Abstract

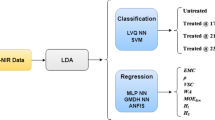

Classification of thermally modified wood (TMW) allowing the distinction between different processing temperatures and the corresponding changes in wood properties is a crucial task in TMW grading. In this study, stress wave evaluation technique was used to classify the heat treatment level. Accordingly, an acoustic emission (AE) sensor and a pair of accelerometers captured stress waves generated by pendulum impact, and the data was used to classify the heat treatment level of thermally modified Western hemlock wood samples. Sensory features were extracted from time, frequency, and wavelet domain analysis. The extracted features were then used to train multilayer perceptron (MLP), group method of data handling (GMDH), and linear vector quantization (LVQ) neural networks for TMW classification. The results showed that while the features extracted from the accelerometers such as stress wave velocity and wood dynamic modulus of elasticity showed poor classification performance, acoustic emission sensory features were effective for classification of TMW. Wavelet domain features lead to better classification than those extracted from time and frequency domains. Feature fusion approach comprising the features from all the signal domains showed the best classification performance that was further improved by using a dimensionality reduction approach. The linear discriminant analysis was conducted on all acoustic emission features and resulted in 91.1% and 89.1% accuracy obtained from the LVQ and GMDH network, respectively. This performance was further increased to 98% and 97% using the LVQ and GMDH models when the input was combined with wood moisture content. The MLP neural network did not seem as suitable as the other two models. Neural network modeling using the captured stress wave data from an AE sensor could therefore be a promising nondestructive evaluation method for TMW classification.

Similar content being viewed by others

References

Bächle H, Zimmer B, Wegener G (2012) Classification of thermally modified wood by FT-NIR spectroscopy and SIMCA. Wood Sci Technol 46(6):1181–1192

Brischke C, Welzbacher CR, Brandt K, Rapp AO (2007) Quality control of thermally modified timber: Interrelationship between heat treatment intensities and CIE L* a* b* color data on homogenized wood samples. Holzforschung 61(1):19–22

Del Menezzi CHS, Amorim MR, Costa MA, Garcez LR (2014) Evaluation of thermally modified wood by means of stress wave and ultrasound nondestructive methods. Mater Sci 20(1):61–66

Diakhate M, Angellier N, Pitti RM, Dubois F (2017) On the crack tip propagation monitoring within wood material: Cluster analysis of acoustic emission data compared with numerical modelling. Constr Build Mater 156:911–920

Du X, Li S, Li G, Feng H, Chen S (2015) Stress wave tomography of wood internal defects using ellipse-based spatial interpolation and velocity compensation. BioResources 10(3):3948–3962

Esteves B, Pereira H (2009) Wood modification by heat treatment: a review. BioResources 4(1):370–404

Garcia RA, de Carvalho AM, de Figueiredo Latorraca JV, de Matos JLM, Santos WA, de Medeiros Silva RF (2012) Nondestructive evaluation of heat-treated Eucalyptus grandis Hill ex Maiden wood using stress wave method. Wood Sci Technol 46(1–3):41–52

González-Peña MM, Hale MD (2009a) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: colour evolution and colour changes. Holzforschung 63(4):385–393

González-Peña MM, Hale MD (2009b) Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 2: Property predictions from colour changes. Holzforschung 63(4):394–401

Gosselink RJA, Krosse AMA, Van der Putten JC, Van der Kolk JC, de Klerk-Engels B, Van Dam JEG (2004) Wood preservation by low-temperature carbonisation. Ind Crops Prod 19(1):3–12

Hietala S, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Structure of thermally modified wood studied by liquid state NMR measurements. Holzforschung 56(5):522–528

Hinterstoisser B, Schwanninger M, Stefke B, Stingl R, Patzelt M (2003) Surface analyses of chemically and thermally modified wood by FT-NIR. In: Acker VJ, Hill C (eds) The 1st European conference on wood modification. Proceeding of the first international conference of the European society for wood mechanics. Ghent University, Belgium, pp 15–20

Johansson D, Morén T (2006) The potential of colour measurement for strength prediction of thermally treated wood. Holz Roh-Werkst 64(2):104–110

Kim KB, Kang HY, Yoon DJ, Choi MY (2005) Pattern classification of acoustic emission signals during wood drying by principal component analysis and artificial neural network. Key Eng Mater 297:1962–1967. https://doi.org/10.4028/www.scientific.net/KEM.297-300.1962

Kohonen T (2001) Self-organizing maps, ser. Information Sciences. Springer, Berlin, p 30

Kwak JS (2006) Application of wavelet transform technique to detect tool failure in turning operations. Int J Adv Manufac Technol 28:1078–1083

Lin WS, Wu JZ (2013) Study on application of stress wave for nondestructive test of wood defects. Appl Mech Mater 401:1119–1123. https://doi.org/10.4028/www.scientific.net/AMM.401-403.1119

Nasir V, Cool J (2018) A review on wood machining: characterization, optimization, and monitoring of the sawing process. Wood Mat Sci Eng. https://doi.org/10.1080/17480272.2018.1465465

Schnabel T, Zimmer B, Petutschnigg AJ, Schönberger S (2007) An approach to classify thermally modified hardwoods by color. For Products J 57(9):105–110

Schwanninger M, Hinterstoisser B, Gierlinger N, Wimmer R, Hanger J (2004) Application of Fourier transform near infrared spectroscopy (FT-NIR) to thermally modified wood. Holz Roh- Werkst 62(6):483–485

Willems W, Lykidis C, Altgen M, Clauder L (2015) Quality control methods for thermally modified wood. Holzforschung 69(7):875–884

Yang Z, Jiang Z, Hse CY, Liu R (2017) Assessing the impact of wood decay fungi on the modulus of elasticity of slash pine (Pinus elliottii) by stress wave non-destructive testing. Int Biodeterior Biodegrad 117:123–127

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest associated with this research.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nasir, V., Nourian, S., Avramidis, S. et al. Stress wave evaluation by accelerometer and acoustic emission sensor for thermally modified wood classification using three types of neural networks. Eur. J. Wood Prod. 77, 45–55 (2019). https://doi.org/10.1007/s00107-018-1373-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1373-1