Abstract

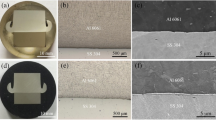

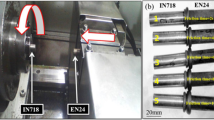

The nickel-based superalloy K418 and alloy steel 42CrMo dissimilar metals friction welding joints lack strength and toughness due to high hardening and poor joining quality at the friction interface. To resolve this issue, a new current inertia friction welding (CIFW) method is carried out by hybrid an external additional electronic current in inertia friction welding (IFW) process. The characteristics of welding formation, the elements’ diffusion, and the mechanical properties of K418–42CrMo dissimilar metal joints are studied by scanning electron microscope, energy dispersive spectrometer, and X-ray diffractometer tools. The experimental results show that hybrid additional electronic current has a significant positive influence on interface characteristics of IFW joints. The required welding time for CIFW to complete a good qualified joint is shortened due to mixture actions of both friction heat and resistance heat. The width of the element diffusion zone increases in CIFW joints, and elements in 42CrMo side diffuse through the K418/42CrMo interface into the K418 side in CIFW joints. The width of the K418/42CrMo bonding interface increases in CIFW joints. The microhardness at the K418/42CrMo bonding interface is decreased in CIFW joints. The mechanical tensile property of CIFW joints is increased obviously. The interface bonding pattern becomes jagged and interlocking perfect formations. These above changes improve the joining quality of K418–42CrMo dissimilar metal friction welding joints. The heat treatment effect and resistance heat effect originated from hybrid external electronic currents are discussed by comparing CIFW with IFW. A new model is proposed to illustrate the interface’s evolution and development mechanism in K418–42CrMo dissimilar metal CIFW.

Similar content being viewed by others

References

Kalsi NS, Sharma VS (2011) A statistical analysis of rotary friction welding of steel with varying carbon in workpieces. Int J Adv Manuf Technol 57:957–967

Reddy GM, Rao KS (2009) Microstructure and mechanical properties of similar and dissimilar stainless steel electron beam and friction welds. Int J Adv Manuf Technol 45:875–888

Sathiya P, Aravindan S, Haq AN (2007) Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int J Adv Manuf Technol 31:1076–1082

Meshram SD, Mohandas T, Reddy G (2007) Friction welding of dissimilar pure metals. J Mater Process Technol 184:330–337

Huang ZW, Li HY, Preuss M, Karadge M, Bowen P, Bray S, Baxter G (2007) Inertia friction welding dissimilar nickel-based superalloys alloy 720Li to IN718. Metall Mater Trans A 38:1608–1620

Sare C, Ismail E (2009) Investigation of the mechanical properties and microstructure of friction welded joints between AISI 4140 and AISI 1050 steels. Mater Des 30:970–976

Moat RJ, Hughes DJ, Steuwer A, Iqbal N, Preuss M, Bray SE, Rawson M (2009) Residual stresses in inertia-friction-welded dissimilar high-strength steels. Metall Mater Trans A 40:2098–2108

Luo J, Zhao GJ, Luo Q, Wang XJ, Xu XL (2010) Element diffusion on interface of 35CrMnSi/T3 inertial radial friction weld. J Xi’an Jiaotong Univ 44:63–67

Sahin M (2009) Joining of stainless steel and copper materials with friction welding. Ind Lubr Tribol 61:319–324

Kimura M, Kasuya K, Kusaka M, Kaizu K, Fuji A (2009) Effect of friction welding condition on joining phenomena and joint strength of friction welded joint between brass and low carbon steel. Sci Technol Weld Join 14:404–412

Shin HS, Park JS, Jung YC, Ahn JH, Yokoyama Y, Inoue A (2009) Similar and dissimilar friction welding of Zr–Cu–Al bulk glassy alloys. J Alloys Compd 483:182–185

Wang D, Xiao BL, Ma ZY, Zhang HF (2009) Friction stir welding of Zr55Cu30Al10Ni5 bulk metallic glass to Al-Zn-Mg-Cu alloy. Scr Mater 60:112–115

Shoji T, Kawamura Y, Ohno Y (2004) Friction welding of bulk metallic glasses to different ones. Metall Mater Trans A 375–377:394–398

