Abstract

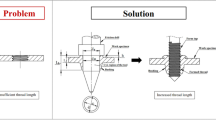

The main purpose of this research is to develop a new type of thermal friction drill made of sintered carbide. In addition, to optimize the machining process of the thermal friction drilling using Taguchi method is explored. The experiments were conducted on a 30 × 30 × 2 mm SUS 304 stainless steel plate. The effects of friction angles (FA), friction contact area ratio (FCAR), feed rate (FR), and spindle speed (SS) on the two quality characteristics, surface roughness (SR) and bushing length (BL), were also investigated. After conducting all the experimental trials, the analysis procedure followed. Firstly, the significance of the four parameters on the two quality characteristics was examined by ANOVA. Then the optimal combination levels of parameters for SR and BL were determined based on the S/N ratios. Finally, confirmation experiments were conducted to verify the experimental findings. Results showed that FA and SS were the significant machining parameters that most intensively affect SR while FCAR was the only significant parameter for BL. Specially, the SR and BL were greatly improved when used in the optimized parameters settings. More importantly, the performance of the friction drill was conducted 60 runs. The thermal friction drill demonstrated a smoother, mirror-like surface and showed less wear. This proved that thermal friction drilling provided the better machining performance and longer tool life.

Similar content being viewed by others

References

Cantero JL, Tardío MM, Canteli JA, Marcos M, Miguélez MH (2005) Dry drilling of alloy Ti-6Al-4V. Int J Mach Tools Manuf 45:1246–1255

Noordin MY, Venkatesh VC, Sharif S (2007) Dry turning of tempered martensitic stainless tool steel using coated cermet and coated carbide tools. J Mater Process Technol 185:83–90

Lin T-R (2002) Cutting behavior of a TiN-coated carbide drill with curved cutting edges during the high-speed machining of stainless steel. J Mater Process Technol 127:8–16

Nouari M, List G, Girot F, Géhin D (2005) Effect of machining parameters and coating on wear mechanisms in dry drilling of aluminium alloys. Int J Mach Tools Manuf 45:1436–1442

Bono M, Jun N (2001) The effects of thermal distortions on the diameter and cylindricity of dry drilled holes. Int J Mach Tools Manuf 41:2261–2270

Kerkhofs M, Van Stappen M (1994) The performance of (Ti, Al)N-coated flow drills. Surf Coat Technol 68(69):741–746

Miller SF, Blau PJ, Shih AJ (2005) Microstructural alterations associated with friction drilling of steel, aluminum, and titanium. J Mater Eng Perform 14:647–653

Miller SF, Li R, Wang H, Shih AJ (2006) Experimental and numerical analysis of the friction drilling process. Transactions of the ASME 128:802–810

Miller SF, Tao J, Shih AJ (2006) Friction drilling of cast metals. Int J Mach Tools Manuf 46:1526–1535

Miller SF, Blau PJ, Shih AJ (2007) Tool wear in friction drilling. Int J Mach Tools Manuf 47:1636–1645

Lee SM, Chow HM, Yan BH (2007) Friction drilling of IN-713LC cast superalloy. Mater Manuf Processes 22:893–897

Chow HM, Lee SM, Yang LD (2008) Machining characteristic study of friction drilling on AISI 304 stainless steel. J Mater Process Technol 207:180–186

Lee SM, Chow HM, Huang FY, Yan BH (2009) Friction drilling of austenitic stainless steel by uncoated and PVD AlCrN- and TiAlN-coated tungsten carbide tools. Int J Mach Tools Manuf 49:81–88

Bagci E, Ozcelik B (2006) Analysis of temperature changes on the twist drill under different drilling condition based on Taguchi method during dry drilling of Al 7075-T651. Int J Adv Manuf Technol 29:629–636

Yang LD, Lin CT, Chow HM (2009) Optimization in MAF operations using Taguchi parameter design for AISI304 stainless steel. Int J Adv Manuf Technol 42:595–605

Lin YC, Yan BH, Huang FY (2001) Surface improvement using a combination electrical discharge machining with ball burnish machining based on the Taguchi method. Int J Adv Manuf Technol 18:673–682

Lin C-T, Yang LD, Chow HM (2007) Study of magnetic abrasive finishing in free-form surface operations using the Taguchi method. Int J Adv Manuf Technol 34:122–130

Kurt M, Bagci E, Kaynak Y (2009) Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int J Adv Manuf Technol 40:458–469

Deng CS, Chin JH (2005) Hole roundness in deep hole drilling as analysed by Taguchi methods. Int J Adv Manuf Technol 25:420–426

Gaitonde VN, Kamik SR, Achyutha BT, Siddeswarappa B (2007) Methodology of Taguchi optimization for multi-objective drilling problem to minimize burr size. Int J Adv Manuf Technol 34:1–8

Jain NK, Jain VK, Jha S (2007) Parametric optimization of advanced fine-finishing processes. Int J Adv Manuf Technol 34:1191–1213

Bagci E, Aykut S (2006) A study of Taguchi optimization method for identifying optimum surface roughness in CNC face milling of cobalt-based alloy (stellite 6). Int J Adv Manuf Technol 29:940–947

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper has not been published elsewhere nor has it been submitted for publication elsewhere.

Rights and permissions

About this article

Cite this article

Ku, WL., Hung, CL., Lee, SM. et al. Optimization in thermal friction drilling for SUS 304 stainless steel. Int J Adv Manuf Technol 53, 935–944 (2011). https://doi.org/10.1007/s00170-010-2899-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2899-5