Abstract

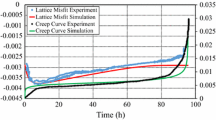

A model for high temperature creep of single crystal superalloys is developed, which includes constitutive laws for nonlocal damage and viscoplasticity. It is based on a variational formulation, employing potentials for free energy, and dissipation originating from plasticity and damage. Evolution equations for plastic strain and damage variables are derived from the well-established minimum principle for the dissipation potential. The model is capable of describing the different stages of creep in a unified way. Plastic deformation in superalloys incorporates the evolution of dislocation densities of the different phases present. It results in a time dependence of the creep rate in primary and secondary creep. Tertiary creep is taken into account by introducing local and nonlocal damage. Herein, the nonlocal one is included in order to model strain localization as well as to remove mesh dependence of finite element calculations. Numerical results and comparisons with experimental data of the single crystal superalloy LEK94 are shown.

Similar content being viewed by others

References

Durand-Charre M.: The Microstructure of Superalloys. Gordon and Breach, New York (1997)

Mughrabi H., Tetzlaff U.: Microstructure and high-temperature strength of monocrystalline nickel-base superalloys. Adv. Eng. Mater. 2, 319–326 (2000)

Prasad S.C., Rao I.J., Rajagopal K.R.: A continuum model for the creep of single crystal nickel-base superalloys. Acta Mater. 53, 669–679 (2005)

Pollock T.M., Argon A.S.: Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. Mater. 40, 1–30 (1992)

Svoboda J., Lukáš P.: Modelling of kinetics of directional coarsening in Ni-Superalloys. Acta Mater. 44, 2557–2565 (1996)

Svoboda J., Lukáš P.: Modelling of recovery controlled creep in nickel-base superalloy single crystals. Acta Mater. 45, 125–135 (1997)

Svoboda J., Lukáš P.: Model of creep in 〈001〉-oriented superalloy single crystals. Acta Mater. 46, 3421–3431 (1998)

Svoboda J., Lukáš P.: Creep deformation modelling of superalloy single crystals. Acta Mater. 48, 2519–2528 (2000)

Becker A.A., Hyde T.H., Sun W., Andersson P.: Benchmarks for finite element analysis of creep continuum damage mechanics. Comput. Mater. Sci. 25, 34–41 (2002)

Dunne F.P.E., Otheman A.M., Hall F.R., Hayhurst D.R.: Representation of uniaxial creep curves using continuum damage mechanics. Int. J. Mech. Sci. 32, 945–957 (1990)

Kowalewski Z.L., Hayhurst D.R., Dyson B.F.: Mechanisms-based creep constitutive equations for an aluminium alloy. J. Strain Anal. 29, 309–316 (1994)

Naumenko K., Altenbach H.: Modeling of Creep for Structural Analysis. Springer, Berlin (2007)

Kachanov L.M., Hayhurst D.R., Dyson B.F.: Time of the fracture process under creep conditions. Izv. Akad. Nauk SSSR, Otd. Tekh. Nauk 8, 26–31 (1958)

Hayhurst R.R.: Stress redistribution and rupture due to creep in a uniformly stretched thin plate containing a circular hole. J. Appl. Mech. Tech. Phys. 20, 381–390 (1972)

Zyczkowski M.: Creep damage evolution equations expressed in terms of dissipated power. Int. J. Mech. Sci. 42, 755–769 (2000)

Onsager L.: Reciprocal relations in irreversible processes. I. Phys. Rev. 37, 405–426 (1931)

Onsager L.: Theories and problems of liquid diffusion. Ann. N.Y. Acad. Sci. 46, 241–265 (1945)

Ziegler H.: Some extremum principles in irreversible thermodynamics with applications to continuum mechanics. In: Sneddon, I.N., Hill, R. (eds) Progress in Solid Mechanics, pp. 92–193. North-Holland, Amsterdam (1963)

Krajcinovic D.: Constitutive equations for damage materials. J. Appl. Mech. 50, 355–380 (1983)

Ziegler H.: Continuum damage mechanics: Part 1-general concepts. J. Appl. Mech. 55, 59–64 (1988)

Murakami S., Kamiya K.: Constitutive and damage evolution equations of elastic-brittle materials based on irreversible thermodynamics. Int. J. Mech. Sci. 39, 473–486 (1997)

Hesebeck O.: Irreversibility, stability and maximum dissipation in elastoplastic damage. Int. J. Damage Mech. 9, 329–351 (2000)

Ibrahimbegovic A., Jehel P., Davenne L.: Coupled damage-plasticity constitutive model and direct stress interpolation. Comput. Mech. 42, 1–11 (2008)

Svoboda J., Fischer F.D., Fratzl P., Kroupa A.: Diffusion in multi-component systems with no or dense sources and sinks for vacancies. Acta Mater. 50, 1369–1381 (2002)

