Abstract

To develop a reliable monitor method for inspecting the quality and strength of the clinched steel and pre-strained aluminum joints, the electrical resistance method was introduced. A 0.7-mm thick galvanized SAE1004 steel and 1.0-mm thick pre-strained aluminum AA6111-T4 were clinched, and the section parameters, the electric resistance, and strength of the clinched joints were measured. The strengths of the clinched joints were evaluated and correlated with the bottom thickness and electrical resistance of the joints. The results showed that the pre-strained aluminum from pre-stamping significantly increased the electrical resistance (R) and decreased the variation of electrical resistance (ΔR) and strength of the clinched joint. Both the ΔR and bottom thickness can detect the strength variation for the clinched as-received and pre-strained aluminum-steel joints, but the ΔR was more sensitive than the bottom thickness to reflect the effect of aluminum pre-straining on the joint strength. Therefore, it may be more appropriate to use the variation of electrical resistance to inspect the strength of the clinched steel and aluminum joints.

Similar content being viewed by others

References

Miller WS, Zhuang L, Bottema J, Wittebrood AJ, De Smet P, Haszler A, Vieregge A (2000) Recent development in aluminum alloys for the automotive industry. Mater Sci Eng A280:37–49

Abe Y, Mori K, Kato T (2012) Joining of high strength steel and aluminum alloy sheets by mechanical clinching with dies for control of metal flow. J Mater Process Technol 212:884–889

Michalos G, Makris S, Papakostas N, Mourtzis D, Chryssolouris G (2010) Automotive assembly technologies review: challenges and outlook for a flexible and adaptive approach. CIRP J Manuf Sci Technol 2:81–91

Briskham P, Blundell N, Han L, Hewitt R, Young K, Boomer D (2006) Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminum automotive sheet. http://www.sae.org/SAE 2006 World Congress & Exhibition Technical Papers, SAE paper 2006-01-0774.

Varis J (2006) Economics of clinching joint compared to riveted joint and example of applying calculations to a volume product. J Mater Process Technol 172:130–138

Mechanical joining, http://aluminum.matter.org.uk

Varis J (2006) Ensuring the integrity in clinching process. J Mater Process Technol 174:277–285

Oudjene M, Ben-Ayed L (2008) On the parametrical study of clinch joining of metallic sheets using the Taguchi method. Eng Struct 30:1782–1788

Coppieters S, Cooreman S, Sol PLH, Van Houtte P, Debruyne D (2011) Reproducing the experimental pull-out and shear strength of clinched sheet metal connections using FEA. Int J Mater Form 4:429–440

Mucha J (2011) The analysis of lock forming mechanism in the clinching joint. Mater Des 32:4943–4954

Varis JP, Lepisto J (2003) A simple testing-based procedure and simulation of the clinching process using finite element analysis for establishing clinching parameters. Thin-Walled Struct 41:691–709

Nong N, Keju O, Zhang Y, Zhiyuan Q, Changcheng T, Feipeng L (2003) Research on press joining technology for automotive metallic sheets. J Mater Process Technol 137:159–163

Xiaocong H (2010) Recent development in finite element analysis of clinching joints. Int J Adv Manuf Technol 48:607–612

Vishara J, Ho MK, Hoon NJ, Tae KM, Min SJ, Yong LH, Bok HB (2010) Rigid-plastic and elastic-plastic finite element analysis on the clinching joint process of thin metal sheets. Met Mater Int 16:339–347

Chan-Joo L, Kim J-Y, Sang-Kon L, Dae-Cheol K, Byung-Min K (2010) Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J Mech Sci Technol 24:123–126

De Paula AA, Aguilar MTP, Pertence AEM, Cetlin PR (2007) Finite element simulations of the clinch joining of metallic sheets. J Mater Process Technol 182:352–357

Hamel V, Roelandt JM, Gacel JN, Schmit F (2000) Finite element modeling of clinch forming with automatic remeshing. Comput Struct 77:185–200

