Abstract

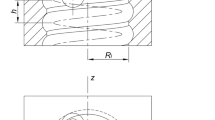

The classical conjugation and envelope method is very accurate and effective for forward and inverse calculations of grinding helical surfaces. However, this method involves complicated mathematics and requires that the profiles be continuous. It can also result in undercutting or interference to the desired surface profiles. In this paper, a new approach is proposed to simulate the grinding process of helical surfaces on cutting tools. The paper begins with the reconstruction of cutter helicoids from sampled points. Using the recovered helical parameters from the sample points, the cross-sectional profile of the cutter surface is derived using a polynomial curve. A numerical method for calculating the profile of the grinding wheel required for the cutter surface profile is then provided. Finally, an optimization method is presented for solving the problem of inverse calculation to determine the helical surface profile for a given grinding wheel profile and setting parameters. The feasibility of the approach is tested by simulation results, which shows that the proposed approach can eliminate undesired tool-work interferences and undercutting.

Similar content being viewed by others

References

Sheth DS, Malkin S (1990) CAD/CAM for geometry and process analysis of helical groove machining. Ann CIRP 39:129–132

Ehmann KF (1990) Grinding wheel profile definition for the manufacture of drill flutes. Ann CIRP 39:153–156

Kang SK, Ehmann KF, Lin C (1996) A CAD approach to helical groove machining, mathematical model and model solution. Int J Mach Tools Manuf 36:144–153

Kaldor S, Rafael AD, Messinger D (1988) On the CAD of profiles for cutters and helical flutes. Ann CIRP 37:53–55

Oancea N, Oancea VG (1997) Geometrical design of cutting tools with surfaces of revolution for helical surfaces. PProc Inst Mech Eng, Part C. J Mech Eng Sci 211:559–566

Veliko I, Gentcho N (1998) Profiling of rotation tools for forming of helical surfaces. Int J Mach Tools Manuf 38:1125–1148

Ivanov V, Nankov G, Kirov V (1998) CAD-orientated mathematical model for determination of profile helical surfaces. Int J Mach Tools Manuf 38:1001–1015

Xiao D-Z , Gao Y, Wang Z-Q, Liu D-M (2002) Influence of the meshing clearance on the performance of the conjugate helical surfaces. J Mater Process Technol 120:140–143

Mohan LV, Shunmugam MS (2004) CAD approach for simulation of generation machining and identification of contact lines. Int J Mach Manuf Technol 44:717–723

Zhang W, Wang X, He F, Xiong D (2006) A practical method of modelling and simulation for drill fluting. Int J Mach Tools Manuf 46:667–672

Pottmann H, Wallner J (2001) Computational line geometry. Springer, Berlin Heidelberg New York

Patrikalakis NM, Maekawa T (2002) Shape interrogation for computer-aided design and manufacturing. Springer, Berlin Heidelberg New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, Y., Wang, J., Guo, D. et al. Modeling and numerical simulation for the machining of helical surface profiles on cutting tools. Int J Adv Manuf Technol 36, 525–534 (2008). https://doi.org/10.1007/s00170-006-0860-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0860-4