Abstract

This paper presents the design, fabrication and testing of a Magnetorheological (MR) steering damper for motorcycles. After exploring many possible configurations of the MR valve, the proposed design makes sure that the damper is test- and research- friendly in that the damper can be easily assembled and disassembled with simple tools and procedures. The structural and functional integrity of the damper was maintained even with the simple layout of the damper. The dimensions of the MR valve are optimally determined by using finite element analysis. The damper performance under steady shear is experimentally evaluated with an INSTRON test machine. The test results showed that the prototype had fulfilled the basic requirements of the desired MR fluid steering damper.

Similar content being viewed by others

References

[1] Hough S (2000) Proficient motorcycling. BowTie Books, Mission Viejo, CA

[2] Li WH, Du H, Chen G, Yeo SH, Guo NQ (2002) Nonlinear rheological behavior of MR fluids: step strain experiments. Smart Mater Struct 11:209–217

[3] Choi SB, Nam MH, Lee BK (2000) Vibration control of an MR seat damper for commercial vehicles. J Intellig Mater Sys Struct 11:936–944

[4] Dyke SJ, Spencer Jr. BF, Sain MK, Carlson JD (1996) Modeling and control of magnetorheological dampers for seismic response reduction. Smart Mater Struct 5:565–575

[5] Ahmadian M, Pare C (2000) A quarter-car experimental analysis of alternative semiactive control methods. Journal Intellig Mater Sys Struct 11:604–612

[6] Ericksen EO, Gordaninejad F (1999) A magneto-rheological fluid shock absorber for an off-road motorcycle. In: Proceedings of the Asia-Pacific Vibration Conference, Singapore, 15–17 December, 1999, pp 267–271

[7] Yoo JH, Wereley NM (2002) Design of a high-efficiency magnetorheological valve. In: Bossis G (ed) Proceedings of the 8th International Conference on ER Fluids, MR Suspensions, pp 281–287

[8] Jolly MR, Bender JW,, Carlson JW (1999) Properties and applications of commercial MR Fluids. J Intellig Mater Sys Struct 10:5–13

[9] Li WH, Zhang PQ, Tang X, Wang XJ (2000) Numerical study of electrorheological fluids flowing through an annular gap. J Institut Engin Sing 40:47–52

[10] Chen ZY, Tang X, Zhang GC, Jin Y, Ni W, Zhu YR (1998) A novel approach of preparing ultrafine magnetic metallic particles and the magnetorheology measurement for suspensions containing these particles. In: Proceedings of the 6th International Conference on ER Fluids, MR Suspensions, 1998, pp 486–493

[11] Karl U, Steven E (1995) Product design and development. McGraw-Hill, New York

[12] Li WH Du H, Guo NQ (2003) Finite element analysis and simulation evaluation of an MR valve. Int J Adv Manufact Technol 21(6):438–445

Author information

Authors and Affiliations

Corresponding author

Appendix 1. The function of components in the steering damper

Appendix 1. The function of components in the steering damper

-

1.

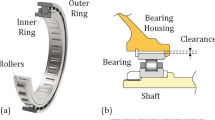

Casing. Serves as a casing to hold all components in place. In addition, it is a cylinder for containing MR fluid and also the housing for the sliding piston action. It combines with the piston and sliding rod to provide structural strength for the transverse action of the sliding rod.

-

2.

Sliding rod. A rod that connects the input steering force to the piston. Also a structural member that supports the damper against transverse steering input forces. It combines with the sliding rod guide to ensure that the piston sliding action is parallel to the inner walls of the casing.

-

3.

Flux return. A cylinder that surrounds the core. It provides a path for the cylinder/piston magnetic flux to run from the core across the gap, to this flux return cylinder which directs the magnetic flux to the other end of the core, back across the gap at the other end of the core to complete the loop. Other than the above magnetic function, it is a casing that holds the core and rod together as a piston assembly.

Design a) An extra annular orifice between the casing inner wall and the flux return cylinder provides for fluid flow path so as to have low off-state damping force.

Design b) A piston seal is mounted on the outer surface of the cylinder. This seal prevents leakage of MR fluid across the flux return cylinder and directs all MR fluid to flow through the MR fluid gap.

-

4.

Core. The primary function of the core is to provide a magnetic flux concentration from the wire coil. It carries some axial load from the sliding rod.

-

5.

Spoke A. A structural member that holds the core and flux return cylinder together. Has to have slots for MR fluid to flow through the spoke into the MR fluid gap.

-

6.

Sliding guide. A guide for the sliding rod to ensure that the rod movement is parallel to the inner surface of the casing and minimises eccentricity.

-

7.

Oil seal. An effective static oil seal that prevents leakage of MR fluid from the ends of the casing. Also serves as a dust cap.

-

8.

Retaining device. Snap ring and groove whose job is to hold the oil seal and sliding guide in place against the shoulder machined into the casing inner surface. It also acts as the outermost stopper to halt the sliding action of the rod.

Rights and permissions

About this article

Cite this article

Li, W.H., Du, H. & Guo, N.Q. Design and testing of an MR steering damper for motorcycles. Int J Adv Manuf Technol 22, 288–294 (2003). https://doi.org/10.1007/s00170-002-1473-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1473-1