Abstract

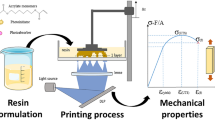

Micro-stereolithography technology makes it possible to fabricate free-form three-dimensional (3D) microstructures using a focused UV beam with a very small focal diameter to solidify a UV-curable liquid photopolymer. Generally, expensive UV lasers and complex optical systems are required. However, in this study, we developed a more economical and simpler micro-stereolithography technology using a UV lamp as a light source and optical fiber as the light delivery system. We conducted photopolymer solidification experiments to examine the characteristics of the developed micro-stereolithography apparatus. To achieve an adequate solidification width and depth, a photostabilizer was mixed with a conventional photopolymer and then tested. The developed apparatus could be used to fabricate 3D microstructures by modifying the fabrication conditions for a given photopolymer. Several 3D microstructures were fabricated.

Similar content being viewed by others

References

Ikuta K, Hirowatari K (1993) Real three-dimensional micro fabrication using stereolithography and metal mold. Proc IEEE International Workshop on Micro Electro Mechanical Systems (MEMS’93), pp 42–47

Ikuta K, Maruo S, Kojima S (1998) New micro stereo lithography for freely movable 3D micro structure. Proc IEEE International Workshop on Micro Electro Mechanical Systems (MEMS’98), pp 290–295

Bertsch A, Zissi S, Jezequel JY, Corbel S, Andre JC (1997) Microstereolithography using a liquid crystal display as dynamic mask-generator. Microsyst Technol 3(2):42–47

Bertsch A, Lorenz H, Renaud P (1999) 3D microfabrication by combining microstereolithography and thick resist UV lithography. Sens Actuators 73:14–23

Bertsch A, Bernhard P, Vogt C, Renaud P (2000) Rapid prototyping of small size objects. Rapid Prototyping J 6(4):259–266

Bertsch A, Jiguet S, Berhard P, Renaud P (2003) Microstereolithography: A Review. Mat Res Soc Symp Proc 758:L.L.1.1-L.L.1.1–11

Lee IH, Cho D-W, Lee ES (2004) Development of micro-stereolithography systems for the fabrication of three-dimensional micro-structure. J Korean Soc Precis Eng 21(2):29–36

Lee IH, Cho D-W (2003) Micro-stereolithography photopolymer solidification patterns for various laser beam exposure conditions. Int J Adv Manuf Technol 22(5–6):410–416

Lee IH, Cho D-W (2004) An investigation on photopolymer solidification considering laser irradiation energy in micro-stereolithography. Micro Syst Technol 10(8–9):592–598

Ikuta K, Ogata T, Tsubio M, Kojima S (1996) Development of mass productive micro stereo lithography (Mass-IH Process). Proc of IEEE International Workshop on Micro Electro Mechanical Systems (MEMS’96), pp 301–306

Bertsch A, Jezequel JY, Andre JC (1997) Study of spatial resolution of a new 3D microfabrication process: the microstereolithography using a dynamic mask-generator technique. J Photochem Photobiol A 107:275–281

Maruo S, Kawata S (1998) Two-photon-absorbed near-infrared photopolymerization for three-dimensional microfabrication. J Microelectromechan Syst 7(4):411–415

Sun H-B, Takada K, Kim M-S, Lee K-S, Kawata S (2003) Scaling laws of voxels in two-photon photopolymerization nanofabrication. Appl Phys Lett 83(6):1104–1106

Maruo S, Ikura K (1999) Movable microstructures made by two-photon three-dimensional microfabrication. Int Symp Micromechatron Human Sci 173–178

Strickler JH, Webb WW (1991) Three-dimensional optical data storage in refractive media by two-photon point excitation. Opt Lett 16(22):1780–1782

Sun H-B, Matsuo S, Misawa H (1999) Three-dimensional photonic crystal structures achieved with two-photon-absorption photopolymerization of resin. Appl Phys Lett 74(6):786–788

Pan E-Y, Pu N-W, Tong Y-P, Yau H-F (2003) Scaffold-like micro-well structures fabricated by two-photon-absorption photopolymerization. J Med Biol Eng 23(2):79–84

Kim S-H, Jung D-J, Joo J-Y, Jeong S-H (2006) Modification of the curing characteristics of the photocurable resin FA1260T for 3D microfabrication using microstereolithography. J Korean Soc Precis Eng 23(6):174–179

Internet website http://www.cibasc.com

Liska R, Schwager F, Maier C, Cano-Vives R, Stampfl J (2005) Water-soluble photopolymers for rapid prototyping of cellular materials. J Appl Polym Sci 97:2286–2298

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, J.S., Kang, HW., Lee, I.H. et al. Development of micro-stereolithography technology using a UV lamp and optical fiber. Int J Adv Manuf Technol 41, 281–286 (2009). https://doi.org/10.1007/s00170-008-1461-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1461-1