Abstract

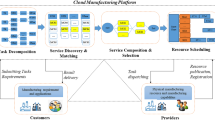

Cloud manufacturing has experienced a rapid development in the past several years. The research on its theories, technologies, and applications still keeps attracting attentions from more and more researchers. One of the most important issues to its improvements and quality of manufacturing service is the optimization of value network. This paper researched the optimization method of cloud manufacturing value network based on the Analytic Hierarchy Process (AHP) method and the dynamic programming of business decisions computing model. According to the function of decision-making model, this paper used the AHP and dynamic programming method to establish the mathematical model of cloud manufacturing service value network for seeking the best value chain, and on this basis, established a different model to get the optimal result under the different conditions by time, cost, and resources.

Similar content being viewed by others

References

Wang T, Guo S, Lee C-G (2014) Manufacturing task semantic modeling and description in cloud manufacturing system. Int J Adv Manuf Technol 71:2017–2031

Slywotzky A (1998) The profit zone [M]. Times Books, Illustrated edition. pp 1-56

Berger S, Sturgeon T, Kurz C (1999) Globalition, value networks and national models. Memorandum prepared for the IPC Globalization meeting

Taljuri S, Baker RC, Sarkis J (1999) A framework for designing efficient value chain networks. Int J Prod Econ 62(1–2):133–144

Carney M (1991) The competitiveness of network production: the role of trust and asset specificity. Comp Econ Organ 35(4):36–40

Kathandaraman P, Wilson DT (2001) The future of competition: value-creating networks. Industrial Marketing Management

Xuan Z (2005) Multinational corporation value network and competitive advantage: group competition based on customer delivered value. China Economic Publishing House, vol 35, no. 5, pp 56–59

Allee V (2008) Value network analysis and value conversion of tangible and intangible assets. J Intellect Cap 1

YuanL, Yi L (2001) Value based network management (I): characteristics and formation. J Ind Eng Manag:201–205

Smith MA, Kumar RL (2004) A theory of application service provider (ASP) use from a client perspective. Inf Manage 41(8):977–1002

Smith AD, Rupp WT (2002) Application service providers (ASP): moving downstream to enhance competitive advantage. Inf Manag Comput Secur 10(2):64–72

Leem CS, Lee HJ (2004) Development of certification and audit processes of application service provider for IT outsourcing. Technovation 24(1):63–71

Walsh KR (2003) Analyzing the application ASP concept: technologies, economies, and strategies. Commun ACM 46(8):103–107

Kern T, Kreijger J, Willcocks L (2002) Exploring ASP as sourcing strategy: theoretical perspectives, propositions for practice. J Strateg Inf Syst 11(2):153–177

Shukla C, Vazquez M, Frank Chen F (1996) Virtual manufacturing: an overview. Comput Ind Eng 31(1):79–82

Wang Q, Yung KL (2001) A heuristic genetic algorithm for subcontractor selection in a global manufacturing environment. IEEE Trans Syst Man Cybern Part C Appl Rev 31(2):79–82

Newman ST, Nassehi A, Xub XW (2008) Strategic advantages of interoperability for global manufacturing using CNC technology. Robot Comput Integr Manuf 24(6):699–708

Tao F, Zhang L, Lu K, Zhao D (2012) Study on manufacturing grid resource service optimal-selection and composition framework. Enterp Inf Syst 6(2):237–264

Tao F, Zhao D, Zhang L (2010) Resource service optimal-selection based on intuitionistic fuzzy set and non-functionality QoS in manufacturing grid system. Knowl Inf Syst 25(1):185–208

Tao F, Zhao D, Hu Y, Zhou Z (2010) Correlation-aware resource service composition and optimal-selection in manufacturing grid. Eur J Oper Res 201(1):129–143

Tao F, Zhao D, Hu Y, Zhou Z (2008) Resource service composition and its optimal-selection based on particle swarm optimization in manufacturing grid system. IEEE Trans Ind Inf 4(4):315–327

Tao F, Hu Y, Zhou Z (2009) Application and modeling of resource service trust-QoS evaluation in manufacturing grid system. Int J Prod Res 47(6):1521–1550

Tao F, Zhang L, Nee AYC (2011) A review of the application of grid technology in manufacturing. Int J Prod Res 49(13):4119–4155

Shen W, Haoa Q, Wanga S, Lia Y, Ghenniwac H (2007) An agent-based service-oriented integration architecture for collaborative intelligent manufacturing. Robot Comput Integr Manuf 23(3):315–325

Shen W, Norrie DH (1999) Agent-based systems for intelligent manufacturing: a state-of-the-art survey. Knowl Inf Syst 1:129–156

Yusufa YY, Sarhadib M, Gunasekaran A (1999) Agile manufacturing: the drivers, concepts and attributes. Int J Prod Econ 1:129–156

