Abstract

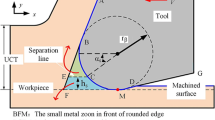

This article develops a model simulating the formation of the tension condition on the flank surface of a tool’s tooth in orthogonal cutting based on the example of face milling and using the plastic theory of contact interaction of bodies. A calculation was performed in the ANSYS/LS-DYNA program using the finite element method. The model allows us to determine the stress value on the cutting tool’s flank surface for various cutting modes. Analysis of the orthogonal cutting process has been carried out using the simulation model that allows the following to be defined: the flank surface stress diagram model, introducing the flank wear value defined by the processes of the shear zone, and contact interaction of the cutting tool’s flank surface and the workpiece. The basic and normal cutting force components in the cross section perpendicular to the cutting edge were obtained. Our main result is the mathematical model of the force in the orthogonal cutting scheme, introducing the force components on the front surface conditioned by the processes of the shear zone and on the flank surface of the cutting tool, introducing the flank wear value.

Similar content being viewed by others

References

Albrecht P (1960) New developments in the theory of the metal cutting processes, part 1. The ploughing process in metal cutting. ASME J Eng Ind 82:348–357

Zorev NN (1961) Mechanics of metal cutting. Moscow, Mashgiz

Stevenson R (1998) The measurement of parasitic forces in orthogonal cutting. Int J Mach Tools Manuf 38(1–2):113–130

Cui X, Zhao J (2012) Cutting force and tool wear in face milling of hardened steel. Mat Sci Forum 723:77–81. doi:10.4028/www.scientific.net/MSF.723.77

Chang C-S (2001) A force model of face milling tool considering wear. J Chin Soc Mech Eng Trans Chin Inst Eng Ser C/Chung-Kuo Chi Hsueh Kung Ch’eng Hsuebo Pao 22(3):187–202

Matsumura T, Shimada M, Teramoto K, Usui E (2013) Predictive cutting force model and cutting force chart for milling with cutter axis inclination. Int J Autom Technol 7(1):30–38

Pimenov DY, Guzeev VI, Koshin AA (2011) Influence of cutting conditions on the stress at tool rear surface. Rus Eng Res 31(11):1151–1155. doi:10.3103/S1068798X11110207

Popov A, Dugin A (2014) Effect of uncut chip thickness on the ploughing force in orthogonal cutting. Int J Adv Manuf Technol 76(9–12):1937–1945. doi:10.1007/s00170-014-6423-1

Lipatov AA, Chigirinskii YL, Kormilitsyn SI (2010) Determining the cutting forces at the rear tool surface. Rus Eng Res 30(11):1158–1160. doi:10.3103/S1068798X10110183

Popov A, Dugin A (2012) Experimental methods of determining the cutting forces at the tool rear surface. Rus Eng Res 32(1):68–69. doi:10.3103/S1068798X12010248

Popov A, Dugin A (2013) A comparison of experimental estimation methods of the ploughing force in orthogonal cutting. Int J Mach Tools Manuf 65:37–40. doi:10.1016/j.ijmachtools.2012.09.003

Guo Y, Chou Y (2004) Determination of ploughing force and its influence on material properties in metal cutting. J Mater Process Technol 148(3):368–375. doi:10.1016/j.jmatprotec.2004.02.052

Karpat Y, Özel T (2006) Predictive analytical and thermal modeling of orthogonal cutting process—part II: effect of tool flank wear on tool forces, stresses, and temperature distributions. J Manuf Sci E-T ASME 128(2):445–453. doi:10.1115/1.2162591

Wang J, Huang CZ, Song WG (2003) The effect of tool flank wear on the orthogonal cutting process and its practical implications. J Mater Process Technol 142(2):338–346. doi:10.1016/S0924-0136(03)00604-6

Tang ZT, Liu ZQ, Pan YZ, Wan Y, Ai X (2009) The influence of tool flank wear on residual stresses induced by milling aluminum alloy. J Mater Process Technol 209(9):4502–4508. doi:10.1016/j.jmatprotec.2008.10.034

