Abstract

Truss optimization based on the ground structure approach often leads to designs that are too complex for practical purposes. In this paper we present an approach for design complexity control in truss optimization. The approach is based on design complexity measures related to the number of bars (similar to Asadpoure et al. Struct Multidisc Optim 51(2):385–396 2015) and a novel complexity measure related to the number of nodes of the structure. Both complexity measures are continuously differentiable and thus can be used together with gradient based optimization algorithms. The numerical examples show that the proposed approach is able to reduce design complexity, leading to solutions that are more fit for engineering practice. Besides, the examples also indicate that in some cases it is possible to significantly reduce design complexity with little impact on structural performance. Since the complexity measures are non convex, a global gradient based optimization algorithm is employed. Finally, a detailed comparison to a classical approach is presented.

Similar content being viewed by others

References

Achtziger W (1999a) Local stability of trusses in the context of topology optimization. part i: exact modelling. Struct Optim 17(4):235–246

Achtziger W (1999b) Local stability of trusses in the context of topology optimization. part ii: a numerical approach. Struct Optim 17(4):247–258

Achtziger W (2007) On simultaneous optimization of truss geometry and topology. Struct Multidisc Optim 33(4-5):285–304

Asadpoure A, Guest J, Valdevit L (2015) Incorporating fabrication cost into topology optimization of discrete structures and lattices. Struct Multidisc Optim 51(2):385–396

Ben-Tal A, Jarre F, Koc̆vara M, Nemirovski A, Zowe J (2000) Optimal design of trusses under a nonconvex global buckling constraint. Optim Eng 1(2):189–213

Bendsøe M, Ben-Tal A, Zowe J (1994) Optimization methods for truss geometry and topology design. Struct Optim 7(3):141–159

Cheng G, Guo X (1997) 𝜖-relaxed approach in structural topology optimization. Struct Optim 13:258–266

Dobbs M, Felton L (1969) Optimization of truss geometry. J Struct Div ASCE 95:2105–2118

Dorn W, Gomory R, Greenberg H (1964) Automatic design of optimal structures. J Mec 3:25–52

Fleron P (1964) The minimum weight of trusses. Bygningsstat Medd:81–96

Hagishita T, Ohsaki M (2009) Topology optimization of trusses by growing ground structure method. Struct Multidisc Optim 37(4):377–393

He L, Gilbert M (2015) Rationalization of trusses generated via layout optimization. Struct Multidisc Optim 52(4):677–694

Hemp W (1973) Optimum structures. Clarendon Press, Oxford

Kirsch U (1990) On singular topologies in optimum structural design. Struct Optim 2(3):133–142

Koc̆vara M, Zowe J (1996) How mathematics can help in design of mechanical structures. In: Griffiths D, Watson G (eds) Numerical analysis. Longman Scientific and Technical, Harlow, pp 76–93

Lopez RH, Ritto TG, Sampaio R, Cursi JESD (2014) A new algorithm for the robust optimization of rotor-bearing systems. Eng Optim 46(8):1123–1138

Luenberger DG, Ye Y (2008) Linear and nonlinear programming, 3rd edn. Springer, New York

Luersen MA, Le Riche R (2004) Globalized nelder-mead method for engineering optimization. Comput Struct 82(23-26):2251–2260

Luersen MA, Le Riche R, Guyon F (2004) A constrained, globalized and bounded nelder-mead method for engineering optimization. Struct Multidisc Optim 27:43–54

Luersen MA, Le Riche R, Lemosse D, Le Maître O (2006) A computationally efficient approach to swimming monofin optimization. Struct Multidisc Optim 31(6):488–496

Martínez P, Martín P, Querin OM (2007) Growth method for size, topology, and geometry optimization of truss structures. Struct Multidisc Optim 33(1):13–26

Michell A (1904) The limits of economy of material in frame-structures. Phil Mag 8(47):589–597

Nocedal J, Wright S J (1999) Numerical optimization. Springer, New York

Parkes E (1975) Joints in optimum frameworks. Int J Solids Struct 11(9):1017–1022

Pedersen P (1970) On the minimum mass layout of trusses. In: AGARD Conference Proceedings n. 36

Pedersen P (1972) On the optimal layout of multi-purpose trusses. Comput Struct 10:803–805

Prager W (1974) A note on discretized michell structures. Comput Methods Appl Mech Eng 3(3):349–355

Ritto TG, Lopez RH, Sampaio R, Cursi JESD (2011) Robust optimization of a flexible rotor-bearing system using the campbell diagram. Eng Optim 43(1):77–96

Romstad K, Wang C (1968) Optimum design of framed structures. J Struct Div ASCE 94:2817–2845

Rozvany G (1996) Difficulties in truss topology optimization with stress, local buckling and system stability constraints. Struct Optim 11(3-4):213–217

Rozvany G, Hou MZ (1991) A note on truss design for stress and displacement constraints by optimality criteria methods. Struct Optim 3(1):45–50

