Abstract

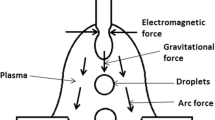

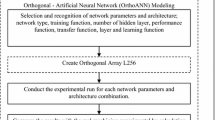

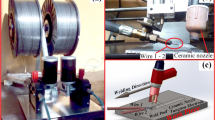

The purpose of this work is to optimize the weld bead geometry of Inconel 718 alloy gas tungsten arc (GTA) welds that are coated with activating flux before welding. In order to obtain the optimal welding parameters with multiple quality characteristics (QCs) such as penetration and depth-to-width ratio (DWR) of weld bead, the Taguchi method (TM), gray relational analysis (GRA), and a neural network (NN) are employed in this work. The TM is first used to construct a database for the NN. The GRA is adopted to solve the problem of multiple QCs. The gray relational grade (GRG) obtained from the GRA is used as the output of the backpropagation (BP) NN. Then, a NN with the Levenberg–Marquardt BP (LMBP) algorithm is used to provide the nonlinear relationship between welding parameters and GRG of each specimen. The optimal parameters of the activated GTA welding process are determined by simulating parameters using a well-trained BPNN model. The experimental procedure of the proposed approach not only improves the DWR of weld bead but also increases the penetration of Inconel 718 alloy welds.

Similar content being viewed by others

References

Lucas W, Howse D (1996) Activating flux-increasing of performance and productivity of the TIG and plasma processes. Weld Met Fabr 64(1):11–17

Huang HY, Shyu SW, Tseng KH, Chou CP (2006) Study of the process parameters on austenitic stainless steel by TIG-flux welding. J Mater Sci Technol 22(3):367–374

Yang CL, Lin SB, Liu FY, Wu L, Zhang QT (2003) Research on the mechanism of penetration increase by flux in A-TIG welding. J Mater Sci Technol 19(1):225–227

Lin HL, Chou CP (2010) Optimization of the GTA welding process using combination of the Taguchi method and a neural-genetic approach. Mater Manuf Process 25:631–636

Chern TS, Tseng KH, Tsai HL (2011) Study of the characteristics of duplex stainless steel activated tungsten inert gas welds. Mater Des 32:255–263

Huang CA, Wang TH, Lee CH, Han WC (2005) A study of the heat-affected zone (HAZ) of an Inconel 718 sheet welded with electron-beam welding (EBW). Mater Sci Eng, A 398:275–281

Madhusudhana RG, Srinivasa MCV, Srinivasa RK, Prasad RK (2009) Improvement of mechanical properties of Inconel 718 electron beam welds—influence of welding techniques and postweld heat treatment. Int J Adv Manuf Technol 43:671–680

Janaki RGD, Vanugopal RA, Prasad RK, Reddy GM, Sarin SJK (2005) Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds. J Mater Process Technol 167:73–82

Deng J (1989) Introduction to grey system. J Grey Syst 1(1):1–24

Lin JL, Lin CL (2002) The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. Int J Mach Tool Manuf 42:237–244

Hsiao YF, Tarng YS, Huang WJ (2008) Optimization of plasma arc welding parameters by using the Taguchi method with the grey relational analysis. Mater Manuf Process 23:51–58

Tsao CC (2009) Grey-Taguchi method to optimize the milling parameters of aluminum alloy. Int J Adv Manuf Technol 40:41–48

Patel KM, Pandey PM, Rao PV (2010) Optimization of process parameters for multi-performance characteristics in EDM of Al2O3 ceramic composite. Int J Adv Manuf Technol 47:1137–1147

Su CT, Chiang TL (2003) Optimizing the IC wire bonding process using a neural networks/genetic algorithms approach. J Intell Manuf 14:229–238

Kim IS, Jeong YJ, Lee CW (2003) Prediction of welding parameters for pipeline welding using an intelligent system. Int J Adv Manuf Technol 22:713–719

Khaw JFC, Lim BS, Lim LEN (1995) Optimal design of neural networks using Taguchi method. Neurocomputing 7:225–245

Lin HL, Chou CP (2008) Modeling and optimization of Nd:YAG laser micro-weld process using Taguchi method and a neural network. Int J Adv Manuf Technol 37:513–522

Saglam H (2011) Tool wear monitoring in bandsawing using neural networks and Taguchi's design of experiments. Int J Adv Manuf Technol 55:969–982

Kuo CFJ, Wu YS (2006) Application of a Taguchi-based neural network prediction design of the film coating process for polymer blends. Int J Adv Manuf Technol 27:455–461

Tseng KH, Hsu CY (2011) Performance of activated TIG process in austenitic stainless steel welds. J Mater Process Technol 211:503–512

Chandrasekhar N, Vasudevan M (2010) Intelligent modeling for optimization of A-TIG welding process. Mater Manuf Process 25:1341–1350

Phadke MS (1989) Quality engineering using robust design. Prentice-Hall, Upper Saddle River

Xu YL, Dong ZB, Wei YH, Yang CL (2007) Marangoni convection and weld shape variation in A-TIG welding process. Theor Appl Fract Mech 48:178–186

Lu S, Fujii H, Sugiyama H, Nogi K (2003) Mechanism and optimization of oxide fluxes for deep penetration in gas tungsten arc welding. Metall Mater Trans A 34A:1901–1907

Dong W, Lu S, Li D, Li Y (2011) GTAW liquid pool convections and the weld shape variations under helium gas shielding. Int J Heat Mass Transf 54:1420–1431

Goodarzi M, Choo R, Takasu T, Toguri JM (1998) The effect of the cathode tip angle on the gas tungsten arc welding arc and weld pool: II. The mathematical model for the weld pool. J Phys D: Appl Phys 31:569–583

Lin HL, Chou CP (2006) Optimisation of the GTA welding process using the Taguchi method and a neural network. Sci Technol Weld Join 11(1):120–126

Ross PJ (1988) Taguchi techniques for quality engineering. McGraw-Hill, New York

Coit DW, Jacson BT, Smith AE (1998) Static neural network process model: considerations and cases studies. Int J Prod Res 36(11):2953–2967

Funahashi K (1989) On the approximate realization of continuous mapping by neural network. Neural Netw 2:183–192

Hagan MT, Demuth H, Beale M (1996) Neural network design. PWS-Kent, Boston

Hagan MT, Menhaj MB (1994) Training feedforward networks with the Marquardt algorithm. IEEE Trans Neural Netw 5(6):989–993

Demuth H, Beale M (1998) Neural network toolbox—for use with MATLAB. The Math Works, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, HL. Optimization of Inconel 718 alloy welds in an activated GTA welding via Taguchi method, gray relational analysis, and a neural network. Int J Adv Manuf Technol 67, 939–950 (2013). https://doi.org/10.1007/s00170-012-4538-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4538-9