Waldorf DJ, Kapoor SG, DeVor RE (1999) Worn tool forces based on ploughing stresses. SME Tech Paper MR (MR99–171): 1–6

Waldorf DJ, Kapoor SG, DeVor RE (1998) A slip-line field for ploughing during orthogonal cutting. ASME J of Manuf Sci Eng 120(4):693–699

Manjunathaiah J, Endres WJ (2000) A new model and analysis of orthogonal machining with an edge-radiused tool. J Manuf Sci E-T ASME 122(3):384–390

Schimmel RJ, Endres WJ, Stevenson R (2000) Effect of zero-clearance lands in orthogonal machining in light of an internally consistent material model. Mach Sci Technol 4(1):101–125

Coelho RT, Braghini JA, Valente CMO, Medalha GC (2003) Experimental evaluation of cutting force parameters applying mechanistic model in orthogonal milling. J Braz Soc Mech Sci Eng 25(3):247–253

Kishawy HA, Haglund AJ, Deiab IM (2006) An analysis of machining with honed tools using ale finite element model: ploughing force and minimum chip thickness. Trans N Am Manuf Res Inst SME 34:277–284

Liu K, Melkote SN (2007) Finite element analysis of the influence of tool edge radius on size effect in orthogonal micro-cutting process. Int J Mech Sci 49(5):650–660. doi:10.1016/j.ijmecsci.2006.09.012

Chermenskii ON, Borisov ED (2009) Analysis of cutting on the basis of plasticity theory. Rus Eng Res 29(2):169–174. doi:10.3103/S1068798X09020130

Dundur ST, Das NS (2009) Slipline field modeling of orthogonal machining for a worn tool with elastic effects and adhesion friction at the contact regions. J Mater Process Technol 209(1):18–25. doi:10.1016/j.jmatprotec.2008.01.022

Wyen C-F, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann Manufac Techn 59(1):93–96. doi:10.1016/j.cirp.2010.03.056

Afazov SM, Ratchev SM, Segal J (2010) Modelling and simulation of micro-milling cutting forces. J Mater Process Technol 210(15):2154–2162. doi:10.1016/j.jmatprotec.2010.07.033

Storch B, Zawada-Tomkiewicz A (2012) Distribution of unit forces on the tool edge rounding in the case of finishing turning. Int J Adv Manuf Technol 60(5–8):453–461. doi:10.1007/s00170-011-3617-7

Afazov SM, Ratchev SM, Segal J (2012) Prediction and experimental validation of micro-milling cutting forces of AISI H13 steel at hardness between 35 and 60 HRC. Int J Adv Manuf Technol 62(9–12):887–899. doi:10.1007/s00170-011-3864-7

Annoni M, Biella G, Rebaioli L, Semeraro Q (2013) Microcutting force prediction by means of a slip-line field force model. Procedia CIRP 8:558–563. doi:10.1016/j.procir.2013.06.150

Oraby SE (2013) Influence of regular and random cutting tool deformation on the cutting force of three-dimensional turning operation. Int J Mach Mach Mater 14(4):311–341. doi:10.1504/IJMMM.2013.057585

Wang BB, Xie LJ, Wang XB, Chen XL (2014) Simulation studies of the cutting process on SiCp/Al composites with different volume fraction of reinforced SiC particles. Mat Sci Forum 800–801:321–326. doi:10.4028/www.scientific.net/MSF.800-801.321

Uysal A, Altan E (2014) A new slip-line field modeling of orthogonal machining with a rounded-edge worn cutting tool. Mach Sci Technol 18(3):386–423. doi:10.1080/10910344.2014.925375

Zhang H, Wang X, Pang S (2014) A mathematical modeling to predict the cutting forces in microdrilling. Math Probl Eng 2014:543298. doi:10.1155/2014/543298

Wang G, Dong H, Guo Y, Ke Y (2015) Dynamic cutting force modeling and experimental study of industrial robotic boring. Int J Adv Manuf Technol (Article in Press). doi:10.1007/s00170-015-8166-z

Rebaioli L, Biella G, Annoni M, Rhett Mayor J, Semeraro Q (2015) Applicability of an orthogonal cutting slip-line field model for the microscale. Proc Inst Mech Eng B J Eng Manuf 229(12):2250–2264. doi:10.1177/0954405414553456

