Abstract

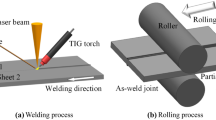

In this study, the influence of weld cross-sectional profiles and microstructure, under different welding conditions, was investigated on the mechanical properties of pulsed Nd:YAG laser-welded joint of Ti6A14V alloy. The V- and H-shaped weld cross-section profiles were obtained under low and high heat input, respectively. The microstructure in the fusion zone (FZ) of V- and H-shaped welded joint consisted of a fine acicular martensitic α′ solidification structure within the prior-β grains, responsible for the maximum hardness in the FZ. Tensile tests revealed that the V-shaped welded joint fractured at the near heat-affected zone (HAZ)/base metal (BM) interface, but the H-shaped welded joint fractured in the BM. Furthermore, the tensile strength of the V-shaped welded joint was lower than that of the H-shaped welded joint. This was attributed to the fact that the heterogeneity of strain distribution at the interface of HAZ and BM of the V-shaped welded joint was greater than that of the H-shaped welded joint during tensile process.

Similar content being viewed by others

Reference

Bergmann JP (2005) Mechanical behaviour of overlap joints of titanium. Sci Technol Weld Join 10:50–60

Li Z, Gobbi SL, Norris I, Zolotovsky S, Richter KH (1997) Laser welding techniques for titanium alloy sheet. J Mater Process Technol 65:203–206

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) A mathematical model to predict impact toughness of pulsed-current gas tungsten arc-welded titanium alloy. Int J Adv Manuf Technol 35:852–858

Lathabai S, Jarvis BL, Barton KJ (2001) Comparison of keyhole and conventional gas tungsten arc welds in commercially pure titanium. Mater Sci Eng A 299:81–93

Barreda JL, Santamaram F, Azpiroz X (2001) Electron beam welded high thickness Ti–6Al–4V plates using filler material of similar and dissimilar composition to the base metal. Vaccum 62:143–150

Zhang Y, Sato YS, Kokawa H, Park SHC, Hirano S (2008) Microstructural characteristics and mechanical properties of Ti–6Al–4V friction stir welds. Mater Sci Eng A 485:448–455

Blackburn JE, Allen CM, Hilton PA, Li L, Hoque MI, Khan AH (2010) Modulated Nd:YAG laser welding of Ti–6Al–4V. Sci Technol Weld Join 15:433–439

Balasubramanian TS, Balasubramanian V, Manickam MAM (2011) Fatigue crack growth behaviour of gas tungsten arc, electron beam and laser beam welded Ti–6Al–4V alloy. Mater Des 32:4509–4520

Li RF, Li ZG, Zhu YY, Rong L (2011) A comparative study of laser beam welding and laser-MIG hybrid welding of Ti–Al–Zr–Fe titanium alloy. Mater Sci Eng A 528:1138–1142

Li C, Muneharua K, Takao S, Kouji H (2009) Fiber laser-GMA hybrid welding of commercially pure titanium. Mater Des 30:109–114

Akman E, Demir A, Canel T, Sınmazçelik T (2009) Laser welding of Ti6Al4V titanium alloys. J Mater Process Technol 209:3705–3713

Qi YL, Deng J, Quan H, Zeng LY (2000) Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater Sci Eng A 280:177–181

Zhang JX, Xue Y, Gong SL (2005) Residual welding stresses in laser beam and tungsten inert gas weldments of titanium alloy. Sci Technol Weld Join 10:643–646

Chen HC, Pinkerton AJ, Li L (2011) Fibre laser welding of dissimilar alloys of Ti–6Al–4V and Inconel 718 for aerospace applications. Int J Adv Manuf Technol 52:977–987

Chen YB, Chen SH, Li LQ (2009) Effects of heat input on microstructure and mechanical property of Al/Ti joints by rectangular spot laser welding-brazing method. Int J Adv Manuf Technol 44:265–272

Squillace A, Prisco U, Ciliberto S, Astarita A (2012) Effect of welding parameters on morphology and mechanical properties of Ti–6Al–4V laser beam welded butt joints. J Mater Process Technol 212:427–436

Krasnoperov MY, Pieters RRGM, Richa IM (2004) Weld pool geometry during keyhole laser welding of thin steel sheets. Sci Technol Weld Join 9:501–506

Cao X, Jahazi M (2009) Effect of welding speed on butt joint quality of Ti–6Al–4V alloy welded using a high-power Nd:YAG laser. Opt Lasers Eng 47:1231–1241

Tzeng YF (2000) Parametric analysis of the pulsed Nd:YAG laser seam-welding process. J Mater Process Technol 102:40–47

Tzeng YF (2000) Process characterisation of pulsed Nd:YAG laser seam welding. Int J Adv Manuf Technol 16:10–18

Zhang JX, Song X, Li Z (2012) Investigation into plastic damage behavior of the CO2 laser deep penetration welded joint for Ti–6Al–4V alloy. Eng Fract Mech 83:1–7

Betegón C, Peňuelas I, Coz JJD (2008) Numerical analysis of the influence of material mismatching in the transition curve of welded joints. Eng Fract Mech 75:3464–3482

Elmer JW, Palmer TA, Babu SS, Zhang W, DebRoy T (2004) Phase transformation dynamics during welding of Ti–6Al–4V. J Appl Phys 95:8327–8339

Gao XL, Zhang LJ, Liu J, Zhang JX (2013) A comparative study of pulsed Nd:YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater Sci Eng A 559:14–21

Rodrigues DM, Menezes LF, Loureiro A, Fernandes JV (2004) Numerical study of the plastic behaviour in tension of welds in high strength steels. Int J Plast 20:1–18

Helbert AL, Feaugas X (1997) The influence of internal stresses on plastic instabilities in α/β titanium alloys. Scr Mater 36:1067–1073

Ashmawi WM, Zikry MA (2003) Grain boundary effects and void porosity evolution. Mech Mater 35:537–552

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, XL., Zhang, LJ., Liu, J. et al. Effects of weld cross-section profiles and microstructure on properties of pulsed Nd:YAG laser welding of Ti6Al4V sheet. Int J Adv Manuf Technol 72, 895–903 (2014). https://doi.org/10.1007/s00170-014-5722-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5722-x