Gunasekaran A (1999) Agile manufacturing: a framework for research and development. Int J Prod Econ 62(1):87–105

Aurich JC, Schweitzer E, Fuchs C (2007) Life cycle management of industrial product-service systems. Proc Adv Life Cycle Eng Sustain Manuf Bus:171–176

Meier H, Roy R, Seliger G (2011) Industrial product-service systems—IPS2. CIRP Ann Manuf Technol 59(2):607–627

Tao F, Zhang L, Venkatesh VC, Luo Y, Cheng Y (2012) Cloud manufacturing: a computing and service-oriented manufacturing model. Proc Inst Mech Eng B J Eng Manuf 225(10):1969–1976

Tao F, Laili Y, Xu L, Zhang L (2013) FC-PACO-RM: a parallel method for service composition optimal-selection in cloud manufacturing system. IEEE Trans Ind Inf 9(4):2023–2033

Xu X (2012) From cloud computing to cloud manufacturing, robotics and computer-integrated manufacturing. Proc Inst Mech Eng B J Eng Manuf 28(1):75–86

Tao F, Zuo Y, Da Xu L, Zhang L (2014) IoT-Based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans Ind Inf 10(2):1547–1552

Liu LL, Yu T, Cao HW, Shi ZB (2004) TQCS-based scheduling approach for manufacturing grid. J Dong Hua Univ (English Edition) 21(6):43–48

Yuan YP, Yu T, Xiong F (2005) QoS-based dynamic scheduling for manufacturing grid workflow. In: Proc. 9th Int. Conf. Computer Supported Cooperative Work in Design (CSCWD 2005), Coventry, U.K., May 24–26, pp 1123–1128

Deng H, Chen L, Wang CT, Deng QN (2006) A grid-based scheduling system of manufacturing resources for a virtual enterprise. Int J Adv Manuf Technol 28(28):137–141

Tao F, Laili YJ, Da Xu L, Zhang L (2013) FC-PARO-RM: a parallel method for service composition optimal-selection in cloud manufacturing system. IEEE Trans Ind Inf 9(4):2023–2030

Zhang Y, Zhang G, Liu Y; Hu D (2015) Research on services encapsulation and virtualization access model of machine for cloud manufacturing. J Intell Manuf, published on line:15.march

Liu A, Li Q, Huang L, Xiao M (2010) FACTS: a framework for fault-tolerant composition of transactional web services. IEEE Trans Serv Comput 3(1):46–59

Baresi L, Bianculli D, Ghezzi C, Guinea S, Spoletini P (2007) Validation of web service compositions. IET Softw 1(6):219–232

Tao F, Zhao DM, Hu YF, Zhou ZD (2008) Resource service composition and its optimal-selection based on swarm optimization in manufacturing grid system. IEEE Trans Ind Inf 4(4):315–327

Xuefen M, Xudong D, Shudong S (2004) Optimization deployment of networked manufacturing resources. Comput Integr Manuf Syst 10(5):523–527

Sheng Y, Chao Y, Fei L et al (2010) Optimal allocation model and its genetic algorithms of outsourcing production resources in multi-task. J Chongqing Univ 33(3):49–55

Jiangguo J, Na X, Fuguo Z et al (2006) Partner selection of agile supply chain based on ant colony optimization algorithm. J Syst Simul 18(12):3377–3379

Wihong S, Yixiong F (2010) Network manufacturing resource optimized allocation for mass customization. J Nanjing Univ Sci Technol: Nat Sci 34(2):238–242

Huang BH, Li CH, Yin C, Tao F (2014) A chaos control optimal algorithm for QoS-based service composition selection in cloud manufacturing system. Enterp Inf Syst 8(4):445–463

Kulvatunyou B, Ivezic N, Lee Y (2014) On enhancing communication of the manufacturing service capability information using reference ontology. Int J Comput Integr Manuf 27(12):1105–1135

Dobrescu G. Yoram Reich Progressive sharing of modules among product variants. 2003(09)

Gulati R, Nohria N, Zaheer A (1999) Strategic networks. Strateg Manag J 21(3):125–157

Porter ME (1990) Competitive advantage of nation. Free Press, New York, pp 77–80

Fan ZP, Jiang YP, Xiao SH (2001) Consistency of fuzzy judgment matrix and its properties. Control Decis 16(1):142–145

Lu YJ (2002) Weight calculation method of fuzzy analytical hierarchy process. Fuzzy Syst Math 16(2):79–85

Xu ZS (2001) Algorithm for priority of fuzzy complementary judgment matrix. J Syst Eng 16(4):311–314

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, X., Li, R., Cao, Y. et al. The value network optimization research based on the Analytic Hierarchy Process method and the dynamic programming of cloud manufacturing. Int J Adv Manuf Technol 84, 425–433 (2016). https://doi.org/10.1007/s00170-015-8198-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8198-4