Abstract

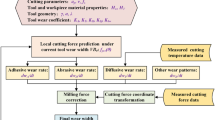

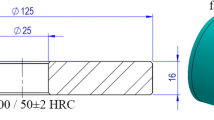

Flank wear of an alumina-based ceramic cutting tool was determined in hard turning two workpieces (AISI 4340 and 52100 hardened steels) at three cutting speeds (142, 181, and 264 m/min) to devise a real-time monitoring system. Results of the six turning tests were assessed using Kruskal–Wallis test, regression models, and linear trend analysis. Multiple non-linear regression models that explained variation in flank wear as a function of time (second) had a range of \( R_{\rm{adj}}^2 \) values of 27.7% for the test 4340-142 to 95% for the test 52100-181. Linear trend models revealed that the highest flank wear rate of the ceramic cutting tool belonged to the test 52100-181. Interaction effect of the three cutting speeds and the two workpiece types was determined to account for 82.2% of variation in flank wear (P < 0.001). The real-time monitoring system designed in this study appeared to be promising in terms of determining and quantifying flank wear behavior of the ceramic cutting tool and optimal hard turning conditions.

Similar content being viewed by others

References

Taylor FW (1907) On the art of cutting metals. Trans Am Soc Mech Eng 28:31–350

Grzesik W, Wanat T (2006) Surface finish generated in hard turning of quenched alloy steel parts using conventional and wiper ceramic inserts. Int J Mach Tools Manuf 46:1988–1995

Benga GC, Abrao AM (2003) Turning of hardened 100Cr6 bearing steel with ceramic and PCBN cutting tools. J Mater Process Technol 143:237–241

Stachowiak GW, Stachowiak GB (1994) Wear behaviour of ceramic cutting tools. Key Eng Mater 96:137–164

Liu Y, Liu J, Zhu B (1997) Wear performance and mechanism of Si3N4 composite ceramic cutting tool. Tribology 17:105–114

Yang WH, Tarng YS (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84:122–129

Rech J, Kusiakband A, Battaglia JL (2004) Tribological and thermal functions of cutting tool coatings. Surf Coat Technol 186:364–371

Yallese MA, Chaoui K, Zeghib N, Boulanouar L, Rigal JF (2009) Hard machining of hardened bearing steel using cubic boron nitride tool. J Mater Process Technol 209:1092–1104

Zhu KP, Wong YS, Hong GS (2009) Wavelet analysis of sensor signals for tool condition monitoring: a review and some new results. Int J Mach Tools Manuf 49:537–553

Byrne G, Dornfeld D, Inasaki I, Ketteler G, Konig W, Teti R (1995) Tool condition monitoring (TCM)—the status of research and industrial application. Ann CIRP 44:541

Liang SY, Rogelio LH, Robert GL (2004) Machining process monitoring and control: the state-of-the-art. J Manuf Sci Eng 126:297–310

Castejona M, Alegre E, Barreiro J, Hernandez LK (2007) On-line tool wear monitoring using geometric descriptors from digital images. Int J Mach Tools Manuf 47:1847–1853

Oguamanam DCD, Raafat H, Taboun SM (1994) A machine vision system for wear monitoring and breakage detection of single-point cutting tools. Comput Ind Eng 26(3):575–598

Kurada S, Bradley C (1997) A review of machine vision sensors for tool condition monitoring. Comput Ind 34(1):55–72

Wang WH, Hong GS, Wong YS, Zhu KP (2007) Sensor fusion for on-line tool condition monitoring in milling. Int J Prod Res 45(21):5059–5116

Altintas Y (1988) In-process detection of tool breakages using time series monitoring of cutting forces. Int J Mach Tools Manuf 28(2):157–172

Huang SN, Tan KK, Wong YS, Silva CW, Goh HL, Tan WW (2007) Tool wear detection and fault diagnosis based on cutting force monitoring. Int J Mach Tools Manuf 47:444–451

Yaldiz S, Unsacar F, Saglam H (2006) Comparison of experimental results obtained by designed dynamometer to fuzzy model for predicting cutting forces in turning. Mater Des 27:1139–1147

Sutter G, Molinari A (2005) Analysis of the cutting force components and friction in high speed machining. J Manuf Sci E-T ASME 127:245–250

Chen JC, Chen WL (1999) A tool breakage detection system using an accelerometer sensor. J Intell Manuf 10(2):187–197

Dimla DE, Lister PM (2000) On-line metal cutting tool condition monitoring I: force and vibration analyses. Int J Mach Tools Manuf 40:739–768

Berger BS, Minis I, Harley J, Rokni M, Papadopoulos M (1998) Wavelet based cutting state identification. J Sound Vib 213(5):813–827

Li X (2002) A brief review: acoustic emission method for tool wear monitoring during turning. Int J Mach Tools Manuf 42:157–165

Sun J, Hong GS, Rahman M, Wong YS (2004) Identification of feature set for effective tool condition monitoring by acoustic emission sensing. Int J Prod Res 42(5):901–918

Haber RE, Jiménez JE, Peres CR, Alique JR (2004) An investigation of tool-wear monitoring in a high-speed machining process. Sens Actuators, A 116:539–545

Li X, Tso SK, Wang J (2000) Real time tool condition monitoring using wavelet transforms and fuzzy techniques. IEEE Trans Syst Man Cybern, Part C 31(3):352–357

Salgado DR, Alonso FJ (2007) An approach based on current and sound signals for in-process tool wear monitoring. Int J Mach Tools Manuf 47:2140–2152

Li W, Li D, Ni J (2003) Diagnosis of tapping process using spindle motor current. Int J Mach Tools Manuf 43:73–79

Ghasempoor A, Jeswiet J, Moore TN (1999) Real time implementation of on-line tool condition monitoring in turning. Int J Mach Tools Manuf 39(12):1883–1902

Roget J, Souquet P, Gsib N (1988) Application of acoustic emission to the automatic monitoring of tool condition during machining. Mater Eval 46:225–229

Lin J (1995) Inverse estimation of the tool-work interface temperature in end milling. Int J Mach Tools Manuf 35(5):751–760

Dan L, Mathew J (1990) Tool wear and failure monitoring techniques for turning—a review. Int J Mach Tools Manuf 30(4):579–598

Dimla DE (2000) Sensor signals for tool-wear monitoring in metal cutting operations—a review of methods. Int J Mach Tools Manuf 40:1073–1098

Choudhury SK, Jain VK, Rama Rao ChVV (1999) On-line monitoring of tool wear in turning using a neural network. Int J Mach Tools Manuf 39:489–504

Liu Q, Altintas Y (1999) On-line monitoring of flank wear in turning with multilayered feed-forward neural network. Int J Mach Tools Manuf 39(12):1945–1959

Cakan A, Ozkaner V, Yildirim MM (2008) Quantifying cutting and wearing behaviors of TiN- and CrN-coated AISI 1070 steel. Sensors 8:6984–6998

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cakan, A. Real-time monitoring of flank wear behavior of ceramic cutting tool in turning hardened steels. Int J Adv Manuf Technol 52, 897–903 (2011). https://doi.org/10.1007/s00170-010-2793-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2793-1