamanian, M. & Golozar, M.A. Comparison of pulsed and continuous current gas tungsten arc welding in dissimilar welding between UNS S32750 and AISI 321 in optimized condition. Int J Adv Manuf Technol 97, 687–696 (2018). https://doi.org/10.1007/s00170-018-1963-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1963-4