Abstract

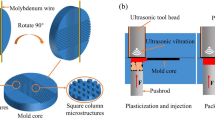

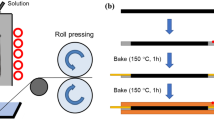

Micro-injection molding (μIM) is considered to be an important method for fabricating micro-needle array which is widely researched in recent years, and mold temperature is one of the important factors that affect the mold filling quality of the polymer melt during the micro-injection molding. In this paper, an infrared heating method is adopted to raise the mold temperature rapidly for improving molding quality of micro-needle array. According to the simulation of the reflector type, which has an important effect on the efficiency of infrared heating system, an infrared heating system with high efficiency is developed and used in the developed infrared-heating-assisted μIM system. A series of verification experiments are carried out to verify the feasibility and the heating effect of the developed system. The experimental results show that the developed infrared heating system can achieve high efficiency and uniform heating of mold surface and the infrared-heating-assisted μIM process for fabricating micro-needle array can improve mold filling capability of the polymer melt and optimize the replication quality (filling height, uniformity, and shrinkage) of parts.

Similar content being viewed by others

References

Prausnitz MR (2004) Microneedles for transdermal drug delivery. Adv Drug Deliv Rev 56(5):581–587

Goncalves SB, Oliveira MJ, Peixoto AC, Silva AF, Correia JH (2016) Out-of-plane neural microelectrode arrays fabrication using conventional blade dicing. Int J Adv Manuf Technol 85(1):431–442

Michaeli W, Opfermann D, Kamps T (2007) Advances in micro assembly injection moulding for use in medical systems. Int J Adv Manuf Technol 33(1):206–211

Oh J, Liu K, Medina T, Kralick F, Noh H (2014) A novel microneedle array for the treatment of hydrocephalus. Microsyst Technol 20(6):1169–1179

Wang MH, Zhu D (2009) Fabrication of multiple electrodes and their application for micro-holes array in ECM. Int J Adv Manuf Technol 41(1):42–47

Park IB, Ha YM, Lee SH (2010) Cross-section segmentation for improving the shape accuracy of microstructure array in projection microstereolithography. Int J Adv Manuf Technol 46(1):151–161

Li K, Ju J, Xue Z, Ma J, Feng L, Gao S, Jiang L (2013) Structured cone arrays for continuous and effective collection of micron-sized oil droplets from water. Nat Commun 4(4):2276–2276

Valdés-Ramírez G, Li YC, Kim J, Jia W, Bandodkar AJ, Nuñez-Flores R, Miller PR, Wu SY, Narayan R, Windmiller JR, Polsky R, Wang J (2014) Microneedle-based self-powered glucose sensor. Electrochem Commun 47:58–62

Forvi E, Bedoni M, Carabalona R, Soncini M, Mazzoleni P, Rizzo F, O’Mahony C, Morasso C, Cassarà DG, Gramatica F (2012) Preliminary technological assessment of microneedles-based dry electrodes for biopotential monitoring in clinical examinations. Sens Actuators A 180(180):177–186

Zhou W, Song R, Pan X, Peng Y, Qi X, Peng J, Hui KS, Hui KN (2013) Fabrication and impedance measurement of novel metal dry bioelectrode. Sens Actuators A 201(10):127–133

Jiang BY, Zhou MY, Weng C, Zhang L, Lv H (2016) Fabrication of nanopillar arrays by combining electroforming and injection molding. Int J Adv Manuf Technol 86(5–8):1319–1328

Lu Z, Zhang KF (2009) Morphology and mechanical properties of polypropylene micro-arrays by micro-injection molding. Int J Adv Manuf Technol 40(5):490–496

Sha B, Dimov S, Griffiths C, Packianather MS (2007) Micro-injection moulding: factors affecting the achievable aspect ratios. Int J Adv Manuf Technol 33(1–2):147–156

Kim WW, Gang MG, Min BK, Kim WB (2014) Experimental and numerical investigations of cavity filling process in injection moulding for microcantilever structures. Int J Adv Manuf Technol 75(1–4):293–304

Qiu Z, Zheng H, Fang FZ, Wang HY (2012) Longitudinal ultrasound-assisted micro-injection moulding method. Nanotechnol Precis Eng 10(2):170–176

Gao S, Qiu Z, Ma Z, Yang Y (2016) Flow properties of polymer melt in longitudinal ultrasonic-assisted micro-injection molding. Polym Eng Sci. doi:10.1002/pen.24455

Qiu Z, Yang X, Zheng H, Gao S, Fang F (2015) Investigation of micro-injection molding based on longitudinal ultrasonic vibration core. Appl Opt 54(28):8399–8405

Attia UM, Alcock JR (2010) Optimising process conditions for multiple quality criteria in micro-injection moulding. Int J Adv Manuf Technol 50(5):533–542

Kurt M, Kaynak Y, Kamber OS, Mutlu B, Bakir B, Koklu U (2010) Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int J Adv Manuf Technol 46(5):571–578

Chen SC, Peng HS, Chang JA, Jong WR (2004) Simulations and verifications of induction heating on a mold plate. Int Commun Heat Mass Transfer 31(7):971–980

Kim DH, Kang MH, Chun YH (2001) Development of a new injection molding technology: momentary mold surface heating process. J Injection Molding Technol 5(4):229–232

Xiao CL, Huang HX (2014) Development of a rapid thermal cycling molding with electric heating and water impingement cooling for injection molding applications. Appl Therm Eng 73(1):710–720

Jeng MC, Chen SC, Minh PS, Chang JA, Chung CS (2010) Rapid mold temperature control in injection molding by using steam heating. Int Commun Heat Mass Transfer 37(9):1295–1304

Chang PC, Hwang SJ (2006) Experimental investigation of infrared rapid surface heating for injection molding. J Appl Polym Sci 102(4):3704–3713

Chang PC, Hwang SJ (2006) Simulation of infrared rapid surface heating for injection molding. Int Commun Heat Mass Transfer 49(21–22):3846–3854

Saito T, Satoh I, Kurosaki Y (2002) A new concept of active temperature control for an injection molding process using infrared radiation heating. Polym Eng Sci 42(12):2418–2429

Yu MC, Young WB, Hsu PM (2007) Micro-injection molding with the infrared assisted mold heating system. Mater Sci Eng A 460(14):288–295

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, S., Qiu, Z., Ma, Z. et al. Development of high efficiency infrared-heating-assisted micro-injection molding for fabricating micro-needle array. Int J Adv Manuf Technol 92, 831–838 (2017). https://doi.org/10.1007/s00170-017-0169-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0169-5