Sahin M (2009) Joining of stainless-steel and aluminium materials by friction welding. Int J Adv Manuf Technol 41:487–497

Shinoda T, Miyahara K, Ogawa M, Endo S (2001) Friction welding of aluminum and plain low carbon steel. Weld Int 15:438–445

Seli H, Ismail A, Rachman E, Ahmad ZA (2010) Mechanical evaluation and thermal modelling of friction welding of mild steel and aluminium. J Mater Process Technol 210:1209–1216

Taban E, Gould JE, Lippold JC (2010) Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: Properties and microstructural characterization. Mater Des 31:2305–2311

Zimmerman J, Wlosinski W, Lindemann ZR (2009) 2Thermo-mechanical and diffusion modelling in the process of ceramic–metal friction welding. J Mater Process Technol 9:1644–1653

Dey HC, Ashfaq M, Bhaduri AK, Rao KP (2009) Joining of titanium to 304L stainless steel by friction welding. J Mater Process Technol 209:5862–5870

Fukumoto S, Inoue T, Mizuno S, Okita K, Tomita T, Yamamoto A (2010) Friction welding of TiNi alloy to stainless steel using Ni interlayer. Sci Technol Weld Join 15:124–130

Wang Y, Luo J, Wang XM, Xu XL (2013) Interfacial characterization of T3 copper/35CrMnSi steel dissimilar metal joints by inertia radial friction welding. Int J Adv Manuf Technol 68:1479–1490

Nada R, Aleksandar S, Milorad J, Vukic L, Ruzica N, Bozidar K (2009) Quality analysis of Al–Cu joint realized by friction welding. Tehnicki Vjesnik 16:3–7

Sathiya P, Aravindan S, Haq AN (2005) Mechanical and metallurgical properties of friction welded AISI 304 austenitic stainless steel. Int J Adv Manuf Technol 26:505–511

Chen DJ, Xu XL, Xu YZ, Wu W (2004) Quality controlling method of K418 and 42CrMo inertia friction welding joints. Weld Join 2:46–48

Lee JW (1992) Inertia friction welding of a gas turbine rotor. Weld Rev Int 11:189–192

Du SG, Fu L, Wang JW, Cao Y (2003) Forming mechanism of carbide band in friction welding joint of superalloy K418 and steel 42CrMo. Chinese J Nonferr Metal 13:323–327

Du SG, Fu L, Cao Y, Wang JW (2004) On strengthening the friction welding joint between K418 turbo disk and 42CrMo shaft. J Northwest Polytech Univ 22:112–115

Chen DJ, Xu XL, Xu YZ, Wu W (2008) Inertia friction welding of dissimilar materials between K418 turbine disk and 42CrMo shaft. Weld Join 6:58–60, 68

Luo J, Wang XJ, Wang JX (2009) New technological methods and designs of stir head in resistance friction stir welding. Sci Technol Weld Join 14:650–654

Fu L, Du SG (2006) Effects of external electric field on microstructure and property of friction welded joint between copper and stainless steel. J Mater Sci 41:4137–4142

Wang SY, Zhang GF, Qiu FX, Guo Y (1994) Heat soerce behavior of conducting friction welding and its influence on technology process. J Xi’an Jiaotong Univ 28:130–134

Teker T (2013) Evaluation of the metallurgical and mechanical properties of friction-welded joints of dissimilar metal combinations AISI2205/Cu. Int J Adv Manuf Technol 66:303–310

Arivazhagan N, Singh S, Prakash S, Reddy GM (2008) An assessment of hardness, impact strength, and hot corrosion behaviour of friction-welded dissimilar weldments between AISI 4140 and AISI 304. Int J Adv Manuf Technol 39:679–689

Sunay TY, Sahin M, Altintas S (2009) The effects of casting and forging processes on joint properties in friction-welded AISI 1050 and AISI 304 steels. Int J Adv Manuf Technol 44:68–79

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, J., Li, L., Dong, Y. et al. A new current hybrid inertia friction welding for nickel-based superalloy K418–alloy steel 42CrMo dissimilar metals. Int J Adv Manuf Technol 70, 1673–1681 (2014). https://doi.org/10.1007/s00170-013-5441-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5441-8