Abstract

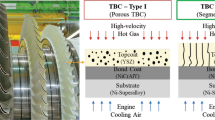

High grinding temperature restricts the machining efficiency and precision of some aeronautical difficult-to-machine materials. Aiming to enhance heat exchange with the grinding zone and reduce grinding temperature, heat pipe grinding wheel (HPGW) provides a novel method through improving the thermal conductivity of grinding wheel assisted by heat pipe. In this paper, the structure of HPGW is introduced and the workpiece temperature and energy partition in wet grinding using HPGW based on a wheel-fluid composite surface model is analyzed. Wet grinding experiments including creep feed grinding, high-speed shallow grinding and high-efficiency deep grinding (HEDG) are carried to investigate the cooling characteristics of HPGW according to the workpieces of titanium alloy Ti-6A1-6 V and Inconel 718. Compared with using the traditional grinding wheel, the results show that using HPGW in creep feed grinding and HEDG can maintain a lower grinding temperature and avoid the burnout under a relatively high removal rate, but cooling effect of HPGW is not obviously different from the traditional grinding wheel in high-speed shallow grinding due to a small heat input at the evaporator of HPGW.

Similar content being viewed by others

References

Harebell S, Woolley NH, Tridimas YD, Allanson DR, Rowe WB (2000) The effects of cutting fluid application methods on the grinding process. Int J Mach Tool Manu 40:209–223

Morgan MN, Jackson AR, Wu H, Baines-Jones V, Batako A, Rowe WB (2008) Optimisation of fluid application in grinding. CIRP Ann Manuf Technol 57:363–366

Mao C, Tang XJ, Zou HF, Zhou ZX, Yin WW (2012) Experimental investigation of surface quality for minimum quantity oil–water lubrication grinding. Int J Adv Manuf Technol 59:93–100

Hadad MJ, Tawakoli T, Sadeghi MH, Sadeghi B (2012) Temperature and energy partition in minimum quantity lubrication-MQL grinding process. Int J Mach Tool Manu 54–55:10–17

Morgan MN, Barczak L, Batako A (2012) Temperatures in fine grinding with minimum quantity lubrication (MQL). Int J Adv Manuf Technol 60:951–958

Manimaran G, Kumar PM, Venkatasamy R (2014) Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 59:76–83

Elanchezhian J, Kumar PM, Manimaran G (2015) Grinding titanium Ti-6Al-4V alloy with electroplated cubic boron nitride wheel under cryogenic cooling. J Mech Sci Technol 29:4885–4890

Nguyen T, Liu M, Zhang LC (2014) Cooling by sub-zero cold air jet in the grinding of a cylindrical component. Int J Adv Manuf Technol 73:341–352

Lee PH, Lee SW (2011) Experimental characterization of micro-grinding process using compressed chilly air. Int J Mach Tool Manu 51:201–209

Bhaskar P, Chattopadhyay AK, Chattopadhyay AB (2010) Development and performance evaluation of monolayer brazed cBN grinding wheel on bearing steel. Int J Adv Manuf Technol 48:935–944

Chen JY, Huang H, Xu XP (2009) An experimental study on the grinding of alumina with a monolayer brazed diamond wheel. Int J Adv Manuf Technol 41:16–23

Liang L, Quan YM, Ke ZY (2011) Investigation of tool-chip interface temperature in dry turning assisted by heat pipe cooling. Int J Adv Manuf Technol 54:35–4317

Liang L, Quan YM (2013) Investigation of heat partition in dry turning assisted by heat pipe cooling. Int J Adv Manuf Technol 66:1931–1941

He QS, Fu YC, Xu HJ, Ma K (2014) Investigation of a heat pipe cooling system in high-efficiency grinding. Int J Adv Manuf Technol 70:833–842

He QS, Fu YC, Chen JJ, Zhang W (2016) Investigation on heat transfer performance of heat pipe grinding wheel in dry grinding. J Manuf Sci Eng 138:111009–1–111009–8

He QS, Fu YC, Xu HJ, Ma K, Chen C (2013) Development of annular heat pipe grinding wheel for high efficiency machining of TC4 titanium alloy. Acta Aeronautica Et Astronautica Sinica 34:1740–1747

Guo CS, Malkin S (2000) Energy partition and cooling during grinding. J Manuf Process 2:151–157

Malkin S, Guo C (2007) Thermal analysis of grinding. CIRP Ann Manuf Techn 56:760–782

Funding

This study receives financial support from the Youth Science Foundation of China (No. 51605144) and the National Natural Science Foundation of China (No. U1604254 and No. 51775170).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Q., Fu, Y., Chen, J. et al. Experimental investigation of cooling characteristics in wet grinding using heat pipe grinding wheel. Int J Adv Manuf Technol 97, 621–627 (2018). https://doi.org/10.1007/s00170-018-1881-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1881-5