Abstract

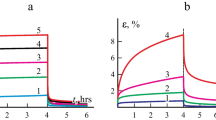

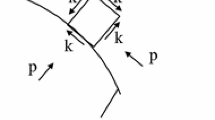

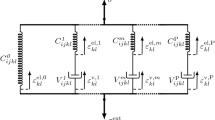

The main objective of the present paper is to compare, by means of a problem permitting a closed-form solution, qualitative behavior of solutions based on three models of strain hardening plasticity and two models of viscoplasticity. The elastic portion of the strain tensor is neglected. The study focuses on the solution behavior near frictional interfaces. The solution behavior essentially depends on the model chosen. Such features of the solutions as nonexistence and singularity are emphasized. The key constitutive parameter that divides all the models considered into two groups is the saturation stress. In particular, under certain conditions no solution satisfying the regime of sticking exists for the models that involve the saturation stress. Qualitative comparison with numerous experimental observations is made. It is concluded that models with a saturation stress, including the models considered in the present paper, may be capable of describing the generation of a narrow layer of severe plastic deformation in the vicinity of frictional interfaces.

Similar content being viewed by others

References

Rees D.W.A.: Basic Engineering Plasticity. Elsevier, Amsterdam (2006)

Voce E.: The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 74, 537–562 (1948)

Perzyna P.: The constitutive equations for rate sensitive plastic materials. Q. Appl. Math. 20, 321–332 (1963)

Adams M.J., Briscoe B.J., Corfield G.M. et al.: An analysis of the plane-strain compression of viscous materials. Trans. ASME J. Appl. Mech. 64, 420–424 (1997)

Ridley N., Bate P.S., Zhang B.: Material modelling data for superplastic forming optimization. Mater. Sci. Eng. A 410–411, 100–104 (2005)

Sinczak J., Kusiak J., Lapkowski W., Okon R.: The influence of deformation conditions on the flow of strain rate sensitive materials. J. Mater. Process. Technol. 34, 219–224 (1992)

Alexandrov S., Richmond O.: Couette flows of rigid/plastic solids: analytical examples of the interaction of constitutive and frictional laws. Int. J. Mech. Sci. 43, 653–665 (2001)

Alexandrov S., Mishuris G.: Viscoplasticity with a saturation stress: distinguished features of the model. Arch. Appl. Mech. 77, 35–47 (2007)

Alexandrov S., Mishuris G.: Qualitative behaviour of viscoplastic solutions in the vicinity of maximum-friction surfaces. J. Eng. Math. 65, 143–156 (2009)

Wang J.-P.: A new evaluation to friction analysis for the ring test. Int. J. Mach. Tools Manuf. 41, 311–324 (2001)

Chandrasekharan S., Palaniswamy H., Jain N., Ngaile G., Altan T.: Evaluation of stamping lubricants at various temperature levels using the ironing test. Int. J. Mach. Tools Manuf. 45, 379–388 (2005)

Griffiths B.J.: Mechanisms of white layer generation with reference to machining and deformation processes. Trans. ASME J. Tribol. 109, 525–530 (1987)

Akcan S., Shah S., Moylan S.P., Chhabra P.N., Chandrasekar S., Yang H.T.Y.: Formation of white layers in steels by machining and their characteristics. Metall. Mater. Trans. 33, 1245–1254 (2002)

Kajino S., Asakawa M.: Effect of “additional shear strain layer” on tensile strength and microstructure of fine drawn wire. J. Mater. Process. Technol. 177, 704–708 (2006)

Veldhuis S.C., Dosbaeva G.K., Elfizy A., Fox-Rabinovich G.S., Wagg T.: Investigations of white layer formation during machining of powder metallurgical Ni-based ME 16 superalloy. J. Mater. Eng. Perform. 19, 1031–1036 (2010)

Sanabria V., Mueller S., Reimers W.: Microstructure evolution of friction boundary layer during extrusion of AA 6060. Proced. Eng. 81, 586–591 (2014)

Alexandrov, S., Jeng, Y.-R., Hwang, Y.-M.: Generation of a fine grain layer in the vicinity of frictional interfaces in direct extrusion of AZ31 alloy. ASME J. Manuf. Sci. Eng. 137, Paper 051003 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Alexandrov, S., Goldstein, R. Effect of constitutive equations on qualitative behavior of solutions in the vicinity of bi-material interfaces at large plastic strains. Continuum Mech. Thermodyn. 28, 1635–1643 (2016). https://doi.org/10.1007/s00161-015-0486-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-015-0486-6