Svoboda J., Fischer F.D., Fratzl P.: Diffusion and creep in multi-component alloys with non-ideal sources and sinks for vacancies. Acta Mater. 54, 3043–3053 (2006)

Martin J.B., Ponter A.R.S.: A note on a work inequality in linear viscoelasticity. Q. Appl. Math. 24, 161–165 (1966)

Maier G.: Some theorems for plastic strain rates and plastic strains. J. Mecanique 8, 5–19 (1969)

Halphen B., Nguyen Q.S.: Sur les matériaux standards généralisés. J. Mecanique 14, 39–63 (1975)

Maugin G.A.: The Thermomechanics of Plasticity and Fracture. Cambridge University Press, Cambridge (1992)

Hackl K., Fischer F.D.: On the relation between the principle of maximum dissipation and inelastic evolution given by dissipation potentials. Proc. R. Soc. Lond. A 464, 117–132 (2008)

Hackl K., Fischer F.D., Svoboda J.: A study on the principle of maximum dissipation for coupled and non-coupled non-isothermal processes in materials. Proc. R. Soc. Lond. A 467, 1186–1196 (2011)

Hackl K., Fischer F.D., Svoboda J.: A study on the principle of maximum dissipation for coupled and non-coupled non-isothermal processes in materials. Proc. R. Soc. Lond. A 467, 2422–2426 (2011)

Pollock T.M., Argon A.S.: Directional coarsening in nickel-base single crystals with high volume fractions of coherent precipitates. Acta Metall. Mater. 42, 1859–1874 (1994)

Nathal M.V., Ebert L.J.: The influence of cobalt, tantalum, and tungsten on the microstructure of single crystal nickel-base superalloys. Metall. Mater. Trans. A 16, 1849–1862 (1985)

Nabarro F.R.N.: Rafting in superalloys. Metall. Mater. Trans. A 27, 513–530 (1996)

Coujou A., Benyoucef M., Legros M., Clément N.: Role of the γ/γ′ interface on the mechanical properties of single crystals nickel base superalloys. Solid State Pheno. 59(60), 185–200 (1998)

Mälzer G., Hayes R.W., MacK T., Eggeler G.: Miniature specimen assessment of creep of the single-crystal superalloy LEK94 in the 1000° C temperature range. Metall. Mater. Trans. A 38, 314–327 (2007)

Hackl K., Heinen R.: A micromechanical model for pretextured polycrystalline shape-memory alloys including elastic anisotropy. Continuum Mech. Therm. 19, 499–510 (2008)

Dimitrijevic B.J., Hackl K.: A method for gradient enhancement of continuum damage models. Tech. Mechanik 28, 43–52 (2008)

Dimitrijevic B.J., Hackl K.: A regularization framework for damage-plasticity models via gradient enhancement of the free energy. Int. J. Numer. Method Biomed. Eng. 27, 1199–1210 (2011)

Estrin Y., Mecking H.: Unified phenomenological description of work hardening and creep based on one-parameter models. Acta Mater. 32, 57–70 (1984)

Ghosh R.N., Curtis R.V., McLean M.: Creep deformation of single crystal superalloys—modelling the crystallographic anisotropy. Acta Metall. Mater. 38, 1977–1992 (1990)

Méric L., Poubanne P., Cailletaud G.: Single crystal modeling for structural calculations: Part 1—model presentation. J. Eng. Mater. Tech. 113, 162–170 (1991)

Méric L., Cailletaud G.: Single crystal modeling for structural calculations: Part 2—finite element implementation. J. Eng. Mater. Tech. 113, 171–182 (1991)

Zienkiewicz O.C., Taylor R.L.: The Finite Element Method. Volume 1: The Basis. Butterworth-Heinmann, London (2000)

Taylor, R.L.: A Finite Element Analysis Program, Programmer Manual. University of California, Berkeley. http://www.ce.berkeley.edu/projects/feap/ (2008)

Vladimirov I.N., Reese S., Eggeler G.: Constitutive modelling of the anisotropic creep behaviour of nickel-base single crystal superalloys. Int. J. Mech. Sci 51, 305–313 (2009)

Srinivasan R., Eggeler G., Mills M.J.: γ′-cutting as rate-controlling recovery process during high-temperature and low-stress creep of superalloy single crystals. Acta Mater. 48, 4867–4878 (2000)

Schreuer, J., Mazzolai, G., Agudo, J., Eggeler, G., Hackl, K.: Correlation between microstructure and elastic properties of the single crystal superalloy LEK94 at temperatures up to 1400K. Poster, European Symposium on Superalloys and Their Application 25–28 May 2010, Wildbad Kreuth, Germany

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Trinh, B.T., Hackl, K. A model for high temperature creep of single crystal superalloys based on nonlocal damage and viscoplastic material behavior. Continuum Mech. Thermodyn. 26, 551–562 (2014). https://doi.org/10.1007/s00161-013-0317-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-013-0317-6