Stolpe M, Svanberg K (2001) On the trajectories of the epsilon-relaxation approach for stress-constrained truss topology optimization. Struct Multidisc Optim 21(2):140–151

Sved G, Ginos Z (1968) Structural optimization under multiple loading. Int J Mec Sci 10:803–805

Torii AJ, Lopez RH, Luersen MA (2011) A local-restart coupled strategy for simultaneous sizing and geometry truss optimization. Lat Am J Solids Stru 8:335–349

Torii AJ, Lopez RH, Miguel LFF (2015) Modeling of global and local stability in optimization of truss-like structures using frame elements. Struct Multidisc Optim 51:1187–1198

Zhou M (1996) Difficulties in truss topology optimization with stress and local buckling constraints. Struct Optim 11(2):134– 136

Acknowledgments

The authors would like to thank CNPq and CAPES for the financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A Derivatives of complexity measures

The derivative of C b according to a given design variable is given by

where

The derivative of C n according to a given design variable is given by

The derivative ∂ c/∂ b j is as presented in (11). The derivative ∂ b j /∂ x i , on the other hand, is simply

Note that both derivatives are very simple to evaluate and should not lead to significant increases in the computational effort required for sensitivity analysis.

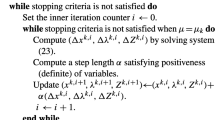

Appendix B Global optimization algorithm

The global optimization algorithm used in this paper is based on starting local searches from different initial design vectors. The algorithm is very similar to the restart procedure first proposed by Luersen et al. (2004) and already applied for truss optimization by Torii et al. (2011).

We first start the local search with an initial design vector x 0 to obtain an optimum design \(\mathbf {x}_{0}^{\ast }\). Both x 0 and \(\mathbf {x}_{0}^{\ast }\) are then included in a set of design vectors

that will store design vectors where we already started/ended local searches. The next step is to randomly generate a set of M trial design vectors y i

satisfying the bounds on the design variables, but not necessarily satisfying the nonlinear constraints (check of nonlinear constraints are avoided because of the computational costs involved). The average distance from all trial vectors y i ∈T to all vectors in S 0 is then evaluated, i.e.,

where card (S 0) stands for cardinality of S 0 (i.e. number of elements in S 0) and ∥.∥ is some vector norm (in this work Euclidean norm is used). We then take the next starting point as the one in T with maximum average distance from the vectors in S 0, i.e.,

In this way we choose a starting point that is, in the average sense, the most distant from the ones in S 0. A new local search is then started with x 1 to obtain an optimum design \(\mathbf {x}_{1}^{\ast }\) and both vectors are included in a new set S 1 (together with x 0 and \(\mathbf {x}_{0}^{\ast }\)). A new set of trial vectors T is randomly generated and the process is repeated. After k restarts (k+1 local searches) we have the set of starting/found design vectors

we randomly generate a set of trial vectors T and choose the new starting design vector as the one that maximizes

The parameters required to use this algorithm are the number of local searches k to be made and the number of trial vectors M generated before each restart. The local searches can be made using any optimization algorithm. In this paper an interior point algorithm is used (Nocedal and Wright, 1999; Luenberger and Ye, 2008).

The only difference between this algorithm and the one proposed by Luersen et al. (2004) is that here we take the trial vector y i ∈T that maximizes the average distance from the ones in S k . In the original approach the new starting design vector was chosen as the one that minimizes a normal multidimensional probability density function, representing the probability of arriving at some point from S k when starting from some trial vector y i ∈T.

Appendix C Prager-Parkes’ approach

The approach presented by Prager (1974) and Parkes (1975) was originally conceived for problems based on volume minimization. The idea is to replace the real volume of the structure, given by \(V = {\sum }_{i=1}^{m} l_{i} x_{i}\) (where l i are the bars lengths), by the modified volume

where s>0 is a parameter named by Parkes (1975) as joint radius. In this way, shorter bars are penalized in comparison to longer ones. In order to see this fact, it is interesting to rewrite V p as

with

This expression puts in evidence that the approach is the same as multiplying the volume of each bar l i x i by a unitary cost per volume ϕ(l i ). This cost per volume, however, is smaller the longer the bar is (i.e. \(\lim _{l_{i} \rightarrow \infty } \phi (l_{i}) = 1\)). On the other hand, for shorter bars we have \(\lim _{l_{i} \rightarrow 0} \phi (l_{i}) = \infty \), i.e. shorter bars have increased unitary costs. In this way, the optimization algorithm will try to avoid shorter bars, that are comparatively more expensive than longer ones. It is important to point out that this approach was originally developed in order to tackle analytical solutions.

Rights and permissions

About this article

Cite this article

Torii, A.J., Lopez, R.H. & F. Miguel, L.F. Design complexity control in truss optimization. Struct Multidisc Optim 54, 289–299 (2016). https://doi.org/10.1007/s00158-016-1403-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-016-1403-8