Uysal A, Altan E (2015) Effect of ploughing force on cutting forces in micro-cutting with a rounded-edge cutting tool. Mater Today: Proc 2(1):224–229. doi:10.1016/j.matpr.2015.04.026

Armarego IJA, Braun RH (1977) Metal cutting. Mashinostroenie, Moscow

Black DT (1979) Model of the stress due to plastic flow in metal cutting. Trans ASME 4:124–126

Arola D, Ramulu M (1997) Orthogonal cutting of fiber-reinforced composites: a finite element analysis. Int J Mech Sci 39(5):597–613

Vahid K, Lundblad M, Lindgren L-E (2001) Numerical and experimental analysis of orthogonal metal cutting. Doctoral Thesis. Instituten för Maskintechnik Avdelningen för Datorstödd maskinkonstruktion, 28, ISSN: 1402–1544•ISRN: LTU-DT. 01/28--SE p. 7

Koshin AA (1995) Theory and optimization of the accuracy of multiple-cutter machining. Dis ... Dr. eng. sciences, Chelyabinsk: South Urals State University

Birger IA, Panovko YG (1968) Strength, stability, vibration. Handbook in three volumes. Vols. 1 and 2. Moscow, Mashinostroenie

Sedov LI (1970) Continuum mechanics, vol 1. Mashinostroenie, Moscow, p. 492

Luriye AI (1970) Elasticity theory. Science, Moscow 940 p

Jeffriss G, Swirls B (1970) Mathematical physics methods. Translated from English. / Edited by Zharova V.N. Moscow, Mir., 352 p

Korchak SN (1971) Influence of technological factors on the productivity in milling steel parts: Dis ... Dr. eng. sciences, Chelyabinsk: South Urals State University

D’yakonov AA (2012) Improvement of grinding speeds by assessing the machinability of materials. Rus Eng Res 32(7–8):604–607. doi:10.3103/S1068798X12060068

Polukhin PI, Gun GY, Galkin AM (1976) Resistance of metals and alloys to plastic deformation. Metallurgiya, Moscow

AG Rahshtadta, VA Brostrema (1976). Handbook metallist: Handbook in 5 volumes. Vol. 2, Mashinostroenie, 720 p

Gallagher R (1984) Finite element analysis. Fundamentals: Trans. from English Moscow. Mir. 428 p

Komvopoulos K, Erpenbeck SA (1990) Finite element modeling of orthogonal metal cutting. ASME Mater Div 20:1–23

Chen L, El-Wardany TI, Harris WC (2004) Modelling the effects of flank wear land and chip formation on residual stresses. CIRP Ann Manuf Technol 53(1):95–98. doi:10.1016/S0007-8506(07)60653-2

Swenson ED, Black JT (2011) Finite element model tuning with spatially-dense 3D modes. Exp Mech 51(6):933–945. doi:10.1007/s11340-010-9421-8

Daoud M, Chatelain JF, Bouzid A (2015) Effect of rake angle on Johnson-Cook material constants and their impact on cutting process parameters of Al2024-T3 alloy machining simulation. Int J Adv Manuf Technol 81(9–12):1987–1997. doi:10.1007/s00170-015-7179-y

ANSYS Release 10.0 Documentation

Guzeev VI, Batuev VA, Surkov IV (2005) Cutting regimes for turning and mill-boring machines with program numerical control.Spravochnik, Guzeev VI, Ed, Moscow: Mashinostroenie

Poletika MF (1969) Contact loads on the tool cutting surfaces. Mashinostronie, Moscow

Guzeev VI (1994) More productive contour machining of parts of different precision on numerically controlled lathes and milling machines, Dis. .. Dr. eng. sciences, Chelyabinsk: South Urals State University

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pimenov, D.Y., Guzeev, V.I. Mathematical model of plowing forces to account for flank wear using FME modeling for orthogonal cutting scheme. Int J Adv Manuf Technol 89, 3149–3159 (2017). https://doi.org/10.1007/s00170-016-9216-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9216-x