Oudjene M, Ben-Ayed L, Delameziere A, Batoz JL (2009) Shape optimization of clinching tools using the response surface methodology with moving least-square approximation. J Mater Process Technol 209:289–296

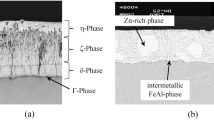

Abe Y, Kishimoto M, Kato T, Mori K (2009) Joining of hot-dip coated steel sheets by mechanical clinching. Int J Mater Form 2(suppl 1):291–294

Francesco L (2013) Influence of process parameters in mechanical clinching with extensible dies. Int J Adv Manuf Technol 66:2123–2131

Xiaocong H, Fulong L, Baoying X, Huiyan Y, Wang Yuqi G, Fengshou BA (2014) Numerical and experimental investigations of extensible die clinching. Int J Adv Manuf Technol. doi:10.1007/s00170-014-6078-y

Roux E, Bouchard PO (2013) Kriging metamodel global optimization of clinching joining processes accounting for ductile damage. J Mater Process Technol 213:1038–1047

Coppieters S, Pascal L, Van Hecke R, Cooreman S, Sol H, Van Houtte P, Debruyne D (2013) Numerical and experimental study of the multi-axial quasi-static strength of clinched connections. Int J Mater Forming 6:437–451

Saberi S, Enzinger N, Vallant R, Cerjak H, Hinterdorfer J, Rauch R (2008) Influence of plastic anisotropy on the mechanical behavior of clinching joint of different coated thin steel sheets. Int J Mater Form 1(suppl 1):273–276

Kato T, Abe Y, Mori K (2008) Plastic joining of dissimilar material of high tensile strength steel and aluminum alloy sheets. Weld Int 22:575–581

Neugebauer R, Mauermann R, Dietrich S, Kraus C (2007) A new technology for the joining by forming of magnesium alloys. Prod Eng 1:65–70

Neugebauer R, Kraus C, Dietrich S (2008) Advances in mechanical joining of magnesium. CIRP Ann Manuf Technol 57:283–286

Brown RA (1977) Electrical resistivity of dislocations in metals. J Physics F: Metal Physics 7(7):1283–1295

Karolik AS, Luhvich AA (1994) Calculation of electrical resistivity produced by dislocations and grain boundaries in metals. J Phys Condens Matter 6:873–886

Watts BR (1988) The contribution of the long-range strain field of dislocations in metals to their electrical resistivity. Journal of Physics F: Metal Physics 18:1183–1195

Gibiansky LV, Torquato S (1995) Rigorous link between the conductivity and elastic moduli of fiber reinforced materials. Philosophical Trans Royal Soc (London) A353:243–278

Gibiansky LV, Torquato S (1993) Link between the conductivity and elastic moduli of composite materials. Phys Rev Lett 71:2927–2930

Gibiansky LV, Torquato S (1996) Connection between the conductivity and bulk modulus of isotropic composite materials. Proc: Math, Phys Eng Sci 452(1945):253–283

Adeosun SO, Sekunowo OI, Balogun SA, Osoba LO (2011) Effect of deformation on the mechanical and electrical properties of aluminum-magnesium alloy. J Miner Mat Charact Eng 10:553–560

Park D-Y, Niewczas M (2008) Plastic deformation of Al and AA5754 between 4.2 K and 295 K. Mater Sci Eng A491:88–102

Dominguez D, Sevostianov I (2011) Cross-property connection between work-hardening coefficient and electrical resistivity of stainless steel during plastic deformation. Int J Fract 167:281–287

de Silva Paulo Maria O, de Abreu Hamilton Ferreira G, de Albuquerque Victor Hugo C, de Lima NP, Tavares João Manuel RS (2011) Cold deformation effect on the microstructures and mechanical properties of AISI 301LN and 316 L stainless steels. Mater Des 32:605–614

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, T., Liu, ZX. & Wang, PC. Quality inspection of clinched joints of steel and aluminum. Int J Adv Manuf Technol 76, 1393–1402 (2015). https://doi.org/10.1007/s00170-014-6362-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6362-x