Abstract

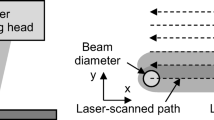

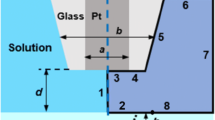

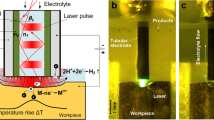

This paper presents two different laser electrochemical machining (LECM) methods: point-by-point method and scan method. Experiments about the two LECM methods were performed on the aluminum alloy plates placed in a shallow container filled with NaNO3 electrolyte 2 mm above. Then, the scanning electron microscopy and the optical profiling system were used to analyze machining quality and morphology characteristics of two different machining methods. For the point-by-point method, the shape accuracy at the starting point, finishing point, and node of line cross is lower. Compared with the point-by-point method, the better etching morphology was gained by the scan method in the experiments. The influence of the scan speed on machining quality and groove width was investigated. The better etching surface quality and the higher etching efficiency were gained when the scan speed varied from 0.1 to 0.15 mm/s. These results demonstrate that laser electrochemical machining by the scan method is a promising method to achieve complex profiles.

Similar content being viewed by others

References

Sjöström T, Su B (2011) Micropatterning of titanium surfaces using electrochemical micromachining with an ethylene glycol electrolyte. Mater Lett 65(3489):3492

AKM D s, Pajak PT, Mcgeough JA, Harrison DK (2011) Thermal effects in laser assisted jet electrochemical machining. CIRP Ann-Manuf Technol 60:243–246

Datta M, Romankiw LT (1989) Jet and laser-jet electrochemical micromachining of nickel and steel. J Electrochem Soc 136(2251):2256

Zhang H, Xu JW (2012) Laser drilling assisted with jet electrochemical machining for the minimization of recast and spatter. Int J Adv Manuf Technol 62(1055):1062

Stephen A, Sepold G, Metev S, Vollertsen F (2004) Laser-induced liquid-phase jet-chemical etching of metals. J Mater Process Technol 149(536):540

Shin HS, Chung DK, Park MS, Chu CN (2011) Analysis of machining characteristics in electrochemical etching using laser masking. Appl Surf Sci 258(1689):1698

Lyskov II (2000) Laser-electrochemical formation of microholes. Proceedings of the 4th Korea-Russia International Symposium 3: 404 ~ 406.

Long YH (2009) Study on thermal-mechanical effect in excimer laser electrochemical etching process. Appl Laser 29(303):308

Li XH, Wang ZL, Zhao WS (2006) The electrochemical micromachining based on multifunction tool for micromachining. J Shanghai Jiaotong Univ 40(909):913

Zhang ZY, Zhu D, Wang MH (2007) Theoretical and experimental research into electrochemical micromachining using nanosecond pulse. Chin J Mech Eng-en 43(208):213

Rosenkranz C, Lohrengel M (2016) M, Schultze J W (2005) The surface structure during pulsed ECM of iron in NaNO3. Electrochim Acta 50:2009

Tong H, LI Y, Hu MH (2012) Experimental research on effects of process parameters on servo scanning 3D micro electrical discharge machining. Chin J Mech Eng-en 25:114–121

Kibria G, Doloi B, Bhattacharyya B (2013) Experimental investigation and multi-objective optimization of Nd:YAG laser micro-turning process of alumina ceramic using orthogonal array and grey relational analysis. Opt Laser Technol 48(16):27

Dai YT, Xu G, Tong XL (2012) Deep UV laser etching of GaN epilayers grown on sapphire substrate. J Mater Process Technol 212(492):496

Bhattacharyya B, Munda J (2003) Experimental investigation on the influence of electrochemical machining parameters on machining rate and accuracy in micromachining domain. Int J Mach Tool Manuf 43(1301):1310

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Cai, M., Feng, Q. et al. Comparison of different laser-assisted electrochemical methods based on surface morphology characteristics. Int J Adv Manuf Technol 71, 565–571 (2014). https://doi.org/10.1007/s00170-013-5508-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5508-6